Embarking on your sewing journey begins with mastering the fundamental straight stitch. This essential technique forms the backbone of countless projects, from simple repairs to intricate garments. Understanding its nuances, from stitch length and tension to proper fabric handling, is the key to achieving professional-looking results and building confidence with every seam.

This guide is meticulously crafted to demystify the process of sewing your very first straight stitch. We will walk you through selecting the right tools, setting up your sewing machine with precision, and practicing the stitch itself. You’ll discover practical tips for sewing a perfectly straight line, troubleshoot common issues, and learn how the subtle adjustments of stitch length and tension can dramatically impact your finished work.

Prepare to transform simple fabric into something beautifully constructed.

Introduction to Straight Stitch Sewing

Welcome to the foundational step of your sewing journey! The straight stitch is the bedrock upon which nearly all sewing projects are built. Understanding and mastering this seemingly simple stitch is the key to unlocking a world of creative possibilities, from mending everyday items to crafting intricate garments. It’s the most fundamental stitch a sewing machine can produce, and its versatility makes it indispensable.The straight stitch is the workhorse of sewing, essential for creating seams, hems, and decorative elements.

Its strength and simplicity make it suitable for a vast array of fabrics and applications. Whether you’re joining two pieces of fabric together, creating a neat edge, or adding a touch of detail, the straight stitch is your go-to.

The Fundamental Importance of the Straight Stitch

The straight stitch is the most basic and widely used stitch in sewing. Its importance lies in its ability to create strong, durable, and aesthetically pleasing seams and finishes. Without the straight stitch, the construction of most fabric items would be impossible. It’s the primary method for physically connecting fabric pieces, providing the structural integrity that allows garments and other textile items to hold their shape and withstand wear.

Primary Uses and Applications of the Straight Stitch

The applications of the straight stitch are incredibly broad, touching almost every aspect of sewing. It serves as the primary method for constructing garments, creating the seams that hold them together. Beyond construction, it’s vital for hemming, which involves folding and stitching the raw edge of fabric to create a clean and finished appearance. Upholstery, quilting, and general mending also rely heavily on the strength and precision of the straight stitch.Here are some of the primary uses:

- Seam Construction: Joining two or more pieces of fabric together to create the structure of a project. This is fundamental for garment making, bag construction, and more.

- Hemming: Creating a finished edge on fabric, typically by folding the raw edge over and stitching it down. This prevents fraying and provides a neat appearance.

- Topstitching: Stitching on the outside of a project for both decorative and functional purposes, such as reinforcing seams or adding a design element.

- Quilting: Stitching through multiple layers of fabric and batting to hold them together and create texture.

- Appliqué: Attaching one piece of fabric onto another for decorative purposes.

- General Mending: Repairing tears, holes, or loose seams in existing garments and textiles.

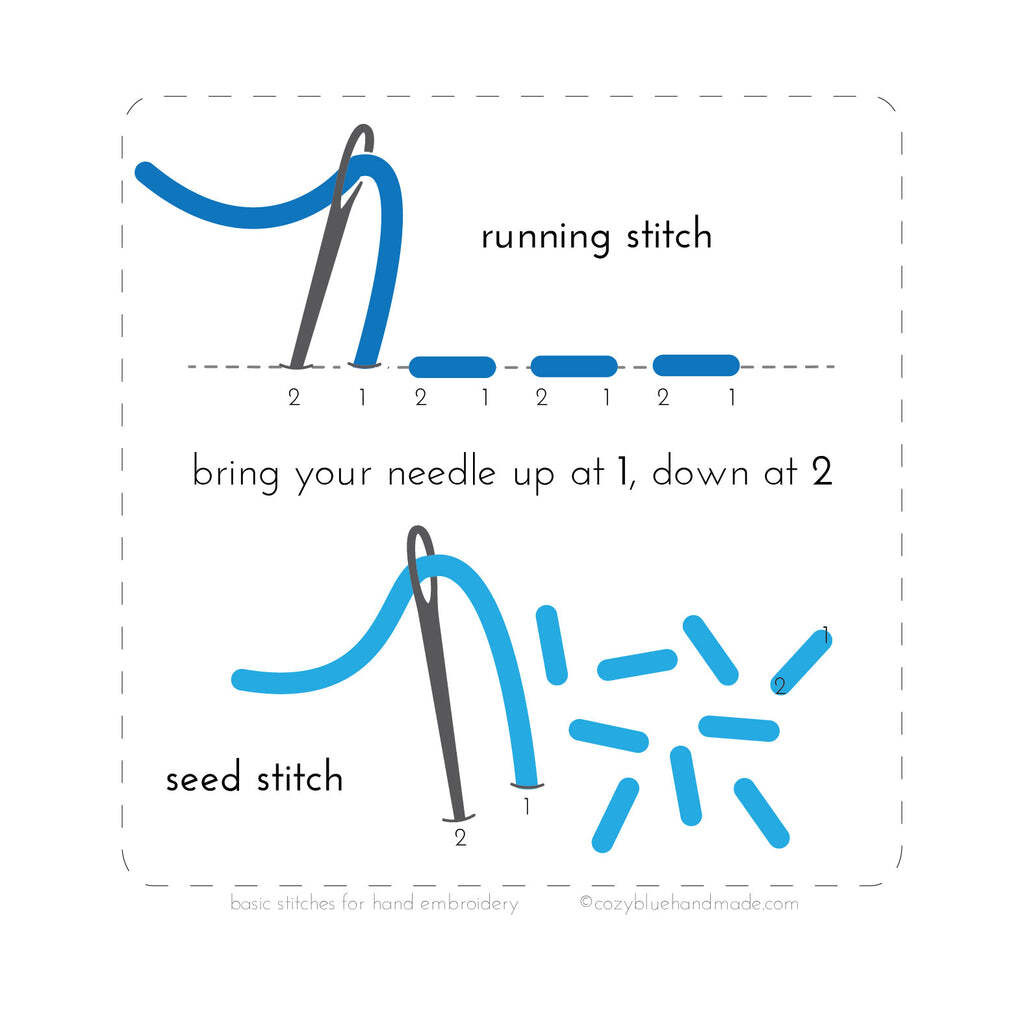

Basic Anatomy of a Straight Stitch

A straight stitch is characterized by its uniform, linear appearance. When looking closely at a properly formed straight stitch, you’ll notice two key elements that determine its look and function: stitch length and tension.

Stitch Length

The stitch length refers to the distance between each individual stitch. This setting on your sewing machine directly impacts the strength and appearance of the stitch.

- Short stitch length (e.g., 1.0-2.0 mm): Creates a denser stitch. This is ideal for areas that require extra strength, such as the beginning and end of seams (backstitching) or when sewing delicate fabrics where fewer stitches per inch are needed to avoid tearing. It also provides a more finished look on hems.

- Medium stitch length (e.g., 2.0-3.0 mm): This is the standard, all-purpose stitch length suitable for most general sewing tasks, such as constructing seams on medium-weight fabrics.

- Long stitch length (e.g., 3.0-4.0 mm): Creates a looser, more spaced-out stitch. This is useful for temporary stitching (basting), gathering fabric, or for decorative purposes on certain fabrics where a more open stitch is desired.

Tension

Tension refers to the balance of forces exerted by the upper thread (from the needle) and the lower thread (from the bobbin) as they interlock. Proper tension is crucial for a neat and secure stitch.

A balanced tension ensures that the stitches are neither too tight nor too loose, creating a clean line of stitching on both sides of the fabric with no puckering or looping.

If the tension is too high on the top thread, the stitches will look tight and may pull the fabric. If the tension is too low, the stitches will be loose and may loop on the underside. The bobbin tension is usually set at the factory and rarely needs adjustment, but the needle tension is adjustable via a dial on most sewing machines.

Beginner’s Perspective: Why Mastering the Straight Stitch is Crucial

For anyone new to sewing, the straight stitch is your first and most important teacher. It’s the fundamental building block that allows you to learn how your sewing machine operates and how different fabric types react to stitching. Practicing straight stitches helps you develop essential skills like controlling the fabric as it feeds through the machine, maintaining a consistent distance from the edge (seam allowance), and understanding how stitch length and tension affect the final outcome.Mastering the straight stitch provides a solid foundation for all future sewing endeavors.

It builds confidence and ensures that your projects will be well-constructed and durable. Before you can tackle complex patterns or intricate techniques, you need to be able to confidently sew a straight line. This skill is transferable to every sewing project you will ever undertake.

Essential Tools and Materials

Embarking on your sewing journey with a straight stitch is an exciting first step. To ensure a smooth and successful experience, gathering the right tools and materials is paramount. This section will guide you through the essentials, from the fundamental tools to the specific choices that will make your initial projects a pleasure to create.Understanding the purpose and function of each item will empower you to make informed decisions as you build your sewing kit.

We will delve into the specifics of needles, threads, and fabrics, providing you with the knowledge to select the best options for your beginner straight stitch endeavors.

Core Sewing Tools

Every sewing project, no matter how simple, benefits from a foundational set of tools that enhance precision and ease of use. These items are the workhorses of the sewing world and are indispensable for creating neat and durable stitches. Investing in quality basic tools will serve you well throughout your sewing adventures.A beginner’s toolkit should include the following essential items:

- Sewing Machine: The primary tool for creating straight stitches efficiently. For beginners, a basic mechanical machine is often recommended due to its simplicity and durability.

- Scissors: A sharp pair of fabric scissors is crucial for clean cuts. Dedicated fabric scissors should only be used for fabric to maintain their sharpness.

- Measuring Tape: A flexible tape measure is necessary for accurate fabric measurements and pattern layout.

- Seam Ripper: An indispensable tool for correcting mistakes. It allows for the precise removal of stitches without damaging the fabric.

- Pins: Straight pins are used to hold fabric pieces together before sewing, ensuring they do not shift during stitching. Ballpoint or silk pins are often preferred for their fine points.

- Iron and Ironing Board: Pressing seams as you sew is a critical step for professional-looking results. A good iron and a stable ironing board are vital.

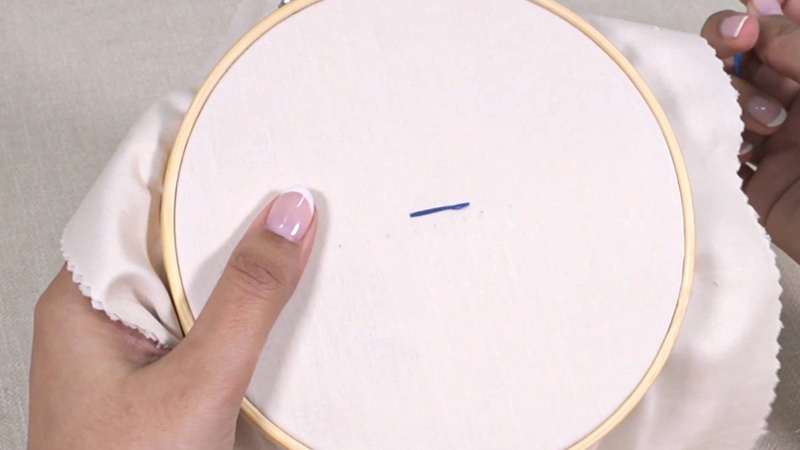

- Chalk or Fabric Marker: Used for marking cutting lines and seam allowances on fabric. Water-soluble or air-erasable markers are excellent choices for beginners.

- Thread Spool Holder: Keeps your thread organized and prevents tangles, especially when using multiple spools.

Sewing Needles and Their Suitability

The needle is the direct interface between your thread and fabric, and choosing the right type significantly impacts the quality of your stitch and the integrity of your fabric. Different needle types are designed to penetrate various fabric structures effectively, preventing snags, tears, and skipped stitches.Sewing machine needles come in various sizes and point types, each suited for specific applications:

- Universal Needles: These are the most common and versatile needles, suitable for a wide range of fabrics from lightweight cottons to medium-weight knits and wovens. They are a good starting point for beginners.

- Sharp Needles: Also known as “Sharps” or “Microtex” needles, these have a very fine, sharp point, ideal for piercing densely woven fabrics like silk, linen, and microfibers without causing damage.

- Ballpoint Needles: These needles have a rounded tip that pushes the fabric threads apart rather than cutting them, preventing runs and snags in knits and stretchy fabrics.

- Denim/Jeans Needles: These are strong and sharp needles designed to penetrate thick and tough fabrics like denim, canvas, and upholstery.

Needle size is indicated by a number (e.g., 70/10, 80/12, 90/14). Smaller numbers indicate finer needles for delicate fabrics, while larger numbers denote sturdier needles for heavier materials. For your first straight stitch projects, universal needles in sizes 80/12 or 90/14 are excellent choices for common fabrics like cotton.

Thread Selection for Different Fabrics

Thread is the binding element of your sewing, and its strength, weight, and fiber content must complement the fabric you are using. Using the correct thread ensures that your seams are durable and that the thread does not break during sewing or under stress.Consider these factors when selecting thread:

- Fiber Content: Polyester thread is a popular choice for its strength, durability, and versatility, suitable for most fabrics. Cotton thread is good for 100% cotton fabrics, especially for garments.

- Weight: Thread weight refers to its thickness. All-purpose polyester threads are typically in the medium weight range, suitable for most general sewing. Heavier threads are used for upholstery or denim, while finer threads are for delicate fabrics.

- Color: For practice, a neutral color like white, black, or grey is practical. For actual projects, choose a thread color that matches your fabric as closely as possible, or opt for a contrasting color for decorative effect.

For your initial straight stitch practice on common fabrics like cotton, a good quality all-purpose polyester thread (often labeled as “all-purpose” or “medium weight”) in a neutral color is highly recommended.

Recommended Fabrics for Practice

Practicing your straight stitch on the right fabrics will build your confidence and hone your skills without unnecessary frustration. Fabrics that are stable, easy to handle, and do not fray excessively are ideal for beginners.Here are some excellent fabric choices for practicing straight stitches:

- Quilting Cotton: This is a very popular choice for beginners. It is a woven fabric, typically 100% cotton, with a stable weave that does not stretch. It’s easy to cut, press, and sew, and it doesn’t fray too much. It comes in a vast array of colors and prints.

- Linen Blends: While pure linen can be a bit slippery, linen blends (often with cotton or polyester) offer some of the crispness of linen with improved stability and ease of handling. They press well and are relatively easy to stitch.

- Denim (Lightweight): Lightweight denim or chambray can be a good choice once you are comfortable with basic cottons. They are stable woven fabrics that hold their shape well, though they can be a bit thicker to sew through.

- Canvas (Lightweight): Similar to denim, lightweight canvas offers stability and a smooth surface for practicing straight stitches. It’s a durable fabric that is easy to manage.

Avoid very slippery fabrics like silk or satin, very stretchy knits, or very thick, heavy fabrics for your very first straight stitch practice sessions.

Beginner’s Straight Stitch Practice Materials Checklist

To get started with your first straight stitch project, having a clear list of necessary items will streamline your preparation and ensure you have everything at hand. This checklist focuses on the absolute essentials for practicing and completing a simple straight stitch project.Here is a recommended materials checklist for a beginner:

| Item | Quantity/Notes |

|---|---|

| Sewing Machine | In good working order, with a power cord and foot pedal. |

| Sewing Machine Needles | A pack of universal needles (sizes 80/12 and 90/14). |

| All-Purpose Thread | One spool of polyester thread in a neutral color (white, black, or grey). |

| Fabric for Practice | At least 1-2 yards of quilting cotton or a similar stable woven fabric. |

| Fabric Scissors | A sharp pair dedicated for fabric. |

| Measuring Tape | Flexible for accurate measurements. |

| Straight Pins | A box of about 50-100 pins. |

| Seam Ripper | For correcting any errors. |

| Iron and Ironing Board | For pressing seams. |

| Chalk or Fabric Marker | For marking fabric. |

Setting Up Your Sewing Machine for Straight Stitch

Preparing your sewing machine correctly is a crucial step in achieving beautiful and consistent straight stitches. This section will guide you through the essential setup processes, ensuring your machine is ready for success. A well-prepared machine makes the entire sewing experience smoother and more enjoyable, leading to professional-looking results.

Threading the Sewing Machine

Threading your sewing machine properly is fundamental for any stitching, especially for a clean straight stitch. The thread path needs to be precise to ensure the needle receives the thread correctly and that the loop formation with the bobbin thread is balanced. Incorrect threading can lead to skipped stitches, thread breakage, or uneven tension.To thread your sewing machine for a straight stitch:

- Begin by raising the presser foot and lowering the needle to its highest position.

- Locate the spool pin and place your spool of thread on it, ensuring the thread unwinds smoothly from the spool.

- Follow the numbered guides on your machine, typically starting with threading through the first tension disc, then looping around the second tension disc.

- Pass the thread through the take-up lever, ensuring it goes from right to left (or as indicated by your machine’s diagram).

- Continue guiding the thread down through the lower thread guides, often located near the needle.

- Finally, thread the needle from front to back (or side to side, depending on your machine model). Gently pull about 4-6 inches of thread through the eye of the needle.

Winding a Bobbin

A properly wound bobbin is essential for consistent stitch formation. An unevenly wound bobbin can cause the thread to snag, break, or create a messy underside to your stitching. The goal is to have a smooth, even layer of thread that unwinds without resistance.To wind a bobbin correctly:

- Place an empty bobbin onto the bobbin winder spindle.

- Secure the bobbin by pushing it onto the spindle until it clicks or locks into place.

- Take the end of the thread from your spool and guide it through the small hole on the bobbin.

- Hold the end of the thread taut and press the foot pedal lightly to start winding. Wind a few turns by hand to secure the thread end.

- Move the bobbin winder mechanism into the engaged position, usually by sliding a small lever or pushing the bobbin spindle to the side.

- Begin winding the bobbin by pressing the foot pedal. Keep an even pressure on the thread as it winds onto the bobbin.

- Once the bobbin is nearly full, stop winding and disengage the bobbin winder mechanism.

- Cut the thread and remove the full bobbin from the spindle.

It’s important to use bobbins that are specifically designed for your sewing machine model, as they vary in size and shape.

Inserting the Bobbin

The bobbin case houses the bobbin and works in conjunction with the needle thread to create stitches. Proper insertion ensures that the bobbin thread is fed correctly to the needle.The steps for inserting a bobbin into the machine are as follows:

- Locate the bobbin case area, which is usually a small compartment under the needle plate.

- If your machine has a removable bobbin case, carefully remove it.

- Place the wound bobbin into the bobbin case, ensuring the thread unwinds in the correct direction as per your machine’s manual. Typically, the thread should unwind counter-clockwise for most machines.

- Guide the bobbin thread through the small slit or notch in the bobbin case, pulling it taut to ensure it’s seated correctly.

- If your machine has a shuttle hook system (no removable bobbin case), you will typically insert the bobbin directly into the bobbin housing, ensuring the thread unwinds in the designated direction.

- Gently pull the thread to confirm the bobbin is secure and the thread is flowing freely.

Selecting the Appropriate Stitch Length

The stitch length setting determines how far the fabric moves forward with each needle penetration, directly influencing the density and appearance of your stitches. For a standard straight stitch, a medium length is generally suitable for most fabrics and purposes.For a straight stitch, consider these stitch length guidelines:

- 1.5mm to 2.5mm: This range is excellent for fine fabrics, detailed work, or when you want a dense, secure stitch, such as for appliqué or basting.

- 2.5mm to 3.5mm: This is the most common and versatile range for general sewing on medium-weight fabrics like cotton, linen, and blends. It provides a good balance of strength and speed.

- 3.5mm and above: Longer stitches are typically used for temporary purposes like basting or for very thick fabrics where shorter stitches might create too much bulk.

Always perform a test stitch on a scrap piece of your fabric to determine the best stitch length for your specific project.

Adjusting Stitch Tension

Stitch tension refers to the balance between the upper thread (from the needle) and the lower thread (from the bobbin). Proper tension is vital for creating a neat, strong stitch that lies flat on both sides of the fabric. Uneven tension can result in puckering, loops, or skipped stitches.To adjust stitch tension for optimal straight stitch results:

- Upper Tension: This is usually adjusted with a dial or lever on the front or top of your machine. Lower numbers typically mean looser tension, and higher numbers mean tighter tension.

- Bobbin Tension: The bobbin tension is adjusted by a small screw on the bobbin case (if applicable) or by the bobbin housing itself. This adjustment is less frequent but crucial for overall balance.

The goal is to achieve a balanced stitch where the needle thread and bobbin thread meet and interlock precisely in the middle of the fabric layers.

A properly balanced straight stitch will look the same on both the top and bottom of the fabric, with no visible loops or puckering.

Perform test stitches on a scrap of your fabric. If the upper thread is looping on the underside, increase the upper tension slightly or decrease the bobbin tension. If the bobbin thread is showing on the top side, decrease the upper tension slightly or increase the bobbin tension. Make small, incremental adjustments and re-test until the tension is perfect.

Visual Description of a Properly Set Up Sewing Machine for a Straight Stitch

Imagine your sewing machine ready for action. The spool of thread is seated on the spool pin, unwinding smoothly. The thread follows a clear path, guided through the tension discs, the take-up lever, and all the designated guides, culminating in the needle’s eye. The needle is correctly inserted and at its highest point. The bobbin, wound evenly and securely, is housed within the machine, with its thread pulled through to meet the upper thread.

The presser foot is lowered, holding the fabric taut, and the stitch length and tension dials are set to your desired parameters. The machine appears neat, with no loose threads or tangled parts, signifying it’s prepared to create precise and beautiful straight stitches.

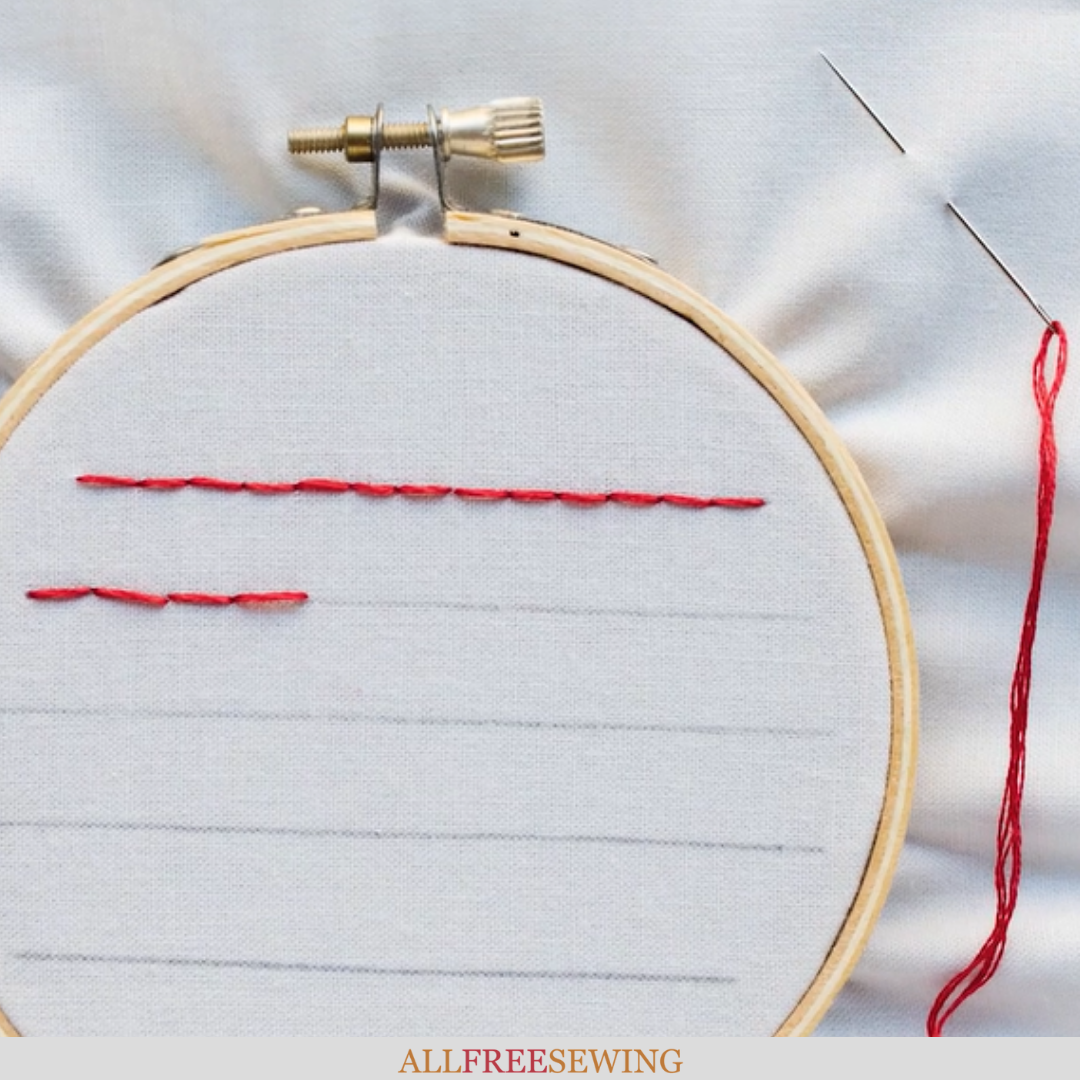

Practicing the Straight Stitch on Fabric

Now that you have a foundational understanding of your sewing machine and the necessary tools, it’s time to put your knowledge into practice by sewing your very first straight stitch on fabric. This section will guide you through the essential steps to achieve clean, consistent straight stitches, covering everything from guiding the fabric to reinforcing your seams. Mastering the straight stitch is the cornerstone of all sewing techniques, so let’s begin this exciting journey.This phase is crucial for building muscle memory and confidence.

It involves carefully controlling the fabric as it moves under the needle, ensuring a smooth and even stitch line. We will break down each step to make it as clear and manageable as possible for beginners.

Guiding Fabric Under the Presser Foot

The way you guide the fabric is paramount to achieving a straight and even stitch. The sewing machine does the work of pulling the fabric through, so your role is to gently steer it. Avoid pushing or pulling the fabric forcefully, as this can lead to uneven stitches, skipped stitches, or even damage to your fabric or machine.To guide the fabric, place it flat on the machine bed with the edge aligned with the markings on your needle plate or presser foot.

Gently lower the presser foot onto the fabric. Then, with your hands placed a comfortable distance from the presser foot, lightly hold the fabric on either side. Use your fingertips to guide the fabric, allowing the feed dogs of the machine to move it forward. Maintain a consistent speed and pressure. Your hands should move with the fabric, not against its direction of travel.

Imagine you are gently nudging the fabric along its path.

Starting and Ending a Straight Stitch Seam Securely

Properly starting and ending a seam prevents it from unraveling during use or washing. This involves a technique called backstitching, which effectively locks the stitches in place.To start a seam securely, place your fabric under the presser foot with the needle in its highest position. Lower the presser foot. Turn the handwheel towards you to lower the needle into the fabric at the starting point.

Sew forward for about 2-3 stitches. Then, engage the reverse lever or button on your machine and sew backward over those same stitches for the same distance. Release the reverse lever and continue sewing forward to complete your seam.To end a seam securely, sew forward until you reach the end of your desired seam length, typically about 1-2 centimeters from the fabric edge.

Engage the reverse lever or button and sew backward over the last few stitches. Release the reverse lever and sew forward again to the fabric edge. For extra security on seams that will bear a lot of stress, you can repeat the backstitch once more. After backstitching, raise the presser foot, lift the needle to its highest position, and carefully pull the fabric away from the machine.

Use your scissors to snip the threads, leaving a tail of about 10-15 centimeters.

Sewing a Straight Line Without a Guide

While many sewing machines have markings on the needle plate or presser foot to help you sew a straight line, there will be times when you need to sew a straight stitch without these visual aids, or when the markings aren’t sufficient for your needs. This requires developing a keen eye and a steady hand.To sew a straight line without a guide, practice observing the needle and the edge of the fabric.

You can also use the edge of the presser foot as a guide if it aligns with your desired seam allowance. For instance, if you want a 1.5 cm (or 5/8 inch) seam allowance, and your presser foot has a marking or edge that is exactly 1.5 cm from the needle, you can align the fabric edge with that marking.

Consistent practice is key. Focus on keeping the fabric edge parallel to the needle and the direction of sewing. Imagine a straight line extending from the needle to the end of the fabric, and try to keep your fabric following that imaginary line.

Backstitching to Reinforce the Beginning and End of a Seam

Backstitching is a fundamental technique for creating durable seams. It involves sewing in reverse over a few stitches to create a strong knot that prevents the seam from unraveling.The procedure for backstitching is as follows:

- Start sewing forward on your fabric.

- After sewing 2-3 stitches, locate the reverse lever or button on your sewing machine.

- Press and hold the reverse lever/button to sew backward over the stitches you just made.

- Release the reverse lever/button and continue sewing forward to complete your seam.

- When you reach the end of your seam, repeat steps 2-4 to backstitch over the final stitches.

This process creates a dense area of stitches at the beginning and end of your seam, acting as a secure anchor.

Step-by-Step Guide for Sewing a Straight Seam Along a Fabric Edge

Sewing along a fabric edge is a common task, often used for hemming or creating simple seams. This process requires careful alignment and consistent guidance of the fabric.Here is a step-by-step guide:

- Prepare your fabric by pressing it flat and marking your seam line or hem if necessary.

- Place the fabric under the presser foot with the needle in its highest position. Align the fabric edge with the desired seam allowance marking on your machine’s needle plate or presser foot.

- Lower the presser foot.

- Turn the handwheel towards you to lower the needle into the fabric at the starting point.

- Sew forward for 2-3 stitches.

- Engage the reverse lever/button and sew backward over those stitches for the same distance to backstitch.

- Release the reverse lever/button and continue sewing forward, guiding the fabric to maintain a consistent distance from the edge and the needle.

- As you approach the end of your seam, slow down.

- Sew forward to the end of the desired seam length.

- Engage the reverse lever/button and sew backward over the last few stitches to backstitch.

- Raise the presser foot, lift the needle to its highest position, and carefully remove the fabric.

- Snip the threads, leaving a tail of about 10-15 cm.

Common Beginner Errors When Sewing a Straight Stitch and How to Correct Them

It is perfectly normal for beginners to encounter a few hiccups when learning to sew a straight stitch. Understanding these common mistakes and their solutions will help you improve quickly.Here are some typical beginner errors and their corrections:

- Uneven Stitches: This can occur if the fabric is being pushed or pulled, or if the sewing speed is inconsistent.

- Correction: Gently guide the fabric without forcing it. Ensure your hands move with the fabric, allowing the machine’s feed dogs to do the work. Practice sewing at a steady, consistent speed.

- Skipped Stitches: This often happens due to incorrect needle insertion, a dull or bent needle, or threading issues.

- Correction: Ensure the needle is inserted correctly and is the appropriate type for your fabric. Check that the machine is threaded properly, both for the top thread and the bobbin. Try a new, sharp needle.

- Thread Bunching or Looping Underneath: This is usually a sign of improper upper thread tension or incorrect threading.

- Correction: Re-thread the upper thread, ensuring it is seated correctly in all the tension discs and guides. Adjust the upper thread tension dial to a slightly higher number.

- Sewing Off the Fabric Edge: This happens when the fabric is not aligned correctly or is allowed to drift away from the guide.

- Correction: Pay close attention to the markings on your needle plate or presser foot. Keep the fabric edge consistently aligned with your chosen guide. If necessary, use a piece of tape as a temporary guide on the machine bed.

- Seam Unraveling: This is a direct result of not backstitching at the beginning or end of a seam.

- Correction: Always remember to backstitch at least 2-3 stitches at the start and end of every seam.

Advanced Straight Stitch Techniques and Tips

Now that you have a solid understanding of the basic straight stitch, it’s time to explore techniques that will elevate your sewing projects. Mastering these advanced skills will not only improve the appearance and durability of your seams but also open up a world of creative possibilities. We will delve into the impact of different presser feet, learn how to navigate curves and corners with precision, ensure consistent seam allowances, troubleshoot common issues, and even design a project to put your newfound skills to the test.

Presser Foot Influence on Straight Stitch Sewing

The presser foot is a crucial component of your sewing machine, guiding the fabric and ensuring even tension. Different presser feet are designed for specific tasks, and understanding their function can significantly enhance your straight stitch sewing.

- Standard Presser Foot: This is the most common foot and is suitable for general straight stitching on most fabrics. It provides a stable platform for guiding the fabric.

- Walking Foot: Ideal for sewing multiple layers of fabric or slippery materials, the walking foot feeds the top and bottom layers of fabric evenly, preventing shifting and puckering. This is particularly useful for quilting and sewing thick materials.

- Zipper Foot: This specialized foot allows you to sew very close to the edge of a zipper, ensuring a neat and professional finish. It can be adjusted to the left or right of the needle.

- Edge Stitching Foot (or Topstitching Foot): This foot has a small guide that runs along the edge of the fabric or a folded seam, helping you create perfectly straight and evenly spaced topstitching.

- Rolled Hem Foot: While primarily used for creating narrow rolled hems, this foot can also be adapted for very precise straight stitching along delicate edges, ensuring a clean and finished appearance.

Sewing Curves and Corners with a Straight Stitch

Executing smooth curves and sharp corners with a straight stitch requires practice and a few key techniques. These skills are essential for creating professional-looking garments and decorative items.To sew a curve:

- Begin sewing as usual, guiding the fabric with your hands.

- As you approach the curve, slow down your sewing speed.

- Gently pivot the fabric as you sew, allowing the needle to create a series of small stitches that follow the curve. Avoid trying to force a continuous curve with large movements; instead, make small adjustments to the fabric’s direction.

- For tighter curves, you may need to stop with the needle down in the fabric and pivot more frequently.

To sew a corner:

- Sew up to the point where the corner begins.

- Stop with the needle down in the fabric, precisely at the corner point.

- Lift the presser foot.

- Pivot the fabric 90 degrees.

- Lower the presser foot and continue sewing along the next edge.

- For an outward-facing corner, you can also lift the presser foot and pivot the fabric without stitching, then lower the foot and continue.

Achieving Consistent Seam Allowances

Consistent seam allowances are vital for ensuring that your pattern pieces fit together correctly and that your finished project has a professional look. A seam allowance is the distance between the edge of the fabric and the stitching line.Several methods can help you achieve consistent seam allowances:

- Machine Markings: Most sewing machines have markings on the needle plate that indicate common seam allowance measurements (e.g., 1/4 inch, 3/8 inch, 5/8 inch). Use these as a guide to align your fabric edge.

- Seam Gauge: A seam gauge is a small ruler with a sliding marker that you can set to your desired seam allowance. Place it on your machine bed or use it to mark your fabric.

- Painter’s Tape: For very precise or unusual seam allowances, you can use painter’s tape to create a guide on your machine’s needle plate. Place the tape at the desired distance from the needle.

- Edge of Presser Foot: If your presser foot has a specific edge that consistently aligns with your desired seam allowance, you can use that as a visual cue.

- Marking Fabric: For particularly tricky fabrics or when accuracy is paramount, you can use a fabric marker or chalk to draw your seam allowance line on the fabric before sewing.

“Precision in seam allowance is the foundation of a well-constructed garment.”

Troubleshooting Common Straight Stitch Issues

Even with practice, you might encounter common issues with your straight stitches. Understanding the potential causes and solutions will help you get back to sewing smoothly.

| Problem | Possible Causes | Solutions |

|---|---|---|

| Skipped Stitches | Incorrect needle type or size for the fabric | Use the correct needle (e.g., universal, ballpoint for knits, sharp for wovens) and ensure it’s not bent or dull. |

| Needle inserted incorrectly | Ensure the flat side of the needle faces the back of the machine and is fully inserted. | |

| Thread tension issues | Adjust upper and lower thread tension; re-thread the machine. | |

| Uneven Stitches (Puckering or Looping) | Incorrect thread tension | Adjust upper and lower thread tension. Often, the upper tension is too tight or the lower tension is too loose. |

| Wrong needle for the fabric | Use a needle appropriate for the fabric type. For knits, a ballpoint needle prevents skipped stitches and damage. | |

| Sewing too fast or too slow | Maintain a consistent sewing speed. | |

| Thread Breaking | Thread tension too high | Reduce upper thread tension. |

| Burred needle or presser foot | Inspect the needle and presser foot for any rough spots or damage; replace if necessary. |

Practice Project: The Simple Patch Pouch

To consolidate your understanding of straight stitch techniques, a simple patch pouch is an excellent project. It requires sewing multiple straight stitches, including seams, a hem, and potentially decorative topstitching. Project Description:This project involves creating a small, unlined pouch with a simple flap closure. It’s designed to practice straight seams, turning a hem, and optionally, adding decorative topstitching for a polished finish.

Materials:

- Two pieces of fabric for the main pouch (e.g., 8″ x 6″ each)

- One piece of fabric for the flap (e.g., 8″ x 4″)

- Matching or contrasting thread

- Sewing machine with a straight stitch

- Scissors

- Pins

Steps:

- Prepare the Flap: Take the flap piece and fold it in half lengthwise, right sides together. Sew along the long edge with a 1/4 inch seam allowance. Turn right side out and press. Topstitch along the folded edge for a neat finish (this is a great place to practice your edge stitching foot if you have one).

- Prepare the Pouch Body: Take one of the pouch body pieces. Fold down the top edge by 1/2 inch, then fold down another 1/2 inch to create a double hem. Press and stitch close to the folded edge to secure the hem. Repeat for the second pouch body piece.

- Attach the Flap: Place one of the hemmed pouch body pieces right side up. Pin the raw edge of the prepared flap to the top raw edge of the pouch body, with the flap facing down (so when you turn it, it will face upwards). Sew across the top with a 1/4 inch seam allowance.

- Sew the Pouch Sides: Place the second hemmed pouch body piece right side down on top of the first piece, aligning all raw edges. Sew down the two sides and across the bottom with a 1/2 inch seam allowance. Leave the top open.

- Turn and Finish: Turn the pouch right side out. You can use a point turner to gently push out the corners. Your simple patch pouch is complete, showcasing your straight stitch skills!

Appearance of a Well-Executed Straight Stitch

A properly executed straight stitch is characterized by its neatness, consistency, and strength. Observing its appearance on both sides of the fabric is key to identifying a quality stitch.On the right side of the fabric:

- The stitches should appear as a single, unbroken line of thread.

- They should be evenly spaced and consistent in length.

- There should be no visible looping or puckering of the fabric.

- The stitch should lie flat and blend seamlessly with the fabric.

On the wrong side of the fabric:

- The stitches should form a series of small, uniform loops or interlocking threads that mirror the stitches on the right side.

- The thread should not be excessively loose, creating large loops, nor should it be pulled so tight that it distorts the fabric.

- The tension should be balanced, meaning the upper and lower threads meet neatly in the middle of the fabric layers.

“A good straight stitch is a testament to careful machine setup and precise fabric handling.”

Understanding Stitch Length and Tension

The appearance and durability of your sewing projects are significantly influenced by two fundamental settings on your sewing machine: stitch length and tension. Mastering these elements is crucial for achieving professional-looking and long-lasting results. This section will delve into what each setting controls and how they interact to create the perfect stitch.

Stitch Length Explained

Stitch length refers to the distance between each individual stitch. It is typically measured in millimeters (mm) on your sewing machine dial or digital display. The stitch length you choose directly impacts the fabric’s durability and how it drapes. Shorter stitches create a denser seam that is stronger and less likely to fray, making them ideal for high-stress areas or fine fabrics.

Longer stitches, on the other hand, create a more open seam that can be more flexible and may be suitable for decorative purposes or certain types of fabric where a less rigid seam is desired.

The Role of Stitch Tension

Stitch tension refers to the balance of pressure applied by the top thread and the bobbin thread as they interlock. The goal is to achieve a “balanced” stitch where both threads meet evenly in the middle of the fabric. Proper tension ensures that the stitches lie flat, look neat on both sides of the fabric, and hold the fabric together securely without puckering or breaking.

Your sewing machine has adjustable tension settings for both the top thread and, on some machines, the bobbin.

Visual and Functional Differences of Stitch Length

A stitch that is too long will appear as distinct, widely spaced loops of thread on the fabric. Functionally, these stitches are weak and prone to breaking, especially under strain. They can also unravel easily. Conversely, a stitch that is too short will appear as very dense, almost compressed lines of thread. While this can offer strength, excessively short stitches can cause the fabric to pucker, lead to thread breakage due to the strain of pulling through the fabric, and create a stiff, unattractive seam.

Consequences of Unbalanced Tension

Unbalanced tension is a common sewing issue that can manifest in several ways. If the top thread tension is too loose, the bobbin thread will likely show on the top side of the fabric, creating loops or a “scrappy” appearance. If the top thread tension is too tight, the top thread will pull the bobbin thread through to the top, causing puckering and potentially breaking the top thread.

If the bobbin tension is too loose, you’ll see loops of the bobbin thread on the top side. If the bobbin tension is too tight, the bobbin thread will pull the top thread down, causing puckering and potentially thread breakage.

Recommended Stitch Length and Tension Settings for Common Fabrics

Achieving optimal stitch quality often involves adjusting your machine’s settings based on the fabric you are using. The following table provides a general guideline for recommended stitch lengths and typical tension settings for various fabric types. Remember that these are starting points, and you may need to make slight adjustments based on your specific machine and the fabric’s exact weight and weave.

| Fabric Type | Recommended Stitch Length (mm) | Typical Tension Setting (out of 4) |

|---|---|---|

| Lightweight Cotton | 1.5 – 2.0 | 3 |

| Medium Weight Denim | 2.0 – 2.5 | 3.5 – 4 |

| Knit Fabric | 2.0 – 2.5 (with stretch stitch if available) | 3 |

Fabric Handling for Straight Stitch Accuracy

Achieving perfectly straight stitches is significantly influenced by how you handle the fabric as it passes under the sewing machine needle. Proper fabric manipulation ensures consistent stitch length, prevents puckering, and ultimately leads to a professional-looking finish. This section will guide you through the essential techniques for managing your fabric effectively.The fundamental principle of fabric handling is to allow the feed dogs of your sewing machine to do the work of moving the fabric.

Your role is to gently guide it, ensuring it moves smoothly and evenly without any external force. This natural movement is crucial for consistent stitch formation.

Feeding Fabric Smoothly and Evenly

To feed fabric smoothly, begin by placing it under the presser foot, ensuring the needle is lowered into the fabric at the starting point. As you begin sewing, your hands should be positioned lightly on either side of the presser foot, not directly in front of the needle. Your hands act as stabilizers, providing gentle guidance rather than propulsion. Imagine your hands are there to keep the fabric from drifting left or right, or from bunching up.

The feed dogs, located beneath the presser foot, are designed to grip the fabric and move it forward with each stitch.

The Importance of Not Pulling or Pushing Fabric

Pulling or pushing the fabric while sewing will disrupt the feed dogs’ action and lead to uneven stitches. If you pull the fabric, you are essentially forcing it through the machine at a rate faster than the feed dogs can manage, resulting in elongated stitches and potential skipped stitches or thread breakage. Conversely, pushing the fabric can cause it to bunch up, creating tight, short stitches and a puckered appearance.

The machine is engineered to move the fabric; your hands are there to ensure it moves straight and unimpeded.

Keeping Fabric Aligned with the Seam Guide

Maintaining alignment with the seam guide is critical for sewing straight lines, especially when creating seams. Most sewing machines have markings on the needle plate that serve as seam guides, indicating distances from the needle (e.g., 1/4 inch, 3/8 inch, 5/8 inch). Position the edge of your fabric along the desired seam guide marking before you start sewing. As you sew, keep your eye on the fabric edge and how it relates to the seam guide, making minor adjustments with your guiding hands to keep it perfectly aligned.

This visual cue is your primary tool for sewing a straight seam.

Visualizing Natural Fabric Movement

When sewing correctly, the fabric should appear to move naturally and effortlessly under the presser foot. You will see a steady, even progression of fabric disappearing under the presser foot and emerging from the back. There should be no tension or strain visible in the fabric itself. It should lie flat as it moves, without any wrinkles or bulges forming in front of or behind the needle.

The stitch length will remain consistent, reflecting the smooth, unimpeded journey of the fabric.To summarize best practices for fabric handling, consider the following list of “dos and don’ts” for beginners:

- Do: Gently guide the fabric with your hands, applying minimal pressure to keep it steady and on course.

- Do: Ensure the fabric edges are aligned with your chosen seam guide before and during sewing.

- Do: Keep your focus on the fabric edge as it relates to the seam guide, making subtle adjustments as needed.

- Do: Allow the sewing machine’s feed dogs to move the fabric naturally; your role is to guide, not to drive.

- Don’t: Yank or force the fabric through the machine, as this disrupts stitch formation and can damage the fabric or machine.

- Don’t: Let the fabric bunch up in front of the presser foot; this indicates you are pushing or not guiding smoothly.

- Don’t: Pull the fabric from behind the needle, as this creates uneven stitches and can cause skipped stitches or thread breakage.

- Don’t: Hold the fabric taut or create tension, as this will distort the fabric and result in puckered seams.

Epilogue

As we conclude our exploration of the straight stitch, remember that practice is your greatest ally. By understanding the interplay of stitch length, tension, and fabric handling, you’ve gained the foundational skills to create neat, durable seams. Whether you’re hemming a garment, assembling a quilt, or embarking on a new creative endeavor, your ability to sew a perfect straight stitch will serve as a reliable and satisfying building block for all your future sewing adventures.