Embarking on the journey of sewing zippers can feel daunting, but with the right tools and techniques, it becomes an art form. This guide will illuminate the path to mastering the zipper foot, transforming a potentially intricate task into a seamless and rewarding experience for any sewing enthusiast.

We will explore the fundamental purpose and diverse applications of the zipper foot, from identifying the correct attachment for your machine to skillfully maneuvering fabric and zipper for professional-looking results. Whether you’re a beginner seeking clarity or an experienced sewer looking to refine your skills, this comprehensive overview promises to equip you with the knowledge to confidently tackle any zipper project.

Introduction to Zipper Feet

A zipper foot is a specialized sewing machine attachment designed to make the process of sewing zippers significantly easier and more precise. Its unique construction allows the needle to get very close to the edge of the zipper teeth, resulting in a neat and professional finish. This attachment is a fundamental tool for anyone looking to achieve professional-looking results when incorporating zippers into their sewing projects.The primary function of a zipper foot is to guide the fabric and the zipper teeth close to the needle.

Unlike a standard presser foot, which has a wide base that would interfere with the zipper teeth, a zipper foot has a narrow base with a groove on the underside. This groove accommodates the zipper teeth, allowing the needle to stitch directly beside them without skipping or breaking. This close proximity is crucial for securely attaching the zipper and for creating a clean, flat appearance.Zipper feet are commonly used with a wide range of sewing machines, including most mechanical and computerized domestic sewing machines.

The attachment mechanism typically involves a screw that secures the foot to the presser bar. Most modern machines are designed to accommodate standard zipper feet, and if your machine uses a different attachment system, specialized adapters may be available.The benefits of using a zipper foot for sewing zippers are numerous and directly contribute to a higher quality finished product.

- Precision Stitching: The design allows for stitches to be placed extremely close to the zipper teeth, ensuring a secure attachment and preventing fabric from getting caught.

- Professional Appearance: This close stitching creates a clean, flat, and professional-looking zipper insertion, which is often difficult to achieve with a standard foot.

- Ease of Use: It simplifies the process of sewing zippers, making it less frustrating and more efficient, especially for beginners.

- Versatility: Zipper feet can be used for both centered and invisible zippers, although specific techniques may vary.

Identifying and Preparing the Zipper Foot

Selecting and correctly attaching the zipper foot are crucial initial steps for achieving professional-looking zipper installations. This specialized presser foot is designed to get your needle as close as possible to the zipper teeth, ensuring a neat and secure stitch. Proper identification and preparation will prevent sewing machine issues and fabric damage, setting you up for success.A standard zipper foot is easily distinguishable from other presser feet by its distinctive shape.

It typically features a narrow, often C-shaped or U-shaped, opening on one side, allowing the needle to stitch very close to a raised edge like a zipper or a piping cord. The other side of the foot is usually solid and designed to glide smoothly over the fabric.

Locating the Correct Zipper Foot

To ensure optimal performance and compatibility, it is essential to identify the zipper foot that is specifically designed for your sewing machine model. Manufacturers often create presser feet with unique attachment mechanisms or specific clearances that are tailored to their machines. Using a generic or incompatible foot can lead to skipped stitches, fabric distortion, or even damage to your machine’s needle plate or the foot itself.To find the correct zipper foot:

- Consult your sewing machine’s user manual. This is the most reliable source for identifying compatible accessories.

- Visit the sewing machine manufacturer’s official website. They usually have a section dedicated to accessories and parts where you can search by model number.

- Check the packaging of your sewing machine. Often, a zipper foot is included as a standard accessory.

- If unsure, contact the sewing machine manufacturer’s customer support or visit an authorized dealer. They can help you pinpoint the exact part number for your machine.

Common Features and Components of a Standard Zipper Foot

Understanding the typical components of a zipper foot will help you recognize and utilize it effectively. While designs may vary slightly between brands, the core functionality remains consistent.A standard zipper foot generally includes:

- Narrow Toe/Groove: This is the most defining feature, an elongated slot or groove on one side of the foot. This allows the needle to swing from side to side and stitch extremely close to the edge of the fabric or the zipper teeth.

- Presser Foot Shank Connector: This is the part that attaches to the sewing machine’s presser foot holder. It’s designed to be compatible with either a low-shank or high-shank system, which is common across many sewing machine brands.

- Smooth Underside: The bottom of the foot is typically smooth to allow it to glide effortlessly over various fabric types without snagging.

- Clearance for Needle Movement: The design ensures there is sufficient space for the needle to move from left to right (if your machine has a zigzag stitch) without striking the foot.

Attaching a Zipper Foot to the Sewing Machine

The process of attaching a zipper foot is generally straightforward and follows the same basic principle as changing any other presser foot. It is important to ensure the machine is powered off and the needle is in its highest position before beginning.To attach a zipper foot:

- Lower the Presser Foot Lifter: Ensure the presser foot lifter arm is in the down position.

- Remove the Existing Foot: Most sewing machines have a quick-release mechanism. Press the lever or button located behind the presser foot holder, and the current foot will detach. If your machine requires a screw to be loosened, use a screwdriver to remove the old foot.

- Position the Zipper Foot: Hold the new zipper foot so that its shank aligns with the presser foot holder. The groove or narrow toe of the zipper foot should be positioned to accommodate the needle.

- Engage the Attachment Mechanism:

- For machines with a quick-release system, simply push the zipper foot upwards until it clicks securely into place on the presser foot bar.

- For machines requiring screws, align the foot and use the provided screw and screwdriver to fasten it securely to the presser foot holder. Ensure it is snug but do not overtighten.

- Raise the Presser Foot Lifter: Lift the presser foot lifter arm to ensure the foot is properly seated and the needle is positioned correctly within the foot’s groove.

“The precision of a zipper foot lies in its ability to bring the needle infinitesimally close to the edge, creating a clean, professional finish.”

Basic Zipper Insertion Techniques

Now that you’re familiar with your zipper foot and how to prepare it, let’s delve into the practical application of attaching a zipper to your sewing projects. This section will guide you through the fundamental steps, ensuring a professional and neat finish every time. We’ll cover everything from positioning your fabric and zipper correctly to managing the zipper pull as you sew.

Attaching a Zipper to Fabric

Attaching a zipper is a common sewing task, and using the zipper foot makes it significantly easier to achieve a clean stitch line close to the zipper teeth. This technique is applicable to a wide range of projects, from garment fly fronts and dress plackets to cushion covers and bags. The process involves carefully aligning the zipper tape with the edge of your fabric and guiding it through the sewing machine.

The specialized design of the zipper foot allows you to get very close to the zipper’s teeth, which is crucial for both aesthetic appeal and the functional integrity of the zipper.

Fabric and Zipper Positioning for Accurate Stitching

Precise placement of the fabric and zipper is paramount for a successful zipper insertion. This ensures that the zipper is straight, evenly spaced from the fabric edge, and that the final stitch line is both secure and visually appealing. Here’s how to position your materials for accurate stitching:

- Prepare the Fabric Edges: Ensure the edges of your fabric where the zipper will be attached are finished neatly. This could involve a simple hem, a serged edge, or a facing, depending on your project.

- Align the Zipper Tape: Place the zipper face down onto the right side of one fabric edge. The teeth of the zipper should be aligned with the raw edge of the fabric, or a predetermined seam allowance away from it, as specified by your pattern.

- Secure the Zipper: Baste the zipper tape to the fabric edge by hand or machine, or use fabric clips to hold it in place. This temporary attachment prevents shifting during the sewing process.

- Position Under the Foot: With the zipper foot attached to your machine, lower the needle into the fabric approximately 1/4 inch from the zipper teeth. The foot’s design allows you to move the needle to either the left or right side, enabling you to stitch very close to the teeth. For the initial stitch, you will typically position the foot so the needle is to the right of the zipper teeth, stitching along the left edge of the zipper tape.

Sewing Close to Zipper Teeth

The ability to sew close to the zipper teeth is the primary advantage of using a zipper foot. This proximity ensures that the zipper tape is securely attached and that the finished product looks professional. Follow these methods for sewing close to the zipper teeth:

- Zipper Foot Adjustment: The zipper foot has a channel or groove on one side that allows the needle to pass very close to the zipper teeth without hitting them. You can often adjust the position of the foot on your machine to move the needle further left or right, depending on which side of the zipper you are sewing.

- Stitch Placement: For a standard centered or invisible zipper, you will typically sew the first side by positioning the zipper foot so the needle is to the right of the zipper teeth. This allows you to stitch along the left edge of the zipper tape, very near to the teeth.

- Consistent Seam Allowance: Maintain a consistent seam allowance from the zipper teeth throughout your stitching. This is usually around 1/8 inch, but always refer to your pattern for specific instructions.

- Second Side Stitching: After sewing the first side, you will typically reposition the fabric and zipper to sew the second side. This often involves turning the fabric and zipper assembly, and adjusting the zipper foot’s position on the machine to stitch along the other edge of the zipper tape.

Handling the Zipper Pull While Sewing

A common challenge when sewing zippers is encountering the zipper pull, which can obstruct your sewing path and potentially damage your needle or machine. Knowing how to manage the pull is essential for uninterrupted sewing. Here are methods for handling the zipper pull:

- Zip it Up (or Down): Before you begin sewing over the area where the zipper pull is located, open the zipper partially. This means if you are sewing the first side of a zipper, you’ll want to zip the pull down away from where you are about to sew. Conversely, if you are sewing the second side, you’ll zip the pull up away from your sewing path.

- Sew to the Pull: Stitch as close to the zipper pull as possible without hitting it.

- Pause and Adjust: When your needle is a safe distance from the zipper pull (e.g., 1/2 inch to 1 inch away), stop your machine with the needle down.

- Move the Pull: Carefully reach under the presser foot and gently move the zipper pull past the area you have just sewn. Ensure the pull is moved completely out of the path of the zipper foot.

- Continue Sewing: Once the zipper pull is safely out of the way, lower your presser foot and continue sewing.

- Securing the Ends: Remember to backstitch at the beginning and end of your zipper insertion to secure the stitches. For the top of the zipper, ensure you stitch across the very top of the zipper tape to lock the pull in place and prevent it from coming off.

Advanced Zipper Insertion and Applications

Now that you are comfortable with the basic zipper foot and its standard applications, let’s explore some more intricate techniques and creative uses for your zipper foot. This section will guide you through mastering invisible zippers, enhancing projects with exposed zippers, and tackling challenging placements like curves and corners, as well as integrating zippers into accessories.

Invisible Zipper Insertion

Invisible zippers offer a seamless and polished finish, making them ideal for garments where a discreet closure is desired. The key to success lies in carefully preparing the zipper and fabric, and using the specialized groove on the zipper foot to guide the zipper tape.

To achieve an invisible zipper:

- Prepare the Zipper: Before sewing, gently press the zipper teeth open with a warm iron. This action straightens them and makes them easier to stitch over. Be cautious not to melt synthetic zipper teeth; use a pressing cloth if necessary.

- Position the Zipper: Place the zipper face down onto the right side of the fabric seam allowance, aligning the zipper teeth with the raw edge of the fabric. The zipper tape should be centered within the seam allowance.

- Attach the Zipper Foot: Replace your standard presser foot with the zipper foot. Ensure the needle is positioned in the groove of the zipper foot that corresponds to the side of the zipper teeth you are currently sewing.

- Sew the First Side: With the zipper foot in place, sew along the edge of the zipper teeth, guiding the zipper tape into the foot’s groove. Stitch as close to the teeth as possible without actually sewing over them.

- Open and Press: Once the first side is sewn, open the fabric flat and press the seam away from the zipper.

- Prepare for the Second Side: Flip the fabric to the wrong side. Re-position the zipper so that the unsewn teeth are aligned with the raw edge of the second seam allowance.

- Sew the Second Side: Attach the zipper foot again, ensuring the needle is in the correct groove for the second side of the zipper. Sew along the zipper teeth, again keeping as close as possible without sewing over the teeth.

- Finish the Seam: Once both sides of the zipper are sewn, you can finish the seam below the zipper as you normally would, using a standard presser foot.

“The magic of an invisible zipper lies in its subtlety; the fabric should appear to magically close without any visible evidence of a closure.”

Exposed and Decorative Zipper Applications

Exposed or decorative zippers add a distinct style element to garments and accessories, serving as both a functional closure and a design feature. The zipper foot is essential for achieving neat and professional results when working with these bolder zippers.

When working with exposed zippers, consider these applications:

- Fashion Garments: Employ exposed zippers on jackets, skirts, and dresses for a modern, edgy look. The zipper pull can also be a statement piece.

- Bags and Pouches: Use contrasting color zippers or those with decorative pulls on tote bags, clutches, or pencil cases to add visual interest.

- Home Decor: Decorative zippers can be incorporated into cushion covers or upholstery for a unique touch.

To sew an exposed zipper:

- Prepare the Fabric: Finish the raw edges of the fabric where the zipper will be inserted.

- Position the Zipper: Place the zipper face up on the right side of the fabric, aligning the zipper teeth with the seam line. The zipper tape will extend into the seam allowance.

- Use the Zipper Foot: Attach the zipper foot and select the groove that allows you to stitch close to the zipper teeth.

- Sewing: Stitch along one side of the zipper teeth, guiding the zipper tape into the foot’s groove. Repeat for the other side. The goal is to have the zipper teeth prominently visible on the right side of the fabric.

Sewing Zippers into Curved Edges or Corners

Attaching zippers to non-straight edges requires careful manipulation of the fabric and zipper to ensure a smooth and professional finish. The zipper foot, with its ability to get close to the teeth, is invaluable here.

Sewing a zipper around a curve or into a corner presents unique challenges:

- Curves: For gentle curves, you can often ease the fabric and zipper together as you sew. For tighter curves, it may be beneficial to clip the seam allowance of the zipper tape at intervals, being careful not to cut into the stitches.

- Corners: When attaching a zipper to a corner, you will typically sew up to the corner point, pivot the fabric, and then continue sewing along the next edge. You may need to reinforce the corner with a few backstitches.

Procedure for curved edges:

- Prepare the Zipper and Fabric: Mark the curve on your fabric. Align the zipper tape with the marked line on the right side of the fabric.

- Use the Zipper Foot: Attach the zipper foot and select the appropriate groove.

- Sew Slowly: Begin sewing, guiding the zipper tape into the foot’s groove. Sew slowly and deliberately, easing the fabric and zipper around the curve. You may need to stop with the needle down, lift the presser foot, and reposition the fabric slightly to navigate the curve smoothly.

- Clipping (for tight curves): If the curve is very tight, make small snips into the zipper tape’s seam allowance, stopping just short of the zipper teeth. This allows the tape to lie flatter.

Procedure for corners:

- Prepare: Mark the corner on your fabric. Pin the zipper tape to the right side of the fabric along the seam line.

- Sew to the Corner: Using the zipper foot, sew along the first edge until you reach the corner point.

- Pivot: Stop with the needle down in the fabric at the corner. Lift the presser foot, pivot the fabric 90 degrees, and lower the presser foot.

- Continue Sewing: Continue sewing along the second edge, guiding the zipper tape into the foot’s groove.

- Reinforce: For added durability, consider backstitching at the corner.

Attaching Zippers to Bags or Other Accessories

Zippers are a fundamental component in bag making, providing secure and accessible closures. The zipper foot is indispensable for neatly installing zippers into the various panels and seams of bags and other accessories.

When attaching zippers to bags, the process often involves working with thicker materials and multiple layers of fabric. The zipper foot’s design is crucial for navigating these challenges.

Procedure for attaching a zipper to a bag panel:

- Prepare the Bag Panels: Ensure the edges of the bag panels where the zipper will be attached are finished or appropriately prepared.

- Position the Zipper: Place the zipper face down on the right side of one bag panel, aligning the zipper teeth with the seam line. The zipper tape will extend into the seam allowance.

- Attach the Zipper Foot: Select the appropriate zipper foot and ensure the needle is in the correct groove for the side of the zipper you are sewing.

- Sew the First Side: Sew along the zipper teeth, guiding the tape into the foot’s groove. For bags, you may encounter thicker interfacing or batting; sew slowly and carefully.

- Attach the Second Panel: Open the first panel flat. Align the second bag panel right side down onto the exposed zipper tape, so the zipper teeth are sandwiched between the two panels.

- Sew the Second Side: Attach the zipper foot again, ensuring it’s positioned correctly for the second side of the zipper. Sew along the zipper teeth, enclosing the raw edges of both bag panels within the seam.

- Topstitching (Optional but recommended): Once the zipper is sewn in, you can topstitch along the right side of the bag, near the zipper teeth, to further secure the zipper and create a decorative finish. Use the zipper foot for this step as well, guiding the fabric so the stitching is parallel to the zipper.

Considerations for different accessories:

- Clutches and Wallets: These often require precise zipper placement and may benefit from interfacing for structure.

- Backpacks and Totes: These can involve heavier duty zippers and may require reinforcing stitches at stress points.

- Pouches: Simple pouches are excellent practice for basic zipper insertion into straight seams.

Troubleshooting Common Zipper Foot Issues

Even with the best preparation, sometimes your sewing machine and zipper foot might present a few challenges. Understanding these common issues and their solutions will ensure a smoother sewing experience and a professional-looking finish on your zippers. This section addresses those occasional hiccups and provides practical advice to overcome them.When you encounter difficulties while sewing zippers with your zipper foot, it’s often related to stitch quality, fabric handling, or the needle’s interaction with the zipper.

Fortunately, most of these problems have straightforward fixes that involve minor adjustments to your machine settings or sewing technique.

Skipped Stitches and Uneven Seams

Skipped stitches can occur when the needle doesn’t properly engage the fabric or thread, leading to gaps in your stitching. Uneven seams might result from inconsistent fabric feeding or incorrect presser foot pressure.To address skipped stitches, ensure your sewing machine is properly threaded with good quality thread. Check that the needle is new and the correct type and size for your fabric.

A bent or dull needle is a common culprit. For uneven seams, verify that the presser foot is correctly attached and that the fabric is feeding smoothly under it. If your machine has adjustable presser foot pressure, experiment with a slightly lighter setting for delicate fabrics.

Adjusting Tension and Stitch Length

The correct tension and stitch length are crucial for creating neat and secure zipper seams. Incorrect settings can lead to puckering, thread breakage, or weak stitches.For optimal zipper sewing, it’s generally recommended to use a medium stitch length, typically between 2.0 and 2.5 mm. This provides enough security without being so long that it compromises the seam’s strength.

For most fabrics, a stitch length of 2.0-2.5 mm is ideal for zipper insertion.

Tension adjustments depend on your sewing machine and the thread you are using. Start with the default tension setting and test on a scrap of your fabric. If the stitches look loopy on the underside, you may need to increase the top tension or decrease the bobbin tension. Conversely, if the stitches are loopy on the top, decrease the top tension or increase the bobbin tension.

Fabric Bunching and Needle Hitting Zipper Teeth

Fabric bunching is often a sign that the fabric is not being fed evenly or that the presser foot is applying too much pressure. The needle hitting zipper teeth can be a more serious issue, potentially damaging both the needle and the zipper.To prevent fabric bunching, ensure that the fabric is laid flat and is not being pulled or pushed as you sew.

Some sewers find it helpful to use a stabilizer or a piece of tissue paper under delicate fabrics. If the needle is hitting the zipper teeth, the most common cause is that the zipper foot is not correctly positioned. Ensure the foot is attached so that the needle is positioned to stitch to the side of the zipper tape, not directly over the teeth.

If your zipper foot has adjustable positions, experiment with shifting it to the left or right.

Maintaining the Zipper Foot for Longevity

Proper care of your zipper foot will ensure its functionality and extend its lifespan, preventing issues before they arise.Regular cleaning is essential. After each use, gently wipe the zipper foot with a soft, dry cloth to remove any lint or stray threads that may have accumulated. For more stubborn residue, a cotton swab lightly dampened with rubbing alcohol can be used, but ensure the foot is completely dry before reattaching it to your machine.

Inspect the foot periodically for any signs of wear or damage, such as cracks or bent components. If damage is found, it is best to replace the foot to avoid further problems with your sewing.

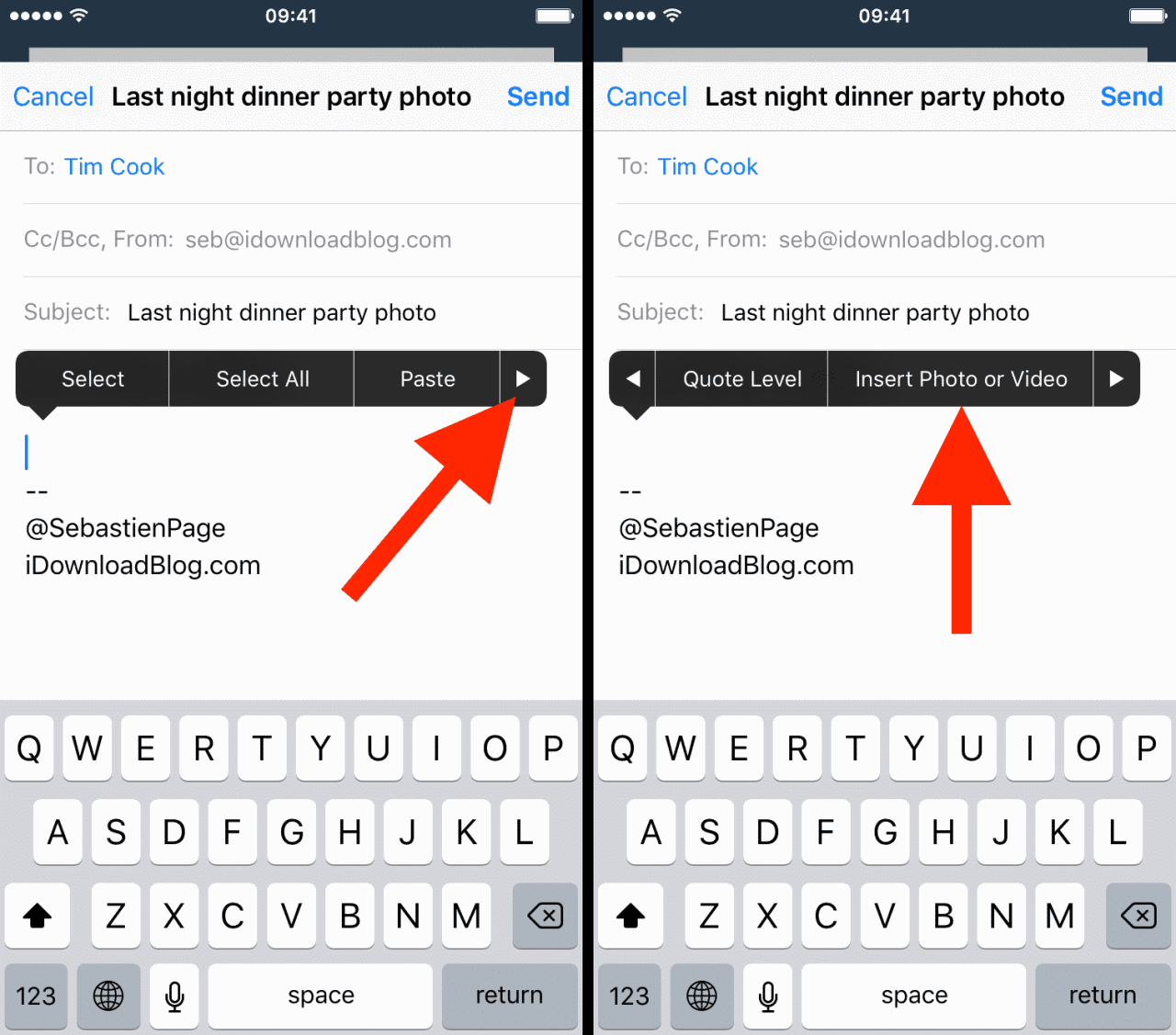

Visualizing Zipper Foot Usage

Understanding how a zipper foot works visually can significantly enhance your sewing accuracy and the professional finish of your projects. This section focuses on what to look for when a zipper foot is used correctly, from the fabric and zipper’s position to the resulting stitch quality.The zipper foot is specifically designed to get your needle close to the zipper teeth without hitting them.

This proximity is crucial for a neat and strong zipper insertion. By observing the process and the outcome, you can better anticipate how your machine will behave and what a well-executed zipper should look like.

Correctly Sewn Zipper Appearance

A correctly sewn zipper using a zipper foot will exhibit several key visual characteristics that denote precision and a professional finish. The most apparent is the alignment of the stitch line to the zipper teeth.

- Seam Alignment: The row of stitches will run parallel and very close to the zipper teeth, typically just a few millimeters away. This close proximity ensures the fabric is securely attached to the zipper tape without any looseness or bunching.

- Stitch Neatness: The stitches themselves will be even, consistent in length, and free from skipped stitches or excessive tension. A consistent stitch line creates a clean, defined edge along the zipper.

- Fabric Lay: The fabric on either side of the zipper will lie flat and smooth, without puckering or distortion. This is a direct result of the presser foot guiding the fabric accurately during the sewing process.

- Zipper Tape Coverage: The stitches should neatly secure the zipper tape to the fabric, preventing the tape from becoming visible from the right side of the garment or bag.

Physical Setup Under the Presser Foot

The physical arrangement of the fabric and zipper beneath the zipper foot is fundamental to its guiding function. The specialized design of the foot allows for this precise positioning.The zipper foot has an offset toe, meaning it’s not centered like a standard presser foot. This offset allows you to position the needle on either the left or right side of the foot, depending on which side of the zipper you are sewing.

| Component | Positioning and Function |

|---|---|

| Zipper Teeth | The zipper teeth are positioned directly next to the raised edge of the zipper foot. This keeps the teeth away from the needle’s path. |

| Zipper Tape | The zipper tape, the fabric strip onto which the teeth are attached, lies flat beneath the foot. The foot presses down on the tape and the adjacent fabric. |

| Fabric | The main fabric piece is positioned alongside the zipper tape, directly under the presser foot. The foot guides both the fabric and the zipper tape, ensuring they feed evenly. |

| Needle | The needle descends through the small opening in the presser foot, positioned to stitch precisely along the edge of the zipper tape and into the main fabric. |

Motion of Needle and Presser Foot

The synchronized movement of the needle and the zipper foot is what creates the strong and aesthetically pleasing zipper seam. Understanding this dynamic interaction helps in controlling the sewing speed and fabric feed.As the sewing machine operates, the presser foot maintains consistent downward pressure on the fabric and zipper tape. Simultaneously, the needle moves up and down, piercing the fabric and tape at a controlled rate.

The offset toe of the zipper foot acts as a guide, keeping the edge of the zipper teeth snug against its raised side. This ensures that as the fabric and zipper feed through, the needle consistently stitches at the optimal distance from the teeth.

The feed dogs of the sewing machine work in conjunction with the presser foot to move the fabric and zipper forward. The zipper foot’s design ensures that this feeding action is smooth and controlled, preventing misalignment or skipped stitches. The result is a continuous, straight line of stitching that securely attaches the zipper to the project.

End of Discussion

In conclusion, the zipper foot is an indispensable tool that unlocks a world of possibilities in garment construction and accessory creation. By understanding its mechanics, mastering attachment, and practicing the techniques Artikeld, you are well-equipped to achieve beautifully integrated zippers every time. Embrace these insights and elevate your sewing projects with newfound confidence and precision.