Embark on a journey to elevate your sewing projects with the art of professional topstitching. This comprehensive guide unlocks the secrets to achieving that coveted polished finish, transforming your creations from homemade to haute couture. We’ll delve into the foundational principles, essential tools, and meticulous techniques that distinguish masterful topstitching.

Discover how understanding the nuances of stitch selection, thread choice, and machine setup can dramatically impact the final aesthetic. From mastering straight lines and perfect corners to navigating challenging fabrics and troubleshooting common issues, this guide provides actionable insights and practical advice for sewers of all levels. Prepare to enhance the durability, style, and overall visual appeal of your garments and accessories.

Understanding the Fundamentals of Professional Topstitching

Professional topstitching is more than just a decorative element; it’s a key technique that elevates the perceived quality and craftsmanship of any sewn project. It involves sewing a visible line of stitching on the outside of a garment or item, typically at a consistent distance from an edge or seam. When executed with precision, topstitching provides structure, enhances durability, and creates a clean, polished aesthetic that signals attention to detail and expertise.

Mastering these foundational principles will set your projects apart and give them a truly professional finish.The core principles of effective topstitching revolve around precision, consistency, and appropriate material selection. Achieving a professional look requires a keen eye for detail and an understanding of how different elements interact. This includes selecting the right thread, needle, and stitch length, as well as maintaining an even distance from the edge.

When these elements are harmonized, the topstitching becomes a deliberate design feature that enhances the overall appeal of the finished product.

Essential Sewing Machine Features for Professional Topstitching

To achieve superior topstitching results, certain sewing machine features are particularly beneficial. These functionalities are designed to provide greater control and consistency, which are paramount for a polished outcome. Investing in or understanding how to best utilize these features on your current machine can significantly improve the quality of your topstitching.

- Adjustable Stitch Length: A precise stitch length is crucial. For topstitching, a slightly longer stitch length (e.g., 2.5-3.5 mm) is often preferred to make the stitching more visible and decorative. The ability to fine-tune this setting ensures optimal appearance on different fabrics.

- Adjustable Presser Foot Pressure: For fabrics that are thick, delicate, or stretchy, being able to adjust the pressure of the presser foot prevents stretching, puckering, or damage. This allows for even feeding of the fabric, resulting in consistent stitch lines.

- Walking Foot or Even Feed Foot: This accessory is invaluable for evenly feeding multiple layers of fabric, preventing shifting and ensuring that topstitching lines remain parallel and consistent, especially on challenging materials like quilting cottons or vinyl.

- Edge Stitching Foot or Binder Attachment: Specialized presser feet, such as an edge stitching foot, guide the fabric to maintain a uniform distance from the edge. Binder attachments are also excellent for creating neat, folded edges with topstitching.

- Needle Up/Down Function: This feature allows the needle to stop in the fabric, providing stability when pivoting at corners or pausing to reposition the fabric, which is essential for sharp, clean topstitching turns.

- Clearance Under the Presser Foot: A higher lift for the presser foot is helpful when sewing over thicker seams or multiple layers, ensuring the fabric can be maneuvered easily without distortion.

Topstitching Versus Edge Stitching

While often used interchangeably, topstitching and edge stitching are distinct techniques with different purposes and applications. Understanding their differences is key to selecting the appropriate method for a desired effect. Both involve visible stitching on the exterior of a project, but their placement and function vary.Topstitching refers to a line of stitching placed at a noticeable distance from a seam or edge, typically between 1/8 inch (3 mm) and 1/4 inch (6 mm) away.

Its primary functions are decorative, adding visual interest, and functional, providing reinforcement and structure to areas like collars, cuffs, and pocket flaps. It can also be used to flatten seam allowances and create crisp edges.Edge stitching, on the other hand, is a very close line of stitching, usually sewn within 1/16 inch (1.5 mm) of the folded edge of a seam allowance or hem.

Its main purpose is to secure the folded edge, prevent it from rolling or fraying, and create a very neat, almost invisible finish on the right side of the fabric. It’s often used on garment hems, facings, and the edges of collars and cuffs to achieve a clean, professional boundary.

Common Pitfalls in Professional Topstitching

Learning to topstitch with a professional finish involves navigating several common challenges. Recognizing these pitfalls beforehand allows for proactive measures to avoid them, leading to a smoother learning curve and more satisfying results. Consistent practice and attention to detail are key to overcoming these hurdles.

- Inconsistent Stitch Length: This is one of the most noticeable flaws. Uneven stitch lengths make the topstitching appear sloppy and unprofessional. This can be caused by inconsistent fabric feeding or incorrect tension settings.

- Uneven Distance from the Edge: If the topstitching is too close to the edge, it can cause the fabric to pucker or even tear. If it’s too far, it can look unintentional and detract from the design. This often stems from not using a guide or having an unsteady hand.

- Fabric Puckering or Stretching: Using the wrong needle, thread, or stitch length, or applying too much pressure with the presser foot, can cause the fabric to pucker or stretch, distorting the stitch line and the overall appearance.

- Thread Breaking or Skipped Stitches: Incorrect needle size for the thread and fabric, worn-out needles, or improper machine threading can lead to thread breakage or skipped stitches, interrupting the continuity of the topstitching.

- Poorly Turned Corners: Achieving sharp, crisp corners requires practice. Rushing the process or not properly lifting the presser foot and pivoting the fabric can result in rounded or messy corners.

- Visible Seam Allowance Threads: If the topstitching is too far from the edge or the seam allowance is not trimmed properly, threads from the seam allowance can become visible on the right side, detracting from the clean finish.

Essential Tools and Materials for Topstitching

Achieving a professional topstitched finish requires careful consideration of the tools and materials used. The right selection not only enhances the aesthetic appeal of your project but also contributes significantly to its durability and overall quality. This section delves into the primary components that form the foundation of excellent topstitching.The selection of threads and needles is paramount, as is the choice of the appropriate presser foot.

Each element plays a distinct role in ensuring precision, consistency, and a polished final appearance. Understanding the function and characteristics of each component will empower you to make informed decisions for your specific sewing projects.

Primary Tools and Notions for Professional Topstitching

A well-equipped sewing station is crucial for executing precise and attractive topstitching. The following tools and notions are considered essential for achieving a professional look:

- Sewing Machine: A reliable sewing machine with adjustable stitch length and tension is fundamental. Modern machines often come with specialized feet and settings that aid in topstitching.

- Topstitching Thread: This is typically a thicker, stronger thread designed to be visible and durable.

- Needles: The correct needle type and size are critical for preventing fabric damage and ensuring a clean stitch.

- Presser Feet: Specific presser feet are designed to guide fabric accurately and create even topstitching.

- Seam Ripper: For correcting any errors, a seam ripper is an indispensable tool.

- Fabric Shears and Scissors: Sharp cutting tools are necessary for preparing fabric accurately.

- Measuring Tape and Ruler: Precision in measuring is key for consistent seam allowances and topstitching placement.

- Marking Tools: Chalk, fabric pens, or tailor’s chalk are used to mark stitching lines.

- Iron and Ironing Board: Pressing seams before and during topstitching is vital for a crisp finish.

Ideal Threads for Topstitching

The thread is the most visible element of topstitching, so its selection profoundly impacts the final aesthetic. Choosing the right thread ensures that the topstitching stands out as a decorative and functional element.The characteristics of ideal threads for topstitching revolve around their strength, thickness, and finish. These attributes dictate how the stitch will appear on the fabric and how well it will withstand wear and tear.

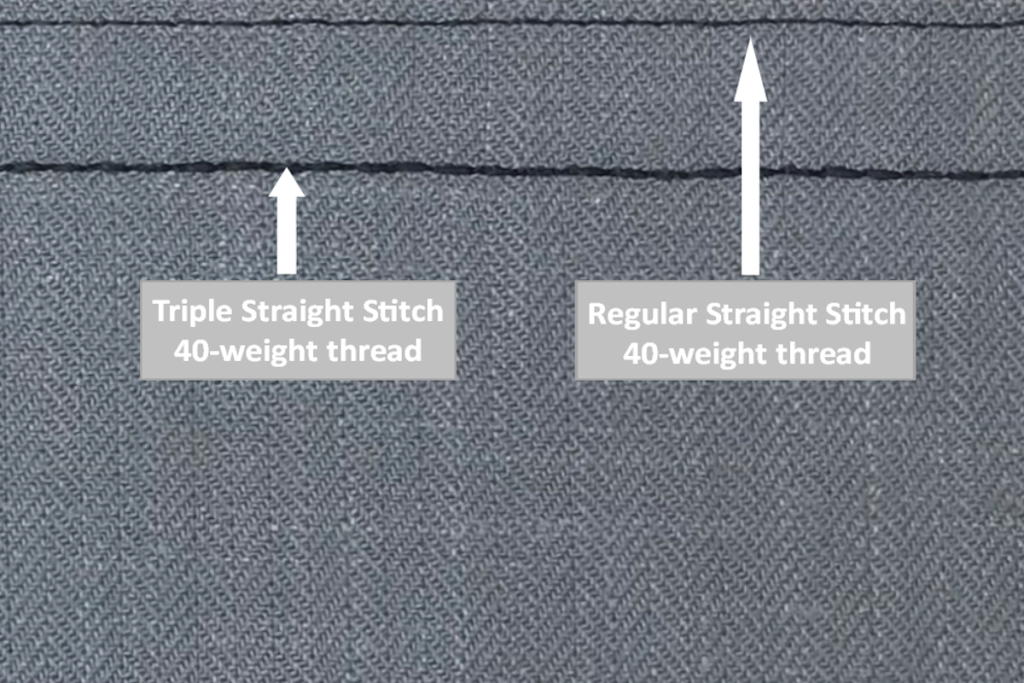

- Weight and Thickness: Topstitching threads are generally heavier than standard all-purpose threads. Common weights include sizes 30, 40, and 50 (where a lower number indicates a thicker thread). Thicker threads create a more prominent, decorative stitch.

- Material: Polyester and cotton are common choices. Polyester offers excellent strength and durability, while cotton provides a more matte, natural appearance. Blends can offer a combination of these properties.

- Finish: Threads can have various finishes, such as mercerized (for a subtle sheen and strength), glazed (for a smoother finish), or matte. The finish affects the thread’s reflectivity and how it interacts with light.

- Color Matching: While contrasting threads are often used for a bold look, matching threads can create a more subtle, integrated design. The choice depends on the desired visual effect.

The Role of Different Presser Feet in Achieving Precise Topstitching

Presser feet are instrumental in guiding fabric and ensuring consistent stitch placement, especially for topstitching where accuracy is paramount. Different feet are designed to address specific topstitching challenges and requirements.The primary function of a presser foot is to hold the fabric securely against the feed dogs while the needle stitches. Specialized topstitching feet offer features that facilitate precise control and create aesthetically pleasing results.

- Standard Presser Foot: While versatile, it offers limited guidance for precise topstitching along edges or in channels.

- Edge Stitching Foot (or Stitch-in-the-Ditch Foot): This foot has a small blade or guide in the center that runs along a seam or fold, allowing you to stitch precisely next to it. It is ideal for stitching in the “ditch” of a seam or for creating a neat edge.

- Zipper Foot: Although primarily for zippers, its narrow design can be useful for topstitching close to a raised edge or in tight spaces.

- Walking Foot: This foot feeds the top layer of fabric at the same rate as the bottom layer, preventing shifting and puckering, which is highly beneficial for topstitching multiple layers or slippery fabrics.

- Blind Hem Foot: While for blind hems, its guide can be adapted for precise topstitching at a consistent distance from an edge.

- Quilting Guides: Many machines can accommodate quilting guides that attach to the presser foot shank, allowing for perfectly parallel topstitching lines at a set distance from an edge.

Selecting the Right Needles for Various Fabric Types and Thread Weights

The needle is the direct interface with the fabric and thread, making its selection critical for preventing skipped stitches, fabric damage, and thread breakage. The type and size of the needle must be coordinated with both the fabric being sewn and the weight of the thread being used.Using the wrong needle can lead to fraying, holes, and an unprofessional appearance.

A correctly chosen needle will pierce the fabric cleanly, creating a smooth path for the thread.

| Fabric Type | Recommended Needle Type | Recommended Thread Weight (Example) | Needle Size Range (Example) |

|---|---|---|---|

| Lightweight Woven Fabrics (e.g., cotton lawn, voile) | Universal, Microtex (sharp tip) | 60-80 | 60/8 – 70/10 |

| Mediumweight Woven Fabrics (e.g., quilting cotton, linen) | Universal, Sharp | 40-60 | 70/10 – 80/12 |

| Heavyweight Woven Fabrics (e.g., denim, canvas) | Denim/Jeans, Sharp | 30-50 | 90/14 – 110/18 |

| Knits (e.g., jersey, interlock) | Ballpoint, Stretch, Jersey | 50-70 | 70/10 – 80/12 |

| Leather and Vinyl | Leather, Sharp | 30-50 | 90/14 – 110/18 |

| Silks and Satins | Microtex, Sharp | 60-80 | 60/8 – 70/10 |

For topstitching, especially with heavier threads like size 30 or 40, it is often beneficial to use a needle that is one or two sizes larger than you would typically use for the fabric. This helps accommodate the thicker thread and prevents it from snagging or breaking.

Preparing Your Fabric and Machine for Topstitching

Achieving a professional finish in topstitching begins long before the needle meets the fabric. Meticulous preparation of both your materials and your sewing machine is paramount to ensuring your stitches are even, consistent, and beautifully integrated into your project. This section will guide you through the essential steps to set yourself up for success.The quality of your topstitching is directly influenced by how well your fabric and machine are prepared.

Skipping these crucial steps can lead to puckering, skipped stitches, uneven tension, and an overall unprofessional appearance, regardless of your skill level. Taking the time to properly prepare will save you frustration and deliver superior results.

Fabric Preparation for Topstitching

Proper fabric preparation ensures that your material lies flat and stable, allowing for precise stitching. Different fabric types require specific approaches to achieve the best outcome.The first step in preparing any fabric for topstitching is to ensure it is clean and free of any finishes that might interfere with the stitching process. Pre-washing fabrics, especially natural fibers like cotton and linen, helps to pre-shrink them, preventing your finished project from distorting after washing.Pressing is a critical stage in fabric preparation.

A well-pressed fabric lies flat, making it easier to guide through the sewing machine and ensuring that your topstitching follows the intended lines accurately. Use the appropriate heat setting for your fabric type, and consider using a pressing cloth for delicate materials to prevent scorching or shine.Stabilization techniques are vital for fabrics that tend to stretch, fray, or are very lightweight.

This helps to provide a more consistent surface for your needle to penetrate and your thread to form stitches.

- Woven Fabrics: For most stable woven fabrics like cotton, linen, and denim, thorough pressing is usually sufficient. Ensure all seams are pressed open or to one side as required by your pattern.

- Knit Fabrics: Knit fabrics, due to their inherent stretch, often benefit from stabilization. A lightweight fusible interfacing applied to the wrong side can help prevent stretching and provide a more stable edge for topstitching. For very stretchy knits, a wash-away stabilizer can be used on the surface during stitching and then removed.

- Delicate Fabrics: For silks, satins, and other delicate fabrics, use a lower heat setting on your iron and a pressing cloth. If stabilization is needed, opt for a very lightweight, sheer fusible interfacing that won’t alter the drape of the fabric.

- Leather and Vinyl: These materials generally do not require pre-washing or stabilization. However, it’s crucial to use the correct needle (e.g., a leather or Teflon foot) and avoid excessive pressing, as heat can damage the material.

Sewing Machine Setup for Optimal Topstitching

Setting up your sewing machine correctly is as important as preparing your fabric. The right adjustments will ensure your machine performs at its best for topstitching.The goal of machine setup for topstitching is to achieve consistent stitch formation and smooth fabric feeding. This involves adjusting tension, stitch length, and selecting the appropriate needle and presser foot.

Tension Adjustment

Tension controls how tightly the upper thread and bobbin thread are pulled together. For topstitching, you want the threads to meet evenly in the middle of the fabric, creating a balanced stitch.

For ideal topstitching, the upper thread should be slightly looser than the bobbin thread, allowing the bobbin thread to sit flush on the fabric’s surface and the upper thread to lie neatly on the top.

You can test your tension on a scrap of the same fabric you will be using for your project. If the bobbin thread is showing on the top side, the upper tension is too tight or the bobbin tension is too loose. If the upper thread is showing on the underside, the upper tension is too loose or the bobbin tension is too tight.

Adjust one dial at a time until you achieve a balanced stitch.

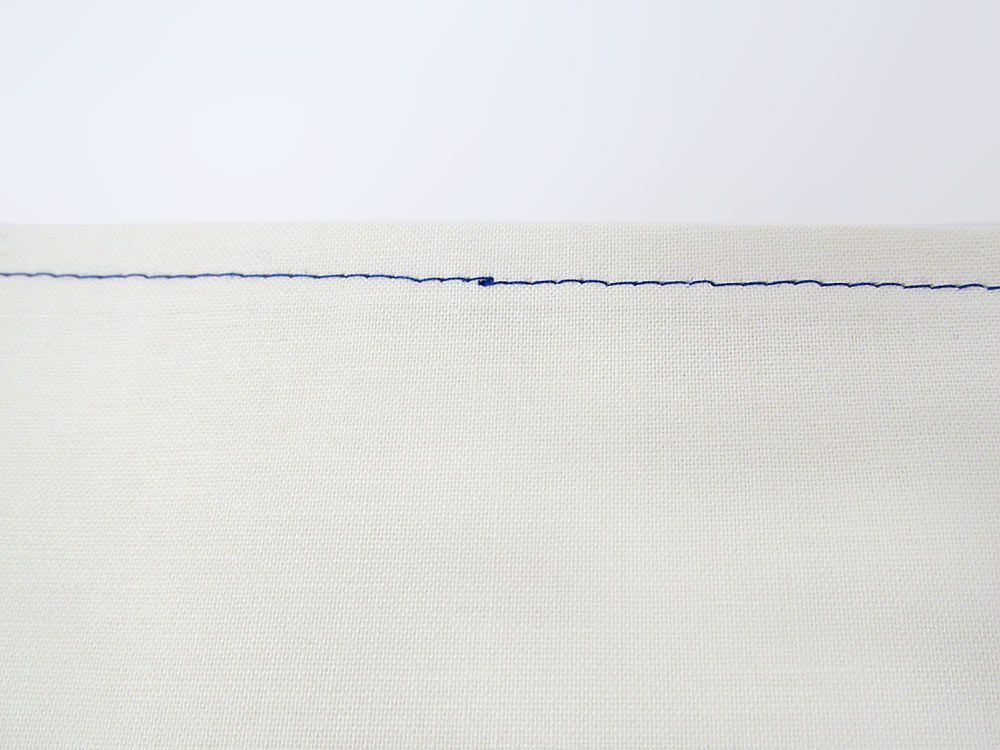

Stitch Length

A slightly longer stitch length is often preferred for topstitching as it creates a more decorative and visible stitch line, while also being more forgiving on certain fabrics.The standard stitch length for many sewing tasks is 2.0-2.5 mm. For topstitching, consider increasing this slightly to 2.5-3.5 mm. This length provides a more pronounced stitch that stands out beautifully on the fabric surface.

Always test on a scrap piece to determine the optimal length for your specific fabric and thread combination.

Needle and Presser Foot Selection

The choice of needle and presser foot significantly impacts the quality of your topstitching.

- Needle: Use a sharp, new needle appropriate for your fabric type. A universal needle in size 80/12 or 90/14 is a good starting point for many fabrics. For denim or canvas, a denim needle (size 90/14 or 100/16) is recommended. For knits, a ballpoint or stretch needle will prevent skipped stitches.

- Presser Foot: A standard presser foot can work, but a walking foot or a stitch-in-the-ditch foot can be invaluable for topstitching. A walking foot feeds multiple layers of fabric evenly, preventing shifting and puckering. A stitch-in-the-ditch foot helps guide the fabric to create perfectly placed topstitching along seams. A roller foot is excellent for slippery or sticky materials like leather or vinyl.

Best Practices for Bobbin Winding and Thread Consistency

Consistent thread is the backbone of beautiful topstitching. This applies to both your upper thread and your bobbin thread.Ensuring your bobbin is wound smoothly and your thread is of good quality and consistent type will prevent interruptions and ensure an even stitch.

- Bobbin Winding: Wind your bobbins slowly and evenly. Avoid overfilling the bobbin, as this can cause it to snag or unravel unevenly. Ensure the thread is winding neatly with no overlaps or loose loops. Use the same type and weight of thread for both the bobbin and the upper spool.

- Thread Quality: Invest in good quality sewing thread. Cheap threads are more prone to breaking, fraying, and creating lint, all of which can negatively impact your topstitching. For topstitching, consider using a slightly heavier weight thread (e.g., a 30wt or 40wt cotton or polyester thread) for the upper thread to make the stitch more prominent. Ensure your bobbin thread is a standard weight (e.g., 50wt or 60wt) and matches the fiber content of your upper thread as closely as possible.

- Thread Condition: Check your thread for any knots, kinks, or fraying before winding your bobbin or threading your machine.

Pre-Topstitching Machine Adjustment Checklist

Before you begin your topstitching, run through this checklist to ensure your machine is perfectly calibrated.This checklist serves as a quick reference to confirm all necessary machine settings and components are in order for optimal topstitching.

- [ ] Needle is sharp and appropriate for fabric type.

- [ ] Presser foot is suitable for the fabric and desired topstitching effect (e.g., walking foot, standard foot).

- [ ] Upper thread tension is set correctly (tested on scrap fabric).

- [ ] Bobbin is wound evenly and is not overfilled.

- [ ] Bobbin thread type and weight are appropriate.

- [ ] Stitch length is set to 2.5-3.5 mm (or as tested on scrap).

- [ ] Machine is clean and free of lint.

- [ ] Fabric is properly prepared (pressed, stabilized if necessary).

- [ ] Thread paths are clear and the thread is properly threaded through the machine.

Mastering Basic Topstitching Techniques

With the fundamentals and tools in place, we now focus on the practical application of topstitching. This section will guide you through achieving clean, precise stitches that elevate your sewing projects from ordinary to professional. Mastering these techniques requires patience and practice, but the results are well worth the effort.This segment delves into the core techniques that form the backbone of professional-looking topstitching.

We will explore how to maintain straight lines, navigate tricky corners and curves, and ensure your stitches are consistently spaced and free from errors.

Sewing a Straight, Consistent Topstitch Along a Seam

Achieving a perfectly straight topstitch along a seam is fundamental to a professional finish. This involves maintaining a consistent distance from the seam line and ensuring your fabric feeds smoothly through the machine.To sew a straight, consistent topstitch:

- Establish your seam allowance: Before you begin stitching, decide on the desired distance from the seam line for your topstitch. A common distance is 1/8 inch (3mm) or 1/4 inch (6mm), but this can vary depending on the project and desired aesthetic.

- Use a seam guide or edge stitching foot: A seam guide, often a metal plate attached to your machine, can be set to a specific distance from the needle, providing a physical fence to guide your fabric. Alternatively, an edge stitching foot (also known as a topstitching foot) has a blade that runs along the seam, allowing you to maintain a consistent distance.

- Mark your stitching line (optional): For extra precision, especially on lighter fabrics or when starting out, you can mark your topstitching line with a fabric marker or chalk.

- Maintain consistent speed and pressure: As you sew, keep your speed steady and apply even pressure on the fabric. Avoid pushing or pulling the fabric, as this can distort the stitch line.

- Guide, don’t force: Gently guide the fabric with your hands, ensuring it stays against the seam guide or edge of the foot. The machine does the work of pulling the fabric through.

- Backstitch at the beginning and end: Secure your topstitching by backstitching a few stitches at the start and end of each line.

Topstitching Corners and Curves with Precision

Navigating corners and curves requires a slightly different approach to maintain the integrity and visual appeal of your topstitching. These areas are often where less experienced sewers encounter difficulties.For precise topstitching on corners:

- Approach the corner: Sew up to the corner point, stopping with your needle down in the fabric.

- Pivot: Lift the presser foot and pivot the fabric so that your next stitching line will be perpendicular to the previous one, forming a crisp corner. Ensure your distance from the edge is consistent.

- Lower the presser foot and continue: Lower the presser foot and resume stitching. For sharp exterior corners, you might want to backstitch a stitch or two at the corner point for added reinforcement.

For precise topstitching on curves:

- Sew slowly: Curves require a slower stitching speed to allow for smooth manipulation of the fabric.

- Lift and pivot frequently: As you approach a curve, stop with the needle down in the fabric. Lift the presser foot and pivot the fabric in small increments, inching your way around the curve.

- Maintain consistent distance: Continuously check that your distance from the seam or edge remains consistent as you pivot. An edge stitching foot is particularly helpful here.

- Guide gently: Use your hands to gently ease the fabric around the curve, ensuring it flows smoothly.

Methods for Achieving Even Stitch Spacing and Avoiding Skipped Stitches

Even stitch spacing contributes significantly to a polished appearance, while skipped stitches can mar the finish. Both are addressed through careful machine setup and technique.To achieve even stitch spacing and avoid skipped stitches:

- Thread quality: Use good quality thread that is appropriate for your fabric. Cheap or old thread can be prone to breaking or causing skipped stitches.

- Needle selection: Ensure you are using the correct needle type and size for your fabric and thread. A sharp, new needle is crucial. For example, a universal needle is suitable for most fabrics, while a ballpoint needle is for knits, and a microtex needle for fine, densely woven fabrics.

- Correct tension: Properly adjust your machine’s tension. If the top thread is too loose, it will create loops on the underside of the fabric. If it’s too tight, the bobbin thread will show on the top. Consult your sewing machine manual for guidance on tension adjustment.

- Presser foot pressure: Some sewing machines allow you to adjust the presser foot pressure. Too much pressure can flatten the fabric and lead to skipped stitches, while too little can cause uneven feeding.

- Smooth fabric feeding: Avoid pulling or pushing the fabric. Allow the feed dogs of your sewing machine to do the work of moving the fabric forward.

- Test on scraps: Always test your stitch length and tension on a scrap of your project fabric before starting on the actual garment.

Practice Exercise for Developing Consistent Topstitching Pressure and Speed

Developing consistent pressure and speed is crucial for achieving professional-looking topstitching. This practice exercise is designed to build muscle memory and fine-tune your control. Exercise: The Topstitching GridThis exercise will help you develop control over your sewing machine’s speed and the pressure you apply to the fabric, leading to more uniform stitch lines. Materials:

- Two pieces of fabric, at least 8×10 inches (20×25 cm) each, preferably from the same material as your project.

- A ruler and fabric marker or chalk.

Instructions:

- Prepare your fabric: Take one piece of fabric. Using your ruler and fabric marker, draw a grid of parallel lines on the fabric, spaced 1/4 inch (6mm) apart. Draw both horizontal and vertical lines. Aim for at least 10-15 lines in each direction.

- Set up your machine: Install a topstitching needle and thread. Set your stitch length to a medium setting, around 2.5mm. If you have an edge stitching foot, attach it.

- Begin stitching: Start at one edge of the fabric and sew along the first horizontal line. Focus on maintaining a consistent speed. Do not try to go fast; prioritize smoothness.

- Maintain consistent pressure: As you sew, consciously focus on applying even, gentle pressure to the fabric with your hands. Avoid jerky movements or excessive force.

- Follow the lines: Continue stitching along each horizontal line, striving for consistency in speed and pressure.

- Repeat vertically: Once you have completed the horizontal lines, turn your fabric and repeat the process with the vertical lines.

- Analyze your results: Examine your stitched lines. Are they straight? Is the stitch length consistent? Are there any skipped stitches? Identify areas where you struggled and focus on those during your next practice session.

- Increase difficulty (optional): Once you feel comfortable with straight lines, try drawing and stitching diagonal lines or simple curves on a separate piece of fabric to further challenge your control.

Consistent practice is the key to mastering any sewing technique. Dedicate time to this exercise before starting your main project to build confidence and precision.

Advanced Topstitching for a Professional Aesthetic

Moving beyond the fundamentals, advanced topstitching techniques elevate your projects from good to exceptional, imparting a polished and professional finish. This section delves into specialized methods for handling various fabric types and achieving decorative effects that showcase your skill and creativity.Successfully topstitching delicate fabrics requires a gentle yet precise approach to avoid damage, while bulky materials demand strategies that integrate smoothly without adding unwanted thickness.

Decorative topstitching opens a world of creative possibilities, transforming simple seams into design features. Understanding the nuances of different needle applications further refines your control and aesthetic outcomes.

Topstitching Delicate Fabrics

Working with delicate fabrics such as silk, chiffon, organza, or fine knits necessitates careful consideration to preserve their inherent beauty and integrity. The goal is to achieve a clean, defined stitch line without puckering, stretching, or distorting the fabric.Here are key techniques for topstitching delicate fabrics:

- Stabilization: Employing a lightweight, water-soluble stabilizer or a sheer fusible interfacing can provide essential support to prevent stretching and puckering. Apply the stabilizer to the wrong side of the fabric before stitching.

- Needle Selection: Use a fine, sharp needle, such as a microtex or sharp needle (size 60/8 or 70/10), to minimize fabric damage and create clean perforations.

- Thread Choice: Opt for fine threads like silk thread or a good quality polyester thread that complements the fabric weight. Avoid heavy or coarse threads that can overwhelm delicate fibers.

- Presser Foot: A walking foot or an even-feed foot is highly recommended for delicate fabrics. These feet help to feed the top and bottom layers of fabric evenly, preventing slippage and ensuring consistent stitch length.

- Stitch Length and Tension: Begin with a slightly shorter stitch length (e.g., 1.8-2.0 mm) and adjust tension carefully. Test on a scrap piece to find the optimal balance that secures the fabric without pulling or causing it to ripple.

- Gentle Handling: Guide the fabric with a light touch, allowing the machine to do the work. Avoid pulling or stretching the fabric as it feeds through the machine.

- Pressing: Press seams from the wrong side using a pressing cloth and a low to medium heat setting appropriate for the fabric type.

Topstitching Bulky Materials

Topstitching on bulky materials like denim, canvas, upholstery fabrics, or multiple layers of thick cotton requires methods that manage the volume and ensure a smooth, professional appearance without creating excessive bulk.Strategies for successful topstitching on bulky materials include:

- Needle and Thread: Use a strong, sharp needle appropriate for the fabric’s weight (e.g., a denim needle or a heavy-duty needle, size 90/14 to 110/18). A strong polyester thread or a heavy-duty cotton thread is suitable. For a pronounced effect, consider using a thicker topstitching thread in the upper looper of a serger or as your main needle thread.

- Presser Foot: A walking foot is invaluable for bulky fabrics, as it helps to feed multiple layers evenly and prevent shifting. A roller foot can also be effective for very thick or sticky materials.

- Seam Allowance and Preparation: Trim seam allowances to reduce bulk where topstitching will occur, especially in areas like collars or cuffs. Press seam allowances flat and in the same direction.

- Stitch Length: A slightly longer stitch length (e.g., 2.5-3.5 mm) is often preferable for bulky fabrics, as it provides better control and a more aesthetically pleasing look on these robust materials.

- Edge Stitching Techniques: When topstitching close to an edge, consider using a zipper foot or a specialized edge-stitching foot to guide the fabric accurately and maintain a consistent distance from the fold.

- Pre-pressing: Thoroughly press all seams and edges before topstitching. This step is crucial for controlling the bulk and ensuring the fabric lies flat.

- Graduated Seam Allowances: In areas where multiple seams converge, consider graduating the seam allowances (trimming them to different widths) to reduce the overall thickness.

Decorative Topstitching Effects

Decorative topstitching transforms functional seams into eye-catching design elements, adding texture, dimension, and visual interest to garments and home décor items. This involves using different threads, stitch types, and placement strategies.Explore these methods for achieving decorative topstitching:

- Contrasting Threads: Use a thread color that stands out significantly from the fabric to create a bold, graphic effect. This is particularly effective on garments, bags, and home furnishings.

- Multiple Threads: Experiment with combining different thread weights or colors in the needle or bobbin for unique textural effects.

- Specialty Threads: Utilize metallic, variegated, or silk threads to add shimmer, color variation, or a luxurious sheen.

- Decorative Stitches: If your sewing machine offers them, explore decorative stitches like zig-zag, heirloom stitches, or embroidery stitches for unique seam embellishments. Ensure the stitch is appropriate for the fabric and desired effect.

- Topstitching Patterns: Create geometric patterns, follow curved lines, or stitch Artikels of motifs. This requires careful marking and precise machine control.

- Satin Stitch Topstitching: For very decorative effects, especially on edges or as an embellishment, a dense satin stitch can be used, though this is more akin to embroidery and requires specific machine capabilities or techniques.

- Piping and Cording: Incorporating decorative cording or piping within a topstitched seam adds a dimensional and refined edge.

Double-Needle Topstitching vs. Single-Needle Techniques

The choice between a double needle and a single needle for topstitching depends on the desired aesthetic, the fabric type, and the specific application. Each offers distinct advantages and results.Here’s a comparison of double-needle and single-needle topstitching:

| Feature | Double-Needle Topstitching | Single-Needle Topstitching |

|---|---|---|

| Appearance | Creates two parallel stitch lines on the right side of the fabric with a zigzag or bar tack on the wrong side, providing a clean, professional, and often decorative finish. | Creates a single stitch line, offering versatility for precise seam finishes, edge stitching, and functional topstitching. |

| Application | Ideal for decorative seams, hemming on knits (creating a coverstitch effect), adding parallel decorative lines on collars, cuffs, and yokes, and achieving a classic jeans look. | Essential for edge stitching, topstitching close to seams, reinforcing stress points, creating precise topstitched details, and when intricate curves or corners are involved. |

| Setup | Requires a double needle, two spools of thread (often of the same color, but can be contrasting), and careful threading of the machine to ensure the bobbin thread engages correctly. | Uses a standard single needle and a single spool of thread. |

| Control & Precision | Can be more challenging to navigate tight curves or corners due to the wider stitch area. Requires careful attention to ensure even tension and stitch formation. | Offers greater control and precision for detailed work, sharp corners, and intricate designs. |

| Fabric Suitability | Works well on wovens and stable knits. On very fine or delicate fabrics, it can sometimes cause puckering if not properly stabilized. | Suitable for virtually all fabric types, from the most delicate to the heaviest, with appropriate needle and thread selection. |

| Example Use | Hemming t-shirts, adding decorative bands to shirts, creating parallel lines on pockets. | Topstitching along a collar edge, creating a decorative border on a placemat, reinforcing a stress seam on a bag. |

Understanding these advanced techniques empowers you to tackle a wider range of projects with confidence, ensuring that every topstitched detail contributes to a truly professional and aesthetically pleasing outcome.

Troubleshooting Common Topstitching Issues

Even with careful preparation and technique, topstitching can sometimes present challenges. Understanding how to identify and resolve these common issues will ensure your projects maintain that polished, professional finish you’re aiming for. This section provides practical solutions to common problems, helping you achieve consistent and beautiful results.Puckering is a frequent frustration in sewing, especially with topstitching where the stitch is visible.

It occurs when the fabric is being gathered or bunched up by the needle and thread as it passes through. This can be caused by a variety of factors related to tension, needle choice, and fabric handling.

Puckering Prevention and Solutions

Puckering during topstitching is often a sign of excess fabric being drawn up by the needle. Addressing the underlying causes, from thread tension to fabric stability, is key to achieving smooth, flat seams.

The primary causes of puckering and their solutions include:

- Incorrect Thread Tension: If the upper thread tension is too tight, it can pull the fabric, causing it to bunch. Conversely, if the bobbin tension is too tight, it can also create puckering. Adjust both upper and bobbin tensions incrementally until the stitches lie flat. A good starting point is to test tension on scraps of your project fabric.

- Wrong Needle: A needle that is too large or too small for the fabric weight can lead to puckering. For instance, a large needle creates a bigger hole, allowing more fabric to be drawn through. Ensure you are using the appropriate needle size and type (e.g., universal, sharp, ballpoint) for your fabric.

- Fabric Handling: Pulling or stretching the fabric as you sew can cause it to distort and pucker. Always guide the fabric gently through the machine without forcing it. Using a walking foot can help feed the fabric evenly, reducing the likelihood of puckering.

- Stitch Length: Very short stitch lengths can sometimes contribute to puckering as the needle perforates the fabric more frequently in a small area. Experiment with slightly longer stitch lengths if puckering persists.

- Presser Foot Pressure: If the presser foot pressure is too high, it can crush the fabric and contribute to puckering. Most machines have adjustable presser foot pressure; try reducing it slightly.

Uneven stitch tension can manifest in various ways, often appearing as loops on one side of the fabric or gaps where the stitches should be. Achieving balanced tension between the upper thread and the bobbin is crucial for secure and attractive topstitching.

Fixing Uneven Stitch Tension

Loops on the fabric surface or gaps between stitches indicate an imbalance in the tension between your upper thread and bobbin. Correcting this requires systematic adjustments to ensure a neat and consistent stitch.

To address uneven stitch tension:

- Identify the Location of Loops/Gaps: If loops are appearing on the top of the fabric, the upper thread tension is likely too loose, or the bobbin tension is too tight. If loops are appearing on the underside (bobbin side), the upper thread tension is too tight, or the bobbin tension is too loose.

- Adjust Upper Thread Tension: Most sewing machines have a dial or numerical setting for upper thread tension. To loosen it, turn the dial to a lower number or in the opposite direction of tightening. To tighten it, increase the number or turn in the direction of tightening. Make small adjustments (e.g., by one increment at a time).

- Adjust Bobbin Tension: The bobbin tension is typically adjusted by a small screw on the bobbin case or bobbin housing. Turning this screw clockwise tightens the tension, and counter-clockwise loosens it. This adjustment is more delicate, so make very small turns.

- Test on Scraps: After each adjustment, sew a few stitches on a scrap piece of your project fabric. Examine the stitches to see if the loops or gaps have disappeared. Continue adjusting until the stitches are balanced, with the upper and bobbin threads meeting neatly within the fabric layers.

- Check Thread Path: Ensure the upper thread is correctly threaded through all the guides, tension discs, and the needle. Sometimes, a skipped guide can cause tension issues.

Skipped stitches and thread breakage are disruptive to the topstitching process, often indicating a problem with the needle, thread, or machine setup. Swiftly diagnosing and resolving these issues will prevent significant delays and ensure the integrity of your stitching.

Correcting Skipped Stitches and Thread Breakage

These common sewing frustrations can often be traced back to issues with the needle, thread, or the way the machine is threaded. By systematically checking these elements, you can quickly get back to producing perfect topstitching.

To resolve skipped stitches and thread breakage:

- Check and Replace the Needle: A bent, dull, or broken needle is a primary cause of skipped stitches and thread breakage. Always use a new, sharp needle appropriate for your fabric. If you suspect a needle issue, replace it immediately.

- Ensure Proper Threading: Double-check that the upper thread is correctly threaded through all the guides, tension discs, and the presser foot. Re-thread the machine entirely, ensuring the presser foot is up when threading to allow the tension discs to open.

- Verify Bobbin Insertion: Make sure the bobbin is inserted correctly and the thread is feeding smoothly from it. For front-loading bobbins, ensure the thread is seated in the bobbin case’s tension spring.

- Examine the Thread: Poor quality thread, knots in the thread, or thread that is too old can cause breakage. Ensure you are using good quality thread and that it is not tangled or knotted.

- Clean the Machine: Lint and dust buildup in the bobbin area and around the feed dogs can interfere with the stitch formation, leading to skipped stitches. Clean your machine regularly according to the manufacturer’s instructions.

- Adjust Tension: As discussed previously, incorrect tension can also lead to skipped stitches and breakage. Ensure your tensions are balanced.

Inconsistent stitch length and wobbly lines detract from the professional appearance of topstitching. These issues often arise from fabric handling, machine speed, or the interaction between the needle and the fabric.

Addressing Inconsistent Stitch Length and Wobbly Lines

Achieving straight, evenly spaced stitches is fundamental to professional topstitching. When lines waver or stitch lengths vary, it suggests a need to refine fabric control, machine speed, and guidance techniques.

Methods for correcting inconsistent stitch length and wobbly lines include:

- Consistent Fabric Feeding: The most common cause of wobbly lines is inconsistent fabric feeding. Ensure you are guiding the fabric smoothly and evenly, without pulling or pushing. A walking foot or even feed dogs can help maintain consistent feeding.

- Machine Speed Control: Sewing at a consistent speed is crucial. Many sewists find it helpful to use the foot pedal to control speed gradually, rather than starting and stopping abruptly. Practicing sewing at a slow, steady pace can improve control.

- Using Machine Guides: Utilize the seam guides on your sewing machine’s throat plate or the edge of your presser foot as a guide. For very precise lines, consider using a seam guide attachment that screws into the machine.

- Stitch Length Adjustment: Ensure your stitch length dial is set correctly and securely. Sometimes, dials can be bumped, inadvertently changing the stitch length.

- Marking Your Lines: For critical topstitching, consider marking your stitching line on the fabric with tailor’s chalk, a water-soluble pen, or even a temporary basting stitch. This provides a visual guide to follow.

- Practice Curves and Corners: Wobbly lines are often more apparent on curves and corners. Practice sewing these areas slowly, lifting the presser foot and pivoting the fabric as needed, while keeping the needle down in the fabric to maintain your position.

Applying Topstitching to Garments and Projects

Topstitching is a decorative and functional sewing technique that adds a professional polish to a wide range of garments and sewing projects. It involves stitching on the outside of a garment, typically close to an edge or seam, to create a visible, often contrasting, line of stitching. This guide will walk you through applying topstitching to specific garment elements, ensuring a crisp, durable, and stylish finish.Applying topstitching effectively transforms simple sewing into artisanal craftsmanship.

It’s not just about aesthetics; it’s about reinforcing seams, defining edges, and adding structural integrity where needed. Mastering these applications will elevate your sewing projects from homemade to haute couture.

Topstitching Collars and Cuffs

Collars and cuffs are key areas where topstitching can dramatically enhance a garment’s appearance and structure. A well-executed topstitch on these elements provides a crisp edge and a refined look.To achieve a professional finish on collars and cuffs, follow these steps:

- Preparation: Ensure your collar and cuff pieces are accurately cut and interfaced if necessary. Press all seams flat before topstitching.

- Stitching Placement: Typically, topstitching on collars and cuffs is placed about 1/8 inch (3mm) to 1/4 inch (6mm) from the folded edge. For a sharper look, aim for the closer measurement.

- Machine Setup: Use a slightly longer stitch length (e.g., 2.5-3.0mm) for topstitching to give it a more prominent and decorative appearance. A contrasting thread color can further highlight the stitching.

- Sewing: Start stitching at a point that will be less visible, such as the underarm seam of a collar or the inner seam of a cuff. Sew slowly and steadily, guiding the fabric with your hands to maintain an even distance from the edge.

- Corners: For sharp corners on collars, stop with the needle down at the corner, lift the presser foot, pivot the fabric, lower the presser foot, and continue stitching.

- Finishing: Backstitch at the beginning and end of your stitching to secure it. Trim any excess threads neatly.

Topstitching Waistbands and Hems

Waistbands and hems are prime candidates for topstitching, as it provides both durability and a clean, finished edge that resists fraying and wear.The process for topstitching waistbands and hems involves several key considerations:

- Waistbands: For elasticated waistbands, topstitching can secure the casing and prevent the elastic from twisting. For non-elasticated waistbands, topstitching can create a defined edge and a decorative element. Stitch close to the seam line where the waistband attaches to the garment body, and potentially on the free edge of the waistband for a double-stitched effect.

- Hems: Topstitching on hems adds weight and stability, preventing the hem from rolling or flipping up. It also provides a visible stitched line that can be a design feature. For curved hems, it’s crucial to ease the fabric gently to avoid puckering.

- Thread Tension: Adjust your thread tension to ensure the stitches are balanced on both sides of the fabric. Too much tension can cause the fabric to pucker, while too little can result in loose, messy stitches.

- Pressing: Thorough pressing before and after topstitching is essential for achieving crisp lines and a professional appearance.

Topstitching Pockets and Other Embellishments

Pockets, plackets, and other decorative elements benefit immensely from topstitching, which not only secures them but also draws attention to their design.Best practices for topstitching these features include:

- Pockets: Topstitch around the opening of patch pockets for a clean finish and to reinforce the edge. For inseam pockets, topstitching can secure the pocket opening and add a decorative line along the garment seam.

- Plackets: Topstitching on shirt plackets reinforces the buttonhole area and creates a defined, professional look. Stitch along the folded edges of the placket.

- Appliqués and Facings: Topstitching can be used to secure appliqués in place and to attach facings, providing a neat edge and a decorative touch.

- Edge Definition: For any embellishment that has an exposed edge, topstitching approximately 1/8 inch from that edge will create a crisp, defined line.

Visual Guide to Topstitching’s Impact on Garment Design

Topstitching serves as a powerful design tool, transforming the ordinary into the extraordinary. It’s a visible element that can guide the eye, add texture, and highlight the craftsmanship of a garment.Consider the following examples of how topstitching enhances overall design:

- Denim Jeans: The iconic arcuates on back pockets and the saddle stitch along inseams and outseams on jeans are classic examples of functional and decorative topstitching that define the garment’s style. The contrast stitching often uses a thicker thread to stand out.

- Tailored Jackets: On tailored jackets, topstitching along lapels, pocket welts, and seams provides structure and a sophisticated finish, emphasizing the garment’s clean lines and sharp tailoring.

- Linen Shirts: A simple linen shirt can be elevated with precisely placed topstitching along the collar, cuffs, and placket, adding a touch of understated elegance and durability.

- Quilted Items: In quilting, echo quilting, which follows the Artikel of appliqué shapes, is a form of topstitching that adds dimension and texture to the fabric.

- Leather Goods: Topstitching on leather bags or accessories not only secures the material but also adds a robust aesthetic, often using heavy-duty threads and specialized needles.

The deliberate placement and execution of topstitching can dictate the perceived quality and style of a finished project, making it an indispensable technique for achieving professional results.

Achieving a Professional Look: Visual Elements

The final polish on any topstitched project lies in the meticulous attention to visual details. These elements, from the subtle interplay of stitch length and thread color to the precision of your lines, collectively elevate your work from functional to truly professional. This section delves into these key visual aspects, offering insights and practical advice to refine your topstitching aesthetic.

Stitch Length and Width Influence

The perceived professionalism of topstitching is significantly influenced by both stitch length and width. A consistent, appropriate stitch length creates a clean, even line that appears deliberate and well-executed. Too short a stitch can look fussy and overly dense, while too long a stitch can appear weak and unprofessional, especially on lighter fabrics. The width of the stitch, often dictated by the presser foot or a specialized topstitching foot, also plays a role in its visual impact.

A consistent width ensures the stitch line is uniform and contributes to a balanced appearance.

Impact of Stitch Length and Width on Professionalism

- Short Stitches (e.g., 1.5-2.0 mm): These create a dense, durable, and visually striking line. They are ideal for decorative purposes or when extra strength is required, such as on denim or heavy canvas. However, on very fine fabrics, they can look bulky.

- Medium Stitches (e.g., 2.5-3.0 mm): This is a versatile range suitable for most garment construction and general topstitching. It offers a good balance of visibility, durability, and a clean aesthetic.

- Long Stitches (e.g., 3.5-4.0 mm): These stitches are less visible and can appear less secure. They are generally not recommended for professional-looking topstitching unless a very subtle effect is desired on specific materials or for a particular design element.

- Stitch Width: A consistent width, typically determined by the presser foot, is crucial. A standard presser foot will create a narrow stitch line. Specialized topstitching feet or edge-stitching feet can create wider, more prominent lines that are ideal for decorative effects or to mimic ready-to-wear finishes. The key is uniformity; any variation in width detracts from the professional appearance.

Thread Color Choice Impact

The choice of thread color is a powerful tool in defining the aesthetic and visibility of your topstitching. It can either blend seamlessly with the fabric for a subtle effect or stand out as a prominent design element.

Thread Color and Topstitching Aesthetics

- Matching Thread: Using a thread color that closely matches the fabric creates a subtle, integrated look. This is often preferred for a clean, minimalist aesthetic, where the topstitching’s primary function is reinforcement rather than decoration. It emphasizes the garment’s structure and silhouette.

- Contrasting Thread: A thread color that stands in contrast to the fabric immediately draws attention to the topstitching. This is a popular technique for adding visual interest, highlighting seams, and creating a decorative element. Think of the iconic orange or gold stitching on denim jeans. The contrast should be intentional and complement the overall design.

- Slightly Darker or Lighter Thread: A subtle variation in shade can add depth and dimension without being overtly contrasting. This can provide a sophisticated look that is more refined than a stark contrast.

- Metallic or Specialty Threads: These threads can add a luxurious or unique shimmer to topstitching, making it a focal point. They are best used judiciously for special occasions or to achieve a specific high-fashion look.

Ensuring Parallel and Equidistant Topstitching Lines

The precision of your topstitching lines is paramount to a professional finish. Lines that are parallel to edges and consistently equidistant create a sense of order and intentionality.

Techniques for Precise Topstitching Lines

Achieving perfectly parallel and equidistant lines requires a combination of careful preparation, the right tools, and practiced technique. Here are some effective methods:

- Edge Stitching Foot: This specialized foot has a guide that runs along the edge of the fabric, allowing you to stitch a consistent distance from the fold or edge. It is invaluable for creating even topstitching along hems, collars, and facings.

- Walking Foot: For thick or slippery fabrics, a walking foot can help feed multiple layers of fabric evenly, preventing shifting and ensuring your topstitching remains parallel to the edge.

- Marking Tools: Use tailor’s chalk, a disappearing ink pen, or a chalk wheel to draw guide lines on your fabric before stitching. This is particularly helpful when the edge-stitching foot cannot be used effectively or for topstitching away from an edge.

- Stitch Regulator (Walking Foot Attachment): Some sewing machines have stitch regulators that can help maintain consistent stitch length, which indirectly contributes to the visual uniformity of parallel lines.

- Practice and Patience: Ultimately, consistent practice is key. Take your time, and don’t be afraid to unpick stitches if they are not perfectly aligned.

Comparison of Topstitching with Different Thread Types

The choice of thread material significantly impacts the visual outcome and tactile feel of your topstitching. Each type offers distinct characteristics that lend themselves to different applications and aesthetic goals.

Visual Outcomes of Various Thread Types

| Thread Type | Visual Characteristics | Typical Applications | Professional Aesthetic Impact |

|---|---|---|---|

| Cotton Thread | Matte finish, natural sheen, can have a slightly textured appearance. Good stitch definition. | Natural fiber garments (cotton, linen, wool), quilting, general sewing. | Provides a classic, understated look. Can appear slightly rustic on some fabrics. |

| Polyester Thread | Smooth, consistent sheen, strong, and durable. Offers excellent colorfastness. | Synthetics, blends, activewear, outerwear, high-stress seams. | Delivers a clean, modern, and durable finish. Its consistency is key for professional results. |

| Silk Thread | Lustrous sheen, very fine and strong. Can be expensive. | Fine silks, delicate fabrics, haute couture, heirloom sewing. | Adds an exquisite, luxurious finish. Best for high-end garments where subtle elegance is desired. |

| Metallic Thread | Shiny, reflective, often with a metallic core. Can be more brittle and harder to work with. | Decorative accents, embellishments, special occasion wear. | Creates a bold, eye-catching statement. Requires careful handling to avoid breakage and ensure a smooth appearance. |

| Rayon/Embroidered Thread | High sheen, vibrant colors, often used for decorative stitching. Less durable than polyester. | Decorative topstitching, embroidery effects on garments. | Adds a pop of color and shine, making the topstitching a prominent design feature. |

Final Review

As we conclude our exploration of How to Topstitch for a Professional Look, it’s clear that precision and attention to detail are paramount. By embracing the fundamental principles, utilizing the right tools, and practicing the techniques Artikeld, you are well-equipped to imbue your sewing projects with a refined and professional appearance. May your stitches be straight, your tension perfect, and your finished pieces a testament to your newfound skill.