Embark on a rewarding sewing journey with our comprehensive guide, “How to Sew with an Elastic Waistband.” This exploration delves into the essential techniques and considerations for creating comfortable, well-fitting, and stylish garments. We’ll uncover the secrets to selecting the right elastic, preparing your materials, and mastering the construction of a flawless waistband, ensuring your projects achieve a professional finish.

From understanding the nuances of different elastic types and widths to precisely measuring for the perfect fit, this guide provides a clear roadmap. We will walk you through the intricacies of preparing your fabric and pattern, constructing various types of casings, and securely inserting the elastic. Furthermore, we’ll address common challenges and offer expert solutions, alongside insights into advanced techniques and decorative finishes.

Understanding Elastic Waistbands

An elastic waistband is a common and effective design element that provides comfort, adjustability, and a secure fit to garments. It’s a versatile solution found in everything from casual wear to activewear and children’s clothing. Understanding the different types of elastic, their properties, and how to select the right width and length is fundamental to achieving a professional and comfortable finish.

This section will delve into these key aspects to equip you with the knowledge for successful elastic waistband construction.

Types of Elastic for Waistbands

Several types of elastic are suitable for waistbands, each offering distinct characteristics that influence the final garment’s feel and function. The choice of elastic depends on the fabric weight, the desired stretch, and the garment’s intended use.

- Knitted Elastic: This is a very popular choice for waistbands due to its good stretch and recovery. It has a soft feel and does not narrow significantly when stretched, making it comfortable against the skin. It’s a good all-purpose elastic suitable for a wide range of fabrics, from lightweight cotton to heavier knits.

- Woven Elastic: Woven elastic is stronger and more durable than knitted elastic. It tends to narrow considerably when stretched, which can affect the fit and appearance if not accounted for. It’s best suited for heavier fabrics and garments that require a firm, non-stretching hold, such as some types of sportswear or structured trousers.

- Braided Elastic: Similar to knitted elastic, braided elastic offers good stretch. However, it can narrow when stretched and may lose some of its elasticity over time, especially with frequent washing and drying. It’s generally less expensive than knitted or woven elastic and is often used in budget-friendly garments or for less demanding applications.

- Clear Elastic: Made from polyurethane, clear elastic is transparent and offers moderate stretch. It’s ideal for delicate fabrics or when a very subtle waistband is desired, as it’s less visible than other types. It’s particularly useful in swimwear, lingerie, or sheer garments.

Properties and Suitability of Elastic Types

The properties of each elastic type dictate its best application. Knitted elastic’s inherent stretchiness and softness make it ideal for casual wear, children’s clothing, and any garment where comfort is paramount. Woven elastic’s rigidity is beneficial for garments needing a secure, unyielding waistband, such as some workwear or structured skirts. Braided elastic, while accessible, is better suited for less frequently worn items or where significant stretch isn’t a primary concern.

Clear elastic is the go-to for situations demanding invisibility and a smooth finish on lighter materials.

Pros and Cons of Elastic Widths

The width of the elastic chosen for a waistband significantly impacts its appearance, comfort, and functionality. A wider elastic generally provides more support and distributes pressure more evenly, leading to a more comfortable fit, especially for heavier garments. Narrower elastics can be more discreet and are suitable for lighter fabrics or garments where a less pronounced waistband is desired.

- Narrow Elastic (e.g., 1/4 inch to 1/2 inch):

- Pros: Discreet, suitable for delicate fabrics, creates a less bulky waistband, good for garments with a smaller casing.

- Cons: May not provide enough support for heavier fabrics, can dig into the skin if the fabric is very light and the elastic is strong, can be more prone to rolling if not secured properly.

- Medium Elastic (e.g., 3/4 inch to 1 inch):

- Pros: Offers a good balance of support and comfort, suitable for a wide range of fabrics, a common choice for many types of garments.

- Cons: Can be slightly more visible than narrow elastic, might be too wide for very delicate or sheer fabrics.

- Wide Elastic (e.g., 1 1/2 inches and wider):

- Pros: Excellent support and comfort, distributes pressure effectively, ideal for heavy fabrics, sportswear, and garments requiring a firm hold, less likely to roll.

- Cons: Can create a very prominent waistband, may be too bulky for some garment styles or lighter fabrics, requires a wider casing.

Determining Correct Elastic Length

Achieving a comfortable and secure elastic waistband relies on using the correct length of elastic. The goal is to have it snug enough to hold the garment in place without being constrictive. A common method involves measuring the wearer’s body and adjusting for desired ease.The general guideline for determining the elastic length is to measure the wearer’s waist and then subtract a percentage, typically between 10% and 20%, from this measurement.

The exact percentage depends on the type of elastic used and the desired fit.

For knitted elastic, a good starting point is to subtract 10-15% from the waist measurement. For woven elastic, which has less stretch, you might subtract 15-20% or even more, depending on its stretch recovery.

Alternatively, you can measure the circumference of the garment’s waist opening where the elastic will sit when laid flat and then measure the elastic to be approximately 75-85% of that measurement. It’s always advisable to cut a slightly longer piece of elastic than you think you’ll need, as you can always trim it down if it’s too loose. It’s also a good practice to test the elastic length on a scrap of fabric before cutting the final piece, especially when working with new patterns or fabrics.

Preparing Your Fabric and Pattern

Before you begin the exciting process of sewing an elastic waistband, proper preparation of your fabric and understanding your pattern are crucial steps. These foundational tasks ensure a smooth sewing experience and a beautifully finished garment. Taking the time to prepare correctly will minimize frustration and lead to a more professional result.Understanding how to prepare your materials and read your pattern is key to success.

This section will guide you through the essential pre-sewing steps.

Fabric Preparation

Preparing your fabric before cutting and sewing is a vital step that prevents shrinkage issues and ensures your finished garment fits as intended. Fabrics, especially natural fibers like cotton and linen, can shrink significantly when washed and dried. Pre-washing mimics this process, so you’re working with a stable material.Here are the essential steps for preparing your fabric:

- Pre-washing: Wash your fabric according to the manufacturer’s instructions, using the same method (e.g., temperature, cycle) you intend to use for the finished garment. This removes sizing agents and allows for any initial shrinkage.

- Drying: Dry the fabric as you normally would. For garments that will be machine-dried, tumble dry your fabric. If you prefer to line dry, do so.

- Ironing: Once the fabric is completely dry, press it thoroughly with a hot iron. This removes wrinkles and creates a flat surface, which is essential for accurate cutting and sewing. Ensure you press from the wrong side of the fabric to avoid any accidental shine marks on the right side.

Reading Your Pattern for Elastic Casing

Sewing patterns contain valuable information that guides you through each step of construction. Identifying where the elastic casing will be formed is a critical early step for garments with elastic waistbands. This area is usually indicated with specific markings and instructions.Patterns will typically denote the casing area in several ways:

- Markings: Look for dashed or dotted lines along the top edge of the garment pieces (e.g., waistband, skirt, pants). These lines often represent the fold line for the casing or the stitching line.

- Notches: Small triangular or diamond shapes cut into the edge of the pattern pieces are notches. These help you align pieces and can sometimes indicate the beginning or end of a casing section.

- Textual Instructions: The pattern envelope and accompanying instruction sheets will have written directions. These will explicitly state when and how to create the elastic casing, often referencing the markings on the pattern pieces.

- Specific Pattern Pieces: Some patterns may have a separate waistband piece designed to fold over and create the casing. Others will integrate the casing directly into the main garment pieces.

Pay close attention to the “Grainline” arrow on your pattern pieces. This indicates the direction in which the fabric should be laid out for cutting, ensuring the fabric drapes and behaves correctly in the finished garment.

Marking and Cutting Fabric for the Waistband Casing

Accurate marking and cutting are paramount for a successful sewing project, especially when dealing with the precision required for an elastic casing. Errors here can lead to an uneven waistband or a casing that doesn’t fit the elastic properly.Follow these guidelines for precise marking and cutting:

- Transfer Pattern Markings: Once your fabric is prepared and laid out, carefully transfer all pattern markings to the fabric. This includes any lines indicating the casing fold, stitching lines, and notches. Use tailor’s chalk, a fabric pen, or a tracing wheel and paper.

- Cut Accurately: Using sharp fabric scissors or a rotary cutter and mat, cut along the outer edge of the pattern pieces. Ensure your cuts are smooth and follow the lines precisely. For the casing, you will be cutting along the indicated edge of the garment piece.

- Double-Check Measurements: Before cutting, always double-check that your fabric is cut to the exact dimensions specified in the pattern instructions. This is especially important for the waistband and any pieces that form the casing.

Pattern Adjustments for Different Body Shapes

While patterns are designed for average figures, incorporating an elastic waistband offers a degree of flexibility. However, some adjustments might still be beneficial for a more flattering and comfortable fit, particularly when dealing with significant variations from the standard pattern size. Elastic waistbands can accommodate a range of sizes, but the casing itself needs to be the correct length and width for the elastic.Consider these potential adjustments:

- Waistband Length: The primary adjustment for an elastic waistband is often the length of the waistband itself. If your waist measurement is significantly larger or smaller than indicated by the pattern’s size chart, you’ll need to adjust the length of the waistband piece or the section of the garment that forms the casing. The goal is to ensure the casing can comfortably accommodate the elastic without being too tight or too loose.

- Casing Width: The pattern will specify a width for the casing. This width should be slightly larger than the width of the elastic you intend to use. If you are using a wider or narrower elastic than recommended, you may need to adjust the casing width accordingly. For example, if the pattern calls for 1-inch elastic and you want to use 1.5-inch elastic, you’ll need to widen the casing fold line and stitching line.

- Hip and Seat Adjustments: For garments like skirts or pants with elastic waistbands, if your hip or seat measurements are larger than the pattern size suggests, you might need to add width to the garment below the waistband. This is a standard pattern adjustment for fit and is independent of the elastic casing itself, but crucial for overall garment comfort.

- Rise Adjustments: For pants, the rise (the distance from the crotch seam to the top of the waistband) can be adjusted. If you have a longer or shorter torso, you may need to lengthen or shorten the front and back rise. This adjustment affects how the waistband sits on your body.

When making adjustments, it’s often helpful to create a muslin or test garment from inexpensive fabric. This allows you to check the fit of the waistband and the casing before cutting into your final fabric. For instance, if you’re unsure about the correct casing width for a specific elastic, cutting a small sample strip and folding it to test the fit of the elastic can be very insightful.

Constructing the Elastic Casing

Creating a well-constructed elastic casing is fundamental to the comfort and fit of garments with elastic waistbands. This section delves into the various methods for achieving a professional and durable casing, ensuring your elastic glides smoothly and your waistband lays flat.A properly executed casing not only secures the elastic but also contributes significantly to the garment’s overall appearance and wearability.

We will explore straightforward techniques for beginners and more refined methods for those seeking a polished finish.

Simple Sewn-Through Elastic Casing

This method involves folding the fabric edge over twice and stitching it down, creating a channel for the elastic. It is a quick and effective technique, ideal for projects where a very clean finish on the inside isn’t the primary concern, or for garments made from sturdier fabrics that hold their shape well.The process begins by folding the top edge of the fabric down by your desired casing width plus approximately 1/4 inch (0.6 cm) to 1/2 inch (1.3 cm) for the initial fold.

Press this fold firmly. Then, fold the edge down again, encasing the raw edge within the fold. The second fold should be just wide enough to accommodate your elastic plus a little extra ease. For instance, if your elastic is 1 inch (2.5 cm) wide, aim for a casing of about 1 1/4 inches (3.2 cm). Press this second fold.Stitch close to the folded edge of the second fold, securing the casing.

Ensure you leave a small opening of about 1 to 2 inches (2.5 to 5 cm) to insert the elastic. After inserting the elastic, carefully stitch the opening closed, reinforcing the stitches.

Folded-Over Casing Techniques

Folded-over casings offer a more refined finish, concealing the raw edge of the fabric within the casing itself. These techniques provide a cleaner look on both the inside and outside of the garment.

Single Fold Casing

The single fold method is best suited for lightweight to medium-weight fabrics and projects where a less bulky waistband is desired. It creates a neat, enclosed edge.Begin by folding the top edge of the fabric down by your desired casing width plus the width of your elastic. Press this fold. Next, fold the raw edge of the fabric up towards the wrong side by about 1/4 inch (0.6 cm) to 1/2 inch (1.3 cm) and press.

This encloses the raw edge. Finally, fold the entire section down again, aligning the folded raw edge with the first fold, to create the casing. The total width of your casing will be the width of your elastic plus the initial fold for the raw edge. Stitch close to the lower folded edge, leaving an opening for elastic insertion.

Double Fold Casing

The double fold technique is a robust and professional method, providing a clean finish and excellent durability. It is particularly good for medium to heavier weight fabrics.Start by folding the top edge of the fabric down by approximately 1/4 inch (0.6 cm) to 1/2 inch (1.3 cm) to the wrong side and press. This initial fold neatly encloses the raw edge.

Then, fold the fabric down again by your desired casing width, ensuring the total folded section is wide enough to accommodate your elastic comfortably. For example, if using 1-inch elastic, the second fold should create a casing of at least 1 1/4 inches (3.2 cm). Press this second fold. Stitch close to the first folded edge, creating a secure channel for the elastic.

Remember to leave an opening for threading the elastic.

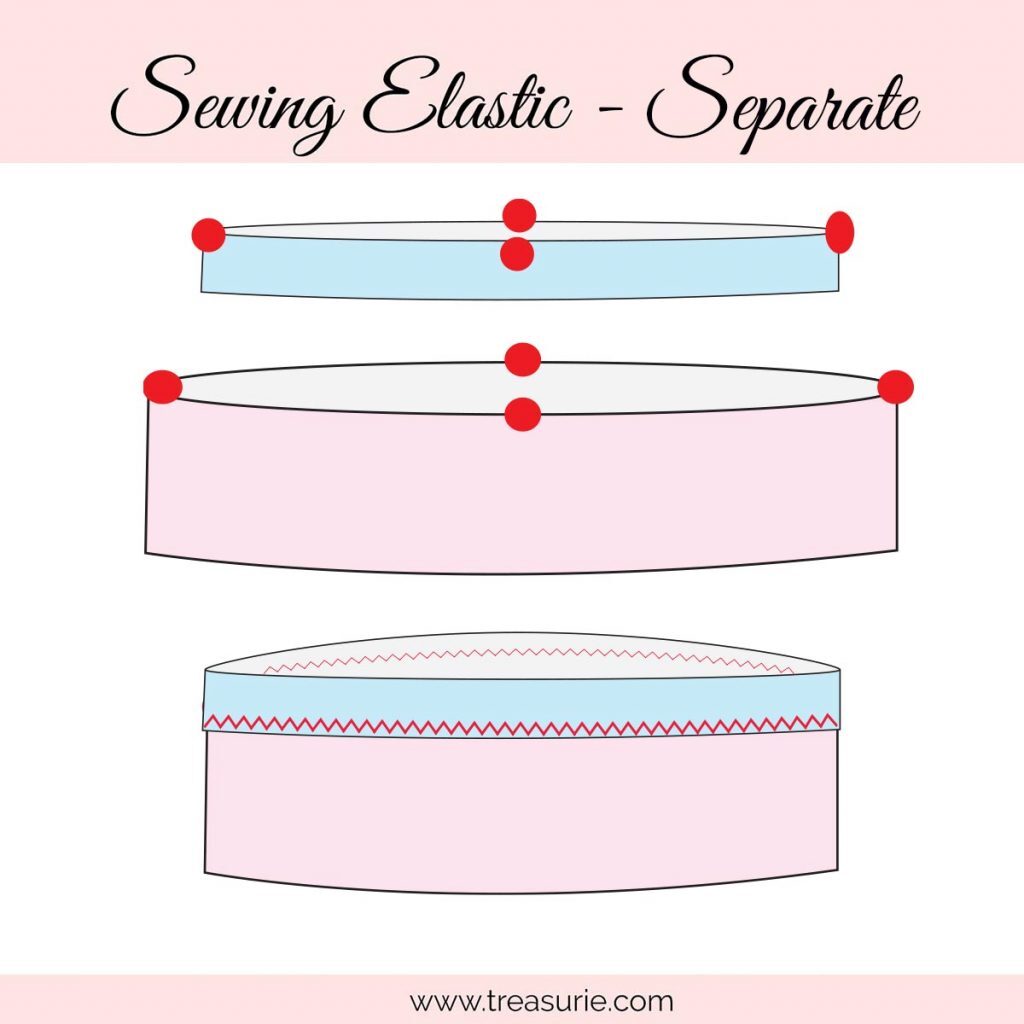

Attaching a Separate Waistband Piece

For a more structured waistband or when working with fabrics that don’t lend themselves to being folded over, attaching a separate waistband piece is an excellent option. This method allows for precise control over the waistband’s appearance and stability.The separate waistband piece is typically cut from the same fabric as the garment or a coordinating fabric. It should be cut to the length of your garment’s waist edge plus seam allowances, and its width should be twice the desired finished waistband width plus seam allowances.To attach, place the waistband piece right sides together with the garment’s waist edge.

Align the raw edges and stitch along the seam allowance. For example, if your garment waist is 30 inches and your waistband piece is cut to 32 inches (including seam allowances), you will stitch these together. Press the seam allowance of the waistband piece upwards, away from the garment. Then, fold the waistband piece in half lengthwise, wrong sides together, creating a fold at the top edge of the waistband.

This fold will form the top edge of your casing. Stitch this folded edge down to the garment, encasing the elastic within the formed channel. Ensure you leave an opening to insert the elastic.

Ensuring Adequate Casing Width

The most crucial aspect of a comfortable elastic waistband is a casing that is wide enough to allow the elastic to move freely without bunching or constricting.

The casing width should always be the width of your elastic plus at least 1/4 inch (0.6 cm) to 1/2 inch (1.3 cm) of ease.

For instance, if you are using 1-inch wide elastic, your casing should measure a minimum of 1 1/4 inches (3.2 cm) to 1 1/2 inches (3.8 cm) when finished. This extra room prevents the elastic from getting stuck or creating an uneven, puckered look. When measuring your fabric for folding or cutting your waistband piece, always account for this extra width.

A quick test is to lay your elastic flat against the folded edge of your casing before stitching to visually confirm there is sufficient space.

Inserting and Securing the Elastic

Now that your elastic casing is beautifully constructed, it’s time to bring it to life by inserting and securing the elastic. This step is crucial for achieving a comfortable and well-fitting waistband that will stand the test of time. We’ll guide you through the process of threading the elastic and ensuring it’s securely attached.This section focuses on the practical steps of getting the elastic into your garment and making sure it stays put.

A well-executed elastic insertion leads to a professional finish and a garment that is a joy to wear.

Threading the Elastic Through the Casing

To successfully thread the elastic through your prepared casing, you will need a tool to guide it. A safety pin or a specialized bodkin are excellent choices for this task.Here’s how to thread your elastic:

- Attach one end of the elastic securely to the open end of a large safety pin. Ensure the elastic is firmly pinned so it won’t slip off during the process.

- Gently push the closed safety pin into one end of the elastic casing.

- Carefully guide the safety pin, with the elastic attached, all the way through the casing until it emerges from the other opening.

- If using a bodkin, thread the elastic through the eye of the bodkin and then proceed as you would with a safety pin.

Joining the Elastic Ends

Once the elastic is threaded through the entire casing, the next critical step is to join its ends securely. This ensures the waistband remains intact and comfortable.Several effective methods exist for joining elastic ends:

- Overlapping and Stitching: Overlap the two ends of the elastic by about 1 to 1.5 inches (2.5 to 3.8 cm). Using a strong stitch, such as a zigzag stitch or a serger, stitch the overlapped ends together multiple times in different directions to create a robust bond. This method is widely used for its durability.

- Butt Joint with Reinforcement: Place the ends of the elastic directly against each other (butt joint). Then, place a small piece of sturdy fabric or a strip of fusible interfacing over the seam and stitch through all layers with a zigzag stitch. This provides extra support to prevent the elastic from stretching or breaking at the join.

- Specialized Elastic Connectors: For some applications, specialized elastic connectors or clips are available, though these are less common for standard garment construction.

It is important to choose a method that provides sufficient strength to withstand the stretching the waistband will endure during wear.

Distributing Elastic Evenly

Achieving a smooth and even finish for your elastic waistband relies on distributing the elastic uniformly within the casing. This prevents bunching and ensures a comfortable fit.To ensure even distribution:

- Before joining the elastic ends, gently pull and stretch the elastic to its full capacity.

- While holding the elastic taut, use your fingers to smooth out any gathers or folds along the casing.

- Once the elastic is threaded, and before you permanently secure the ends, pin the elastic at several points around the casing to hold it in place temporarily. This will help you visualize and adjust the distribution.

- When stitching the casing opening closed, gently stretch the casing slightly as you sew, allowing the elastic to settle evenly.

Taking a moment to distribute the elastic evenly will significantly enhance the professional appearance and comfort of your finished waistband.

Preventing Elastic Twisting

A common issue with elastic waistbands is the tendency for the elastic to twist within the casing during wear. This can be uncomfortable and detract from the garment’s appearance.To prevent elastic twisting:

- Secure Stitching: Ensure the elastic is securely stitched at its joining point. A weak join is more prone to shifting and twisting.

- Tack the Elastic: After joining the elastic ends and before closing the casing opening entirely, tack the elastic to the casing at the side seams or at intervals of about 4-6 inches (10-15 cm). This can be done with a few hand stitches or machine stitches. This tacks the elastic in place, preventing it from rotating freely within the casing.

- Proper Casing Width: Ensure your casing is the correct width for your elastic. If the casing is too wide, the elastic has more room to twist. If it’s too narrow, it can be difficult to insert and may cause friction.

- Quality Elastic: Using a good quality, stable elastic will also contribute to its ability to resist twisting.

By implementing these techniques, you can significantly reduce the likelihood of your elastic twisting, ensuring a consistently comfortable and well-presented waistband.

Illustrative Examples and Visual Aids

To truly master sewing an elastic waistband, it’s beneficial to visualize the desired outcome and understand how different choices impact the final look and feel of your garment. This section will guide you through the visual cues of a well-executed elastic waistband, the effects of varying elastic widths, the influence of fabric selection, and the appearance of a securely joined elastic end.

Appearance of a Well-Constructed Elastic Waistband

A hallmark of a professionally finished garment is an elastic waistband that lies smoothly against the body, exhibiting even gathers without puckering or pulling. The casing should appear flat and unobtrusive, with no visible signs of the elastic struggling to be contained. The stitching along the casing should be neat and consistent, creating a clean line that complements the garment’s design.

When the garment is worn, the waistband should distribute pressure evenly, providing comfort and a flattering silhouette.

Visual Effect of Different Elastic Widths

The width of the elastic directly influences the drape and fit of a garment. Narrower elastics, typically 1/4 to 1/2 inch wide, are ideal for lightweight fabrics and delicate garments like lingerie or children’s wear, creating subtle shaping and minimal bulk. Medium-width elastics, around 3/4 to 1 inch, offer a good balance for general apparel such as skirts, shorts, and trousers, providing sufficient hold without being overly restrictive.

Wider elastics, 1.5 inches and above, are best suited for heavier fabrics or garments requiring more substantial support, like yoga pants or structured waistbands, as they distribute tension over a larger area and can create a more pronounced blousing effect.

Fabric Choice Influences Look and Feel

The fabric used for your garment significantly impacts how the elastic waistband appears and feels. For instance, a flowing silk or rayon will drape beautifully over a narrower elastic, creating elegant gathers that move with the fabric. In contrast, a sturdy cotton twill or denim will hold its shape better with a wider elastic, resulting in a more structured and defined waistband.

Stretchy knit fabrics, such as jersey or ponte, pair well with a variety of elastic widths and can accommodate slight variations in tension for a comfortable, conforming fit. A very thin or slippery fabric might show the elastic more readily through the casing, whereas a thicker or textured fabric will help to disguise it.

Visual Outcome of a Securely Joined Elastic End

A securely joined elastic end is characterized by its durability and invisibility. When properly overlapped and stitched, the seam where the elastic ends meet should be flat and smooth, with no bulky bumps or loose threads. This secure join ensures that the elastic will not pull apart during wear or washing, maintaining the integrity of the waistband. Visually, a well-executed join is practically undetectable from the outside of the garment, contributing to a clean and professional finish.

This is often achieved by overlapping the elastic by at least 1 inch and stitching it securely with a zigzag stitch or a serger.

Epilogue

As we conclude our exploration of “How to Sew with an Elastic Waistband,” you are now equipped with the knowledge and confidence to tackle this fundamental sewing skill. We’ve covered everything from selecting the ideal elastic and preparing your fabric to constructing durable casings and achieving a polished look. Whether you’re a beginner or looking to refine your techniques, the ability to expertly sew an elastic waistband opens up a world of possibilities for creating comfortable and fashionable apparel.