How to Prepare Your Fabric Before Sewing sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail with formal and friendly language style and brimming with originality from the outset.

Embarking on any sewing endeavor, whether for a cherished garment, a cozy quilt, or elegant home decor, begins with a crucial, often overlooked, foundational step: preparing your fabric. This essential process ensures your finished project not only looks professional but also stands the test of time, preventing common frustrations like shrinkage, uneven seams, and distorted designs. Understanding the nuances of fabric preparation is key to unlocking the full potential of your materials and transforming your creative visions into tangible realities.

Understanding Fabric Preparation

Preparing your fabric before you begin sewing is a crucial step that lays the foundation for a successful and professional-looking project. Skipping this vital stage can lead to a multitude of issues that not only compromise the final garment but also waste your time and resources. By taking the time to properly prepare your fabric, you ensure accuracy in your measurements, a better fit, and a more durable finished product.Neglecting fabric preparation can result in several common problems.

Fabrics can shrink unpredictably when washed, meaning your meticulously cut pieces might no longer fit together correctly after the first wash. This shrinkage can also distort the weave of the fabric, leading to uneven seams and a puckered appearance. Furthermore, some fabrics may have manufacturing residues, such as sizing agents or dyes, that can affect their drape, absorbency, or even cause skin irritation.

Pre-washing also helps to identify any flaws or inconsistencies in the fabric that might be missed otherwise.To ensure your sewing projects are built on a solid foundation, having the right tools and materials for fabric preparation is essential. These items will help you clean, stabilize, and ready your fabric for cutting and stitching.

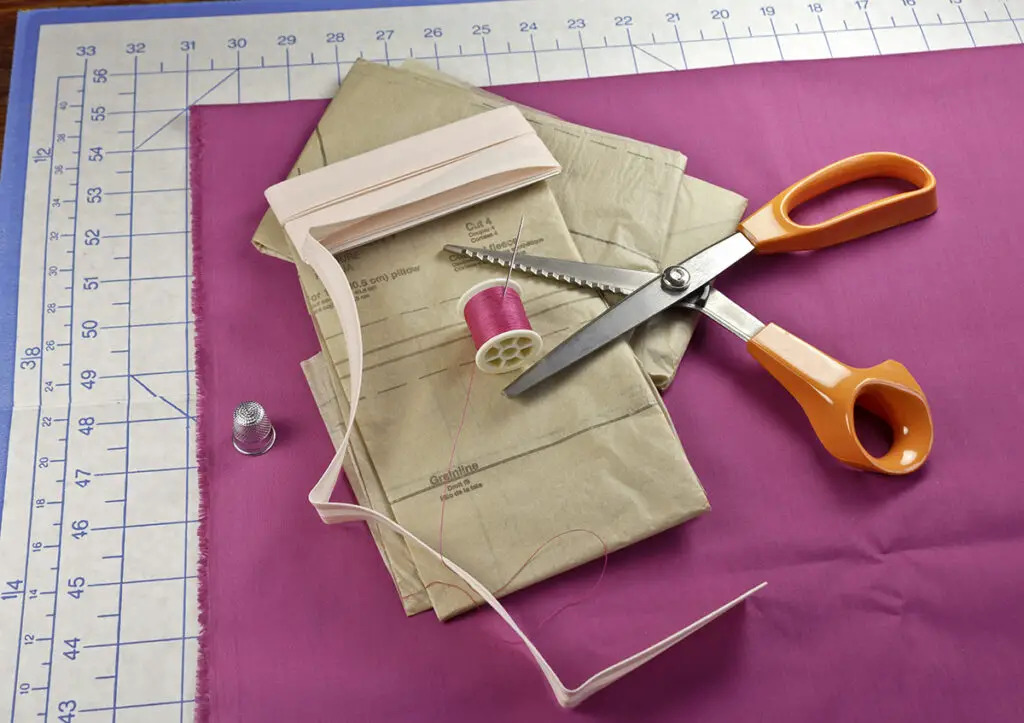

Essential Tools and Materials for Fabric Preparation

The following list Artikels the key items you will need to effectively prepare your fabrics. Having these readily available will streamline the process and ensure you can address the specific needs of different fabric types.

- Washing Machine and Dryer: For pre-washing most common fabrics.

- Iron and Ironing Board: Essential for pressing and removing wrinkles, which is critical for accurate cutting.

- Measuring Tape: To accurately measure fabric dimensions before and after preparation.

- Scissors or Rotary Cutter and Mat: For trimming selvages and squaring fabric if necessary.

- Detergent: A mild detergent is recommended for pre-washing, especially for delicate fabrics.

- Fabric Scissors: Dedicated scissors for cutting fabric to avoid dulling your paper scissors.

- Lint Roller: To remove loose threads and debris from the fabric surface.

- Starch (optional): Can be used to stiffen lightweight fabrics for easier handling and cutting.

- Color Catchers (optional): Recommended for washing brightly colored or dark fabrics to prevent color bleeding onto lighter fabrics.

Pre-Washing and Drying Techniques

Pre-washing your fabric before cutting is a fundamental step to prevent shrinkage and remove any residual chemicals from the manufacturing process. The method of washing and drying should be tailored to the specific fabric type to maintain its integrity and appearance.For most cottons, linens, and stable synthetic blends, a standard machine wash on a warm or cool setting is appropriate.

It is advisable to wash fabrics in batches, separating colors to prevent bleeding. If you are concerned about color bleeding, using a color catcher sheet in the wash is a prudent measure. After washing, fabrics can typically be machine dried on a medium heat setting. However, for more delicate fabrics like silks, rayons, or certain synthetics, it is often best to air dry them to avoid potential damage from heat and agitation.

Always check the fabric’s care label if available for specific washing instructions.

“Shrinkage is the silent saboteur of sewing projects. Pre-washing is your first line of defense.”

Ironing and Pressing for Accuracy

Once your fabric is washed and dried, ironing and pressing are vital steps to ensure flat, smooth surfaces for accurate cutting. Wrinkled or uneven fabric can lead to significant errors in pattern placement and seam allowances, ultimately affecting the fit and finish of your sewn item.When ironing, always use the appropriate heat setting for your fabric type. For natural fibers like cotton and linen, a higher heat is usually suitable, while synthetics and silks require lower temperatures to prevent scorching or melting.

Pressing, as opposed to simply ironing, involves lifting and placing the iron down rather than gliding it. This technique is particularly useful for seams and edges, helping to set them in place without stretching the fabric. For fabrics prone to creasing, such as linen, a bit of steam can be very beneficial. If you are working with a fabric that might be sensitive to direct heat, placing a pressing cloth between the iron and the fabric can provide an extra layer of protection.

Inspecting Fabric for Flaws

Before you begin cutting, a thorough inspection of your fabric is a non-negotiable step. Manufacturing processes can sometimes introduce imperfections such as slubs, snags, holes, or uneven dye lots. Identifying these flaws before cutting will save you from having to piece around them later or, worse, discovering them after the garment is partially or fully assembled.Carefully unfold your fabric and examine it under good lighting, ideally natural light.

Run your hands over the surface to feel for any irregularities. Pay close attention to the selvage edges, as these can sometimes be tighter or have a different texture than the rest of the fabric. If you find a flaw, assess its size and location. Minor imperfections might be worked around by shifting your pattern pieces, while larger or more prominent flaws may necessitate using a different section of the fabric or even discarding that piece if it cannot be salvaged.

Handling Specific Fabric Types

Different fabric types require specialized preparation techniques to achieve the best results. Understanding these nuances is key to working successfully with a wide range of materials.

- Woven Fabrics (Cotton, Linen, Blends): These are generally straightforward. Pre-washing as described above is standard. For crisp cottons or linens, a light starching after ironing can provide added body for easier cutting.

- Knits (Jersey, Interlock): Knits have stretch and can distort easily. It is often recommended to wash and dry knits as you intend to care for the finished garment. Some sewers prefer to let knits hang to dry to minimize stretching. Avoid excessive heat in the dryer.

- Silks and Satins: Many silks and satins are dry-clean only, but if you choose to pre-wash, use a very gentle cycle with cool water and a mild detergent. Air dry completely and press on a low heat setting with a pressing cloth. For very delicate silks, hand washing might be the only option.

- Wool: Wool fabrics can be prone to felting and significant shrinkage. If pre-washing, a cool, gentle hand wash or a very specific wool cycle on a washing machine is advised. Air dry flat. For some wools, especially suitings, a good steam press is often sufficient preparation, as they are already stabilized.

- Rayon/Viscose: These fabrics can be prone to shrinking and can weaken when wet. Pre-wash in cool water and handle gently. Air dry or tumble dry on low. Iron while damp on a medium heat setting.

Pre-Washing and Shrinkage Control

Before you begin cutting into your fabric, it is essential to prepare it to prevent unexpected shrinkage after your garment is sewn. This process, known as pre-washing or preshrinking, mimics the effects of laundering and ensures your finished project maintains its intended size and shape. Failing to pre-wash can lead to disappointment, with clothes shrinking to an unwearable size or seams pulling and distorting.Pre-washing is a critical step in fabric preparation because many natural fibers, such as cotton, linen, and rayon, are susceptible to shrinkage when exposed to water and heat.

This shrinkage occurs as the fibers relax from their tension during the manufacturing process. By washing and drying the fabric before sewing, you allow these fibers to contract fully, thereby stabilizing the material and preventing it from shrinking further once your creation is complete. This ensures your finished garment will fit as intended after its first wash and subsequent wears.

Fabric Pre-Washing Methods

The method for pre-washing fabric depends on its fiber content, weave, and weight. Different fabrics require varying degrees of care to maintain their integrity and prevent damage during the washing process. Understanding these distinctions is key to successful fabric preparation.A general guide to pre-washing different fabric types is as follows:

- Cotton and Linen: These natural fibers are prone to significant shrinkage. They can typically be machine washed in warm or hot water and dried on a medium to high heat setting. However, for delicate cottons or linens, a cooler wash and air drying may be preferable.

- Rayon and Viscose: These regenerated cellulose fibers can shrink considerably and may also lose strength when wet. It is often recommended to hand wash rayon in cool water and lay it flat to dry, or machine wash on a delicate cycle with cold water and air dry.

- Silk: Silk is a delicate natural protein fiber that can shrink and lose its sheen if exposed to high heat or harsh detergents. Hand washing in cool water with a pH-neutral detergent and laying flat to dry is the safest approach. Dry cleaning is also an option for many silks.

- Wool: Wool fibers can felt and shrink dramatically when agitated in hot water. It is best to hand wash wool in cool water with a wool-specific detergent and gently squeeze out excess water without wringing. Lay flat to dry, reshaping as needed. Some wools labeled “superwash” may be machine washable on a delicate cycle.

- Synthetics (Polyester, Nylon, Acrylic): Most synthetic fabrics have minimal shrinkage. They can usually be machine washed in warm water and tumble dried on a medium setting. However, always check the fabric care label for specific instructions.

- Blends: For fabrics that are blends of natural and synthetic fibers, it is best to err on the side of caution and follow the care instructions for the most delicate fiber in the blend.

Determining Fabric Shrinkage Potential

Before embarking on a full pre-wash, it is wise to determine if a fabric is likely to shrink and to what extent. This allows you to tailor your pre-washing method accordingly and avoid unnecessary stress on the material. Testing a small swatch provides valuable insight into how the fabric will behave.To ascertain a fabric’s shrinkage potential and test for it, follow these steps:

- Cut a Swatch: Cut a piece of fabric at least 6 inches by 6 inches from your yardage.

- Mark the Swatch: Using a fabric marker or a permanent pen, draw a precise square on the swatch, measuring exactly 5 inches by 5 inches. Ensure the lines are clear and visible.

- Wash and Dry the Swatch: Launder the swatch using the method you intend to use for the full fabric (e.g., machine wash warm, tumble dry medium).

- Measure After Drying: Once the swatch is completely dry, carefully measure the dimensions of the square you marked.

- Calculate Shrinkage: Subtract the new measurement from the original 5-inch measurement. For example, if the square now measures 4.5 inches, the fabric has shrunk by 0.5 inches. Divide the shrinkage amount by the original measurement (0.5 inches / 5 inches = 0.1) and multiply by 100 to get the percentage of shrinkage (0.1100 = 10%). This gives you an indication of how much you should account for in your pattern pieces.

A fabric that shrinks by 10% will reduce its dimensions by that proportion. If your pattern piece is 20 inches long, a 10% shrinkage would mean it becomes 18 inches long after washing. Therefore, you would need to add at least 2 inches to your pattern piece to compensate.

Washing and Drying Guide for Various Fabric Weights

The weight of a fabric influences how it should be washed and dried to manage shrinkage effectively. Heavier fabrics may require more robust washing and drying cycles, while lighter fabrics demand gentler treatment. A systematic approach ensures that all fabric types are prepared appropriately.Here is a step-by-step guide for washing and drying various fabric weights:

Lightweight Fabrics (e.g., Voile, Lawn, Chiffon, Gauze)

- Washing: Hand wash in cool water with a mild detergent, or machine wash on a delicate cycle with cold water. Avoid overcrowding the washing machine.

- Drying: Gently squeeze out excess water without wringing. For most lightweight fabrics, air drying is recommended. Lay them flat on a clean towel or hang them on a drying rack away from direct sunlight. Some very lightweight synthetics might tolerate a very low heat tumble dry.

Mediumweight Fabrics (e.g., Quilting Cotton, Poplin, Chambray, Linen Blends)

- Washing: Machine wash in warm water with a standard detergent. For fabrics with vibrant colors, consider washing them inside out to preserve color.

- Drying: Tumble dry on a medium heat setting. Remove the fabric while it is still slightly damp to minimize wrinkles and prevent over-drying. You can then press it with an iron.

Heavyweight Fabrics (e.g., Denim, Canvas, Corduroy, Heavy Twill)

- Washing: Machine wash in warm to hot water, depending on the fiber content. Denim and canvas can typically withstand hotter temperatures and more vigorous washing. Washing inside out is advisable for dark or colored heavy fabrics.

- Drying: Tumble dry on a medium to high heat setting. Heavy fabrics may take longer to dry. Ensure they are thoroughly dry before ironing or storing. For very heavy fabrics like denim, consider air drying if you are concerned about excessive shrinkage.

Delicate or Specialty Fabrics (e.g., Silk, Wool, Rayon, Velvet)

- Washing: Hand wash in cool water with a specialized detergent (e.g., wool wash for wool, silk wash for silk). For fabrics like velvet or certain silks, dry cleaning might be the safest option, or follow specific care instructions provided by the manufacturer.

- Drying: Lay flat on a towel, reshaping the fabric as it dries. Avoid hanging delicate fabrics, as their weight when wet can cause stretching. Never put wool or delicate silks in a dryer.

Fabric Grain and Straightening

Understanding and correctly managing fabric grain is a fundamental skill in sewing that significantly impacts the drape, fit, and overall appearance of your finished garment. The grain refers to the direction of the threads within the fabric, and working with it properly ensures your project behaves as intended.Fabric grain is determined by the way woven fabric is constructed on a loom.

The lengthwise threads are called the warp, and they run parallel to the selvage (the finished edge of the fabric). The crosswise threads are called the weft, and they run perpendicular to the selvage, going from one selvage to the other. The bias is any direction that is not parallel or perpendicular to the warp or weft threads, typically running at a 45-degree angle.The significance of fabric grain lies in its effect on how the fabric stretches and drapes.

Warp threads are typically stronger and have less stretch, while weft threads have more give. Cutting fabric on the straight grain (parallel to the selvage) ensures that the garment pieces will hang correctly and resist stretching out of shape during wear. Cutting on the crossgrain can lead to a less stable drape, and cutting on the bias allows for maximum stretch and drape, which is often desired for flowing skirts or fitted bodices.

Identifying Fabric Grain

Correctly identifying the grainline is crucial before cutting any pattern pieces. This can be achieved through several methods, depending on the fabric type.

- Selvage Edge: The most reliable indicator for woven fabrics is the selvage. The grainline is always parallel to the selvage. When laying out pattern pieces, align the grainline marking on the pattern with the selvage edge of the fabric.

- Thread Count: In many woven fabrics, you can observe distinct lines formed by the warp and weft threads. The warp threads often appear more tightly packed and uniform. Gently pull on the fabric in both directions; the direction with less stretch is typically the warp or straight grain.

- Tear Test: For some fabrics, especially natural fibers like cotton and linen, a tear test can be effective. Carefully tear a small piece of fabric in both directions. The tear will usually follow the grainline more cleanly and with less fraying in the direction of the warp. The weft may fray more and result in a less straight tear.

- Visual Inspection: Examine the fabric closely. The warp threads are usually straighter and run the length of the bolt, while the weft threads are woven through them.

Straightening Distorted Fabric Grain

Fabric can become distorted during manufacturing, shipping, or even by handling. A skewed grainline will cause garments to hang unevenly and can lead to twisting or pulling. Straightening the grain ensures that your fabric is true and ready for accurate cutting.

Straightening Woven Fabrics

Woven fabrics are most commonly straightened by addressing the weft threads.

- Cutting or Tearing to the Selvage: The most effective method is to find the weft thread that is furthest from the selvage and appears to be running at an angle. Cut or carefully tear the fabric along this line, removing the excess fabric and bringing the weft threads perpendicular to the selvage. This method works best for fabrics that tear cleanly.

- Pulling the Weft Thread: For fabrics that do not tear easily, locate a weft thread at the selvage edge. Gently pull this thread across the width of the fabric. This will create a slight indentation or line, indicating the true grainline. You can then cut along this line.

- Steaming and Flattening: For some fabrics, especially those with a slight bias, you can gently pull the fabric taut along the grainline and then press with steam. This can help the fibers relax and realign themselves. However, this method is less precise than cutting or pulling threads.

Straightening Knit Fabrics

Knit fabrics behave differently than wovens, and their “grain” is determined by the direction of the loops. Straightening knit fabrics requires a slightly different approach.

- Visual Alignment: For most knit fabrics, the grainline runs parallel to the selvage or the finished edge. The “wales” (vertical columns of loops) should run straight up and down. If the fabric appears to be spiraling or twisting, it’s likely that the grain is off.

- Gentle Pulling and Resting: Lay the knit fabric flat and gently pull it in the direction that seems most straight, aligning the wales. Let the fabric rest for a while, as the fibers may naturally realign. This is often sufficient for minor distortions.

- Cutting with Caution: When cutting knit fabrics, it’s crucial to avoid stretching. Use a rotary cutter and mat for precision, and ensure your pattern pieces are aligned correctly with the grainline as indicated. Unlike wovens, you cannot typically “tear” a knit fabric to straighten it.

- Understanding “Grain” in Knits: In knits, the primary “grainline” runs parallel to the selvage. However, some knits can also stretch more in one direction than the other. It’s important to note this stretch direction and ensure it aligns with your pattern’s requirements, especially for garments that need to hug the body.

“The grainline is the soul of your fabric; respect it, and your garment will have a graceful soul.”

Fabric Finishing and Pressing

Pressing your fabric before cutting and sewing is a crucial step that significantly impacts the final outcome of your project. It ensures accurate cutting, helps in achieving crisp seams, and ultimately leads to a more professional and polished garment. This stage prepares your fabric for the precise work of sewing by smoothing out any wrinkles or distortions that may have occurred during manufacturing, storage, or even pre-washing.Taking the time to properly press your fabric is an investment that pays dividends in the ease of sewing and the beauty of the finished product.

It’s not just about removing wrinkles; it’s about setting the fabric in its ideal state for cutting and construction.

Benefits of Pressing Fabric Before Cutting

Pressing fabric before cutting offers several distinct advantages that contribute to a more successful sewing experience and a higher quality finished garment. It is a fundamental step that should not be overlooked.

- Accurate Cutting: A smoothly pressed fabric allows for precise cutting of pattern pieces. Wrinkles or folds can lead to miscalculations, resulting in pieces that are not the correct size or shape, which can cause fitting issues later on.

- Improved Seam Quality: Pressing ensures that fabric lies flat, making it easier to sew straight seams. It also helps to set stitches and create sharp, defined edges, contributing to a professional finish.

- Easier Handling: Fabric that has been pressed is generally more stable and easier to maneuver under the sewing machine needle, reducing the likelihood of puckering or skipped stitches.

- Visual Inspection: Pressing can reveal any subtle flaws in the fabric, such as slubs, thin spots, or printing errors, that might not be as apparent on wrinkled material. This allows you to make informed decisions about pattern placement or to avoid these areas altogether.

Pressing Best Practices for Different Fabric Types

Different fabrics require varying approaches to pressing to avoid damage and achieve the best results. Understanding these nuances is key to preserving the integrity and beauty of your materials.

- Cotton and Linen: These natural fibers are quite resilient and can generally withstand higher heat. Press them with the grain, using a medium to hot iron setting. A press cloth can be beneficial for preventing scorching or shine marks, especially on darker colors or textured weaves.

- Silk: Silk is a delicate fiber that requires lower heat and care. Always press silk on the wrong side using a low heat setting. A press cloth is highly recommended to protect the sheen and prevent water spots. Avoid using steam directly on silk unless specified by the fabric manufacturer.

- Wool: Wool fabrics benefit from steam and moderate heat. Press wool on the wrong side using a press cloth. For a crisp finish, you can use steam generously, but avoid over-pressing, which can flatten the texture. Techniques like “pressing and lifting” rather than “sliding” the iron can help maintain the fabric’s structure.

- Synthetics (Polyester, Nylon, Rayon): Synthetic fabrics are sensitive to heat and can melt or scorch easily. Always test a small, inconspicuous area first. Use a low to medium heat setting and a press cloth. Rayon, in particular, can be prone to water spots, so a press cloth is essential.

- Knits: Knits can stretch out of shape easily when pressed. It’s often best to use a steam-only setting or a very low heat. Press from the wrong side, and avoid stretching the fabric as you press. Some knit fabrics benefit from pressing from the right side with a press cloth to set the stitches.

Appropriate Steam and Iron Settings for Various Materials

Selecting the correct iron setting and judicious use of steam are paramount to successful fabric pressing. Overlooking these details can lead to fabric damage, rendering your material unusable for your project.

The general rule of thumb for iron settings is to start low and gradually increase the heat if necessary, always testing on a scrap piece of fabric first.

Here is a guide to common fabric types and their recommended settings:

- Cotton: Medium-high to high heat, with steam.

- Linen: High heat, with steam.

- Silk: Low heat, dry or with minimal steam, always use a press cloth.

- Wool: Medium-high heat, with generous steam, using a press cloth.

- Polyester: Low to medium heat, dry or with minimal steam, use a press cloth.

- Nylon: Low heat, dry, use a press cloth.

- Rayon: Medium heat, dry or with minimal steam, use a press cloth to prevent water spots.

- Acetate: Low heat, dry, use a press cloth.

When using steam, ensure your iron’s water reservoir is filled with distilled or demineralized water to prevent mineral buildup and potential staining on your fabric. For fabrics that are particularly delicate or prone to scorching, using a dry iron with a press cloth is the safest approach.

Sequence of Pressing Steps for a Typical Sewing Project

A systematic approach to pressing throughout a sewing project ensures that each component is perfectly prepared before assembly, leading to a professional and well-constructed final product. This sequence emphasizes pressing at key stages to manage fabric and seams effectively.

- Initial Fabric Pressing: Before cutting any pattern pieces, press the entire yardage of your fabric according to its type and fiber content. This removes any wrinkles or distortions from the bolt and ensures accurate measurements.

- Pressing Pattern Pieces: After cutting, gently press each pattern piece to remove any temporary wrinkles from handling. Be mindful of the grainline and avoid stretching the fabric.

- Pressing Seam Allowances: As you sew seams, press the seam allowances flat. For most seams, pressing them open or to one side (depending on the pattern instructions and fabric type) is recommended. This creates a clean and flat seam that will not add bulk.

- Pressing Darts and Shaping: Press darts and other shaped seams according to the pattern instructions. This typically involves pressing towards the narrow end of the dart or in the direction indicated by the pattern.

- Pressing Facings and Interfacings: Ensure that facings and any applied interfacings are smoothly pressed before they are attached to the main garment pieces.

- Pressing Hemlines: Before stitching hems, press the hem allowance accurately. This creates a crisp fold that makes stitching much easier and ensures a uniform hem depth.

- Final Pressing: Once the garment is fully assembled, give it a final, thorough press. This is where you refine all the seams, hems, and any other details to achieve a polished, professional look. Use appropriate heat and steam for the fabric type, and consider using a tailor’s ham or sleeve board for pressing curved areas.

Handling Specialty Fabrics

Specialty fabrics, while offering unique textures and aesthetics, often require a more nuanced approach to preparation to ensure successful sewing outcomes. Understanding their specific properties is key to avoiding common pitfalls and achieving professional results. This section will guide you through the intricacies of preparing fabrics like silk, linen, denim, upholstery, drapery, and stretch materials.

Many specialty fabrics present unique challenges due to their delicate nature, slippery texture, or tendency to behave unpredictably when handled. For instance, silks can snag easily, linens may wrinkle severely, and denim can be stiff and heavy. Upholstery and drapery fabrics, often wider and heavier, also demand specific preparation techniques. Stretch and performance fabrics require attention to their elasticity to maintain their intended function.

Common Challenges with Silk, Linen, and Denim

Preparing these popular specialty fabrics involves addressing their distinct characteristics. Silks, known for their lustrous sheen and smooth drape, can be notoriously slippery and prone to water spotting. Pre-washing silk is generally not recommended as it can alter its texture and sheen; instead, spot cleaning with a damp cloth or professional dry cleaning is often preferred. If you must pre-wash, use a gentle detergent and cool water, testing a swatch first.

Linens, while durable and breathable, are prone to significant wrinkling and shrinkage. It is crucial to pre-wash linen to account for any shrinkage before cutting your pattern pieces. Denim, a sturdy cotton twill, can also shrink considerably and may have excess dye that can bleed. Pre-washing denim is highly recommended to set the dye and pre-shrink the fabric.

Pre-Treatment Methods for Slippery or Delicate Fabrics

Slippery and delicate fabrics, such as charmeuse silk, satin, or fine chiffons, require careful handling to prevent snags, runs, or distortion. For slippery fabrics, a temporary stabilization method can be employed. This might involve using a very fine silk or polyester thread for basting, or even a temporary spray adhesive designed for fabric, applied sparingly to hold layers in place during cutting.

For delicate fabrics, such as lace or fine silks, it is advisable to handle them minimally and avoid aggressive pressing. Using a press cloth is essential to protect the fabric surface from direct heat and potential scorching. Some delicate fabrics may benefit from a light starching of a test swatch to provide a bit more body for easier cutting and handling, but this should always be tested first.

Handling and Preparing Upholstery and Drapery Fabrics

Upholstery and drapery fabrics are often wider, heavier, and designed for durability and specific visual effects. Before cutting, it is important to inspect these fabrics for any flaws, such as slubs, uneven weaves, or dye inconsistencies, especially since they are often purchased in larger quantities. For drapery fabrics, consider the “hand” or drape of the fabric. Some fabrics may need to be hung for a period to allow them to relax and settle, preventing uneven hems or distortion after installation.

Upholstery fabrics, particularly those with pile or texture, need careful attention to ensure the nap or pattern direction is consistent across all pieces. For both types, if pre-washing is necessary (check manufacturer’s instructions), it should be done with the same method intended for the final cleaning of the finished item, and always test for colorfastness.

Checklist for Preparing Stretch or Performance Fabrics

Stretch and performance fabrics, engineered for elasticity and specific functionalities like moisture-wicking or compression, require a different preparation strategy to preserve their inherent properties.

Here is a checklist to guide you through preparing these dynamic materials:

- Inspect for Flaws: Carefully examine the fabric for any snags, runs, or manufacturing defects, paying close attention to the stretch direction.

- Pre-Washing (if applicable): Many performance fabrics are designed to be washed. Wash according to the manufacturer’s instructions, using a mild detergent and avoiding fabric softeners, which can clog the pores and reduce breathability or moisture-wicking properties. Do not use high heat in the dryer.

- Drying: Air drying is often recommended for stretch fabrics to prevent heat damage to elastic fibers. If machine drying is necessary, use a low heat setting.

- Shrinkage Check: While many performance fabrics are stabilized, it’s still wise to cut a small swatch and wash/dry it to confirm any minimal shrinkage.

- Grainline and Stretch Direction: Ensure you are cutting with the grain and that the primary stretch runs in the intended direction for your pattern. The stretch is often more pronounced in one direction than the other.

- Cutting Surface: Use a cutting mat and a rotary cutter or very sharp scissors to avoid distorting the fabric. A slightly sticky cutting mat can help keep slippery stretch fabrics from shifting.

- Handling: Handle stretch fabrics gently to avoid stretching them out of shape before cutting. Avoid excessive pinning, which can create permanent holes; consider pattern weights instead.

Inspecting and Repairing Fabric

Before you begin the exciting process of cutting and sewing, a thorough inspection of your fabric is a crucial step that ensures the quality and professionalism of your finished project. This meticulous examination allows you to identify and address any imperfections that could otherwise detract from your garment’s appearance or structural integrity. Taking this time upfront can save you considerable frustration and rework later in the sewing process.Common fabric defects can range from subtle variations to more obvious flaws.

Identifying these issues early on allows you to either work around them, repair them, or in some cases, decide if the fabric is suitable for your intended project at all. This proactive approach is fundamental to achieving a polished and professional outcome in your sewing endeavors.

Common Fabric Defects

It is essential to be aware of the various types of imperfections that can occur in fabric. Recognizing these defects will enable you to spot them quickly during your inspection.

- Slubs: These are thicker, irregular sections in the yarn that appear as bumps or knots on the fabric’s surface. They can disrupt the smooth texture and visual flow of the fabric.

- Holes: These can range from tiny pinpricks to larger tears or bald spots where threads are missing. Holes can compromise the fabric’s strength and appearance.

- Dye Inconsistencies: This category includes variations in color, such as streaks, spots, or uneven dyeing. These can manifest as lighter or darker patches, or a general lack of uniformity in the color.

- Thread Breaks: Occasional breaks in the warp or weft threads can create gaps or thin areas in the fabric.

- Weft Bars: These appear as horizontal lines across the fabric, often caused by tension variations during weaving.

- Pattern Misalignment: In patterned fabrics, the design elements might not align correctly, creating a disjointed or unprofessional look.

Mending Minor Fabric Imperfections

Fortunately, many minor fabric flaws can be skillfully mended before cutting, preventing them from impacting your final garment. The goal is to make these repairs as invisible as possible.

- For Slubs: If a slub is minor and not too prominent, you can sometimes gently tease it apart with a needle to make it less noticeable. For larger slubs, consider carefully snipping them if they are loose, or if they are integral to the weave, you may need to avoid cutting through that area or consider if the fabric is still suitable.

- For Small Holes: Small holes can often be repaired by carefully catching the surrounding threads with a fine needle and thread that matches the fabric color. Gently pull the threads together to close the gap. For slightly larger holes, you might need to darn the area by weaving new threads across the hole, mimicking the existing weave.

- For Dye Inconsistencies: If a dye inconsistency is a small spot, you might be able to carefully touch it up with a fabric marker or dye pen, ensuring it blends seamlessly. For larger areas of inconsistency, it may be best to try and incorporate the flaw into the design by placing it in a seam allowance or a less visible part of the garment.

- For Thread Breaks: Gently pull the surrounding threads to close any small gaps created by thread breaks. If the break is significant, a darning technique might be necessary.

It’s important to practice these mending techniques on a scrap piece of the same fabric first to ensure you achieve a satisfactory result.

Marking and Noting Fabric Flaws

A systematic approach to marking and noting fabric flaws ensures that you don’t overlook any issues when you begin cutting your pattern pieces. This documentation is invaluable for efficient fabric utilization and for making informed decisions about pattern placement.A clear procedure for marking and noting flaws will enhance your sewing workflow. This involves a visual inspection followed by a clear system of annotation.

- Visual Inspection: Spread your fabric out on a large, well-lit surface. Systematically scan the entire piece, looking for any of the defects mentioned previously. You can do this by holding the fabric up to the light or by running your hands over the surface to feel for irregularities.

- Marking with a Temporary Marker: Use a fabric-specific temporary marker, chalk, or a pin to indicate the location of each flaw. For larger areas of inconsistency, you might draw a light Artikel around the affected zone.

- Noting the Flaw: Keep a notebook or a digital document handy. For each marked flaw, make a brief note describing the type of defect and its approximate location on the fabric (e.g., “slub, 10 inches from selvage, near the center”).

- Consider Pattern Placement: As you mark and note flaws, consider how your pattern pieces will be laid out. You can often strategically place pattern pieces to avoid flaws entirely or to minimize their visibility. For example, a small dye spot might be perfectly hidden within a dart or a seam.

- Prioritize Repairs: If you discover multiple flaws, decide which ones require mending and which can be worked around. Address the mending tasks before proceeding to cutting.

This detailed approach to inspecting and repairing your fabric will contribute significantly to the overall success and aesthetic appeal of your sewing projects.

Fabric Preparation for Specific Projects

The journey from a beautiful fabric bolt to a finished sewing project is significantly influenced by the intended use of that project. Different applications demand tailored preparation techniques to ensure optimal results, longevity, and ease of construction. Understanding these nuances is key to transforming your fabric into a successful creation, whether it’s a garment that drapes perfectly, a quilt that lies flat, or durable home decor.The type of sewing project dictates the emphasis placed on various fabric preparation steps.

While some steps, like checking the grain, are universally important, others, such as pre-washing or specific finishing techniques, become more critical depending on the end use. This section explores how to adapt your fabric preparation strategy to suit the unique demands of various sewing endeavors.

Project Type Influences Preparation

The final outcome of a sewing project hinges on how well the fabric has been prepared for its specific purpose. A garment requires attention to how the fabric will move and feel against the skin, while a quilt prioritizes precision and stability. Home decor items often need to withstand wear and environmental factors. Therefore, a thoughtful approach to preparation, considering the project’s demands, is essential.

Quilting Versus Garment Construction Preparation

Preparing fabric for quilting and garment sewing involves distinct considerations, even though some steps overlap. For quilting, the primary focus is on maintaining structural integrity and achieving precise measurements for piecing. For garments, the emphasis shifts towards the fabric’s drape, hand, and how it will behave during wear and washing.For quilting, pre-washing is often optional, depending on the fabric type and the desired final look.

However, it is highly recommended for 100% cotton fabrics, especially if they are brightly colored, to prevent bleeding and to pre-shrink the fabric, ensuring that the finished quilt doesn’t warp after its first wash. After washing and drying, the fabric must be meticulously pressed to remove all wrinkles and to ensure it is perfectly flat for accurate cutting. The concept of “squaring up” the fabric after washing and drying is crucial.

This involves trimming the selvages and ensuring that the grain lines are perfectly straight and parallel to the edges, creating a true rectangle or square. This accuracy is paramount because even a slight deviation can lead to distorted quilt blocks and an uneven final quilt.Garment sewing, on the other hand, almost always requires pre-washing. This is to account for any shrinkage that might occur in the finished garment during its lifetime.

Different fiber contents will shrink differently, and it’s best to get this shrinkage out of the way before cutting. The “hand” or feel of the fabric is also a significant consideration for garments. Pre-washing can soften some fabrics and improve their drape, making them more comfortable and flattering to wear. Pressing is equally important, not just for ease of cutting but also to ensure that the fabric lies flat and the grain is correctly aligned, which directly impacts how the finished garment will hang and fit.

Preparation for Waterproof or Coated Fabrics

Waterproof or coated fabrics present unique preparation challenges due to their inherent properties. These fabrics often do not react well to traditional pre-washing methods like machine washing and drying, as the heat and agitation can damage the coating or membrane, compromising their water-resistant qualities. Therefore, preparation often involves a more gentle approach.For many waterproof fabrics, a thorough inspection for any factory flaws or damage is the primary step.

If pre-washing is deemed necessary to remove any manufacturing residues or to slightly soften the fabric, it should be done by hand in cool water with a mild detergent. Avoid any harsh chemicals or fabric softeners, as these can degrade the coating. Drying should be done by air-drying, away from direct heat or sunlight. Pressing these fabrics requires extreme caution.

It is generally best to avoid direct ironing altogether. If pressing is absolutely necessary, use a very low heat setting and always place a pressing cloth between the iron and the fabric. Some coated fabrics can be gently steamed from the wrong side to remove wrinkles, but testing this on a small scrap first is highly advisable. The primary goal is to maintain the integrity of the waterproof barrier.

Comparison of Preparation Techniques for Different Project Types

The following table provides a comparative overview of fabric preparation techniques tailored to various sewing projects, highlighting key steps, specific considerations, and potential pitfalls to avoid.

| Project Type | Key Preparation Steps | Specific Considerations | Potential Pitfalls to Avoid |

|---|---|---|---|

| Garment Sewing | Pre-wash, press, check grain, preshrink | Shrinkage, drape, hand, bias stretch, nap direction | Uneven shrinkage, distorted seams, fabric pilling, incorrect nap |

| Quilting | Pre-wash (optional, recommended for cotton), press, square up, check grain | Colorfastness, precise cutting, dimensional stability, starching (optional) | Fabric fraying, inaccurate block sizes, color bleeding, warped quilts |

| Home Decor (e.g., curtains, upholstery) | Pre-wash (if washable), press, account for hemming, consider interfacing | Drape, light blocking, durability, washability, fade resistance, structural integrity | Uneven hems, fabric stretching, loss of shape, poor light blocking, wear and tear |

| Crafts (e.g., bags, accessories) | Press, check grain, consider interfacing or stabilizers | Durability, stiffness, ease of manipulation, clean edges | Fraying edges, weak seams, distortion, fabric tearing |

| Waterproof or Coated Fabrics | Inspect, gentle hand wash (if needed), air dry, minimal pressing | Preserve coating integrity, avoid heat damage, test methods | Damaged coating, loss of water resistance, melted fabric, weakened seams |

Final Wrap-Up

In essence, dedicating time to meticulously prepare your fabric is an investment that pays dividends throughout your sewing journey. From pre-washing to straightening the grain and careful inspection, each step contributes to a smoother, more enjoyable creative process and a superior final product. By mastering these fundamental techniques, you lay the groundwork for countless successful and beautiful sewing projects, ensuring your creations are as durable and flawless as they are aesthetically pleasing.