Embarking on the journey of sewing often involves mastering essential techniques, and the automatic one-step buttonhole stands as a particularly rewarding skill to acquire. This guide is meticulously crafted to transform the process from potentially daunting to delightfully straightforward. We will delve into the intricacies of this remarkable sewing machine feature, illuminating its benefits and the simple steps required to achieve professional-looking results with ease.

Understanding and implementing the automatic one-step buttonhole can significantly elevate the quality and efficiency of your sewing projects. Whether you are a seasoned seamster or just beginning your creative endeavors, this comprehensive exploration will equip you with the knowledge and confidence to tackle buttonholes with precision and flair. We aim to provide a clear and accessible pathway to mastering this fundamental sewing technique.

Understanding the One-Step Buttonhole

The one-step buttonhole feature on a sewing machine is a remarkable innovation designed to simplify a task that can often be intricate and time-consuming. This automated process allows you to create perfectly sized and uniformly stitched buttonholes with a single, continuous action. It transforms a potentially daunting sewing technique into an accessible and efficient one, even for those relatively new to sewing.At its core, the one-step buttonhole stitch is a series of dense stitches that form a complete buttonhole without requiring manual intervention for each side or direction.

The machine is programmed to sew the two sides of the buttonhole, the front bar tack, and the back bar tack in one continuous cycle. This eliminates the need to re-position the fabric or change stitch settings multiple times, as would be necessary with traditional buttonhole methods.

The Fundamental Concept of a One-Step Buttonhole Stitch

The fundamental concept of a one-step buttonhole stitch lies in the machine’s ability to execute a predetermined sequence of stitches automatically. This sequence is specifically designed to create a durable and aesthetically pleasing buttonhole. The machine first identifies the length of the buttonhole based on the button you are using. It then proceeds to sew the sides, followed by the reinforcing bar tacks at either end, all without the operator needing to perform any manual adjustments during the process.

Benefits of Using an Automatic One-Step Buttonhole Feature

The advantages of employing an automatic one-step buttonhole feature are numerous, significantly enhancing the sewing experience. This feature not only saves considerable time but also ensures a high degree of precision and consistency that can be difficult to achieve manually.Here are the key benefits:

- Time Efficiency: The most apparent benefit is the dramatic reduction in the time required to create buttonholes. What might take several minutes of careful manual stitching can be accomplished in seconds.

- Consistency and Uniformity: Every buttonhole created with this feature will be identical in size and stitch density, leading to a professional and polished finish on garments and projects.

- Ease of Use: The automation simplifies the process, making it accessible to sewers of all skill levels, including beginners who might otherwise find buttonhole creation intimidating.

- Reduced Errors: By minimizing manual intervention, the likelihood of errors such as uneven stitching or incorrect placement is significantly decreased.

- Professional Results: The consistent, clean lines and reinforced ends produced by the one-step system result in a professional-looking outcome that elevates the quality of your sewing projects.

Typical Components Enabling One-Step Buttonholes

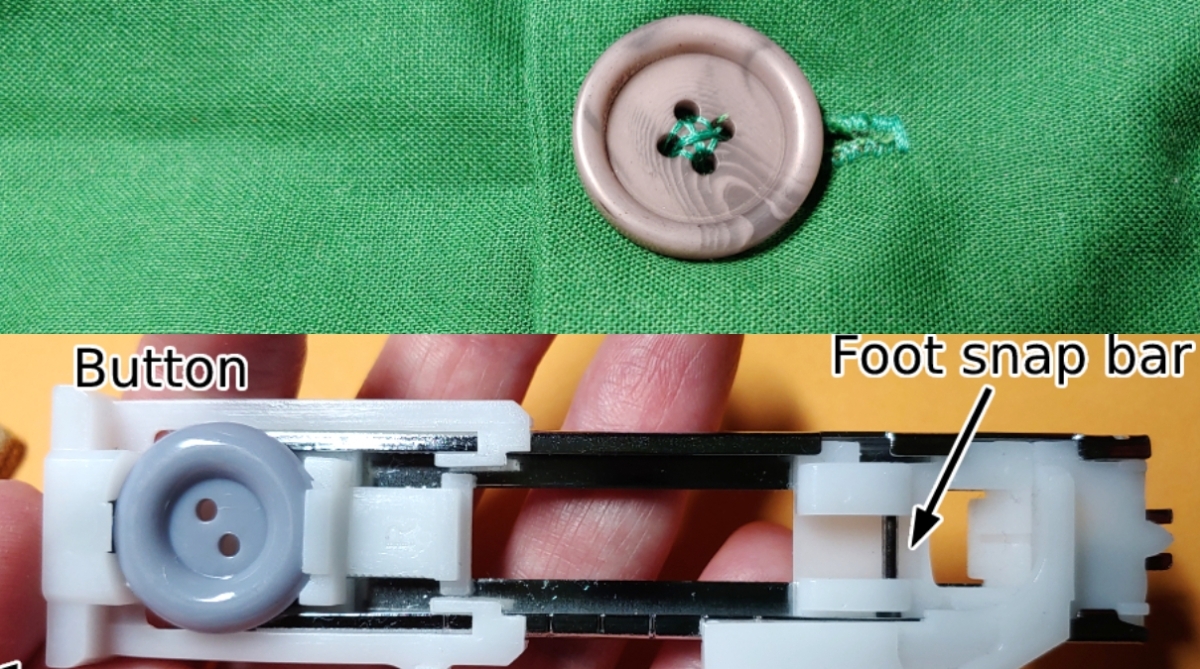

The magic of the one-step buttonhole is made possible by a combination of specialized components and technology within the sewing machine. These elements work in harmony to guide the fabric and execute the complex stitch sequence.The primary components that facilitate one-step buttonholes include:

- Buttonhole Foot: This is the most crucial accessory. The one-step buttonhole foot typically has a channel on the underside to guide the button. Many have a sliding mechanism that allows you to insert your button, and the machine will automatically measure and set the buttonhole length based on the button’s dimensions.

- Specialized Feed Dog System: Some machines have a feed dog system that can be lowered or engaged in a specific way to allow for the backward and forward movement required for buttonhole stitching. The one-step foot often works in conjunction with this system, or its own mechanism, to control fabric movement.

- Internal Programming and Motors: The sewing machine’s internal computer and motors are programmed to execute the precise sequence of stitches. This includes controlling the needle’s movement, the feed dogs, and the stitch type (typically a dense zigzag stitch for the sides and a straight stitch for the bar tacks).

- Stitch Selector Dial or Screen: While the process is one-step, you will typically select the one-step buttonhole function on your machine’s stitch selector dial or digital screen. This tells the machine to prepare for the automated sequence.

Essential Tools and Materials

To successfully create automatic one-step buttonholes, having the right tools and preparing your materials beforehand is crucial. This section will guide you through the necessary sewing machine accessories, suitable fabric types, and a checklist to ensure you’re fully prepared before you begin.Having the correct sewing machine accessories specifically designed for buttonholes will make the process smoother and yield professional results.

These accessories are often integrated into your machine’s functionality or are simple attachments that enhance its capabilities.

Sewing Machine Accessories for One-Step Buttonholes

The following sewing machine accessories are essential for creating automatic one-step buttonholes:

- Buttonhole Foot: This is the most critical accessory. It’s designed with a channel or groove on the underside that guides the button as the machine stitches the buttonhole. The length of the buttonhole is determined by the size of the button placed within this foot.

- Buttonhole Dial or Setting: Many modern sewing machines have a dedicated buttonhole setting or dial. This allows you to select the buttonhole size and stitch pattern, often automatically adjusting the stitch length and density for each step of the buttonhole creation.

- Needles: Ensure you have sharp, appropriate sewing machine needles for your fabric type. A universal needle is often sufficient for many fabrics, but for heavier materials, a denim or leather needle might be necessary.

- Thread: Use good quality all-purpose polyester thread. For a more prominent buttonhole, you might consider using buttonhole twist thread or a thicker thread, but ensure your machine can handle it.

Suitable Fabric Types for Automatic Buttonholes

While automatic buttonholes can be created on a wide variety of fabrics, some perform better and require less preparation than others. The key is to choose fabrics that have enough body to hold their shape without stretching or fraying excessively during the stitching process.It is important to consider the weight and weave of the fabric. Very lightweight, slippery fabrics or very bulky, napped fabrics can present challenges that may require additional stabilization.The following fabric types are generally well-suited for automatic buttonholes:

- Woven Cottons: Quilting cottons, poplin, and broadcloth are excellent choices. They are stable, easy to press, and hold stitches well.

- Linen Blends: Fabrics that combine linen with cotton or polyester offer good stability and a refined finish. Pure linen can be a bit more prone to fraying.

- Denim and Twill: These sturdy woven fabrics are ideal for garments like jeans and trousers. Their inherent strength helps them withstand the stitching process.

- Gabardine: A tightly woven fabric that is durable and holds its shape well, making it suitable for outerwear and structured garments.

- Medium-Weight Synthetics: Polyester blends, suiting fabrics, and some stable rayons can also work effectively. Avoid very thin or very stretchy synthetics.

Preparatory Materials Checklist

Before you begin creating your one-step buttonholes, having all your materials ready will streamline the process and prevent interruptions. This checklist ensures you have everything you need at your fingertips.Taking a moment to gather and prepare these items will contribute significantly to a successful and enjoyable sewing experience.

- Fabric: Pre-washed and pressed to remove any shrinkage or imperfections.

- Pattern Pieces: With buttonhole markings clearly indicated.

- Buttons: To measure and test the buttonhole size.

- Thread: Matching or contrasting, as desired, wound onto a bobbin.

- Sewing Machine: With the correct needle inserted and the buttonhole foot attached.

- Scissors or Rotary Cutter and Mat: For precise fabric cutting.

- Seam Ripper: For any necessary adjustments or corrections.

- Marking Tools: Such as tailor’s chalk, a fabric pen, or a pencil, to transfer buttonhole placement from the pattern.

- Iron and Ironing Board: Essential for pressing seams and ensuring crisp edges.

- Stabilizer (Optional): Interfacing or a tear-away stabilizer may be needed for very lightweight, stretchy, or loosely woven fabrics to prevent puckering and stretching.

Preparing Your Sewing Machine

To successfully create automatic one-step buttonholes, ensuring your sewing machine is correctly set up is paramount. This involves selecting the right accessories and configuring your machine’s settings to work harmoniously with the buttonhole function. A well-prepared machine will lead to consistent and professional-looking results.This section will guide you through the essential steps of preparing your sewing machine, from attaching the specialized buttonhole foot to understanding the specific stitch settings and ensuring your bobbin is ready for the task.

Attaching the Buttonhole Foot

The correct foot is crucial for the automatic one-step buttonhole process. This specialized foot is designed to measure the button and automatically create the buttonhole to the appropriate size.

- Ensure your sewing machine is turned off and unplugged for safety.

- Locate the presser foot holder on your machine.

- Remove the existing presser foot by lowering the presser foot lifter, then pressing the release lever or screw that secures the foot. Consult your machine’s manual if you are unsure of this process.

- Identify your machine’s specific one-step buttonhole foot. It typically has a groove on the underside to accommodate the button and a sliding mechanism to adjust its length.

- Align the buttonhole foot with the presser foot holder and lower it into place. It should click or snap securely into position.

- Ensure the foot is firmly attached before proceeding.

Selecting the Appropriate Stitch Setting

The one-step buttonhole function on your machine is a pre-programmed stitch sequence. Selecting the correct setting activates this sequence, allowing the machine to perform all the necessary stitches automatically.Most modern sewing machines with a one-step buttonhole feature will have a dedicated dial or button for this function. When you select the buttonhole setting, the machine will typically default to a specific stitch width and length that is optimized for buttonholes.

It’s important to consult your sewing machine’s manual to identify the exact location and method for selecting this setting. Some machines may require you to move a lever or select a specific symbol on the stitch selection dial.

Winding and Inserting the Bobbin Thread

The bobbin thread plays a vital role in the structure and appearance of your buttonhole, providing the necessary strength and finish. Properly winding and inserting the bobbin ensures a continuous and even supply of thread throughout the buttonhole creation process.Before starting, ensure you have the correct type of bobbin and thread that is compatible with your sewing machine.

- Winding the Bobbin:

- Place a spool of your chosen thread onto the spool pin.

- Thread the machine as if you were going to sew, but guide the thread through the bobbin winder tension disk.

- Insert the end of the thread through a hole in your bobbin.

- Hold the end of the thread firmly and engage the bobbin winder mechanism according to your machine’s instructions. This usually involves pushing a lever or turning a dial.

- Start the winding process. Ensure the thread winds evenly across the bobbin. If it starts to wind unevenly, stop and reposition the thread.

- Once the bobbin is full, disengage the bobbin winder and cut the thread.

- Inserting the Bobbin:

- Open the bobbin case area on your sewing machine. This is usually a compartment at the base of the machine, either under a removable plate or in a front-facing bobbin shuttle.

- Place the wound bobbin into the bobbin case, ensuring the thread unwinds in the correct direction as indicated by your machine’s manual (usually counter-clockwise).

- Pull the thread through the tension spring or slot in the bobbin case.

- Close the bobbin cover or reinsert the bobbin shuttle.

- Bring the bobbin thread up to the needle by holding the upper thread tail and turning the machine’s handwheel towards you one full rotation. This will loop the bobbin thread and bring it up through the needle plate.

Fabric Preparation and Marking

Proper fabric preparation and accurate marking are foundational steps to achieving professional-looking one-step buttonholes. This stage ensures that your buttonholes are not only correctly placed but also consistently sized and positioned, leading to a polished and functional garment.Stabilizing your fabric prevents stretching and distortion during the sewing process, which is particularly crucial for delicate or loosely woven materials. Accurate marking provides a precise guide for your sewing machine, eliminating guesswork and ensuring symmetry.

Fabric Stabilization Techniques

Stabilizing the fabric before marking and sewing buttonholes is essential for preventing distortion and ensuring crisp, defined results. This is especially important for fabrics that are prone to stretching, such as knits, bias-cut fabrics, or loosely woven materials.Several methods can be employed to achieve adequate stabilization:

- Interfacing: Applying a lightweight to medium-weight fusible or sew-in interfacing to the wrong side of the fabric in the buttonhole area is a common and effective technique. The interfacing adds body and structure, minimizing stretching. For very fine or delicate fabrics, consider using a silk organza or a very lightweight fusible interfacing to avoid adding bulk.

- Starch: A good quality spray starch can temporarily stiffen the fabric, making it easier to handle and mark accurately. This is a quick solution for many woven fabrics. Ensure the starch is evenly applied and allowed to dry completely before proceeding.

- Temporary Basting: For certain fabrics, particularly those that might be damaged by heat from an iron or chemicals from starch, hand-basting the buttonhole area to a piece of stabilizer fabric can provide sufficient support.

- Water-Soluble Stabilizer: This is an excellent option for very stretchy or delicate fabrics like knits or sheer materials. A layer of water-soluble stabilizer is placed either on top of or underneath the fabric (or both) and then dissolves away after sewing.

Accurate Buttonhole Marking

Precise marking of the buttonhole placement is critical for both aesthetic appeal and functional button closure. A misplaced buttonhole can render a garment unusable or significantly detract from its appearance.The process for accurate marking involves several steps:

- Button Measurement: The first step is to accurately measure your button. The buttonhole should be just slightly larger than the button’s diameter to allow for easy insertion and removal without being too loose. For thicker buttons, you might need to add a little extra length to accommodate their depth.

- Marking Placement: Use a reliable marking tool such as a fabric pen, chalk, or tailor’s chalk. For dark fabrics, a silver or white marking pen is ideal. For light fabrics, a dark chalk or pen will be visible. Always test your marking tool on a fabric scrap to ensure it will not leave a permanent mark.

- Using a Template: Many sewing machines come with a buttonhole ruler or template. You can also create your own by using a piece of cardstock or clear plastic. Mark the center line of your buttonhole and then use this template to transfer the exact length and position onto your fabric.

- Marking Both Ends: It is crucial to mark both the start and end points of the buttonhole accurately. This ensures that the machine sews the correct length and that the buttonhole is centered where intended.

- Consider Button Placement: Think about how the garment will be worn. Buttonholes on a placket, for instance, need to be aligned with the edge of the placket. Buttonholes on cuffs should be positioned to allow the cuff to fasten comfortably.

Ensuring Consistent Buttonhole Length

Achieving consistent buttonhole length is paramount for a professional finish and proper functionality. This consistency ensures that all buttons will fit correctly and that the garment closes as intended.The following methods are key to ensuring uniform buttonhole length:

- Button Gauge or Ruler: The most straightforward method is to use a dedicated buttonhole gauge or a small ruler. Place the button against the gauge and adjust it until it fits snugly. This measurement then dictates the length you will set on your sewing machine or mark on your fabric.

- Buttonhole Templates: If your sewing machine has an automatic buttonhole foot, it often has a built-in mechanism for setting the length based on the button. If using a manual buttonhole stitch, you can create a template by drawing the desired buttonhole length on a piece of paper or cardstock. Use this as a guide for marking your fabric.

- Marking with a Ruler: Measure the button’s diameter. Add a small allowance for ease (typically 1/8 inch or 3mm). Mark this total length directly onto your fabric at the desired buttonhole location. Ensure the marking tool is visible and precise.

- Test Samples: Before sewing on your garment, always create a test buttonhole on a scrap of the same fabric, ideally with the same stabilization. This allows you to fine-tune the buttonhole length setting on your machine and verify that the button fits perfectly.

The perfect buttonhole length is the button’s diameter plus a small ease of approximately 1/8 inch (3mm) for standard buttons, allowing for smooth insertion and removal without being too loose.

Executing the One-Step Buttonhole

Now that your machine is set up and your fabric is prepared, it’s time to bring your one-step buttonhole to life. This process is designed to be efficient, with your sewing machine doing most of the work. Understanding how the machine operates during this cycle and what to do if an issue arises will ensure a smooth and successful outcome.The automatic one-step buttonhole function is a marvel of modern sewing technology.

When you engage this feature, your machine cycles through a predetermined sequence of stitches to create a complete buttonhole, from the tacking stitches at each end to the straight stitching along the sides. This significantly reduces the margin for error and saves considerable time compared to manual buttonhole creation.

Sewing a Single Automatic Buttonhole

To sew a single automatic buttonhole, follow these precise steps. Each action is crucial for achieving a professional-looking result.

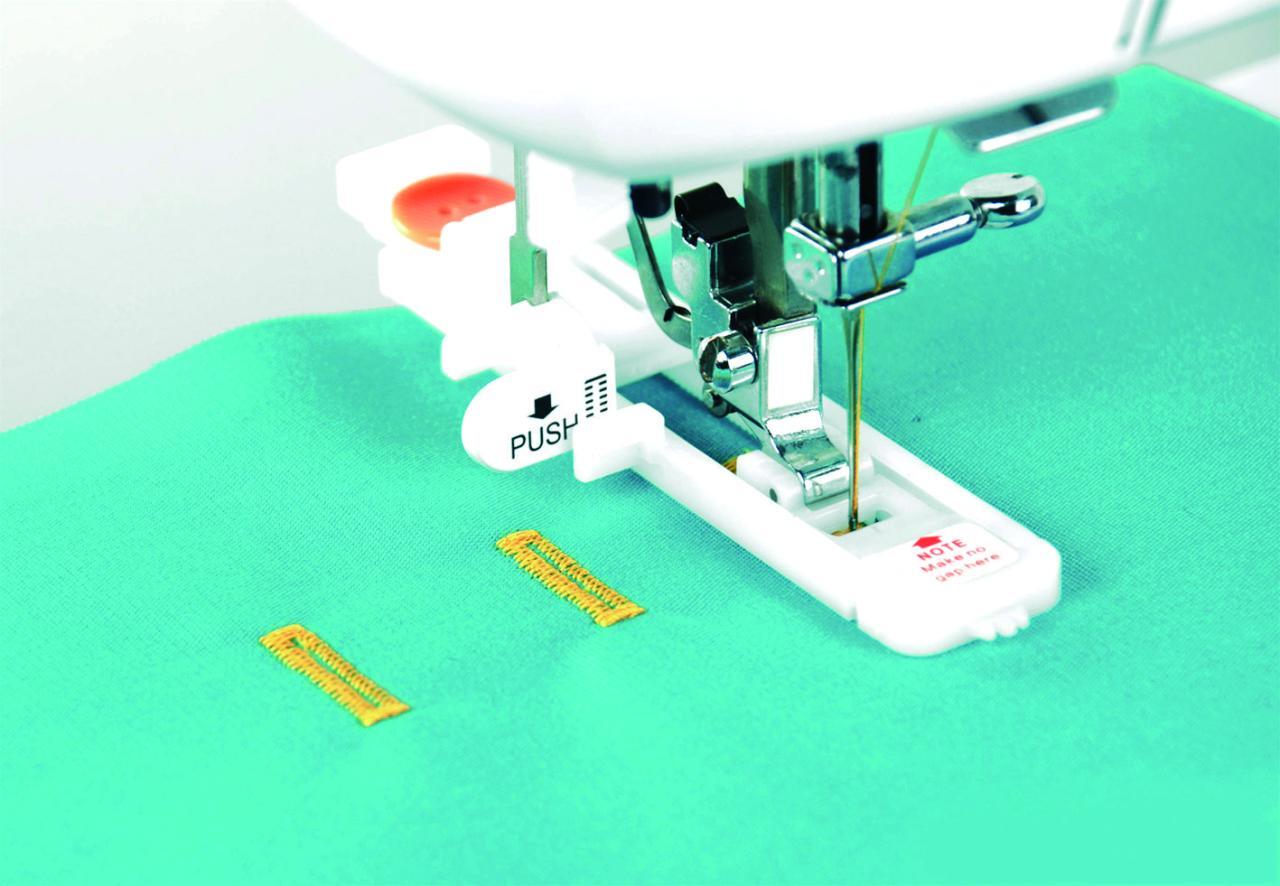

- Attach the appropriate buttonhole foot to your sewing machine. This foot is specifically designed to accommodate the buttonhole mechanism and ensure even stitch distribution.

- Position your fabric under the presser foot with the marked buttonhole line aligned. Ensure the needle is positioned at the starting point of your buttonhole, typically the left side of the marked line.

- Lower the presser foot firmly onto the fabric.

- Engage the one-step buttonhole function on your machine. This is usually activated by a lever or a specific button on the machine’s interface. Refer to your machine’s manual for the exact location and operation.

- Press the foot pedal to begin sewing. The machine will automatically stitch the buttonhole, moving through its programmed sequence.

- Once the machine completes the buttonhole cycle, it will stop automatically.

- Carefully raise the presser foot and remove the sewn buttonhole from the machine.

- Use a seam ripper to carefully open the buttonhole. Insert the seam ripper from one end towards the center, stopping before you reach the tacking stitches at the other end.

Machine Operation During the One-Step Buttonhole Cycle

During the one-step buttonhole cycle, your sewing machine performs a complex series of movements automatically. It’s important to observe this process to understand its mechanics.The machine begins by sewing a series of dense tacking stitches at the starting point of the buttonhole. This reinforces the end to prevent unraveling. Following this, it stitches one side of the buttonhole with a closely spaced zigzag stitch.

Then, it moves to the opposite end to create another set of reinforcing tacking stitches. Finally, it stitches the other side of the buttonhole, mirroring the first side, before completing the cycle. The precise sequence and stitch density are determined by your machine’s internal programming and often can be adjusted through settings or by selecting different buttonhole styles.

The beauty of the one-step buttonhole lies in its automation, ensuring consistent stitch density and length for a professional finish every time.

Addressing Machine Stoppages or Issues Mid-Stitch

While the one-step buttonhole is highly reliable, occasional issues can arise. Knowing how to troubleshoot these situations will save your project.If your machine stops unexpectedly during the buttonhole cycle, remain calm and do not force the handwheel.

- First, check for any obvious obstructions. This could include thread jams, a tangled bobbin, or fabric that has shifted.

- Gently lift the presser foot and carefully remove the fabric from the machine.

- Inspect the needle and the bobbin area for any lint or broken threads. Clean these areas thoroughly according to your machine’s manual.

- Re-thread the machine, ensuring the presser foot is up when threading the top thread and the bobbin is correctly inserted.

- Reposition the fabric under the presser foot, aligning it with the start of the buttonhole. You may need to re-mark the buttonhole if it has shifted significantly.

- Carefully restart the buttonhole cycle. If the issue persists, consult your sewing machine’s manual for specific troubleshooting steps related to buttonhole functions or contact customer support.

Troubleshooting Common Buttonhole Issues

Even with careful preparation and execution, occasional hiccups can occur when creating buttonholes. Understanding these common problems and their solutions will help you achieve consistently professional results. This section will guide you through identifying and resolving issues such as uneven stitch density, incorrect width, and fabric puckering.When your one-step buttonhole doesn’t turn out as intended, it’s often due to a few key factors related to machine settings, fabric handling, or thread tension.

Addressing these systematically will lead to a much smoother sewing experience.

Uneven Stitch Density

Uneven stitch density in a buttonhole can manifest as gaps between stitches or stitches that are too close together in certain areas, making the buttonhole look messy and less durable. This is frequently caused by inconsistent thread tension or issues with the feed dogs.

- Thread Tension: The balance between the upper and bobbin thread is crucial. If the upper thread is too tight, it can pull the bobbin thread to the top, creating gaps. Conversely, if it’s too loose, stitches might bunch up. Experiment with adjusting the upper thread tension dial, usually starting by decreasing the tension slightly.

- Feed Dog Function: The feed dogs are responsible for moving the fabric evenly under the needle. If they are not engaging properly or are set too low, the fabric won’t advance consistently, leading to uneven stitching. Ensure the feed dogs are raised for buttonhole creation and that they are clean and free of lint.

- Presser Foot Alignment: The buttonhole foot needs to be correctly positioned and engaged. If it’s slightly askew, it can affect the evenness of the stitches. Make sure the foot is securely attached and that the fabric is feeding smoothly beneath it.

- Thread Type: Using different types or weights of thread for the upper and bobbin can sometimes cause tension imbalances. It is best to use the same type and weight of thread for both.

Buttonhole Width Adjustment

The width of your buttonhole is determined by the stitch width setting on your sewing machine and the type of buttonhole foot used. If the buttonhole is consistently too wide or too narrow, it needs to be addressed at the source.

- Stitch Width Setting: Most sewing machines allow you to adjust the stitch width for buttonholes. For a standard buttonhole, a width of approximately 3-4mm is common. If your buttonhole is too wide, reduce this setting. If it’s too narrow, increase it. Always test on a scrap of your fabric to find the optimal setting.

- Buttonhole Foot Type: The one-step buttonhole foot is designed to automatically create a buttonhole of a specific width based on its internal mechanism. If your machine has a specific buttonhole foot that offers adjustable width, ensure it is set correctly. If you are using a generic buttonhole foot, the stitch width setting on your machine will be the primary control.

- Fabric Weight: Heavier fabrics might require a slightly wider buttonhole to accommodate the thickness, while very lightweight fabrics might look better with a narrower one. Adjust your stitch width accordingly.

Fabric Puckering Around the Buttonhole

Fabric puckering is an unsightly issue where the fabric bunches up and wrinkles around the stitched buttonhole, compromising the neatness of your garment. This is often a result of tension issues or the fabric not being adequately supported.

- Stabilizer Use: For fabrics prone to stretching or puckering, such as knits or lightweight wovens, using a stabilizer is highly recommended. Apply a tear-away or cut-away stabilizer to the wrong side of the fabric where the buttonhole will be placed. This provides extra support and prevents the fabric from being pulled and distorted by the needle.

- Thread Tension: As mentioned before, incorrect thread tension is a major culprit for puckering. If the upper thread is too tight, it can pull the fabric down, causing it to bunch. Loosen the upper thread tension slightly and re-test.

- Needle Selection: Using the correct needle for your fabric type is essential. A dull or bent needle can snag the fabric and cause puckering. For knits, use a ballpoint or stretch needle. For wovens, a universal needle is usually sufficient.

- Presser Foot Pressure: Some sewing machines allow you to adjust the presser foot pressure. If the pressure is too high, it can crush the fabric, leading to puckering. If your machine has this feature, try reducing the presser foot pressure slightly.

- Slow Sewing Speed: Sewing too quickly can exacerbate puckering. Slow down your sewing speed, especially when stitching the buttonhole, to give the fabric and machine time to work together smoothly.

Finishing and Trimming Buttonholes

Once your one-step buttonhole is sewn, the next crucial step is to carefully open it and tidy up any loose threads. This stage requires precision to ensure a professional finish and to avoid damaging your garment. Proper technique here will make the difference between a handmade look and a polished, store-bought appearance.

Opening the Buttonhole

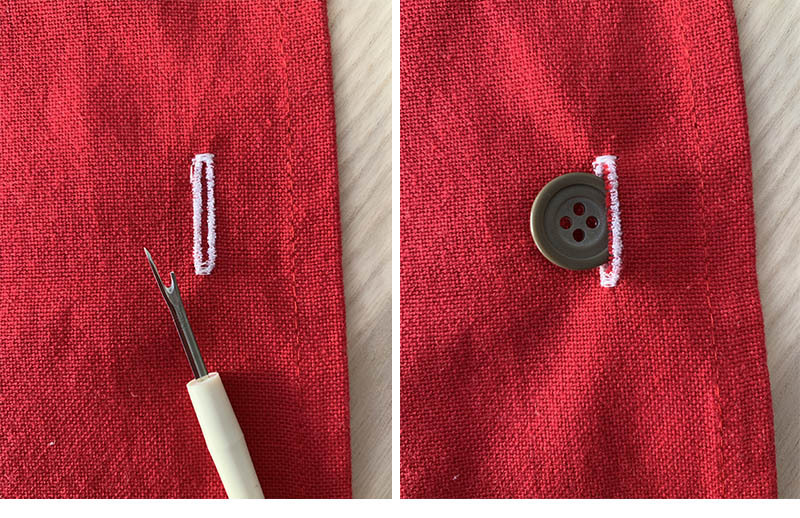

The most critical part of opening a buttonhole is to cut it precisely in the center without piercing through to the other side or too close to the stitch lines. This requires a sharp tool and a steady hand.

- Buttonhole Cutter: This is the most recommended tool for this task. It is designed with a sharp blade that sits on a narrow base, allowing you to control the depth of the cut. Place the cutter directly on the seam of the buttonhole and gently tap or press down to slice through the fabric.

- Seam Ripper: A seam ripper can also be used, but it requires more caution. Carefully insert the pointed tip into the center of the buttonhole’s sewn seam. Gently pull the seam ripper along the stitched line, using the small blade to cut the threads. It’s advisable to use the seam ripper to break the threads first, and then pull them out, rather than trying to cut through the fabric directly with the sharp point.

Preventing Overcutting

Accidentally cutting too far can unravel your buttonhole or create an unsightly opening. Several methods can help you avoid this common pitfall.

- Use a Pin: Before cutting, insert a pin horizontally across the buttonhole at each end, just before the stitching. This acts as a physical barrier, stopping your cutting tool before it reaches the end of the buttonhole. Ensure the pin is placed right up to the edge of the stitch line.

- Control the Depth: When using a buttonhole cutter, apply gentle pressure. If using a seam ripper, make small, controlled movements. Visualize the stitch line and aim to cut only the fabric within that line.

- Practice on Scraps: Before working on your actual garment, practice opening buttonholes on fabric scraps that have been sewn with the same buttonhole settings. This will help you get a feel for your tools and machine’s stitch density.

Trimming Excess Threads

After the buttonhole is opened, you’ll likely have some loose threads from the sewing process. Neatly trimming these contributes significantly to a clean finish.

- Sharp Scissors: Use a small, sharp pair of embroidery scissors or a thread snip. These allow for precise cutting close to the fabric without accidentally snipping the garment.

- Careful Trimming: Gently pull any loose threads away from the fabric and snip them as close to the surface as possible. Be careful not to cut into the main fabric of the garment.

- Inside and Outside: Trim threads from both the right side and the wrong side of the fabric to ensure a completely neat finish.

Advanced Techniques and Variations

Beyond the basic one-step buttonhole, there are several advanced techniques and variations you can explore to enhance your sewing projects. These techniques allow for greater customization, accommodate different button types, and tackle challenging fabrics with confidence. Mastering these will elevate your sewing skills and the professional finish of your garments.

Buttonhole Size Adjustment for Different Buttons

The standard one-step buttonhole function on your machine is typically set for a medium-sized button. However, to ensure a perfect fit for various button diameters, you’ll need to adjust the buttonhole length. This is usually achieved through the machine’s settings, often involving a length adjustment dial or a digital setting.

Always test your buttonhole length on a scrap of the same fabric before sewing on your actual garment.

The process generally involves placing the button under the presser foot, engaging the buttonhole function, and allowing the machine to stitch the buttonhole. For larger buttons, you’ll need to extend the designated stitch length, while smaller buttons require a shorter setting. Some machines have a built-in sensor or a marking on the presser foot that helps guide this adjustment. Refer to your sewing machine’s manual for specific instructions on how to calibrate the buttonhole length for your particular model.

Decorative Buttonholes

Elevate the aesthetic appeal of your garments by incorporating decorative elements into your buttonholes. This can be achieved by experimenting with different thread colors and types, adding a unique visual touch.

Thread Color Variations

Choosing a contrasting thread color for your buttonholes can make them a prominent design feature. For instance, on a navy blue blazer, bright red buttonholes can add a pop of unexpected color. Alternatively, using a subtle tonal variation of the fabric color can create a sophisticated and understated effect.

Thread Type Experimentation

Beyond standard all-purpose polyester thread, consider using specialty threads for decorative buttonholes. Metallic threads can add a touch of shimmer and luxury, perfect for evening wear or special occasion garments. Silk threads offer a beautiful sheen and a smooth finish, ideal for delicate fabrics. For a more textured look, embroidery floss or a thicker cotton thread can be used, though this may require adjusting your machine’s tension and needle.

Always perform a test stitch on a fabric scrap to ensure the specialty thread performs well with your machine.

Sewing Buttonholes on Challenging Fabrics

Certain fabrics present unique challenges when sewing buttonholes due to their structure or stretch. With the right preparation and techniques, you can achieve professional-looking buttonholes even on these tricky materials.

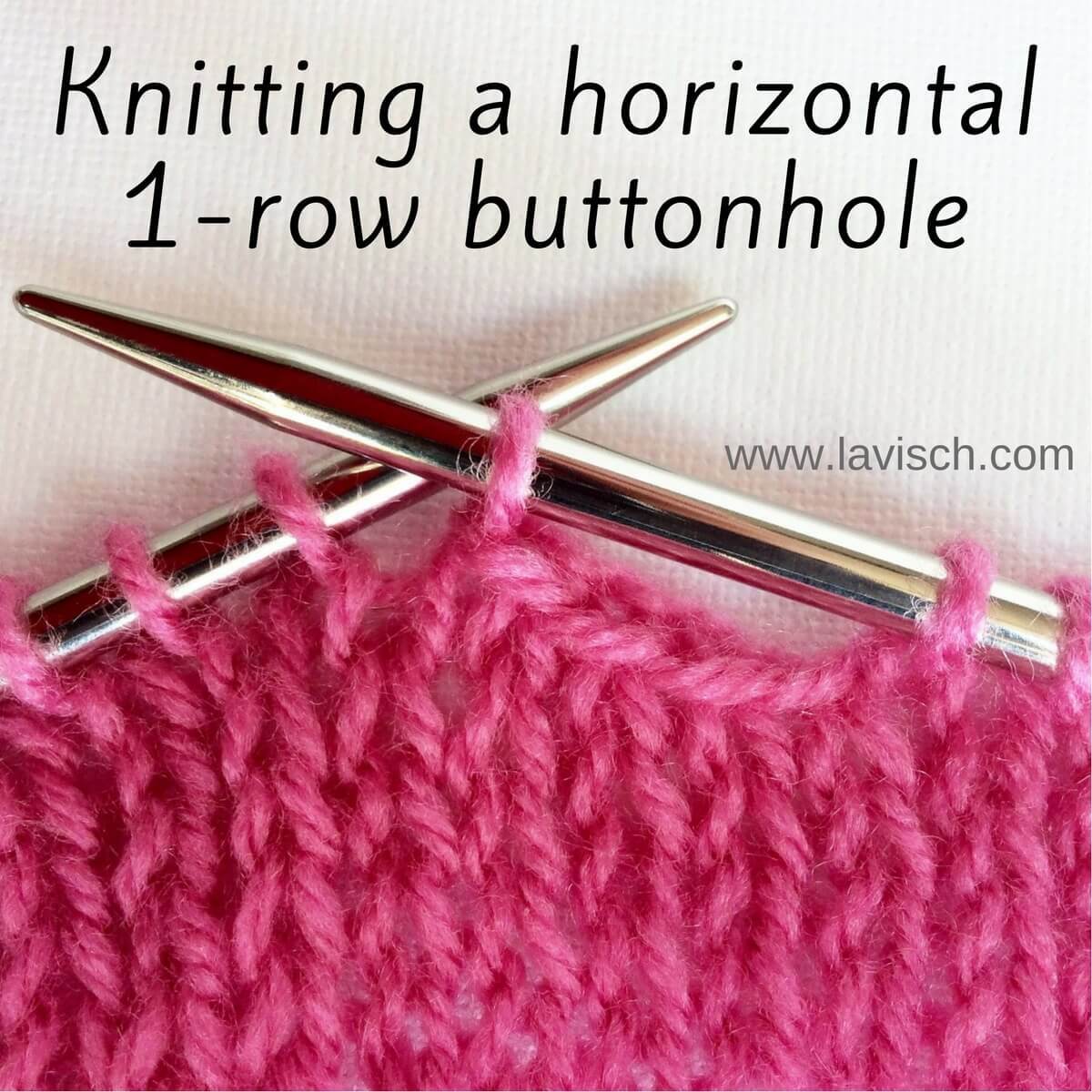

Knits and Stretchy Fabrics

Knits, due to their inherent stretch, can distort when the buttonhole is sewn, leading to a stretched-out or uneven opening. To combat this, it’s crucial to stabilize the fabric before sewing.

- Interfacing: Apply a lightweight fusible interfacing to the wrong side of the fabric in the area where the buttonhole will be sewn. This provides a stable base and prevents stretching.

- Stabilizer Spray: Temporary stabilizer sprays can be used to stiffen the fabric just for the sewing process.

- Tear-Away Stabilizer: Place a piece of tear-away stabilizer underneath the fabric while sewing the buttonhole. This supports the knit and can be easily removed afterward.

- Needle Choice: Use a ballpoint or stretch needle to avoid snagging the knit fibers.

- Machine Settings: Consider reducing your stitch length slightly to create a denser buttonhole that resists stretching.

Heavy Denim and Sturdy Woven Fabrics

Heavyweight fabrics like denim or canvas can be thick and stiff, making it difficult for the sewing machine to feed evenly and stitch through multiple layers.

- Needle Choice: A heavy-duty or denim needle is essential for piercing through these tough materials.

- Presser Foot Pressure: If your machine has adjustable presser foot pressure, reduce it slightly to allow the fabric to feed more easily.

- Hand-Wheel Assistance: For the initial few stitches or when encountering particularly thick areas, you can manually guide the handwheel to ensure the needle penetrates the fabric without skipping stitches.

- Batting/Warping: For very thick seams, you might need to “wash” or “warp” the fabric by hand to soften it or consider using a walking foot for even feeding.

- Marking: Ensure your markings are precise and consider using a fabric marker that won’t bleed through thick denim.

Maintaining Your Buttonhole Foot and Machine

Regular maintenance of your buttonhole foot and sewing machine is crucial for ensuring consistent, high-quality buttonholes. Just like any precision tool, these components require care to function optimally. By implementing a simple maintenance routine, you can prevent common issues, extend the lifespan of your equipment, and achieve professional-looking results with every buttonhole.Proper care not only ensures the longevity of your sewing machine and its attachments but also directly impacts the accuracy and neatness of your buttonholes.

Neglecting maintenance can lead to skipped stitches, uneven stitching, or even damage to your fabric or machine.

Buttonhole Foot Maintenance Routine

Establishing a regular cleaning and inspection schedule for your buttonhole foot will prevent lint buildup and ensure its smooth operation. This routine should be performed after each significant sewing project or at least monthly, depending on your sewing frequency.

- After Each Use: Gently brush away any loose threads or fabric fibers from the foot using a small, soft brush.

- Weekly Cleaning: For a more thorough clean, remove the buttonhole foot from the machine. Use a cotton swab lightly dampened with rubbing alcohol to wipe down the metal and plastic components. Pay attention to the area where the needle passes through and any movable parts.

- Inspection: Before reattaching, visually inspect the foot for any signs of wear, damage, or bent parts. Ensure all components move freely.

Cleaning and Oiling Machine Areas Relevant to Buttonholes

The needle area and feed dog mechanisms are critical for buttonhole creation, as they directly interact with the fabric and guide its movement. Keeping these areas clean and properly oiled is essential for smooth operation and accurate stitching.

Needle Area Cleaning and Oiling

The needle plate and the area surrounding the needle bar are prone to lint and thread accumulation, which can affect stitch formation.

- Cleaning the Needle Plate: With the machine unplugged and the needle removed, use a small brush or a can of compressed air to remove lint from the needle plate. You can also use a lint roller for stubborn debris.

- Cleaning the Needle Bar Area: Gently brush away any lint or dust that has accumulated around the needle bar.

- Oiling the Needle Area: Refer to your sewing machine’s manual for specific oiling points around the needle area. Typically, a drop or two of sewing machine oil applied to the designated points can improve smooth movement. Be careful not to over-oil, as excess oil can stain fabric.

Feed Dog Area Cleaning and Oiling

The feed dogs are responsible for moving the fabric under the needle, and their cleanliness is vital for even stitch distribution, especially for buttonholes.

- Accessing the Feed Dogs: You may need to lower the feed dogs using your machine’s lever. Consult your manual if unsure.

- Cleaning the Feed Dogs: Use a small brush to meticulously remove any lint, thread, or fabric scraps from between the feed dog teeth. Compressed air can also be effective here.

- Oiling the Feed Dog Mechanism: Your machine’s manual will indicate specific oiling points for the feed dog mechanism. Apply a small amount of sewing machine oil as directed.

Seeking Professional Servicing for Buttonhole Mechanisms

While routine maintenance can address most minor issues, certain problems indicate a need for professional attention to ensure the integrity of your buttonhole mechanisms.

- Signs of Needing Professional Servicing:

- Persistent skipped stitches or uneven stitching that cannot be resolved by cleaning, oiling, or needle/thread changes.

- Unusual noises, such as grinding or clicking, emanating from the machine during buttonhole creation.

- The buttonhole mechanism appears bent, damaged, or jammed.

- Inconsistent buttonhole lengths or shapes that do not align with the settings.

- The machine struggles to move the fabric evenly during the buttonhole process.

- When to Schedule Professional Servicing: It is advisable to have your sewing machine, particularly its buttonhole mechanism, serviced by a qualified technician annually or bi-annually, especially if you are a frequent sewer. This proactive approach can identify and rectify potential issues before they lead to more significant problems or costly repairs. A professional service ensures that all moving parts are properly calibrated and lubricated, guaranteeing optimal performance for your buttonhole creation.

Epilogue

In conclusion, the automatic one-step buttonhole is a testament to the ingenuity of modern sewing machines, offering a seamless and efficient way to add a polished finish to any garment or textile creation. By understanding the fundamentals, preparing your tools and machine correctly, and following the Artikeld steps, you can confidently execute perfect buttonholes every time. Remember to troubleshoot any potential issues with patience, and don’t hesitate to explore advanced techniques to further enhance your sewing repertoire.

Happy stitching!