Embarking on a sewing journey with delicate fabrics like chiffon, organza, and georgette presents a unique set of challenges and rewards. These ethereal textiles, known for their transparency and graceful drape, require a thoughtful approach to both preparation and execution to achieve stunning results. Understanding their inherent properties is the first step towards mastering the art of sewing with these beautiful materials.

This guide is designed to equip you with the essential knowledge and techniques needed to navigate the intricacies of working with sheer fabrics. From selecting the perfect material for your project to employing specialized tools and precise stitching methods, we will explore every facet to ensure your creations are both elegant and expertly crafted. Prepare to transform these delicate materials into wearable art.

Understanding Sheer Fabrics

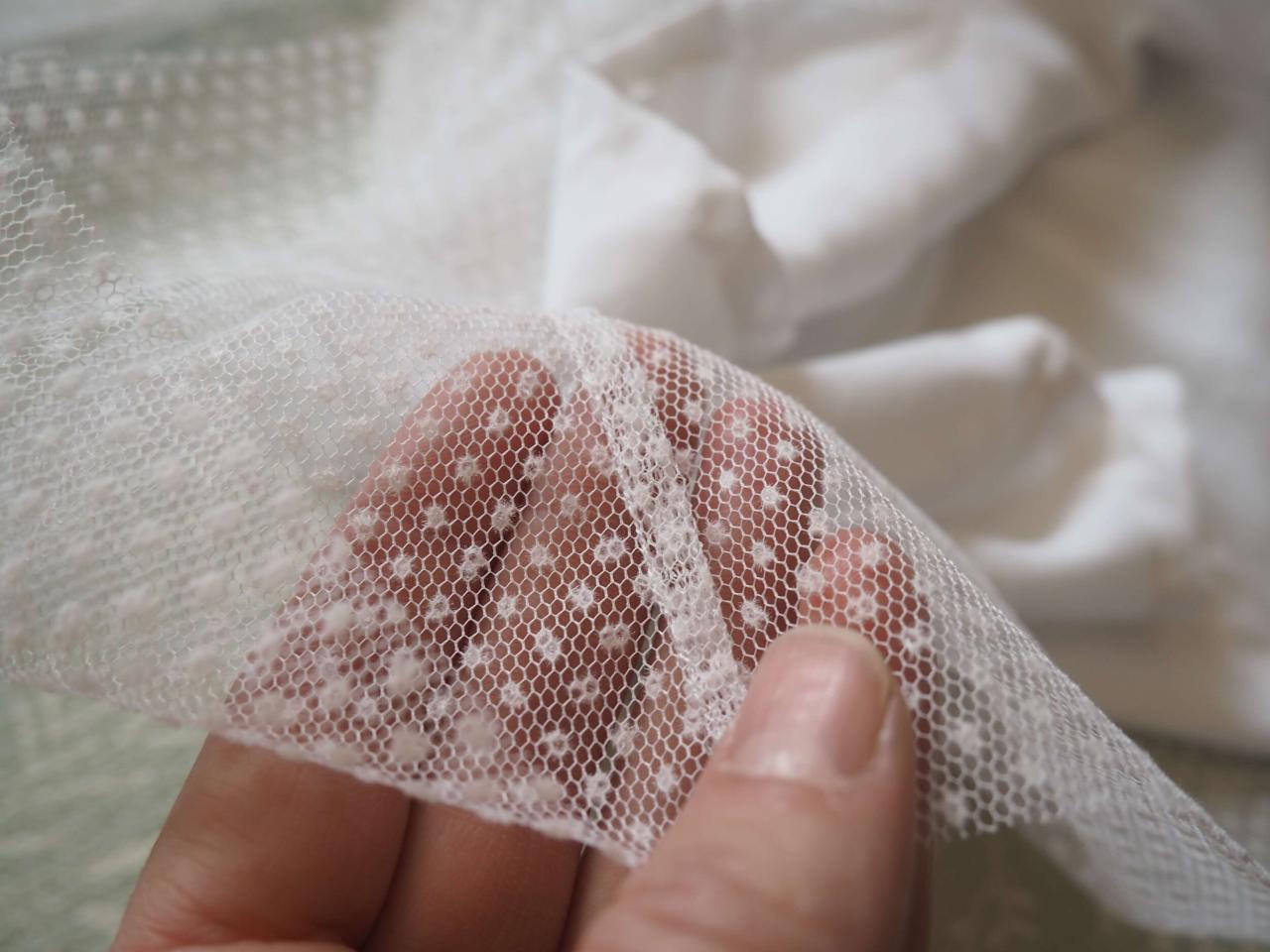

:max_bytes(150000):strip_icc()/sewingchiffon-56b70d0c5f9b5829f8361de9.jpg)

Sewing with sheer fabrics like chiffon, organza, and georgette presents a unique set of challenges and rewards. These materials, known for their delicate translucence and graceful drape, require a different approach to cutting, handling, and stitching compared to their opaque counterparts. Understanding their inherent properties is the first crucial step toward achieving professional and beautiful results.These fabrics are characterized by their lightweight nature and open weave, which allows light to pass through them, creating an ethereal and elegant effect.

However, this delicacy also means they can be prone to snagging, stretching, and fraying, making precision and patience paramount during the sewing process.

Properties of Sheer Fabrics

Sheer fabrics are defined by their distinctive characteristics, which influence their behavior during sewing and their final appearance in a garment.

- Chiffon: Typically made from silk, polyester, or rayon, chiffon has a slightly dull finish and a soft, flowing drape. Its characteristic crepe-like texture comes from highly twisted yarns. It is very lightweight and can be somewhat slippery.

- Organza: Often made from silk or synthetic fibers, organza is stiffer and crisper than chiffon, with a more lustrous sheen. It holds its shape well, making it ideal for structured elements like ruffles, overlays, and decorative accents. Its weave is more open, contributing to its sheerness.

- Georgette: Similar to chiffon but generally heavier and less lustrous, georgette has a slightly duller finish and a more matte appearance. It offers a beautiful drape and is more durable than chiffon, making it a good choice for flowing dresses and blouses.

Common Challenges in Sewing Sheer Fabrics

Working with sheer fabrics can be intimidating due to several common difficulties that arise during the sewing process. Recognizing these challenges allows for proactive preparation and the selection of appropriate techniques.The primary issues stem from the fabric’s tendency to shift, stretch, and fray. Standard sewing practices may not suffice, and specialized tools and methods are often necessary to maintain control and achieve clean finishes.

- Fabric Slippage: The smooth surface of many sheer fabrics makes them prone to sliding around under the needle, leading to uneven seams and distorted shapes.

- Stretching and Distortion: The delicate threads can easily stretch out of shape, especially when handled roughly or when the machine’s feed dogs pull unevenly.

- Fraying: The open weave means that edges can unravel very easily, requiring careful finishing techniques to prevent excessive fraying.

- Needle Penetration: A needle that is too large can create noticeable holes, while a needle that is too small might break or skip stitches on denser sheers.

- Thread Visibility: The sheer nature of the fabric means that thread color and thickness are highly visible, making thread choice and tension critical.

Selecting the Right Sheer Fabric for a Project

The choice of sheer fabric significantly impacts the final look and feel of a garment. Understanding the specific properties of different sheers and how they align with project requirements is essential for successful outcomes.Consider the intended design, the desired drape, and the level of formality when making your selection. Each fabric type lends itself to different styles and applications.

- For flowing, ethereal garments like evening gowns or bridal veils: Chiffon or silk organza are excellent choices due to their softness and graceful movement.

- For structured elements, overlays, or decorative accents: Silk organza or a stiffer polyester organza will provide the necessary body and crispness.

- For blouses, skirts, or dresses with a fluid drape that is slightly more durable: Georgette offers a beautiful balance of drape and resilience.

- For delicate linings or underlayers where a subtle sheen is desired: A lightweight silk or polyester charmeuse with a sheer quality can be used.

Fabric Weight and Drape in Sheer Textiles

The weight and drape of a sheer fabric are its most defining characteristics, influencing how a garment will hang and move. These two factors are intrinsically linked and play a crucial role in the design and construction of sheer garments.Weight refers to how much a fabric weighs per unit area, while drape describes how a fabric falls or hangs when suspended.

For sheer fabrics, these qualities are often exaggerated due to their lightness and fine construction.

- Fabric Weight: Sheer fabrics are by definition lightweight, ranging from extremely fine (like some silks) to moderately light (like some georgettes). A lighter weight often translates to a more delicate and airy feel, while a slightly heavier sheer might offer a bit more body and stability. For instance, a very lightweight chiffon might be almost weightless, while a heavier georgette will have a more noticeable, though still light, presence.

- Drape: The drape of sheer fabrics is what gives them their characteristic flow and elegance. Chiffon and georgette are known for their soft, fluid drape, meaning they fall in graceful folds. Organza, on the other hand, has a stiffer drape, allowing it to hold shape and create volume, such as in puffed sleeves or full skirts. The way a fabric drapes is determined by its fiber content, yarn twist, weave structure, and finishing processes.

The interplay between fabric weight and drape is paramount in achieving the intended aesthetic of any garment constructed from sheer materials.

Essential Tools and Preparations

Successfully sewing with sheer fabrics requires a thoughtful approach to both the tools you use and the way you prepare your materials. These delicate textiles can be unforgiving if not handled with care, making the right equipment and a solid preparation routine crucial for achieving professional-looking results. This section will guide you through the essential tools and preparations that will set you up for success.

Sewing Tools and Notions for Sheer Fabrics

When working with sheer fabrics, specialized tools can make a significant difference in the ease and quality of your sewing. Standard tools may snag, stretch, or distort these fine materials, leading to frustration and imperfect finishes. Selecting the right notions also ensures that your construction methods are appropriate for the fabric’s weight and transparency.Here is a list of recommended sewing tools and notions specifically suited for working with sheer fabrics:

- Fine-point Sewing Machine Needles: Use the smallest needle size possible, such as a size 60/8 or 70/10. These needles are sharp and thin, minimizing the risk of creating visible holes or snags in delicate fabrics like chiffon, organza, or georgette.

- Microtex or Sharp Needles: These needles are designed for precise piercing of fine fabrics and are an excellent choice for sheers.

- Universal or Ballpoint Needles (for knits): If you are working with sheer knits, a fine ballpoint needle will prevent skipped stitches and laddering.

- New, Sharp Scissors or Rotary Cutter: A very sharp cutting tool is paramount. Dull blades will drag on the fabric, causing uneven edges and pulls. Ensure your scissors are dedicated to fabric or that your rotary blade is fresh.

- Fine Thread: Opt for high-quality, fine polyester or silk thread. These threads are strong yet thin enough to disappear into the fabric, avoiding a heavy or visible stitch line.

- Fine-tipped Pins: Use extra-fine, sharp pins to minimize pinholes. Silk pins or micro-pins are ideal.

- Double-Sided Tape or Washable Appliqué Stabilizer: For temporary holding of seams or hems without pins, these can be invaluable.

- French Seam or Rolled Hem Foot: These specialized presser feet are designed to create neat, enclosed seams and delicate hems that are perfect for sheer fabrics.

- Walking Foot or Even-Feed Foot: For fabrics that tend to shift or stretch, a walking foot helps to feed the layers of fabric evenly, preventing distortion.

- Tracing Paper or Silk Organza for Pattern Weights: Using pattern weights instead of pins on the fabric itself helps to prevent any stretching or damage.

Pre-washing and Preparing Sheer Fabrics

Properly pre-washing and preparing sheer fabrics is a critical step that cannot be overlooked. Many sheer fabrics are made from natural fibers like silk or cotton, or synthetic fibers that can react differently to washing and drying. Failing to pre-wash can lead to unexpected shrinkage, distortion, or color bleeding after your garment is completed, ruining your hard work.The general guidelines for pre-washing sheer fabrics involve treating them gently to mimic the conditions they will experience during the garment’s life.

- Identify Fabric Content: Always check the fabric content and care label if available. This will inform the best washing method. For silk chiffon, hand washing in cool water with a pH-neutral detergent is recommended. For synthetic sheers like polyester chiffon, a gentle machine wash on a delicate cycle in cool water may be acceptable.

- Test for Colorfastness: Before washing the entire piece of fabric, cut a small swatch and test for colorfastness. Soak the swatch in cool water and check if any dye bleeds. If it does, you may need to use a color catcher sheet in your wash or consider dry cleaning.

- Gentle Washing: Hand washing is generally the safest method for most sheer fabrics. Use a mild detergent specifically designed for delicates or silk. Swish the fabric gently in cool water; avoid wringing or twisting, which can damage the fibers and cause stretching.

- Machine Washing (with caution): If machine washing, place the fabric in a mesh laundry bag to protect it from snagging and excessive agitation. Select the delicate or hand-wash cycle with cool water and a mild detergent.

- Rinsing: Rinse the fabric thoroughly in cool water until all detergent is removed.

- Drying: Never put sheer fabrics in a hot dryer, as this can cause shrinkage and damage. The best method is to lay the fabric flat on a clean towel, away from direct sunlight or heat, and gently roll it up in the towel to absorb excess moisture. Then, lay it flat or hang it to air dry completely. For silks, avoid hanging as the weight of the water can cause stretching.

- Pressing: Once dry, press the fabric on a low heat setting, using a press cloth to protect the delicate fibers. Ironing while slightly damp can sometimes yield better results.

Using a Rotary Cutter and Mat for Precise Cutting

When it comes to cutting sheer fabrics, precision is paramount. A rotary cutter and mat offer a superior cutting experience compared to traditional scissors for these delicate materials. The sharp, rolling blade of a rotary cutter slices through the fabric cleanly and in a single motion, minimizing the risk of shifting, stretching, or snagging that can occur with scissors.The benefits of using a rotary cutter and mat for sheer materials include:

- Clean, Uninterrupted Cuts: The continuous rolling motion of the rotary cutter ensures a smooth, continuous cut without the need to lift and re-position blades, which can cause fabric to move.

- Reduced Fabric Distortion: Because the fabric is not being pushed or pulled by scissor blades, it remains flat and stable on the mat, leading to more accurate cuts.

- Accuracy and Straight Edges: When used with a quilting ruler, a rotary cutter allows for extremely precise and straight cuts, essential for achieving perfect garment pieces.

- Speed and Efficiency: Once you are comfortable with the technique, rotary cutting can be significantly faster than using scissors, especially for long, straight cuts.

- Minimized Pinning: You can often lay out sheer fabrics flat on the mat and weigh them down with pattern weights, avoiding the need for pins that can leave permanent holes or distort the fabric.

To use effectively, ensure your rotary cutter blade is sharp and your cutting mat is clean and free of debris. Lay the fabric flat and smooth, place your ruler, and then run the rotary cutter along the edge of the ruler with firm, even pressure.

Recommended Stabilizers for Sewing Sheer Fabrics

Stabilizers are invaluable tools when sewing sheer fabrics, providing temporary support to prevent stretching, distortion, and puckering during the sewing process. They can also be used to create a more opaque or structured effect in certain areas of a garment. Choosing the right type of stabilizer and knowing how to apply it can dramatically improve the quality of your finished project.Here is a list of recommended stabilizers and their applications for sewing sheer fabrics:

- Washable Basting Tape/Fusible Web: These are often used as temporary adhesives to hold fabric layers together without pins, especially for hems or appliqué. They are ideal for sheers as they leave no holes and can be easily removed or become part of the seam.

- Temporary Spray Adhesives: These adhesives can be lightly sprayed onto one fabric surface to temporarily bond it to another. They are useful for holding pattern pieces to fabric or for appliqué. Ensure the spray is specifically designed for fabric and leaves no residue.

- Water-Soluble Stabilizers: These stabilizers dissolve in water and are excellent for adding temporary body to very flimsy sheers, especially for embroidery or decorative stitching. They are typically ironed onto the wrong side of the fabric and then rinsed away after sewing.

- Cut-Away Stabilizers: While often used for more stable fabrics, a very lightweight cut-away stabilizer can be used on the wrong side of sheers if a permanent structure is needed, such as in collars or cuffs. However, these are less common for general sheer garment construction due to their permanence.

- Tear-Away Stabilizers: These are useful for adding a bit of body to sheer fabrics for techniques like appliqué or for stabilizing seams that might otherwise stretch out. They are carefully torn away from the back of the stitching. A lightweight tear-away is best for sheers.

- Silk Organza or Batiste as Interfacing: For a more structured and less temporary approach, very lightweight silk organza or fine cotton batiste can be used as an internal interfacing. This is sewn into the garment construction rather than being a temporary stabilizer, providing a subtle body and opacity.

When using any stabilizer, it is always recommended to test it on a fabric scrap first to ensure it does not damage the sheer material or leave unwanted marks.

Cutting Techniques for Sheer Fabrics

Cutting sheer fabrics requires a delicate touch and the right techniques to achieve clean, precise edges without causing fraying or distortion. The slippery nature of materials like chiffon, organza, and georgette can make them challenging to handle, but with careful preparation and the correct tools, you can master this step. This section will guide you through the essential methods for accurately cutting your sheer fabrics.Achieving accuracy in cutting is paramount when working with sheer fabrics, as any slight misstep can be highly visible.

The goal is to create smooth, unfrayed edges that will hold up well to subsequent sewing processes. Strategies for managing these often elusive materials during cutting focus on stability and precision.

Precise Cutting Methods

Ensuring accuracy and preventing fraying are key objectives when cutting sheer fabrics. The inherent delicacy of these materials means that traditional cutting methods may not suffice. Implementing specific techniques will help maintain the integrity of the fabric and the precision of your cuts.Precise cutting is achieved through a combination of fabric preparation, appropriate tools, and controlled movements. The aim is to minimize any stress on the fabric that could lead to stretching, tearing, or excessive fraying.

- Rotary Cutter and Cutting Mat: This is often the preferred method for sheer fabrics. A sharp rotary cutter glides through the fabric with minimal pressure, creating a clean, single-pass cut. Always use a self-healing cutting mat underneath to protect your work surface and ensure a smooth cutting action. Place the fabric flat on the mat, ensuring it is free of wrinkles.

- Sharp Fabric Scissors: If using scissors, ensure they are exceptionally sharp and specifically designated for fabric. Dull scissors can snag and pull the delicate fibers. Use long, sweeping cuts rather than short, choppy ones to maintain a smooth edge. Hold the fabric taut but do not stretch it.

- Paper Scissors for Patterns: When cutting out pattern pieces, it’s advisable to use a separate pair of sharp paper scissors. This prevents any residual sharpness from fabric fibers from dulling your fabric scissors, and vice versa.

- Edge Finishing Consideration: While cutting, be mindful of the intended edge finish. For instance, if you plan to use a French seam, you will need to account for the extra width in your seam allowance.

Handling Slippery and Lightweight Sheer Materials

The inherent slipperiness and lightness of sheer fabrics present unique challenges during the cutting process. Strategies for managing these materials focus on providing stability and control to prevent shifting and distortion.Effective handling of these fabrics involves creating a more secure cutting environment and employing gentle but firm techniques. This ensures that the fabric remains in place for accurate pattern placement and cutting.

- Stabilize with Weights: Instead of pins, which can create holes or distort the fabric, use pattern weights. Place them around the edges of your pattern pieces to hold them securely in place on the fabric. Ensure the weights are heavy enough to prevent movement but not so heavy that they cause the fabric to sag.

- Non-Slip Cutting Surface: Consider using a non-slip mat or placing a thin layer of batting or a rubber mat underneath your fabric when cutting. This can provide a slight grip, reducing the tendency for the fabric to slide.

- Controlled Movements: When using a rotary cutter or scissors, move slowly and deliberately. Avoid jerky motions. Allow the tool to do the work, guiding it smoothly along the pattern lines.

- Cutting in Sections: For very large or particularly slippery pieces, you might find it easier to cut in sections. Cut one pattern piece at a time, or even a portion of a pattern piece, to maintain better control.

Marking Patterns on Sheer Fabrics

Marking patterns on sheer fabrics without leaving permanent or visible marks requires specialized tools and techniques. The transparency of these materials means that any marks made will be easily seen on the right side of the fabric, so subtlety is key.The goal is to transfer pattern markings accurately while ensuring they are temporary or so fine that they will not detract from the finished garment.

This often involves using tools that are either erasable or so fine they disappear with the first wash or steam.

- Chalk Pencils and Tailor’s Chalk: Use very fine tailor’s chalk or a chalk pencil. Apply light pressure and draw thin lines. Ensure the chalk color contrasts well with the fabric color for visibility but is also easily brushed away. Test on a scrap piece first to ensure it brushes off completely.

- Water-Soluble Markers: These markers are designed to disappear when exposed to water or steam. Use them sparingly and with light pressure. Always test on a fabric scrap to confirm complete removal.

- Tailor’s Tacks: A traditional method, tailor’s tacks are small, temporary stitches made through the pattern and fabric. They create small loops that can be snipped apart to mark notches and dots without leaving a visible line.

- Tracing Wheel and Paper: For marking darts and dots, a tracing wheel used with a fine-grade tracing paper can be effective. Use light pressure to avoid damaging the fabric. Ensure the tracing paper is suitable for delicate fabrics.

- Pinning Through Pattern Only: For very simple markings like notches, you can sometimes align the pattern piece and fabric, and then make a tiny snip with sharp-pointed scissors into the seam allowance of the fabric, directly at the notch mark on the pattern. This is a less common but effective method for specific marks.

Cutting Multiple Layers of Sheer Fabric

Cutting multiple layers of sheer fabric simultaneously can save time and ensure consistency across identical pattern pieces. However, it also increases the challenge of keeping the layers perfectly aligned and preventing slippage.To successfully cut multiple layers, the key is to ensure each layer is secured and aligned precisely before any cutting begins. This prevents the layers from shifting relative to each other, which would result in uneven pattern pieces.

- Precise Alignment is Crucial: Before cutting, meticulously align all layers of fabric. Smooth out any wrinkles or folds. Ensure selvages and grainlines are perfectly matched across all layers.

- Secure with Pins or Weights: Use a generous number of fine, sharp pins inserted parallel to the cutting line, or preferably, use pattern weights. If pinning, place pins just inside the seam allowance to avoid interfering with the cutting line.

- Rotary Cutter Recommended: A rotary cutter is highly recommended for cutting multiple layers of sheer fabric. It provides a clean, even cut through all layers at once. Ensure your blade is very sharp.

- Controlled Cutting Motion: Use a slow, steady motion with the rotary cutter. Apply consistent pressure to ensure you cut through all layers cleanly. Avoid lifting the fabric or cutter between passes.

- Consider Cutting One Layer at a Time for Extreme Delicacy: If the fabric is exceptionally fine or prone to static, or if you are new to sewing with sheers, cutting one layer at a time might be a safer option to guarantee perfect results.

Needle and Thread Selection

Selecting the appropriate needle and thread is paramount when working with delicate sheer fabrics like chiffon. These materials are prone to snagging, tearing, and showing needle marks, making the right choices critical for a professional and beautiful finish. A careful selection ensures your stitches are nearly invisible and the fabric remains pristine.The interaction between the needle and the thread with the fabric determines the overall integrity and appearance of your seams.

For sheers, this interaction needs to be as gentle as possible to avoid any damage to the fine weave.

Needle Size and Type

The size and type of needle are the first crucial decisions in sewing sheer fabrics. A needle that is too large will create noticeable holes, while a needle that is too small or the wrong type can snag or break the delicate threads of the fabric.

The following are key considerations for needle selection:

- Size: For most sheer fabrics like chiffon, organza, and georgette, a fine needle is essential. Sizes 60/8, 65/9, or 70/10 are generally recommended. A smaller needle size corresponds to a finer diameter.

- Type: Specialized needles are designed to perform optimally on specific fabric types. For sheers, needles with a very sharp point and a slim shaft are ideal.

Performance of Different Needle Types on Chiffon

Different needle types offer varying performance characteristics when sewing chiffon, directly impacting the stitch quality and fabric integrity. Understanding these differences allows for informed decision-making.

Here’s a comparison of common needle types and their suitability for chiffon:

- Microtex Needles: These needles are specifically designed for fine, tightly woven fabrics and synthetic materials. They have an ultra-sharp point and a slim shaft, minimizing drag and the risk of snagging or creating large holes in chiffon. Their performance is exceptional, resulting in clean, precise stitches.

- Universal Needles: While versatile, universal needles can be less ideal for very fine sheers. If a universal needle is used, opt for the smallest size available (e.g., 60/8 or 65/9). However, they are more prone to snagging or leaving visible holes compared to microtex needles on delicate chiffon.

- Sharp/Quilting Needles: Similar to microtex needles, sharp needles also feature a very fine point and are a good alternative if microtex are unavailable.

Thread Material and Weight

The thread you choose must complement the sheerness and delicacy of the fabric. A heavy or stiff thread will be overly conspicuous and can even damage the fabric, while a thread that is too weak may not hold the seam securely.

Recommendations for suitable thread materials and weights include:

- Material: High-quality polyester thread is generally the best choice for sheer fabrics. It offers good strength, durability, and a slight sheen that can blend well with synthetic sheers. Silk thread is also an excellent, albeit more expensive, option for natural fiber sheers like silk chiffon, providing a luxurious match. Avoid cotton threads for most synthetic sheers as they can be too stiff and may not offer adequate strength.

- Weight: A fine or lightweight thread is crucial. Look for threads labeled as “all-purpose” but specifically choose those in the finer end of the spectrum. A standard polyester thread weight of 40-60 wt (weight) is often suitable. For extremely fine or delicate sheers, consider using a finer silk thread or a specialized fine polyester thread.

Thread Tension Settings

Proper thread tension is vital when sewing sheer fabrics. Incorrect tension can lead to puckering, skipped stitches, or fabric distortion, detracting from the garment’s appearance.

The impact of thread tension settings on sheer fabrics is significant:

- Lower Tension: Generally, a slightly lower upper thread tension setting is recommended for sheer fabrics. This helps to prevent the fabric from being pulled too tightly, which can cause puckering or a wavy seam.

- Balancing Tension: It is essential to balance the upper and bobbin thread tension. The goal is for the stitch to look consistent on both the right and wrong sides of the fabric, with no loops or excessive thread showing.

- Testing is Key: Always test your tension settings on a double layer of your sheer fabric before sewing your actual garment. Adjust the tension incrementally until you achieve a smooth, even stitch that lies flat.

- Bobbin Tension: The bobbin tension should typically be slightly looser than the upper thread tension for a balanced stitch on delicate fabrics.

Sewing Machine Setup and Techniques

Successfully sewing with sheer fabrics like chiffon requires a nuanced approach to your sewing machine setup and techniques. The delicate nature of these materials means that standard settings and methods can often lead to frustration, such as skipped stitches, puckering, or fabric being pulled into the needle plate. By understanding and implementing the correct adjustments and specialized techniques, you can achieve beautiful, professional-looking results.This section will guide you through optimizing your sewing machine for sheer fabrics, addressing common challenges and providing step-by-step instructions for essential techniques.

Optimal Sewing Machine Settings for Sheer Fabrics

Achieving a clean and precise stitch on sheer fabrics hinges on selecting the right stitch length and width. Incorrect settings can cause the fabric to stretch, pucker, or create an uneven, “bitten” appearance. Experimentation on a scrap piece of your sheer fabric is always recommended before commencing your project.The following are the recommended settings:

- Stitch Length: For most sheer fabrics, a shorter stitch length is ideal. A stitch length of 1.5 to 2.0 millimeters is generally suitable. This shorter stitch helps to secure the delicate fibers without creating excessive tension or pulling.

- Stitch Width: For straight stitches, the stitch width should be set to zero, as you are only concerned with the forward and backward movement of the needle. For any decorative or zigzag stitches, which are generally avoided on very fine sheers, a narrow width of 0.5 to 1.0 millimeter is best to minimize stress on the fabric.

- Tension: Sheer fabrics often require a slightly looser upper thread tension than you might use for heavier materials. Begin with your machine’s standard tension setting and then test on a scrap. If you notice the fabric pulling up into the bobbin area or the stitches looking too tight on the right side, decrease the upper tension by a small increment.

Preventing Fabric Pull-Through

One of the most common and frustrating issues when sewing sheer fabrics is the tendency for them to be pulled down into the needle plate, resulting in skipped stitches, fabric damage, and a jammed machine. This occurs because the feed dogs, designed for heavier fabrics, can snag and pull the delicate fibers. Fortunately, several effective methods can prevent this.Here are proven techniques to keep your sheer fabric from being pulled into the needle plate:

- Using a Straight Stitch Needle Plate: Many sewing machines come with or offer an optional straight stitch needle plate. This plate has a smaller, round needle hole, which significantly reduces the chance of the fabric being pulled down. It’s an excellent investment for anyone frequently working with delicate or sheer materials.

- Using a Universal Needle Plate with Tape: If a straight stitch needle plate is not available, you can create a temporary barrier. Use a piece of painter’s tape or a small piece of tissue paper over the needle plate opening. Carefully pierce the tape with your needle to create a small hole. This provides a smoother surface and prevents the feed dogs from catching the fabric.

- Reducing Feed Dog Height: Some sewing machines allow you to lower the feed dogs. Consult your machine’s manual to see if this is an option. Lowering the feed dogs reduces their aggressive grip on the fabric, making it less likely to be pulled down.

- Using Tissue Paper or Stabilizer: Placing a layer of tissue paper or a water-soluble stabilizer directly beneath the sheer fabric can provide support and prevent it from being pulled into the feed dogs. After sewing, the tissue paper can be carefully torn away or dissolved.

Sewing Straight and Curved Seams on Delicate Sheer Materials

Sewing straight and curved seams on sheer fabrics requires a gentle touch and precise control to avoid distortion and ensure smooth, even lines. The key is to guide the fabric rather than push or pull it, allowing the machine to do the work.To achieve clean seams:

- Straight Seams: For straight seams, maintain a consistent, slow speed. Guide the fabric gently from behind the presser foot, allowing the feed dogs to move it forward. Avoid stretching the fabric with your hands, as this will lead to wavy seams. Ensure the fabric edges are aligned perfectly before starting.

- Curved Seams: Sewing curves on sheer fabrics demands even more control. Sew slowly and use the presser foot as a pivot point. For tighter curves, you may need to lift the presser foot slightly and reposition the fabric incrementally. Again, guide the fabric with a light touch; do not force it. For very intricate curves, consider basting the seam first.

Using a Walking Foot or Roller Foot with Sheer Fabrics

A walking foot or a roller foot can be invaluable tools when sewing sheer fabrics. These specialized presser feet are designed to provide even feeding of the fabric from both the top and bottom, which is crucial for preventing puckering and ensuring that delicate materials don’t shift or stretch.Here is a step-by-step procedure for using a walking foot or roller foot:

Using a Walking Foot

A walking foot has a set of feed dogs that work in conjunction with your machine’s feed dogs, ensuring that both layers of fabric move through the machine at the same rate. This is particularly beneficial for preventing the top layer of sheer fabric from lagging behind or stretching.Follow these steps:

- Remove the Standard Presser Foot: Disengage and remove your machine’s standard presser foot and its shank.

- Attach the Walking Foot: Attach the walking foot according to your sewing machine’s manual. Typically, this involves attaching the arm of the walking foot to the needle bar.

- Thread the Machine: Ensure your machine is threaded correctly with the appropriate needle and thread for your sheer fabric.

- Set Machine Settings: Use the recommended stitch length (1.5-2.0 mm) and a straight stitch.

- Position the Fabric: Place your sheer fabric layers under the walking foot, ensuring they are aligned as desired.

- Begin Sewing: Lower the walking foot and begin sewing at a slow, consistent speed. Guide the fabric gently with your hands, but allow the walking foot to do most of the feeding.

- Sewing Curves: For curves, sew slowly and use the walking foot’s feeding action to guide the fabric. You may need to lift the foot slightly to adjust the fabric’s position on very tight curves.

Using a Roller Foot

A roller foot is another excellent option for sheer fabrics. It features small rollers on its sole that help the fabric glide smoothly through the machine, reducing friction and preventing the fabric from sticking or dragging. This is especially helpful for slippery sheers like chiffon or georgette.Follow these steps:

- Remove the Standard Presser Foot: Disengage and remove your machine’s standard presser foot and its shank.

- Attach the Roller Foot: Attach the roller foot to your sewing machine, following your machine’s manual.

- Thread the Machine: Ensure your machine is threaded correctly with the appropriate needle and thread for your sheer fabric.

- Set Machine Settings: Use the recommended stitch length (1.5-2.0 mm) and a straight stitch.

- Position the Fabric: Place your sheer fabric layers under the roller foot, ensuring they are aligned as desired.

- Begin Sewing: Lower the roller foot and begin sewing at a slow, consistent speed. The rollers will help to propel the fabric evenly.

- Sewing Curves: For curves, sew slowly and allow the rollers to guide the fabric. The smooth action of the rollers makes maneuvering around curves much easier.

Both the walking foot and the roller foot significantly improve control and reduce the likelihood of fabric distortion, leading to more professional and satisfying results when working with delicate sheer materials.

Seam Finishes for Sheer Fabrics

Selecting the appropriate seam finish is crucial when working with delicate sheer fabrics like chiffon and organza. These fabrics are prone to fraying, and an improperly finished seam can detract significantly from the garment’s overall appearance and durability. The goal is to create a clean, neat, and almost invisible finish that complements the lightness of the fabric.Several seam finishing techniques are well-suited for sheer materials, each offering a slightly different aesthetic and level of protection against fraying.

The choice often depends on the specific fabric weight, the desired look, and the construction method of the garment.

Seam Finish Suitability for Chiffon and Organza

Understanding which seam finishes work best on chiffon and organza ensures a professional and elegant result. Each technique offers distinct advantages for these lightweight and often slippery materials.

- French Seams: These are an excellent choice for sheer fabrics as they enclose the raw edges completely within the seam, creating a very neat and durable finish. They are particularly effective on chiffon, where a visible seam allowance could be distracting.

- Rolled Hems: While typically used for edges, a very narrow rolled hem can be adapted for seams on extremely lightweight fabrics like the sheerest chiffons. This technique involves folding the fabric edge twice to create a tiny, enclosed hem, which can be applied to the seam allowance itself for a delicate finish.

- Serged Edges: A serger (overlocker) can be used to finish the raw edges of sheer fabrics, but it requires careful tension adjustment and a fine stitch. A narrow rolled hem stitch on a serger is often the most suitable option for chiffon and organza, providing a clean, albeit sometimes slightly more visible, finish than a French seam.

Creating a Narrow Rolled Hem on Sheer Fabric

A narrow rolled hem is a beautiful and delicate finish that works wonderfully on the edges of sheer garments. It creates a tiny, double-folded hem that appears almost invisible and prevents fraying without adding bulk.

- Press the raw edge of the fabric under by approximately 1/8 inch (3mm).

- Press this folded edge again by another 1/8 inch (3mm), enclosing the raw edge completely.

- Stitch very close to the inner folded edge. For an even more refined finish, you can use a twin needle, which creates two parallel lines of stitching on top and a zigzag on the wrong side, giving a professional look.

- Alternatively, a specialty rolled hem foot for your sewing machine can be used. This foot guides the fabric into a tiny double fold as you sew, creating a perfect rolled hem with practice.

Achieving a Clean and Invisible Seam Finish on Lightweight Materials

Creating an invisible seam finish on lightweight materials like chiffon and organza requires precision and attention to detail. The goal is to have the seam disappear into the fabric, enhancing the garment’s ethereal quality.

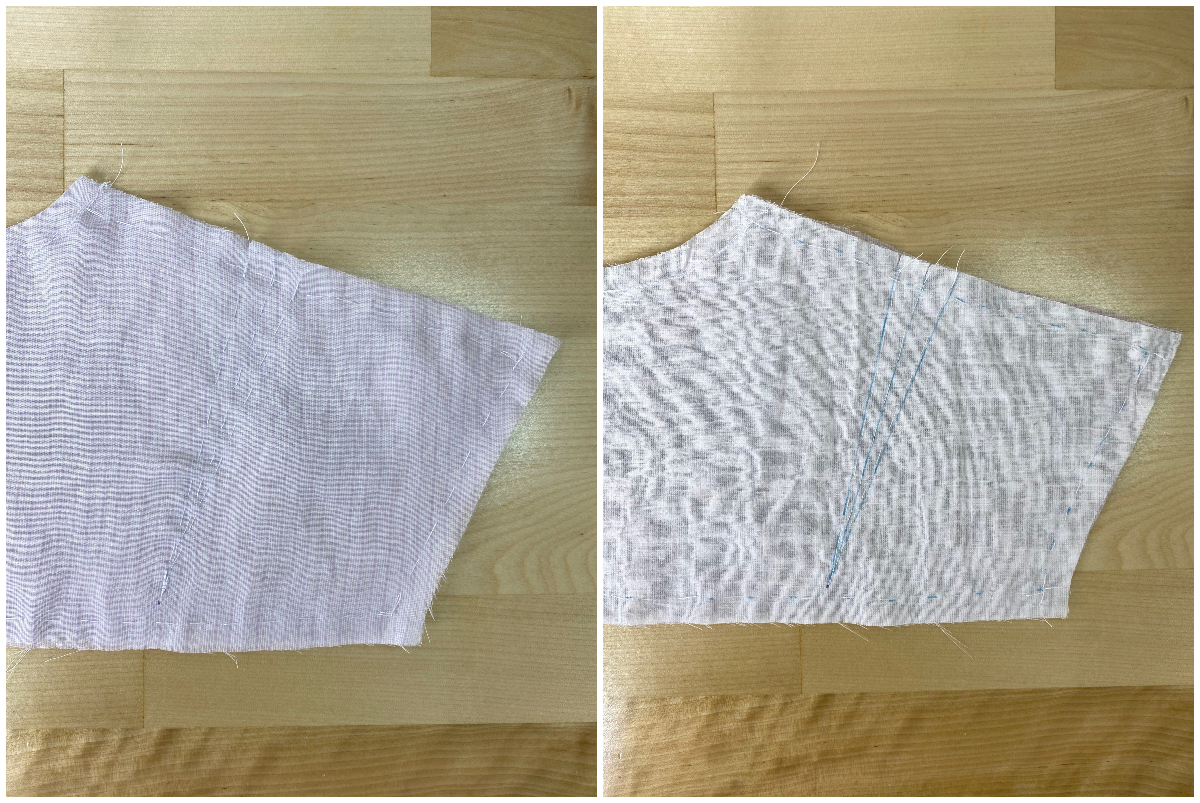

French Seam Construction Steps

French seams are the gold standard for achieving a clean and invisible finish on sheer fabrics. They involve two rows of stitching, with the raw edges neatly enclosed within the seam.

- With the wrong sides of the fabric together, stitch a seam 1/4 inch (6mm) from the raw edge.

- Trim the seam allowance to 1/8 inch (3mm).

- Turn the fabric so the right sides are together, and press the seam flat.

- Fold the fabric again, encasing the raw edges within the fold. Ensure the first seam you stitched is now neatly tucked inside.

- Press this folded edge firmly.

- Stitch again, 1/4 inch (6mm) from the folded edge, enclosing the previous seam allowance. This second stitching line should be on the right side of the garment.

- Press the finished seam to one side. The result is a seam with no raw edges visible on either side of the fabric.

Rolled Hem Stitch on a Serger

For a quick and elegant finish, a rolled hem stitch on a serger is an excellent option, particularly for the edges of scarves or the bottom hems of sheer garments.

- Consult your serger’s manual to set it up for a narrow rolled hem. This typically involves adjusting the differential feed and the stitch width.

- Thread your serger with fine serger thread, often in a matching or coordinating color.

- Practice on a scrap of your sheer fabric to ensure the tension and settings are correct before sewing on your garment.

- Guide the fabric edge into the serger, allowing the rolled hem blade to create the delicate, enclosed edge.

Working with Delicate Edges and Hems

Finishing the edges and hems of sheer fabrics requires a delicate touch and specific techniques to ensure a professional and elegant look without adding bulk or distorting the fabric. These methods are crucial for maintaining the ethereal quality of materials like chiffon, organza, and georgette.Sheer fabrics are prone to fraying and can be easily damaged by aggressive handling. Therefore, choosing the right hemming technique is paramount to creating a smooth, stable, and visually appealing finish that complements the garment’s design.

The following sections detail effective methods for achieving beautiful hems on these delicate materials.

Rolled Hems

Rolled hems are an excellent choice for sheer fabrics as they create a very narrow, almost invisible finish that lies flat and does not add significant weight. This technique is particularly effective for curved edges and delicate fabrics where a traditional double-fold hem would be too bulky.There are two primary ways to achieve a rolled hem:

- Machine Rolled Hem: The sewing machine’s rolled hem foot is designed to fold the fabric edge twice and stitch it in one operation. This foot guides the fabric into a tiny fold, allowing the needle to stitch over it neatly. It’s essential to practice on scrap fabric first to get the tension and speed right.

- Hand-Rolled Hem: For ultimate precision and control, a hand-rolled hem is a beautiful option. This involves folding the raw edge over a scant 1/8 inch, pressing it, then folding it over again to enclose the raw edge. The hem is then secured with small, even whipstitches or blind stitches, catching just a few threads of the main fabric.

Narrow Double-Fold Hems

While a standard double-fold hem can be too heavy for some sheers, a narrow version can be successfully implemented on sturdier sheers like organza or certain types of voile. This method involves folding the raw edge over a small amount, pressing, then folding it over again to enclose the raw edge completely.The key to a successful narrow double-fold hem on sheer fabrics is to keep the folds very small, typically no more than 1/4 inch in total width.

For curved edges, a narrow double-fold hem requires careful easing and clipping. When working with curves, it is beneficial to:

- Clip the seam allowance at regular intervals, especially on tighter curves, to allow the fabric to lie flat.

- Gently ease the fabric as you fold and press, rather than forcing it.

- Consider using a very fine needle and thread, and stitch with a slightly shorter stitch length to ensure the hem is secure without puckering.

Applying Bias Tape to Edges

Applying bias tape is a versatile method for finishing edges, especially those that are difficult to hem conventionally, such as armholes, necklines, and curved seams. It provides a clean, defined edge and can also serve as a decorative element.The process of applying bias tape to sheer fabrics involves:

- Preparation: Cut or purchase double-fold bias tape. For sheer fabrics, it’s often preferable to use single-fold bias tape and fold it over the edge yourself to control the width and avoid excess bulk. Alternatively, you can make your own bias tape from a lightweight coordinating fabric.

- Attachment: Open one fold of the bias tape and align the raw edge of the tape with the raw edge of the sheer fabric, right sides together. Stitch along the first fold of the bias tape, catching both layers.

- Folding and Securing: Fold the bias tape to the other side of the fabric, enclosing the raw edge of the sheer material. Press the tape neatly. You can then stitch the tape down from the right side of the fabric, either in the ditch (along the seam line) or by topstitching close to the folded edge. For a less visible finish, hand-stitch the tape in place using a blind stitch.

Managing Delicate Neckline and Armhole Finishes

Necklines and armholes on sheer garments are particularly prone to showing any imperfections due to their prominent placement. Achieving a clean and durable finish is essential for the overall aesthetic of the garment.Effective techniques for these areas include:

- Facing: A facing cut from the same sheer fabric or a lightweight coordinating fabric provides a clean finish. The facing is sewn to the neckline or armhole edge, then turned to the inside and secured. For sheer fabrics, a narrow seam allowance is recommended, and understitching the facing to the seam allowance is crucial to help it roll to the inside and remain unseen.

- Binding: Similar to applying bias tape, binding with a lightweight fabric or a fine grosgrain ribbon can create a neat edge. This is especially useful for V-necklines or armholes that require a bit more structure. Ensure the binding is narrow enough not to overwhelm the delicate fabric.

- Self-Binding: This technique uses a small strip of the main fabric itself to create a binding. The strip is attached to the right side of the fabric, then turned to the wrong side and secured. This creates a very seamless look.

- Hand Finishing: For very intricate or delicate necklines, hand-finishing with a fine rolled hem or a meticulously applied blind stitch can provide the most elegant result. This allows for precise control over the fabric and ensures no bulk is added.

Handling Difficult Areas and Embellishments

Working with sheer fabrics presents unique challenges, especially when tackling areas that require structure or decorative elements. These sections demand careful attention to detail to maintain the fabric’s delicate nature while achieving a polished and professional finish. This section will guide you through managing these intricate aspects of sewing with sheers.Sheer fabrics, by their very nature, can become bulky or distorted when complex techniques are applied.

Therefore, specific methods are crucial for handling darts, pleats, and structural additions without compromising the garment’s ethereal quality. Similarly, the application of embellishments and the construction of areas like collars and cuffs require a delicate touch and the right techniques to ensure they lie smoothly and securely.

Managing Darts and Pleats on Sheer Fabrics

Darts and pleats are essential for shaping garments, but on sheer fabrics, they can easily add unwanted bulk or become visible from the outside. The key is to minimize the layers of fabric involved and to create sharp, defined lines without a heavy hand.To achieve this, consider the following techniques:

- Reduced Dart Width: Instead of full-width darts, create narrower darts, taking slightly less fabric. This reduces the layers that accumulate at the point.

- Pressing with Care: After stitching, press darts and pleats very gently. Use a pressing cloth to protect the fabric from direct heat. Press the dart or pleat towards the center of the garment or to the side seam, as appropriate, to help it lie flat.

- Basting and Clipping: For pleats, carefully baste them in place before stitching. Clip the pleat allowances at intervals if they become too bulky, being careful not to cut through the stitching line.

- Edge Finishing: For very fine pleats, consider finishing the raw edge of the pleat allowance with a serger or a very narrow rolled hem before stitching the pleat itself.

Attaching Lightweight Interfacings and Linings

Adding structure or opacity to sheer fabrics requires lightweight materials and careful application methods to avoid a stiff or opaque appearance. The goal is to provide support without detracting from the sheer quality of the main fabric.Methods for attaching these materials include:

- Fusible Interfacing: Opt for the lightest weight fusible interfacing available, specifically designed for delicate fabrics. Test it on a scrap piece first to ensure it doesn’t discolor or damage the sheer fabric. Apply with a low heat setting and a pressing cloth, pressing rather than ironing to avoid shifting.

- Sewn-in Interfacing: For a more delicate approach, consider sewing-in interfacing. Cut the interfacing slightly smaller than the pattern piece and baste it to the wrong side of the sheer fabric. Then, stitch through both layers as you would normally.

- Full or Partial Linings: If a lining is desired for opacity or comfort, choose a lightweight lining fabric like silk chiffon, organza, or a fine rayon. For partial linings, consider using it only in specific areas like the bodice or skirt.

- Attachment Methods for Linings: Linings can be attached at the neckline and armholes and then left to hang freely within the garment, or they can be carefully tacked at strategic points (e.g., side seams, hem) to prevent them from shifting. French seams or bound seams are excellent finishing techniques for lining edges.

Applying Embellishments Safely

Adding beads, sequins, or other embellishments to sheer fabrics can create stunning visual effects, but it requires precision to ensure they are securely attached and don’t distort or tear the fabric.Strategies for applying embellishments include:

- Pre-planning Placement: Before sewing, plan the exact placement of your embellishments. Use tailor’s chalk or a temporary marking pen to Artikel your design.

- Beading Needles and Fine Thread: Use very fine beading needles and strong, fine thread that matches the embellishment or the fabric. This minimizes the needle hole size and prevents the thread from being too visible.

- Individual Stitching: For beads and sequins, it is often best to stitch them on individually. For sequins, a single stitch through the center hole is usually sufficient. For beads, a small knot at the back after each bead or a few stitches securing a small cluster can work.

- Reinforcement: For heavier embellishments or areas that will experience stress, consider reinforcing the area on the back with a small piece of lightweight interfacing or a few extra stitches to distribute the tension.

- Avoid Overlapping: Be mindful of how embellishments overlap, as this can create bulk. Plan your design to minimize excessive layering.

Working with Sheer Fabrics in Collars, Cuffs, and Waistbands

These structural areas often require a bit more stability than the main body of a sheer garment. The techniques used must provide definition without adding stiffness or bulk that would detract from the garment’s overall drape and lightness.Effective strategies for these areas include:

- Interfacing Choice: Select a very lightweight, fusible or sew-in interfacing specifically designed for sheer fabrics. A lightweight silk organza can also be used as a stabilizing layer.

- Layering Techniques: For collars and cuffs, you might sandwich a layer of interfacing between two layers of the sheer fabric. Stitch close to the edge, then trim the interfacing seam allowance to reduce bulk.

- French Seams and Bound Edges: Finish the raw edges of collars, cuffs, and waistbands with French seams or narrow, clean-finished binding. This encloses the raw edges neatly and prevents fraying.

- Waistbands: For sheer skirts or dresses, a waistband can be constructed using a facing method, where a separate piece of sheer fabric or a lightweight lining fabric is used to create a clean finish on the inside. Alternatively, a narrow grosgrain ribbon can be used as a stabilizing band on the inside of the waistband.

- Topstitching: If topstitching is desired for decorative effect or to secure layers, use a fine needle and a matching thread. Stitch carefully and evenly to avoid puckering.

Pressing and Finishing

The final pressing and finishing stages are crucial for transforming your sheer fabric creations into polished, professional garments. This is where attention to detail truly shines, ensuring your delicate work looks as exquisite as it feels. Proper pressing techniques prevent damage and enhance the beauty of the fabric, while a thorough final inspection guarantees a flawless result.

Correct Pressing Techniques for Sheer Fabrics

Sheer fabrics are exceptionally delicate and require a gentle approach to pressing to avoid any damage. The primary goals are to set seams and remove wrinkles without causing scorching, stretching, or creating unwanted shine. Always test your iron’s heat setting on a small, inconspicuous scrap of the same fabric before pressing your project.

Using Pressing Cloths and Steam

A pressing cloth is an indispensable tool when working with sheer fabrics. It acts as a protective barrier between the hot iron and the delicate material, distributing heat evenly and preventing direct contact that can lead to scorching or a shiny press mark. For most sheer fabrics, a clean, fine-weave cotton pressing cloth is ideal. Steam can be a valuable ally, helping to relax fibers and remove wrinkles, but it must be used judiciously.

Some very fine silks or synthetic sheers may be sensitive to excessive moisture. When using steam, ensure your iron’s steam setting is appropriate for the fabric and that you are not over-saturating the material.

“Always err on the side of caution with heat and moisture when pressing sheer fabrics.”

Achieving Crisp and Professional Finishes

To achieve crisp and professional finishes on sheer sewn items, focus on pressing each seam and detail as you go. After sewing a seam, press it open or to one side while it’s still flat on the ironing board. This sets the stitches and creates clean lines. For hems, a double-fold hem can provide a beautiful finish. Press each fold meticulously before stitching.

For rolled hems, a specialized foot on your sewing machine can assist, and then a light press will set the delicate roll. Pay close attention to darts, pleats, and any gathered sections, pressing them carefully to maintain their intended shape and structure.

Final Inspection and Pressing Checklist

Before considering your sheer fabric project complete, a final inspection and pressing are essential. This checklist will guide you through the process, ensuring no detail is overlooked.

- Inspect the entire garment under good lighting for any stray threads, skipped stitches, or uneven seams.

- Gently brush away any lint or dust.

- Perform a final, light press of the entire garment, using a pressing cloth and appropriate heat settings.

- Check all hems, seams, and edges to ensure they are smooth and lie flat.

- Verify that any embellishments or decorative elements are secure and have not been damaged during the pressing process.

- Ensure the garment hangs correctly, checking for any distortions or pulling.

Conclusive Thoughts

Mastering the art of sewing with sheer fabrics opens up a world of exquisite design possibilities. By understanding the unique characteristics of materials like chiffon and applying the techniques discussed—from careful cutting and precise needle selection to elegant seam finishes and meticulous pressing—you can confidently create garments that are both beautiful and professionally executed. Embrace the challenge, and let your creativity flow through these delicate textiles to produce truly breathtaking results.