As How to Troubleshoot Skipped Stitches takes center stage, this opening passage beckons readers into a world crafted with good knowledge, ensuring a reading experience that is both absorbing and distinctly original.

Skipped stitches can be a frustrating obstacle for any sewer, leading to uneven seams and incomplete projects. This comprehensive guide delves into the common culprits behind this sewing woe, from needle and thread issues to fabric compatibility and machine maintenance. By understanding the fundamental principles and employing systematic troubleshooting techniques, you can conquer skipped stitches and achieve beautiful, consistent results with confidence.

Understanding Skipped Stitches: The Basics

Skipped stitches are a common and often frustrating sewing issue that can disrupt the smooth flow of your projects. These occurrences manifest as gaps in your seam, where the needle has seemingly failed to connect with the bobbin thread, leaving a loop or a loose thread instead of a secure stitch. Understanding the fundamental reasons behind skipped stitches is the first crucial step in effectively troubleshooting and resolving them.At its core, a skipped stitch is a failure of the needle thread to interlock properly with the bobbin thread.

This interruption in the stitch formation process can be attributed to a variety of factors, ranging from incorrect needle insertion to issues with the tension or the thread itself. Recognizing the visual cues and common scenarios associated with skipped stitches will help you pinpoint the source of the problem more efficiently.

Fundamental Reasons for Skipped Stitches

Skipped stitches arise when the needle thread does not reach the hook or bobbin case at the precise moment required to form a stitch. This timing issue is often a result of a misalignment or an obstruction in the thread path or the stitch formation mechanism. Several key areas can contribute to this problem.The primary reasons for skipped stitches can be categorized as follows:

- Incorrect Needle Insertion: If the needle is not fully inserted into the needle clamp or is inserted backward, it will not align correctly with the hook, leading to skipped stitches. The flat side of the needle, if applicable to your machine, should always face the correct direction as per your sewing machine manual.

- Bent or Damaged Needle: A bent or burred needle can snag the thread or fail to enter the fabric correctly, causing it to miss the bobbin thread. Even a microscopic imperfection can disrupt the stitch formation.

- Wrong Needle Type or Size: Using a needle that is too large or too small for the fabric, or the wrong type of needle (e.g., a ballpoint needle on woven fabric), can lead to improper penetration and skipped stitches. The needle must be compatible with both the fabric and the thread.

- Improper Threading: If the machine is not threaded correctly, especially if the presser foot is down during threading, the thread can bypass the tension discs or get caught in an incorrect path, resulting in skipped stitches.

- Tension Issues: Incorrect upper or lower tension settings can cause the threads to not interlock properly. If the upper tension is too tight, it can pull the needle thread too high, and if too loose, it can prevent proper engagement. Similarly, bobbin tension that is too tight or too loose will affect stitch formation.

- Lint Buildup: Accumulations of lint and debris in the bobbin area, the tension discs, or the feed dogs can obstruct the smooth movement of the thread and the hook, causing skipped stitches.

- Worn or Damaged Hook/Bobbin Case: If the sewing machine’s hook or bobbin case is bent, damaged, or worn, it may not catch the needle thread correctly.

- Fabric Issues: Certain fabrics, particularly very thick, stretchy, or loosely woven materials, can be more prone to skipped stitches if the wrong needle or thread is used.

Common Visual Indicators of Skipped Stitches

Recognizing the signs of a skipped stitch is essential for immediate identification and correction. These visual cues often appear as anomalies within the stitched line.The most common visual indicators include:

- Gaps in the Seam: The most direct indicator is a visible gap where a stitch should be. This looks like a loose loop of thread on the top or bottom of the fabric, or simply an absence of thread where the seam should be.

- Uneven Stitching: Instead of a consistent line of stitches, you might observe an irregular pattern with some stitches present and others missing.

- Looped Threads: You may notice loops of thread on the top or bottom of the fabric, indicating that the needle thread did not properly interlock with the bobbin thread.

- Thread Snapping (Intermittent): While not always present, skipped stitches can sometimes precede or accompany intermittent thread breakage as the thread gets snagged or pulled incorrectly.

Typical Scenarios Where Skipped Stitches Occur

Skipped stitches are not random events; they often happen under specific circumstances that provide clues to their origin. Being aware of these typical scenarios can help you anticipate and prevent the problem.These scenarios often include:

- Starting a New Project: When beginning a new sewing project, especially with a new type of fabric or thread, skipped stitches can occur as the machine and materials adjust.

- Changing Thread or Fabric: Switching from one type of thread to another, or from one fabric weight to another, can necessitate adjustments to needle and tension, and a failure to do so can lead to skipped stitches.

- Sewing Over Thick Seams or Multiple Layers: When the needle encounters a thick area, such as a cross-seam or multiple fabric layers, it can struggle to penetrate cleanly, potentially causing it to miss the bobbin thread.

- Sewing Very Fine or Delicate Fabrics: Extremely thin or delicate fabrics can be easily pushed down into the needle plate by the needle, preventing the hook from catching the thread.

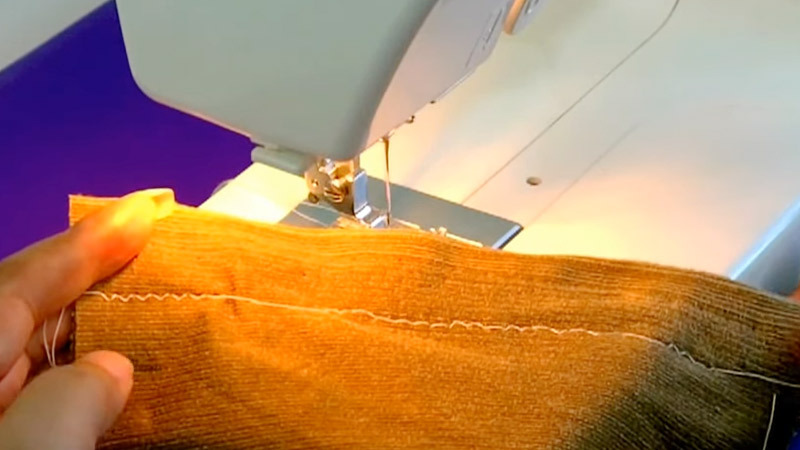

- Sewing Very Stretchy Fabrics: Stretchy knits can distort as they are sewn, which can affect the alignment of the needle and the hook, leading to skipped stitches.

- After Machine Maintenance or Cleaning: If your sewing machine has recently been cleaned or had its bobbin case or needle replaced, a slight misalignment or improper reassembly can cause skipped stitches.

Essential Tools and Preparations

Before diving into the specifics of troubleshooting skipped stitches, it’s crucial to equip yourself with the right tools and perform some essential preparatory steps. Having these items readily available and completing these initial maintenance tasks will make the diagnostic process smoother and more effective.This section Artikels the necessary equipment and the foundational cleaning and maintenance that should be undertaken before attempting to resolve skipped stitches.

A well-prepared sewing machine is the first step towards achieving consistent, beautiful stitches.

Necessary Tools for Diagnosis and Repair

To effectively diagnose and repair skipped stitches, a specific set of tools will be beneficial. These tools aid in accessing, cleaning, and making minor adjustments to your sewing machine.Here is a list of essential tools that will assist you in your troubleshooting efforts:

- Screwdriver Set: A set of small Phillips and flathead screwdrivers is indispensable for disassembling and reassembling machine parts, such as needle plates and presser foot holders.

- Small Brush or Compressed Air: For cleaning lint and debris from intricate areas of the machine, particularly around the needle and bobbin areas.

- Tweezers: Useful for carefully removing tangled threads or small pieces of fabric that may be lodged within the machine.

- Needle Threader: While not directly for troubleshooting, a reliable needle threader can save time and frustration, especially when replacing needles.

- Good Lighting: A bright, focused light source, such as a task lamp, is vital for clearly seeing small components and identifying issues.

- Magnifying Glass: For examining tiny parts, needle eyes, and thread paths for any imperfections or obstructions.

- Lint-Free Cloths: For wiping down machine surfaces and components without leaving behind fibers that could cause future problems.

- Sewing Machine Oil: Essential for lubrication, which is a key aspect of preventative maintenance and can resolve issues caused by friction.

Initial Cleaning and Maintenance Steps

Performing thorough cleaning and basic maintenance before troubleshooting can often resolve skipped stitches by removing common culprits like lint and old oil. These steps ensure that the machine is operating with clean, well-lubricated parts.The following cleaning and maintenance procedures are recommended as a first course of action:

- Clean the Bobbin Area: Remove the bobbin case and bobbin. Use a small brush or compressed air to meticulously remove any lint, dust, or thread fragments accumulated in the bobbin race and around the bobbin driver.

- Clean the Feed Dogs: Raise the feed dogs and use a brush to clean any debris that may be trapped between them. This ensures proper fabric feeding.

- Clean Around the Needle Plate: Remove the needle plate (if your machine allows) and clean thoroughly. Pay attention to the area where the needle passes through.

- Check and Clean the Thread Path: Ensure that the thread guides, tension discs, and take-up lever are free from lint and obstructions.

- Lubricate Moving Parts: Refer to your sewing machine’s manual for specific lubrication points. Apply a small amount of sewing machine oil to designated areas to ensure smooth operation. Avoid over-oiling, as excess oil can attract dirt.

- Wipe Down the Exterior: Clean the exterior of the machine with a lint-free cloth to remove dust and grime.

Pre-Troubleshooting Action Checklist

A systematic approach to pre-troubleshooting can save valuable time and prevent unnecessary adjustments. This checklist ensures that you have covered the most common and easily rectifiable causes of skipped stitches before delving into more complex diagnostics.Before you begin investigating the specific causes of skipped stitches, please review and complete the following actions:

- Ensure the correct type and size of needle is installed for your fabric and thread.

- Verify that the needle is inserted correctly and is not bent or damaged.

- Confirm that the thread is properly threaded through all guides, tension discs, and the needle eye.

- Check that the bobbin is wound evenly and is inserted correctly into the bobbin case.

- Ensure the presser foot is lowered when sewing.

- Inspect the presser foot and needle plate for any damage or debris.

- Confirm that the upper and lower threads are of compatible types and weights.

Needle-Related Issues and Solutions

/skippedstitches-56d9bb4d3df78c5ba02605f0.jpg)

The sewing machine needle is a critical component in creating stitches, and any issue with it can directly lead to skipped stitches. Understanding common needle problems and how to address them is paramount for consistent sewing results. This section will guide you through identifying these issues, proper needle insertion, and selecting the right needle for your fabric.A properly functioning needle is sharp, straight, and correctly inserted.

When these conditions aren’t met, the needle may not penetrate the fabric properly, or it might miss the bobbin thread loop, resulting in skipped stitches. Ensuring your needle is in optimal condition and correctly installed is a foundational step in troubleshooting.

Common Needle Problems Causing Skipped Stitches

Several issues with the sewing machine needle can cause skipped stitches. These range from the needle’s physical condition to its compatibility with the fabric and thread.

- Bent or Damaged Needle: A needle that is bent, even slightly, can deviate from its intended path, causing it to miss the bobbin thread. Damage can also occur from hitting a pin or a hard seam.

- Blunt Needle: Over time, needles become dull from use. A blunt needle struggles to pierce the fabric cleanly, which can lead to thread snagging and skipped stitches.

- Incorrect Needle Type: Using the wrong type of needle for the fabric (e.g., a ballpoint needle on woven fabric or a sharp needle on knits) can cause fabric damage or an inability to create a proper stitch.

- Incorrect Needle Size: A needle that is too large or too small for the thread and fabric can lead to issues. A needle that is too large can create excessive holes, and one that is too small might not be able to carry the thread through the fabric properly.

- Improper Needle Insertion: If the needle is not fully inserted or is inserted incorrectly, it will not align properly with the hook mechanism, leading to skipped stitches.

Correct Needle Insertion Technique

Properly inserting a sewing machine needle ensures it aligns correctly with the machine’s internal mechanisms, facilitating stitch formation. An incorrectly inserted needle is a frequent culprit for skipped stitches.

To insert a sewing machine needle:

- Ensure your sewing machine is turned off and unplugged for safety.

- Loosen the needle clamp screw (usually located on the side of the needle bar) with a screwdriver or by hand if it’s a thumb screw.

- Remove the old needle by pulling it straight down.

- Take a new, correct needle. The flat side of the needle shank should face towards the back of the machine (this is standard for most machines, but always check your manual if unsure).

- Insert the new needle into the needle clamp as far up as it will go.

- Tighten the needle clamp screw securely to hold the needle in place.

- Re-thread your sewing machine and test a few stitches on a scrap piece of fabric.

Importance of Correct Needle Type and Size

Using the appropriate needle type and size is fundamental to successful sewing, especially when troubleshooting skipped stitches. Different fabrics have unique structures and require specific needle points and thicknesses to be pierced cleanly without damage.

Here’s a guide to selecting the right needle:

- Universal Needles: These are good all-around needles for various fabrics but may not be ideal for very fine or very stretchy materials.

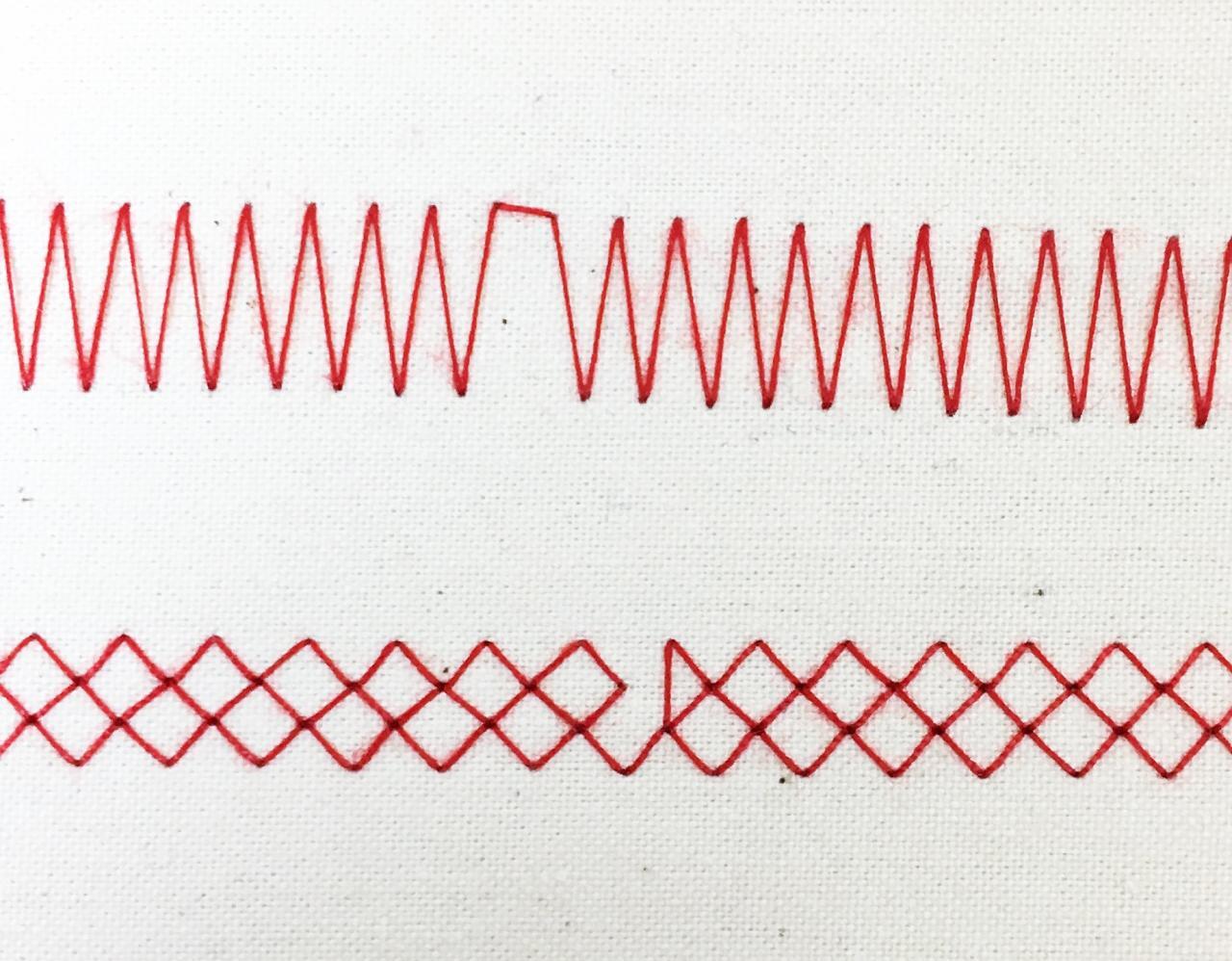

- Ballpoint/Jersey Needles: These have a rounded tip that pushes between fabric fibers rather than piercing them, preventing runs and skipped stitches on knits and stretch fabrics.

- Sharp/Microtex Needles: These have a very fine, sharp point for piercing densely woven fabrics like silk, cotton, and microfiber, ensuring clean stitch holes.

- Leather Needles: These have a cutting point to make a clean slit in leather and vinyl, preventing the material from tearing.

- Denim/Jeans Needles: These are strong and sharp, designed to penetrate multiple layers of thick, sturdy fabrics like denim.

Regarding needle size (often indicated by a number like 70/10, 80/12, 90/14, 100/16):

- Smaller numbers indicate finer needles, suitable for lightweight fabrics and fine threads.

- Larger numbers indicate thicker needles, necessary for medium to heavyweight fabrics and stronger threads.

Using a needle that is too fine for the fabric can cause it to bend or break, while a needle that is too coarse can damage delicate fabrics or create unsightly large holes.

Checking Needle Sharpness and Alignment

Regularly checking your sewing machine needle for sharpness and alignment is a proactive approach to preventing skipped stitches. A compromised needle will inevitably lead to sewing problems.

To check for sharpness:

- Visual Inspection: Hold the needle up to a light source. Look for any signs of dullness, nicks, or burrs along the shaft or tip. A sharp needle will have a fine, intact point.

- Fabric Test: Sew a few stitches on a scrap of fine fabric, such as silk or a lightweight cotton. If the fabric puckers, snags, or if you hear a tearing sound, the needle is likely dull.

To check for alignment (straightness):

- Visual Inspection: With the needle inserted, look at it from the front and side. It should appear perfectly straight and perpendicular to the needle plate.

- Wiggle Test: Gently try to wiggle the needle side-to-side. There should be virtually no play. Any significant wobble indicates a bent needle.

- Machine Check: If you suspect a bent needle, remove it and roll it on a flat surface. If it doesn’t roll smoothly, it’s bent.

“A sharp, straight needle is the foundation of a perfect stitch.”

Thread and Tension Adjustments

Proper thread and tension management are fundamental to achieving consistent and beautiful stitches. Skipped stitches can often be traced back to issues with the thread itself or incorrect tension settings on your sewing machine. Addressing these elements systematically will significantly improve your sewing results and reduce frustration.Thread quality and condition play a surprisingly significant role in stitch formation. Using a thread that is too old, brittle, or has been stored improperly can lead to breakage or fraying, which directly contributes to skipped stitches.

Similarly, the type of thread should be appropriate for your fabric and project. For instance, using a heavy-duty thread on a delicate silk fabric can cause the needle to create a larger hole than the thread can properly fill, leading to gaps. Always opt for high-quality sewing thread from reputable brands, and inspect it for any signs of damage before use.

Thread Quality and Condition

The integrity of your sewing thread is a critical factor in preventing skipped stitches. Old, degraded, or poor-quality threads are prone to weakening, fraying, or even breaking during the sewing process. This can result in incomplete stitches, as the thread may not be able to consistently pass through the fabric and form a loop. Ensure your thread is fresh, smooth, and free from knots or inconsistencies.

Storing threads in a cool, dry place away from direct sunlight will help maintain their quality over time.

Correct Threading Procedures

Accurate threading of both the upper and lower threads is paramount for the sewing machine to function correctly and produce even stitches. An improperly threaded machine is one of the most common culprits behind skipped stitches. The path of the thread must be precise, following all guides and tension discs.To thread the upper thread correctly, follow these steps:

- Ensure the presser foot is in the raised position.

- Place the spool of thread onto the spool pin.

- Guide the thread through the initial thread guides on the machine.

- Pass the thread through the tension discs, ensuring it is seated correctly between them.

- Thread the take-up lever, making sure the thread passes through the eye of the lever.

- Continue threading down through the remaining guides, including the needle clamp guide.

- Finally, thread the needle from front to back or side to side, depending on your machine’s design, leaving a tail of about 4-6 inches.

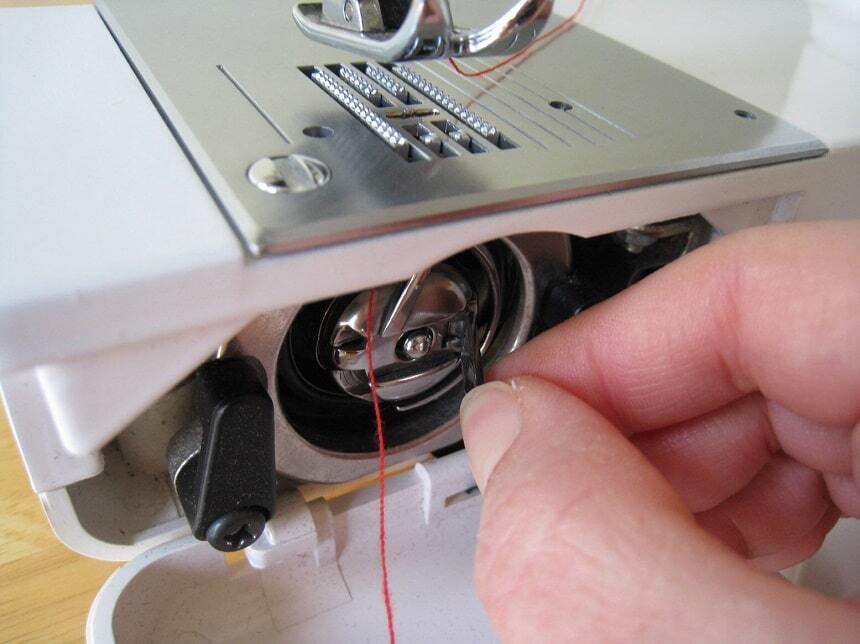

For the lower thread (bobbin), the process typically involves:

- Wind the bobbin evenly with the correct type of thread.

- Insert the bobbin into the bobbin case or bobbin holder, ensuring the thread unwinds in the correct direction (usually counter-clockwise for top-loading machines).

- Draw up the bobbin thread by holding the upper thread tail and turning the handwheel towards you once or twice. This will bring the bobbin thread up through the needle plate.

Upper and Lower Thread Tension Adjustment

Achieving balanced tension between the upper and lower threads is essential for creating strong, neat stitches. When tension is unbalanced, stitches will appear uneven, loopy, or skipped. The tension is controlled by dials on the sewing machine, typically marked with numbers.

The goal is to have the upper and lower threads meet and interlock precisely in the middle of the fabric layers. If the upper thread is too loose, it will create loops on the underside of the fabric. If it’s too tight, the bobbin thread may show on the top. Conversely, if the bobbin thread is too loose, it will cause loops on the top of the fabric, and if it’s too tight, the upper thread may break or cause puckering.

Here’s how to adjust tension:

- Start with a test stitch: Sew a few stitches on a scrap piece of your project fabric.

- Examine the stitch: Observe where the threads are interlocking.

- Adjust upper tension: If loops are visible on the underside, increase the upper tension slightly (move to a higher number). If loops are on the top, decrease the upper tension (move to a lower number).

- Adjust lower tension: The bobbin tension is usually adjusted by a small screw on the bobbin case. Turning this screw clockwise tightens the tension, and counter-clockwise loosens it. This adjustment is less frequent than the upper tension.

- Repeat testing: Make small adjustments and re-test until the stitches are balanced, with no visible loops on either side and a clean, uniform stitch formation.

Re-threading the Machine: A Step-by-Step Process

When troubleshooting skipped stitches, re-threading the entire machine is often the most effective first step. This ensures that any minor misalignments or improper threading are corrected.Follow this systematic process:

- Raise the presser foot: This is crucial to allow the thread to move freely through the tension discs.

- Remove the old thread: Carefully unthread the needle and remove the spool of thread.

- Remove the bobbin: Take out the current bobbin.

- Re-insert the bobbin: Place a fresh bobbin into the bobbin case, ensuring it’s oriented correctly.

- Thread the lower thread: Draw up the bobbin thread by holding the upper thread tail and turning the handwheel towards you.

- Re-thread the upper thread: Follow the exact path for the upper thread, paying close attention to the tension discs and the take-up lever.

- Thread the needle: Ensure the needle is threaded correctly, with a sufficient tail.

- Lower the presser foot: Once both threads are properly in place and the needle is threaded, lower the presser foot.

- Test stitch: Sew a test stitch on a scrap of fabric to verify that the tension is balanced and stitches are forming correctly.

Bobbin and Lower Threading Procedures

The bobbin and its associated threading mechanism are critical components in stitch formation. Issues here can lead to inconsistent stitches, thread breakage, or complete stitch failure. Understanding and correctly executing bobbin winding and insertion is paramount for smooth sewing machine operation.The lower thread, carried by the bobbin, works in tandem with the upper thread to create a secure stitch. Any irregularities in how the bobbin is wound or how the thread is guided can disrupt this delicate balance, manifesting as skipped stitches.

Bobbin Case and Bobbin Issues

Potential problems can arise from both the bobbin case, the component that holds the bobbin, and the bobbin itself. These issues often stem from damage, debris, or incorrect fitting.

- Damaged Bobbin Case: A bent, warped, or cracked bobbin case can prevent the bobbin from rotating freely or cause uneven tension. Inspect the case for any visible signs of damage.

- Debris in Bobbin Case: Lint, dust, or small thread fragments can accumulate in the bobbin case, impeding the smooth movement of the bobbin and affecting thread tension. Regular cleaning is essential.

- Incorrect Bobbin Size or Type: Using a bobbin that is not designed for your specific sewing machine model can lead to a poor fit and improper thread pickup. Always use bobbins recommended by the manufacturer.

- Worn or Damaged Bobbin: A bobbin with nicks, sharp edges, or that is misshapen can snag the thread or cause it to unwind unevenly, contributing to skipped stitches.

Bobbin Winding Procedures

An evenly wound bobbin is fundamental for consistent lower thread delivery. Uneven winding can cause the thread to snag or unravel erratically, leading to stitch problems.

“An evenly wound bobbin ensures a smooth and consistent supply of thread, preventing snags and tension fluctuations.”

To achieve an evenly wound bobbin:

- Secure the Thread: Ensure the thread is properly anchored to the bobbin before starting to wind. Many machines have a small notch or hole for this purpose.

- Maintain Even Tension: Keep a light tension on the thread with your fingers as it feeds onto the bobbin. Avoid pulling too tightly or letting it become slack.

- Guide the Thread: If your machine does not have an automatic thread guide, manually guide the thread back and forth across the bobbin to ensure an even distribution.

- Stop When Full: Do not overfill the bobbin. Most machines have an automatic stop mechanism. Overfilling can cause the thread to spill over and snag.

Bobbin Insertion into Bobbin Case or Shuttle

The correct insertion of the bobbin is crucial for the machine to pick up the lower thread properly. Incorrect placement will prevent stitch formation or cause significant problems.To insert the bobbin correctly:

- Orient the Bobbin: Most machines require the bobbin to be inserted with the thread unwinding in a specific direction (usually counter-clockwise). Refer to your sewing machine manual for the correct orientation.

- Thread the Bobbin Case: After placing the bobbin in the case, the thread must be guided through a small slit or tension spring. This step is vital for setting the correct lower thread tension.

- Ensure Smooth Movement: The bobbin should spin freely within the bobbin case when the thread is gently pulled. If it feels stiff or restricted, recheck the threading and orientation.

For machines with a drop-in bobbin system, the process is similar: place the bobbin in the bobbin holder, ensuring the thread unwinds in the correct direction, and then pull the thread through the designated slot.

Lower Thread Pickup Errors

The successful pickup of the lower thread by the needle is the moment stitch formation begins. Errors in this process are a direct cause of skipped stitches.Common errors in lower thread pickup include:

- Incorrect Bobbin Insertion: As detailed above, if the bobbin is not oriented or threaded correctly, the machine cannot engage the lower thread.

- Thread Jamming: The lower thread can become jammed in the bobbin case or around the bobbin itself, preventing it from feeding smoothly to the needle.

- Needle Not Reaching Thread: The needle might not be descending far enough to loop around the lower thread, or the timing of the needle and bobbin hook might be off (though this is less common and often a timing issue).

- Tension Imbalance: If the lower thread tension is too tight or too loose relative to the upper thread, the loop formed by the upper thread may not be caught correctly by the bobbin hook.

Fabric and Sewing Machine Compatibility

The interplay between your fabric choice and your sewing machine is a critical, yet often overlooked, factor in achieving perfect stitches. Different fabric types possess unique characteristics that can significantly influence how your machine performs and how stitches are formed. Understanding these relationships empowers you to make informed decisions, preventing a common source of skipped stitches.The fundamental principle is that the needle must be able to penetrate the fabric cleanly without snagging or pushing it away, while the thread must be able to pass through the fabric and form a loop with the bobbin thread without undue friction or resistance.

Matching your needle, thread, and presser foot to the specific demands of your fabric is paramount.

Fabric Type Influence on Stitch Formation

The weight, weave, and fiber content of a fabric directly impact stitch formation. Loosely woven fabrics might snag on a sharp needle, leading to skipped stitches, while tightly woven or very smooth fabrics can cause the needle to deflect, also resulting in skipped stitches. Stretch fabrics, due to their inherent elasticity, require specific needle types and stitch settings to prevent the stitches from breaking or the fabric from distorting.

Even the surface texture of the fabric plays a role; a fuzzy fabric might require a different needle point than a slick, satin weave.

Presser Foot Selection for Various Materials

The presser foot’s primary role is to hold the fabric smoothly against the feed dogs as it’s being sewn. Using the wrong presser foot can lead to uneven feeding, fabric distortion, and subsequently, skipped stitches.

- All-Purpose Foot: Suitable for most woven fabrics like cotton, linen, and light to medium-weight synthetics.

- Walking Foot: Essential for sewing multiple layers of fabric, slippery materials, or thick, heavy fabrics like denim and upholstery. It feeds the top and bottom layers of fabric simultaneously, ensuring even movement and preventing shifting.

- Roller Foot: Ideal for sewing leathers, vinyl, and other sticky or heavy materials. The rollers reduce friction, allowing the fabric to glide smoothly under the foot.

- Zipper Foot: Designed to sew close to zippers and cording. While not directly related to skipped stitches in general sewing, using it correctly ensures even pressure for precise stitching.

- Overcasting Foot: Mimics the action of an overlocker, helping to neaten raw edges and prevent fraying, which can indirectly contribute to smoother fabric feeding and fewer skipped stitches in some applications.

- Teflon Foot or Roller Guide Foot: Excellent for slippery fabrics like satin, silk, or vinyl, as they provide a non-stick surface to prevent the fabric from clinging.

Techniques for Sewing Delicate or Stretchy Fabrics

Sewing delicate or stretchy fabrics requires a gentle touch and specialized techniques to avoid skipped stitches and fabric damage.

- Delicate Fabrics (e.g., Silk, Chiffon, Organza): Use a fine, sharp needle (like a microtex or sharp needle) to pierce the fabric cleanly without causing snags or runs. A lower stitch length (around 1.5-2.0mm) can also help create more secure stitches. Consider using a stabilizer underneath to support the fabric.

- Stretchy Fabrics (e.g., Knits, Lycra, Jersey): Employ a ballpoint or stretch needle, which has a rounded point designed to push the fabric fibers apart rather than piercing them, thus preventing skipped stitches and holes. Utilize a stretch stitch on your machine (often a zigzag stitch with a very narrow width and slightly longer stitch length, or a specific lightning bolt stitch) or a serger/overlocker for the most durable and flexible seams.

Avoid pulling or stretching the fabric as you sew; let the feed dogs do the work.

Fabric Type Comparison Table

To further assist in selecting the right combination for success, refer to the following table:

| Fabric Type | Recommended Needle | Recommended Thread | Potential Issues |

|---|---|---|---|

| Lightweight Cotton (e.g., Quilting Cotton, Lawn) | Universal (70/10 to 80/12) | All-purpose polyester or cotton | Needle too large, dull needle, incorrect tension |

| Medium-Weight Cotton (e.g., Poplin, Canvas) | Universal (80/12 to 90/14) | All-purpose polyester | Dull needle, incorrect tension |

| Heavyweight Cotton (e.g., Denim, Twill) | Denim/Jeans (90/14 to 100/16) | Heavy-duty polyester or cotton | Blunt needle, incorrect tension, needle too small |

| Silk (e.g., Charmeuse, Crepe de Chine) | Microtex/Sharp or Universal (60/8 to 70/10) | Silk thread or fine polyester | Needle too large, snagging, incorrect tension |

| Knit/Stretch (e.g., Jersey, Lycra, Fleece) | Ballpoint or Stretch (70/10 to 80/12) | Polyester or stretch thread | Needle too sharp, incorrect stitch type, stretching fabric while sewing |

| Leather/Vinyl | Leather/Groove Point or Universal (90/14 to 100/16) | Heavy-duty polyester or nylon | Needle too small, needle breaking, skipping stitches due to drag |

Feed Dog and Presser Foot Interactions

The smooth progression of fabric through your sewing machine is a coordinated effort between several components, with the feed dogs and presser foot playing critical roles. When these elements are not functioning optimally or are misaligned, skipped stitches can become a frequent and frustrating issue. Understanding their individual functions and how they interact is key to resolving many sewing problems.The feed dogs are small, serrated metal teeth located beneath the needle plate.

Their primary function is to grip the fabric and move it forward, stitch by stitch, ensuring consistent feeding and even stitch length. This rhythmic movement is essential for creating neat and uniform seams. The presser foot, on the other hand, holds the fabric securely against the feed dogs, preventing it from shifting or bunching up. The pressure exerted by the presser foot directly influences how effectively the feed dogs can grip and advance the fabric.

Feed Dog Function and Fabric Movement

Feed dogs operate in a four-step cycle: they rise, move forward, drop, and move backward. This synchronized action pulls the fabric incrementally under the needle. The height and movement of the feed dogs are crucial for proper fabric feeding. If they are too low, they may not grip the fabric effectively, leading to inconsistent movement and potential skipped stitches. Similarly, if they are set too high for a delicate fabric, they could potentially damage the material or cause puckering.

Presser Foot Pressure and Stitch Formation

The presser foot pressure is the force with which the presser foot holds the fabric against the feed dogs. The correct pressure ensures that the fabric is held firmly enough for the feed dogs to grip and advance it without causing undue stress on the fabric or the machine. If the pressure is too light, the fabric might slip, resulting in skipped stitches.

Conversely, excessive pressure can cause the fabric to stretch or distort, leading to uneven stitches and potential skipped stitches, especially with fine or stretchy materials.

Cleaning and Inspecting Feed Dogs

Accumulated lint, thread fragments, and fabric debris can impede the movement and grip of the feed dogs, leading to skipped stitches. Regular cleaning is therefore an essential part of maintenance.Methods for cleaning and inspecting the feed dogs include:

- Visual Inspection: Carefully examine the feed dogs for any visible debris, such as lint, thread ends, or small fabric scraps. Look for any bent or broken teeth, which can indicate damage.

- Brushing: Use a small, stiff brush, such as a seam ripper brush or a dedicated sewing machine cleaning brush, to gently dislodge and remove any accumulated lint or debris from between the feed dog teeth and around the feed dog area.

- Compressed Air: For hard-to-reach areas, a can of compressed air can be effective in blowing away loose debris. Hold the can upright and use short bursts to avoid moisture build-up.

- Sewing Machine Oil (with caution): In some cases, a tiny drop of sewing machine oil on a cotton swab can help loosen stubborn debris. Ensure to wipe away any excess oil thoroughly afterwards, as oil can attract more lint.

- Needle Plate Removal: For a more thorough cleaning, you may need to remove the needle plate. Consult your sewing machine’s manual for specific instructions on how to do this safely. Once removed, you can more easily access and clean the feed dogs and the area beneath them.

Adjusting Presser Foot Pressure

Many modern sewing machines offer adjustable presser foot pressure, allowing you to fine-tune the amount of force applied to the fabric. This adjustment is particularly useful when sewing different types of fabrics, from thick denim to delicate silks.Elaborating on adjusting presser foot pressure:

- Consult Your Manual: The first step is always to refer to your sewing machine’s user manual. It will detail the location and method for adjusting the presser foot pressure, which can vary significantly between machine models. This might involve a dial, a lever, or a screw.

- Understanding the Settings: The pressure settings are typically indicated by numbers or symbols representing light, medium, and heavy pressure. Higher numbers or symbols generally correspond to increased pressure.

- Testing on Scrap Fabric: Before sewing on your project, it is highly recommended to test the presser foot pressure on a scrap piece of the same fabric you are using. Sew a few stitches with the current setting and observe the fabric.

- Adjusting for Different Fabrics:

- Delicate Fabrics (e.g., silk, chiffon): These fabrics often require lower presser foot pressure to prevent stretching, distortion, or damage. A lighter setting ensures the feed dogs can move the fabric without excessive resistance.

- Medium-Weight Fabrics (e.g., cotton, linen): A medium setting is usually appropriate for most standard fabrics, providing a good balance of grip and fabric integrity.

- Heavy Fabrics (e.g., denim, canvas): These fabrics may benefit from higher presser foot pressure to ensure the feed dogs can grip and move them effectively without slipping.

- Observing the Results: If you notice the fabric puckering, stretching, or the feed dogs struggling to move the fabric, adjust the presser foot pressure accordingly. For puckering or stretching, decrease the pressure. If the fabric isn’t feeding smoothly, increase the pressure slightly.

- Making Small Adjustments: It is best to make small, incremental adjustments to the pressure setting rather than large ones. Test again after each adjustment until you achieve smooth fabric feeding and even stitches.

Advanced Troubleshooting Scenarios

While many skipped stitches stem from the fundamental issues discussed previously, certain less common but significant problems can arise. These often require a deeper understanding of your sewing machine’s mechanics and a systematic approach to diagnosis. Addressing these advanced scenarios can save you from further frustration and help maintain the optimal performance of your machine.This section delves into these more intricate causes of skipped stitches, providing practical steps for identification and resolution.

We will explore the critical aspect of machine timing, how to perform diagnostic stitch tests, and the importance of inspecting machine parts for subtle damage. By following a structured troubleshooting sequence, you can efficiently pinpoint and rectify even the most elusive skipped stitch culprits.

Machine Timing Issues

Machine timing refers to the precise synchronization between the needle’s movement and the hook’s rotation, ensuring they meet at the exact moment to form a stitch. When this timing is off, the needle may not be low enough when the hook attempts to catch the thread loop, resulting in skipped stitches. This is a more complex mechanical issue that often requires professional attention, but understanding its implications is crucial for advanced troubleshooting.A common indicator of timing issues is a consistent pattern of skipped stitches, often occurring at regular intervals or in specific areas of the fabric.

If you’ve exhausted all other possibilities, including needle, thread, and tension adjustments, machine timing becomes a strong suspect.

Performing a Basic Stitch Test

A stitch test is an invaluable diagnostic tool that allows you to observe the stitch formation process directly and identify patterns in skipped stitches. By performing a controlled test, you can gather crucial information to narrow down the potential causes.To conduct a stitch test, follow these steps:

- Prepare your machine with a fresh needle and good quality thread, as previously discussed.

- Select a medium-weight, stable fabric that is representative of your usual sewing projects.

- Set your machine to a straight stitch at a medium length (e.g., 2.5mm).

- Sew a continuous seam of at least 6-8 inches without stopping or changing speed.

- Carefully examine the stitching, paying close attention to any skipped stitches. Note where they occur (beginning of seam, middle, end) and their frequency.

- Repeat the test with different stitch lengths and possibly different thread colors to see if the skipping pattern changes.

The results of this test can provide significant clues. For instance, skipped stitches only at the beginning of a seam might point to a threading issue or a tension problem that corrects itself. Consistent skipping throughout the seam, however, could indicate a more fundamental mechanical issue like timing or a damaged machine part.

Identifying and Addressing Burrs or Damage on Machine Parts

Over time, certain parts of your sewing machine can develop small imperfections, such as burrs or nicks, which can snag the thread and cause skipped stitches. These are often subtle and can be easily overlooked.The primary areas to inspect for burrs include:

- Needle Plate: Run your finger gently across the needle plate, especially around the needle hole. If you feel any rough spots or sharp edges, these can catch the thread.

- Hook/Bobbin Case Area: Carefully inspect the shuttle hook and the bobbin case for any visible scratches, nicks, or bent areas. A flashlight can be helpful here.

- Thread Guides: Examine all thread guides, tension discs, and the presser foot for any rough edges or accumulated lint that could impede smooth thread flow.

If you identify a burr or damage, it can often be addressed with fine-grit sandpaper (e.g., 600-grit or higher) or a specialized sewing machine repair tool. Gently sand the affected area in the direction of the thread path to smooth it out. For significant damage or bent parts, professional repair is recommended.

Always unplug your sewing machine before performing any manual inspection or cleaning of internal parts. Safety first!

Systematic Troubleshooting Sequence

When faced with persistent skipped stitches, a systematic approach is essential to avoid confusion and ensure all potential causes are considered. This structured method helps you rule out possibilities efficiently.Begin with the simplest and most common causes, gradually moving towards more complex ones:

- Needle Check: Ensure the needle is the correct type and size for your fabric, is inserted correctly, and is not bent or dull. Replace it if in doubt.

- Thread and Tension: Verify that you are using good quality thread and that the upper and lower tension settings are appropriate for your fabric.

- Bobbin and Threading: Double-check that the bobbin is wound evenly and inserted correctly, and that the upper threading path is clear and accurate.

- Fabric and Machine Compatibility: Confirm that your machine and needle are suitable for the fabric you are using.

- Feed Dogs and Presser Foot: Ensure the feed dogs are raised and functioning correctly, and that the presser foot is engaged and applying appropriate pressure.

- Machine Cleaning and Lubrication: A clean and well-lubricated machine operates more smoothly, reducing the likelihood of thread snags.

- Inspect for Damage: Carefully examine the needle plate, hook, and thread guides for any burrs or damage.

- Machine Timing: If all other steps have been exhausted, consider the possibility of a timing issue, which may require professional service.

By following this sequence, you can methodically eliminate common problems and confidently identify more obscure issues, leading to a resolution for your skipped stitches.

Maintenance and Prevention Strategies

Preventative maintenance is the cornerstone of a smoothly operating sewing machine and the most effective strategy to avoid frustrating skipped stitches. By dedicating a small amount of time to regular upkeep, you can significantly extend the life of your machine and ensure consistent, high-quality sewing results. This proactive approach not only saves you from unexpected breakdowns but also preserves the precision required for intricate stitches.Regular cleaning and oiling are fundamental to keeping your sewing machine in optimal condition.

Dust, lint, and old oil can accumulate over time, hindering the movement of various machine parts and leading to friction, which is a common culprit behind skipped stitches. A clean and properly lubricated machine operates with greater ease and accuracy.

Machine Cleaning Procedures

A clean sewing machine is essential for preventing skipped stitches. Lint and dust can build up in the bobbin area, on the feed dogs, and around the needle plate, interfering with thread flow and stitch formation. Regularly removing this debris ensures that the thread moves freely and that the fabric feeds evenly.A routine cleaning should involve the following steps:

- Brush Away Lint: Use a small brush, often provided with your sewing machine, to gently sweep away lint and thread fragments from the needle plate, bobbin case area, and feed dogs.

- Vacuum Small Areas: For hard-to-reach areas, a small vacuum cleaner designed for electronics or a can of compressed air can be used to dislodge stubborn lint. Be cautious with compressed air to avoid blowing lint deeper into the machine.

- Wipe Down Surfaces: Use a soft, dry cloth to wipe down the exterior and accessible internal parts of the machine. Avoid using harsh chemicals or excessive moisture.

Machine Oiling Procedures

Oiling your sewing machine reduces friction between moving parts, which is crucial for smooth operation and preventing skipped stitches. The frequency of oiling depends on your machine’s manual and how often you use it. Over-oiling can also cause problems, so it’s important to follow the manufacturer’s recommendations.The process of oiling involves:

- Consult Your Manual: Always refer to your sewing machine’s instruction manual for specific oiling points and recommended oil type. Different machines have different lubrication needs.

- Apply Small Drops: Apply a single, small drop of sewing machine oil to each designated oiling point. Excess oil can attract lint and create a gummy residue.

- Run the Machine: After oiling, run the machine at a moderate speed for a few minutes to distribute the oil evenly. Wipe away any excess oil that might drip onto the fabric.

Proper Storage Impact on Performance

How you store your sewing machine can significantly impact its performance and longevity, directly influencing the occurrence of skipped stitches. Improper storage can expose the machine to dust, moisture, and physical damage, all of which can lead to mechanical issues.To ensure optimal performance through proper storage:

- Cover the Machine: Always cover your sewing machine when not in use. This protects it from dust and airborne particles that can accumulate on critical components. Many machines come with a dust cover, or you can use a breathable fabric cover.

- Store in a Stable Environment: Keep your sewing machine in a dry, temperature-controlled environment. Extreme humidity or temperature fluctuations can affect the machine’s metal parts and lubricants.

- Secure During Transport: If you need to move your sewing machine, ensure it is properly secured in its case or a padded bag to prevent jarring or damage to delicate parts.

Weekly and Monthly Machine Upkeep Routine

Establishing a regular maintenance routine is key to preventing skipped stitches and ensuring your sewing machine remains a reliable tool. This routine can be divided into weekly and monthly tasks, allowing for consistent care without becoming overwhelming.

Weekly Upkeep (for regular users)

These tasks are best performed after each significant sewing session or at least once a week if you sew frequently.

- Clean the Bobbin Area: Remove the bobbin and bobbin case and use a small brush to clean out any lint or thread debris.

- Wipe Down the Needle Plate: Ensure the needle plate is free of any fabric fibers or thread ends.

- Check Thread Path: Briefly inspect the thread path for any visible lint or obstructions.

Monthly Upkeep (for regular users)

These tasks are more thorough and should be performed once a month or after approximately 20-30 hours of use.

- Thorough Cleaning: Perform a more detailed cleaning of the feed dogs, under the needle plate, and in any other accessible areas where lint can accumulate.

- Oiling: Refer to your machine’s manual and apply oil to the designated points. Run the machine to distribute the oil.

- Inspect Needles: Check your sewing needles for any signs of dullness, bending, or burrs. Replace them if necessary.

- Check Tension Discs: Gently clean the tension discs with a piece of dental floss or a thin brush to remove any lint that might be trapped between them.

This consistent approach to maintenance will not only help prevent skipped stitches but will also contribute to a more enjoyable and productive sewing experience.

Final Review

Navigating the intricacies of sewing machine mechanics and fabric interactions can transform a vexing problem into a manageable challenge. This exploration of how to troubleshoot skipped stitches has equipped you with the knowledge to identify causes and implement effective solutions. By embracing regular maintenance and understanding the subtle interplay of needle, thread, and fabric, you are well-prepared to maintain a smooth and efficient sewing experience, ensuring your creative endeavors are always stitch-perfect.