Embarking on the journey of sewing is a delightful endeavor, and mastering the nuances of your machine is key to creating beautiful, professional-looking results. At the heart of achieving those perfect stitches lies an often-overlooked yet crucial element: bobbin tension. Understanding and skillfully adjusting this fundamental aspect can transform your sewing experience from frustrating to fulfilling, unlocking a new level of precision and creativity in every project you undertake.

This comprehensive guide will illuminate the path to understanding bobbin tension, from its basic principles to advanced considerations. We will delve into how it impacts the very formation of your stitches, explore common issues, and equip you with the knowledge and tools necessary to diagnose and resolve any imbalances. Prepare to gain confidence as we walk through step-by-step adjustments, troubleshoot persistent problems, and uncover the subtle interactions between tension, thread, and needle.

Understanding Bobbin Tension Basics

The bobbin, a small spool that holds the lower thread, plays a critical role in the sewing machine’s ability to create a stitch. Proper bobbin tension is paramount for achieving balanced stitches and a professional-looking finish to your sewing projects. It works in conjunction with the top thread tension to create a secure and aesthetically pleasing seam.Bobbin tension directly influences how the lower thread interacts with the upper thread.

When the bobbin tension is correctly calibrated, the lower thread is released at a controlled rate, allowing it to interlock with the upper thread precisely at the fabric’s surface. This precise interaction forms a balanced stitch, where neither the top nor the bottom thread is excessively visible on the other side of the fabric.

The Fundamental Role of Bobbin Tension

The bobbin’s primary function is to supply the lower thread for each stitch. The tension mechanism on the bobbin case or bobbin housing controls the rate at which this thread is fed out. This controlled release is essential for creating a balanced stitch. Without adequate control over the bobbin thread, the stitch formation would be compromised, leading to various sewing issues.

How Bobbin Tension Affects Stitch Formation and Overall Seam Quality

The interplay between top and bobbin tension is what creates a stitch. A balanced stitch occurs when the upper and lower threads meet and interlock evenly between the layers of fabric.

- Balanced Stitch: When both tensions are correctly adjusted, the stitch appears the same on both the top and bottom sides of the fabric. This results in a strong, neat, and durable seam.

- Too Loose Bobbin Tension: If the bobbin tension is too loose, the bobbin thread will be pulled out too easily. This can result in the upper thread appearing on the bobbin side of the fabric, creating a loopy or messy appearance. The seam may also be weak and prone to unraveling.

- Too Tight Bobbin Tension: Conversely, if the bobbin tension is too tight, the bobbin thread will be pulled out with difficulty. This often causes the bobbin thread to break, or the upper thread will appear on the top side of the fabric, creating puckering and a strained seam. The stitch will look tight and may even cut into the fabric.

Common Symptoms of Incorrectly Adjusted Bobbin Tension

Observing your stitches can provide immediate clues as to whether your bobbin tension needs adjustment. These symptoms are typically quite noticeable and directly impact the appearance and integrity of your sewing.

- Loopy Stitches on the Underside: This is a classic sign of bobbin tension that is too loose. You will see visible loops of the upper thread on the bobbin side of the fabric.

- Skipped Stitches: While sometimes related to needle issues, skipped stitches can also occur if the bobbin tension is too tight, preventing the needle from properly piercing the fabric and picking up the bobbin thread.

- Thread Breakage (Bobbin Thread): If the bobbin thread consistently breaks, it is a strong indicator that the bobbin tension is set too high.

- Thread Breakage (Top Thread): While less common, if the bobbin tension is extremely tight, it can create resistance that causes the top thread to break as it’s pulled through.

- Puckering Fabric: When the bobbin tension is too tight, the lower thread pulls the fabric too tightly, causing it to pucker, especially along the seam line.

- Visible Bobbin Thread on the Top Side: This symptom suggests that the bobbin tension is too tight, as the lower thread is being pulled up into the upper layer of the fabric.

- Visible Top Thread on the Bobbin Side: This indicates that the bobbin tension is too loose, and the upper thread is not being sufficiently secured by the bobbin thread.

Identifying Bobbin Tension Issues

Understanding how to diagnose bobbin tension problems is crucial for achieving balanced and beautiful stitches. While both top thread and bobbin tension can cause stitching irregularities, recognizing the specific symptoms associated with bobbin tension issues allows for targeted adjustments. This section will guide you through the process of pinpointing whether your bobbin is the primary source of your sewing woes.

The appearance of your stitches on both the right and wrong sides of the fabric offers vital clues. By carefully examining these areas, you can effectively differentiate between top thread and bobbin tension problems. This observational skill is a cornerstone of troubleshooting sewing machine stitch quality.

Observing Stitch Appearance for Diagnosis

The key to identifying bobbin tension issues lies in meticulous observation of the stitch formation on both sides of your fabric. When the bobbin tension is incorrect, it manifests in distinct ways that are usually localized to the underside of the stitch. Conversely, top thread tension problems typically present differently.

To systematically diagnose, perform the following steps:

- Create Test Stitches: Select a scrap piece of the fabric you are currently working with. Sew a few straight stitches, paying close attention to the stitch formation.

- Examine the Right Side: Look at the stitches from the top side of the fabric (the side facing you as you sew).

- If the bobbin tension is too tight, you will likely see small loops or puckering on the right side, where the bobbin thread is pulling the top thread down too firmly.

- If the bobbin tension is too loose, the top thread will appear loose and loopy on the right side, with the bobbin thread not adequately securing it.

- Examine the Wrong Side: Turn the fabric over and examine the stitches from the underside.

- When the bobbin tension is too loose, you will see a lot of the top thread showing on the wrong side. The bobbin thread is not catching the top thread effectively.

- When the bobbin tension is too tight, the bobbin thread will be pulling the top thread down so much that it appears as a tight, almost “drawn” line of bobbin thread on the wrong side, and the top thread might look strained.

- Compare with Balanced Stitches: Ideally, a balanced stitch will look the same on both the right and wrong sides of the fabric, with no visible loops, puckering, or excessive thread showing. The threads should interlock neatly between the two layers of fabric.

Fabric Type Influence on Tension Symptoms

Different fabric types can exhibit bobbin tension imbalances in slightly varied ways due to their weight, weave, and fiber content. Understanding these nuances can further aid in accurate diagnosis.

Here’s how common fabric types might react:

- Lightweight and Fine Fabrics (e.g., silk, chiffon, batiste): These fabrics are more prone to showing puckering and pulling even with minor bobbin tension issues. A slightly too-tight bobbin can cause these delicate materials to gather noticeably. On the wrong side, excessive top thread showing might appear as fine lines rather than distinct loops.

- Medium-Weight Fabrics (e.g., quilting cotton, linen blends): These fabrics provide a good baseline for observing tension. You’ll typically see clear loops on the wrong side if the bobbin tension is too loose, and noticeable puckering on the right side if it’s too tight. The stitches are usually robust enough to show the problem without being obscured by the fabric itself.

- Heavyweight Fabrics (e.g., denim, canvas, upholstery fabric): While these fabrics are more forgiving, significant bobbin tension imbalances can still cause issues. If the bobbin tension is too loose, you might see the top thread lying flat and loose on the wrong side, with the bobbin thread not engaging sufficiently to create a secure stitch. If too tight, the fabric might appear to be pulled into tiny pleats on the right side, especially at the stitch holes.

- Knit Fabrics (e.g., jersey, interlock): These fabrics have inherent stretch, which can sometimes mask minor tension problems. However, a bobbin tension that is too tight can cause the knit to ripple or curl excessively along the seam line on the right side. If the bobbin tension is too loose, you might see a prominent line of top thread on the wrong side, and the stitch might appear weak and prone to breaking when the fabric is stretched.

“The hallmark of correct bobbin tension is a balanced stitch that looks consistent on both sides of the fabric, with threads interlocking neatly within the material.”

Tools and Techniques for Adjustment

Now that we understand the basics and how to identify issues with bobbin tension, let’s move on to the practical steps of making those adjustments. This section will guide you through the necessary tools and the precise techniques required to fine-tune your bobbin tension for optimal sewing results.Successfully adjusting bobbin tension involves a methodical approach, utilizing the right tools and understanding the mechanics of the tension mechanism.

Precision is key, as even small changes can significantly impact your stitches.

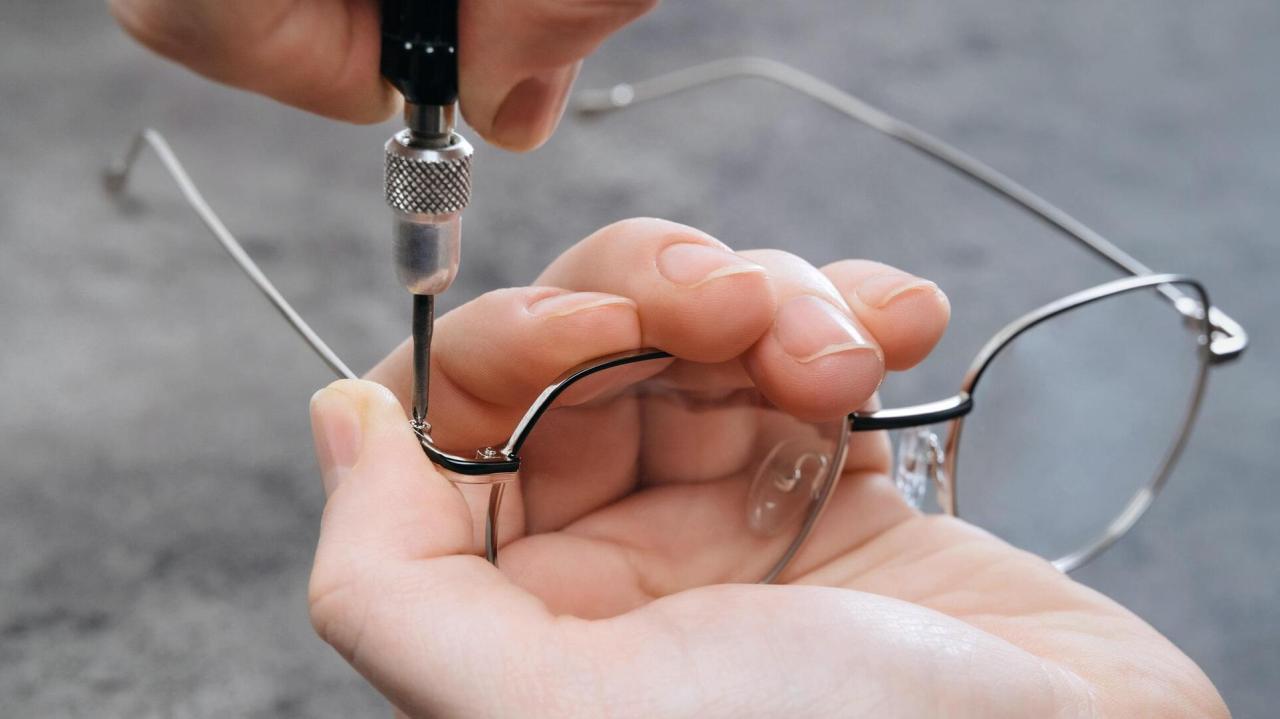

Essential Tools for Bobbin Tension Adjustment

To effectively adjust bobbin tension, a few simple yet crucial tools will be needed. Having these readily available will ensure a smooth and efficient adjustment process.

- Small Phillips Head Screwdriver: This is the most common tool used to turn the bobbin tension screw. Ensure it fits snugly into the screw head to avoid stripping it.

- Small Flathead Screwdriver: Some older machines or specific bobbin cases may use a flathead screw.

- Tweezers: Useful for gently manipulating the thread and holding small parts if necessary.

- Sewing Machine Manual: Always refer to your specific sewing machine’s manual for model-specific instructions and diagrams.

- Scrap Fabric: You’ll need this for testing your stitch quality after each adjustment.

Identifying and Locating the Bobbin Tension Screw

The bobbin tension screw is a small, often unassuming component that plays a vital role in stitch formation. Knowing its location is the first step to making any adjustments.The bobbin tension screw is typically found on the bobbin case itself. When the bobbin case is removed from the sewing machine, you will usually see a small screw on its side.

This screw controls the tension of the thread as it unwinds from the bobbin. In some machines, the bobbin case might be integrated into the machine’s design, and the screw will be accessible from the outside, often near where the bobbin is inserted. Always consult your machine’s manual if you are unsure of its exact location.

Tightening and Loosening Bobbin Tension

Understanding the direction of rotation for the screw is fundamental to adjusting the tension correctly. This principle applies to most sewing machines, but it’s always wise to confirm with your manual.The general rule for adjusting bobbin tension is as follows:

- Tightening: To increase the bobbin tension (making the thread pull tighter), you will typically turn the screw in a clockwise direction. This is often described as “tightening” the tension.

- Loosening: To decrease the bobbin tension (making the thread pull looser), you will typically turn the screw in a counter-clockwise direction. This is often described as “loosening” the tension.

It is important to remember that these are small adjustments. Turning the screw too far in either direction can cause significant problems.

Procedure for Incremental Bobbin Tension Adjustments

Making small, deliberate adjustments is crucial for achieving balanced stitch tension. This systematic approach prevents over-adjustment and allows you to observe the effects of each change.To make precise adjustments to your bobbin tension screw, follow this procedure:

- Prepare for Testing: Thread your sewing machine as usual with your chosen thread, both on the top and in the bobbin. Place a piece of scrap fabric under the presser foot.

- Perform a Test Stitch: Sew a short seam on the scrap fabric.

- Evaluate the Stitch: Examine the stitches on both the top and the underside of the fabric. Look for signs of incorrect bobbin tension as discussed in the “Identifying Bobbin Tension Issues” section.

- Make a Small Adjustment: If an adjustment is needed, use your screwdriver to turn the bobbin tension screw a very small amount. A quarter-turn or even an eighth of a turn is often sufficient. Remember the clockwise (tighten) and counter-clockwise (loosen) directions.

- Retest: Sew another short seam on a fresh section of scrap fabric.

- Evaluate Again: Inspect the new stitches.

- Repeat as Necessary: Continue making small, incremental adjustments and retesting until the top and bobbin threads interlock perfectly in the middle of the fabric layers, creating a balanced stitch.

This iterative process of adjusting and testing ensures you achieve the desired tension without overshooting the mark. Patience and careful observation are your best allies here.

Step-by-Step Bobbin Tension Adjustment Guide

Adjusting bobbin tension is a methodical process that requires patience and careful observation. Following these steps will help you achieve the optimal balance for smooth and professional-looking stitches. It’s crucial to work with scrap fabric of the same type you’ll be using for your project to get the most accurate results.When you begin adjusting bobbin tension, it’s essential to have a systematic approach.

This ensures that you make incremental changes and can easily identify what works best for your machine and thread combination. The following steps will guide you through the process, from initial testing to achieving balanced tension.

Initial Bobbin Tension Test

Before making any adjustments, it’s important to establish a baseline for your current bobbin tension. This allows you to gauge the impact of your adjustments and determine if the tension is too loose, too tight, or just right.To perform the initial test, thread your sewing machine with your chosen top thread and a bobbin wound with the same thread. Place a piece of scrap fabric under the presser foot and lower it.

Sew a straight seam, holding both the top thread and the bobbin thread tails gently towards the back as you start.Now, carefully examine the stitches on both sides of the fabric.

- Top Side: The top threads should lie flat and evenly on the fabric surface. You should not see any bobbin thread loops or puckering.

- Bobbin Side: The bobbin threads should also lie flat. You should not see any top thread loops or excessive tension pulling the fabric.

The ideal stitch will show a slight interlock of the threads between the fabric layers, creating a clean, balanced seam.

Adjusting the Bobbin Tension Screw

The bobbin case, where the bobbin sits, usually has a small screw that controls the tension of the bobbin thread. Turning this screw will either tighten or loosen the bobbin tension. It’s vital to make small, incremental adjustments to avoid over-tightening or over-loosening.To adjust the bobbin tension, you will typically turn the screw in small increments.

- Tightening: Turning the screw clockwise (usually) will increase the tension on the bobbin thread.

- Loosening: Turning the screw counter-clockwise (usually) will decrease the tension on the bobbin thread.

Always make one small adjustment at a time and then re-test your stitch.

Testing and Refining Bobbin Tension

After each minor adjustment to the bobbin tension screw, it is imperative to test the stitch on scrap fabric. This iterative process of adjusting and testing is key to achieving the perfect balance.Perform the same initial test as described above after each adjustment.

- If the bobbin thread is still too loose (loops showing on the top): Tighten the bobbin tension screw slightly (turn clockwise).

- If the bobbin thread is too tight (top thread loops showing on the bobbin side, or fabric puckering): Loosen the bobbin tension screw slightly (turn counter-clockwise).

- If the stitches are uneven or you can still see one thread dominating the other: Continue making small adjustments and re-testing.

The goal is to have the top and bobbin threads meet and interlock precisely in the middle of the fabric layers, creating a neat and secure seam.

Best Practices for Balanced Tension

Achieving balanced tension between the top thread and the bobbin thread is the hallmark of professional sewing. This balance ensures that your stitches are not only aesthetically pleasing but also durable and do not damage the fabric.Consider these best practices for optimal results:

- Use the Same Thread: Always use the same type and weight of thread for both the top and the bobbin. This is the most fundamental rule for achieving balanced tension.

- Thread Quality Matters: Higher quality threads are generally smoother and more consistent, leading to better tension control.

- Correct Needle: Ensure you are using the correct type and size of needle for your fabric and thread. A dull or incorrect needle can cause tension issues.

- Proper Bobbin Winding: A evenly wound bobbin is crucial. If the bobbin is wound too loosely or too tightly, it can affect tension.

- Clean Machine: Lint and debris in the bobbin area or under the presser foot can interfere with smooth thread movement and affect tension.

- Gradual Adjustments: As emphasized, make only small adjustments to the bobbin tension screw at a time.

- Test on Project Fabric: Always test your tension on a scrap piece of the actual fabric you will be using for your project. Different fabrics behave differently.

The “sweet spot” for tension is when both threads are equally balanced, and the stitch appears the same on both the top and bottom of the fabric.

Resetting Bobbin Tension to Default

If you find yourself struggling to achieve the desired tension, or if you’ve made numerous adjustments and are unsure of the current setting, it’s often best to reset the bobbin tension to its default state. This provides a clean slate for you to start the adjustment process again.To reset your bobbin tension, you will need to loosen the tension screw on the bobbin case as much as possible while still keeping the bobbin case in place.

- Loosen Completely: Turn the bobbin tension screw counter-clockwise until it feels like it will come off.

- Test for Looseness: Gently pull the bobbin thread. It should now slide out very freely, almost without resistance.

- Gradual Tightening: Once you have confirmed it’s very loose, begin to tighten the screw in small clockwise turns, testing after each turn.

This process effectively returns the bobbin tension to its loosest setting, allowing you to then build up to the correct tension by gradually tightening it and testing frequently. This methodical reset ensures you aren’t working with a tension that is excessively loose or tight from previous attempts.

Common Bobbin Tension Problems and Solutions

Even with the best tools and techniques, occasional bobbin tension issues can arise. Understanding these common problems and their solutions will help you quickly get back to sewing smoothly. This section will guide you through identifying and resolving the most frequent bobbin tension challenges you might encounter.

Bobbin Thread Loops on Fabric Surface

When the bobbin thread is too loose, it will not be pulled up properly into the fabric by the needle thread. This results in visible loops or “bird’s nests” on the underside of your fabric, indicating that the bobbin tension is weaker than the top thread tension.

Addressing Loose Bobbin Thread

To fix loops on the fabric surface, you need to increase the tension on the bobbin thread. This is achieved by tightening the bobbin case screw.

- Slight Adjustments: Turn the bobbin case screw clockwise in very small increments, typically no more than a quarter turn at a time.

- Test Stitching: After each adjustment, sew a short test seam on a scrap of your fabric.

- Visual Inspection: Examine the stitches. You are looking for a balanced stitch where the bobbin thread is not visible on the top and no loops are forming on the bottom.

- Persistent Loops: If loops persist, continue making small clockwise adjustments and testing until the tension is correct.

Puckering or Visible Bobbin Thread on Top

Conversely, if the bobbin thread is too tight, it will pull the needle thread down too forcefully, causing the fabric to pucker on the top side. In more extreme cases, you might see the bobbin thread appearing as a distinct line on the top of your fabric. This signifies that the bobbin tension is stronger than the top thread tension.

Addressing Tight Bobbin Thread

To resolve puckering or a visible bobbin thread on the top, you need to decrease the tension on the bobbin thread. This is done by loosening the bobbin case screw.

- Counter-Clockwise Turns: Turn the bobbin case screw counter-clockwise in small increments, again, no more than a quarter turn at a time.

- Re-test: Sew a test seam on a fabric scrap after each adjustment.

- Observe Stitch Balance: Aim for a smooth stitch where the threads interlock neatly between the fabric layers.

- Gradual Loosening: Continue to loosen the screw gradually until the puckering disappears and the bobbin thread is no longer visible on the top.

Skipped Stitches Related to Bobbin Tension

Skipped stitches can be a frustrating problem, and while often related to the needle or thread, bobbin tension can also be a contributing factor. If the bobbin thread is too loose, it may not be caught by the needle at the correct moment, leading to a skipped stitch. Similarly, if the bobbin tension is excessively tight, it can create drag that prevents the needle from forming a proper stitch.

Troubleshooting Skipped Stitches

When experiencing skipped stitches, evaluate your bobbin tension as part of a broader troubleshooting process.

- Check Needle and Thread: Ensure your needle is sharp, correctly inserted, and the appropriate type and size for your fabric and thread. Verify that your top thread is not frayed or damaged.

- Bobbin Case Alignment: Make sure the bobbin is inserted correctly and the thread is seated properly in the bobbin case’s tension mechanism.

- Tension Adjustment: If the above are in order, adjust the bobbin tension. If skipped stitches occur with a loose bobbin thread appearance, try tightening the bobbin screw slightly. If they occur with a tight bobbin thread appearance, try loosening it slightly.

- Clean Lint and Oil: Lint buildup in the bobbin area can significantly affect tension and cause skipped stitches. Clean this area thoroughly. Ensure your machine is also properly oiled.

Maintaining Consistent Bobbin Tension Over Time

Achieving consistent bobbin tension is key to uninterrupted and high-quality sewing. Regular maintenance and awareness of how environmental factors can influence your thread will help maintain this consistency.

- Regular Cleaning: Lint accumulation is the primary enemy of consistent tension. Clean the bobbin case and shuttle area after every few bobbin changes or at least once a week with regular use.

- Use Quality Thread: Inconsistent thread thickness or quality can lead to fluctuating tension. Stick to reputable brands and appropriate thread types for your projects.

- Proper Bobbin Winding: Ensure your bobbins are wound evenly and without slack. A poorly wound bobbin can cause tension issues regardless of the bobbin case setting.

- Environmental Factors: Humidity can affect thread and how it moves through the tension discs. Store your threads and machine in a stable environment.

- Periodic Re-calibration: Even with perfect maintenance, it’s good practice to re-test your tension on a scrap piece of fabric every so often, especially when starting a new project or changing thread types.

- Thread Lubrication: For certain specialty threads or fabrics, a thread lubricant might be beneficial to ensure smooth passage through the tension discs.

Advanced Bobbin Tension Considerations

While mastering basic bobbin tension is crucial, several advanced factors can influence its behavior and require careful consideration for optimal stitch quality. Understanding these nuances allows for finer adjustments and troubleshooting in more complex sewing scenarios.Delving deeper into bobbin tension involves recognizing how various materials and machine types interact with this fundamental setting. By addressing these advanced considerations, you can achieve a more professional and consistent finish across a wider range of projects.

Impact of Different Thread Types on Bobbin Tension

The composition and construction of your bobbin thread significantly affect the required tension. Different fibers have varying degrees of elasticity and friction, necessitating adjustments to maintain balanced stitches.

- Cotton Threads: These natural fibers have minimal stretch and can create a slightly stiffer stitch. Bobbin tension might need to be slightly looser compared to polyester to prevent puckering, especially with fine cottons.

- Polyester Threads: Known for their strength and elasticity, polyester threads can accommodate slightly tighter bobbin tension without causing undue stress on the fabric. They are generally forgiving but can still lead to loopy stitches if the bobbin tension is too loose.

- Silk Threads: These fine, lustrous threads are delicate and can break easily. Bobbin tension should be kept very light to avoid damaging the thread and to ensure a smooth, even stitch.

- Specialty Threads (e.g., Metallic, Monofilament, Rayon): These threads often have unique properties. Metallic threads can be prone to fraying, requiring a slightly looser bobbin tension to prevent breakage. Monofilament (invisible) thread is stiff and can cause skipped stitches or puckering if bobbin tension is not carefully balanced. Rayon threads are strong but can lose their sheen if subjected to excessive tension. Always test these threads with a small scrap of your project fabric.

Interaction of Needle Size and Type with Bobbin Tension

The needle is the primary tool for guiding thread through fabric, and its interaction with the bobbin thread is fundamental to stitch formation. The size and type of needle used will influence how the bobbin thread is pulled through and how much resistance it encounters.

- Needle Size: A larger needle creates a bigger hole in the fabric, allowing the bobbin thread to pass through more easily. This might require a slightly tighter bobbin tension to ensure it’s adequately taken up by the upper thread. Conversely, a smaller needle creates a smaller hole, potentially increasing friction and requiring a slightly looser bobbin tension to prevent thread breakage or skipped stitches.

- Needle Type: Different needle points are designed for specific fabrics and threads. For instance, a universal needle is suitable for most general sewing. A ballpoint or stretch needle has a rounded tip that slides between fabric fibers, reducing the chance of snags and tears in knits, which can indirectly affect how smoothly the bobbin thread is drawn. A sharp or microtex needle is ideal for wovens and fine fabrics, providing a clean piercing action that can help create a more consistent stitch with balanced bobbin tension.

Comparison of Bobbin Tension Adjustment Mechanisms on Different Sewing Machines

The method for adjusting bobbin tension varies significantly between different types of sewing machines, reflecting their mechanical and electronic designs.

- Mechanical Sewing Machines: These machines typically feature a physical screw or dial on the bobbin case or bobbin housing.

- Bobbin Case with Screw: Many mechanical machines use a bobbin case that holds the bobbin. This case often has a small screw. Turning the screw clockwise tightens the tension (increases resistance), and counter-clockwise loosens it (decreases resistance).

- External Bobbin Housing Dial: Some older or simpler mechanical machines might have a dial integrated into the bobbin area that directly controls the tension spring.

- Computerized Sewing Machines: These machines offer more sophisticated and often automated tension control.

- Digital Control Panel: Most computerized machines have a digital display where tension can be adjusted using up/down buttons or a slider. The machine’s internal computer then signals the tension mechanism.

- Automatic Tension Control: Many modern computerized machines feature automatic tension control systems. These systems use sensors to detect thread type, fabric thickness, and stitch type, automatically adjusting both upper and bobbin thread tension for optimal results. While convenient, manual override options are usually available for specific situations.

- Integrated Bobbin Case Systems: Even with computerized controls, the underlying mechanism for bobbin tension is often a spring-loaded system within the bobbin housing, but the adjustment is managed electronically.

Pre-Sewing Checks Checklist for Bobbin Tension

Before commencing a sewing project, performing a quick check of your bobbin tension can prevent many potential issues and ensure a smooth start.

A proactive approach to bobbin tension checks saves time and frustration.

- Thread Appropriateness: Confirm that the bobbin thread type and weight match the upper thread and are suitable for the fabric being used.

- Bobbin Winding: Ensure the bobbin is wound evenly and smoothly, without any lumps or slack threads, as this can affect tension consistency.

- Bobbin Insertion: Verify that the bobbin is correctly inserted into the bobbin case or housing, with the thread unwinding in the correct direction as per your machine’s manual.

- Thread Path: Check that the bobbin thread is properly seated in the tension spring of the bobbin case (if applicable) and is not caught on any debris.

- Test Stitch: Always perform a test stitch on a scrap piece of the project fabric. Examine the stitches on both the right and wrong sides of the fabric. Look for:

- Balanced stitches (upper and bobbin threads meeting neatly between fabric layers).

- No visible loops of upper thread on the wrong side (tension too loose).

- No visible loops of bobbin thread on the right side (tension too tight).

- No puckering or pulling of the fabric.

- Needle Check: Ensure the needle is the correct size and type for your fabric and thread, and that it is inserted properly. A dull or bent needle can significantly impact stitch formation and tension.

Closing Notes

As we conclude our exploration of bobbin tension, it’s clear that this essential element is the silent architect of your sewing’s success. By understanding its role, recognizing the signs of imbalance, and confidently applying the adjustment techniques, you’ve gained a powerful skill that will enhance the quality and appearance of all your sewn creations. May your stitches be ever balanced, and your sewing projects bring you immense satisfaction and pride.