How to Digitize a Simple Pattern You Made sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail with formal and friendly language style and brimming with originality from the outset.

This guide will walk you through the straightforward process of transforming your cherished handmade patterns into precise digital files. We’ll cover everything from understanding the core concepts and necessary tools to preparing your physical pattern, exploring various digitization methods, and effectively utilizing software to create usable digital patterns. Whether you’re looking to preserve your creations, share them with others, or adapt them for future projects, this comprehensive approach will equip you with the knowledge to successfully digitize your simple patterns.

Understanding the Basics of Pattern Digitization

Pattern digitization is the process of transforming a physical sewing pattern, typically made of paper or fabric, into a digital format. This digital representation can then be stored, manipulated, and used with various software applications, opening up a world of possibilities for pattern makers, designers, and hobbyists alike. The core idea is to create an accurate digital replica of your original design.The reasons for undertaking this process are manifold and offer significant advantages over relying solely on physical patterns.

Digitizing allows for precise scaling, easy storage without taking up physical space, and the ability to share your designs electronically with others. Furthermore, it enables seamless integration with digital cutting machines and the creation of virtual prototypes, streamlining the entire design and production workflow.

Essential Tools and Materials

To embark on the journey of pattern digitization, a few key tools and materials are necessary. These can range from simple household items to specialized software and hardware, depending on the desired level of precision and the complexity of the pattern. Having the right equipment ensures a smooth and accurate conversion process.A comprehensive list of essential items includes:

- Scanner or Camera: A high-resolution scanner is ideal for capturing detailed images of your pattern. Alternatively, a good quality digital camera with a tripod can be used, provided you maintain consistent lighting and a perpendicular angle to the pattern.

- Computer: A reliable computer with sufficient processing power and storage is required to run the digitization software and store your digital pattern files.

- Digitizing Software: Specialized software is crucial for converting the scanned image into a usable digital pattern format. Options range from free, open-source software to professional-grade CAD programs.

- Measuring Tools: Accurate rulers, measuring tapes, and a precision scale are important for verifying dimensions during the digitization process.

- Paper and Pencil: For creating the initial physical pattern, if you haven’t already done so.

- Masking Tape or Weights: To keep the physical pattern flat and stable during scanning or photography.

The Fundamental Concept of Pattern Digitization

At its heart, pattern digitization involves capturing the precise lines, curves, and measurements of a physical pattern and translating them into a vector-based digital format. This means that the pattern is not just a flat image but a series of mathematical points and lines that can be infinitely scaled without losing quality. This is a significant advantage over raster images, which become pixelated when enlarged.The process typically begins with creating a clean, well-lit, and perfectly flat representation of your physical pattern.

This is achieved through scanning or high-resolution photography. Once the image is captured, it is imported into specialized software. Within this software, the user traces over the lines of the pattern, converting them into digital vectors. Key points, such as notches, grainlines, and seam allowances, are meticulously marked and digitized.

Reasons for Digitizing Handmade Patterns

There are several compelling reasons why an individual or business would choose to digitize a simple handmade pattern. These motivations often revolve around efficiency, precision, and the desire to leverage modern technology.Key advantages include:

- Archiving and Storage: Physical patterns can degrade over time, get lost, or take up considerable space. Digitizing allows for secure, long-term storage of your designs in a fraction of the space, accessible from any device.

- Accuracy and Precision: Digital patterns can be incredibly precise. Once digitized, measurements can be verified and adjusted with exacting accuracy, reducing errors in garment construction.

- Scalability and Modifications: Digital patterns can be easily scaled up or down to create different sizes without redrawing. They can also be modified to incorporate design changes or to create variations of the original pattern.

- Sharing and Collaboration: Digital files can be easily shared with other designers, manufacturers, or clients, facilitating collaboration and global reach.

- Integration with Digital Tools: Digitized patterns can be directly imported into computer-aided design (CAD) software, digital cutting machines, and 3D design programs, significantly streamlining the production process.

- Reduced Material Waste: By precisely laying out digital pattern pieces on a virtual fabric layout (marker making), you can optimize fabric usage and minimize waste, leading to cost savings.

Software and Hardware for Digitization

The choice of software and hardware significantly impacts the accuracy, efficiency, and cost of the pattern digitization process. While some basic tools can be used for simple patterns, more complex designs or professional applications may require dedicated solutions.Hardware considerations:

- Scanners: For patterns up to A3 or ledger size, a flatbed scanner is often sufficient. For larger patterns, a large-format scanner or a wide-format printer with a scanning function might be necessary.

- Digital Cameras: If using a camera, a DSLR or mirrorless camera with a good lens will provide higher resolution and better control over image quality. A sturdy tripod is essential for maintaining consistent height and angle.

- Lighting: Consistent, diffused lighting is crucial to avoid shadows and glare, ensuring the scanner or camera captures the pattern lines clearly. Natural daylight near a window or professional lighting equipment can be used.

Software options:

- Vector Graphics Editors: Software like Adobe Illustrator or Inkscape (free and open-source) can be used for tracing and creating vector patterns. While not specifically designed for sewing patterns, they offer robust tools for drawing and editing.

- Dedicated Pattern Digitizing Software: Programs like Lectra, Gerber AccuMark, or Valentina (free and open-source) are specifically designed for pattern making and digitization. These offer specialized tools for pattern manipulation, grading, and marker making.

- Image Editing Software: Basic image editing software like Adobe Photoshop or GIMP (free and open-source) can be used for preparing scanned images before tracing in vector software.

The accuracy of your digitized pattern is directly proportional to the quality of your initial scan or photograph and the precision with which you trace and define the pattern pieces in your chosen software.

Preparing Your Physical Pattern

Before embarking on the digitization process, it is crucial to meticulously prepare your physical pattern. A well-prepared pattern ensures accuracy and efficiency, leading to a flawless digital representation. This preparation involves ensuring the pattern is in optimal condition for scanning or tracing.Taking the time to properly prepare your physical pattern pieces will significantly enhance the quality of your digitized file and reduce the need for corrections later in the process.

This foundational step is key to achieving professional results.

Ensuring a Clean and Flat Pattern

A clean, flat, and crease-free pattern is essential for accurate digitization. Any imperfections on the physical pattern can translate into errors in the digital version. Therefore, attention to detail in this stage is paramount.Methods for achieving a clean and flat pattern include:

- Ironing: Gently iron your pattern pieces on a low to medium heat setting, using a pressing cloth if necessary, especially for delicate paper or fabrics. Ensure the iron is not too hot to avoid damaging the paper.

- Weighting: For stubborn creases, place heavy, flat objects like books or a pattern weight directly on the folded or creased areas overnight. This helps to flatten the paper naturally.

- Handling: Always handle your pattern pieces with clean hands to avoid transferring dirt or oils. Store them flat or rolled loosely in protective sleeves to prevent new creases from forming.

- Cleaning: If there are any minor smudges or dust, use a soft eraser or a dry cloth to gently remove them. Avoid using water or cleaning solutions, as these can damage the paper.

Measuring and Noting Key Dimensions

Accurate measurements are the backbone of precise pattern digitization. Even with visual tracing, having key dimensions recorded will serve as a crucial reference point and a method for verification. This step ensures that the scale and proportions of your digital pattern are correct.Techniques for accurate measurement and notation include:

- Using a Ruler or Measuring Tape: Employ a flexible, fabric measuring tape for curved edges and a rigid ruler for straight edges. Ensure the measuring tool is placed directly along the seam line or cutting line you intend to digitize.

- Marking Key Points: Identify and mark crucial points such as notches, dart points, apexes, and seam intersections. These points are vital for aligning pattern pieces correctly in digital software.

- Recording Measurements: Write down these measurements directly on the pattern piece in a clear and legible manner. This can include seam lengths, curve lengths, and overall dimensions of each piece. For example, note the length of a sleeve seam or the circumference of a neckline.

- Double-Checking: Always double-check your measurements to ensure accuracy. Small discrepancies can lead to significant issues in the final garment.

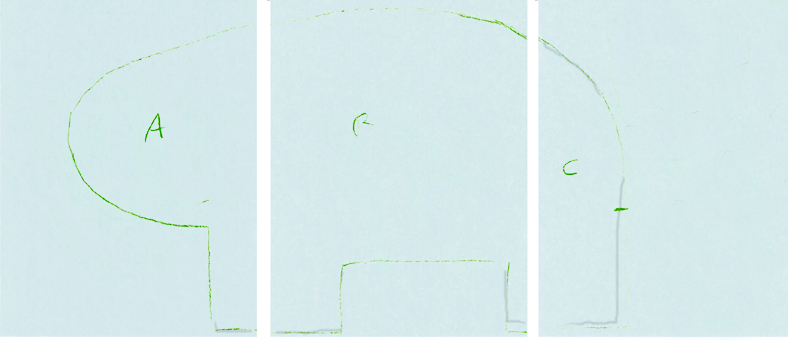

Labeling Pattern Pieces

Clear and consistent labeling of each pattern piece is indispensable for efficient digitization and future reference. Without proper labels, distinguishing between similar pieces or understanding their orientation can become a challenging task.Effective labeling strategies include:

- Unique Identifiers: Assign a unique name or number to each pattern piece. For instance, “Front Bodice,” “Back Bodice,” “Sleeve Left,” “Sleeve Right,” “Collar Top,” “Collar Under.”

- Size Information: If your pattern is for a specific size, clearly indicate this on the label. For example, “Front Bodice – Size M” or “Pattern Size 10.”

- Grainline: Mark the grainline clearly on each piece. This is usually indicated by a long arrow parallel to the selvage. This is critical for fabric cutting and ensuring the pattern drapes correctly.

- Notches and Markings: If there are specific notches or markings on the pattern piece, briefly note their purpose or location on the label, e.g., “Waist Notch,” “Shoulder Seam Mark.”

- Placement: Place the labels in a corner or an inconspicuous area of the pattern piece to avoid interfering with the actual pattern lines. Use a pencil or a non-bleeding pen for labeling.

Digitization Methods: Scanning vs. Photographing

Choosing the right method to digitize your physical pattern is crucial for achieving accurate and usable digital files. Both scanning and photographing offer distinct advantages and disadvantages, and understanding these will help you select the most suitable approach for your needs. This section will delve into a comparison of these two primary methods, detailing optimal techniques for each and guiding you towards the best file formats for storing your digitized patterns.

Software Options for Digitizing

Once your physical pattern pieces are prepared and you’ve chosen your digitization method, the next crucial step is selecting the right software to transform your scanned or photographed images into usable digital patterns. The software landscape ranges from readily available, free tools to specialized, professional applications, each offering different levels of control and functionality. Understanding these options will empower you to choose the most suitable and cost-effective solution for your needs.The choice of software significantly impacts the precision, editability, and final output of your digitized pattern.

For simple patterns, you might find that basic image editors suffice for cleanup and tracing, while more complex projects or a desire for professional-grade vectorization might lead you to invest in dedicated pattern digitization or vector graphics software.

Basic Image Editing Software for Pattern Cleanup

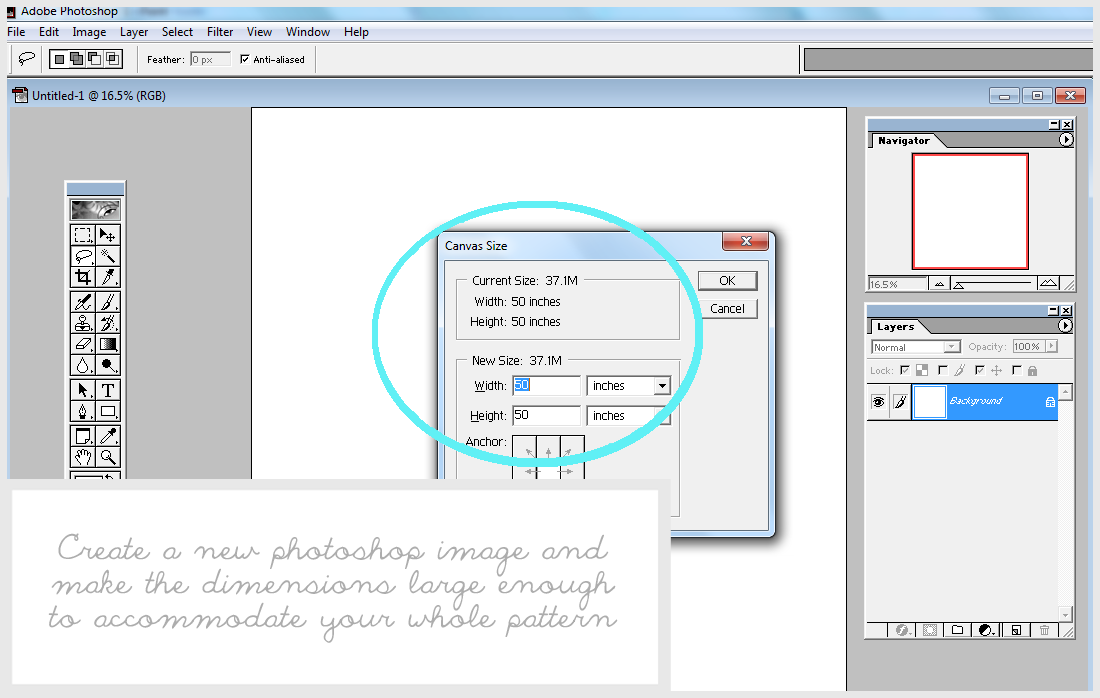

For patterns that are scanned or photographed, the initial digital image may contain imperfections such as shadows, creases, or background noise. Basic image editing software is excellent for rectifying these issues, ensuring a clean canvas for subsequent tracing. These tools are widely accessible, often free, and user-friendly, making them a great starting point for any digitizing project.A typical workflow for cleaning up scanned or photographed pattern pieces using basic image editing software involves several key steps:

- Opening the Image: Load your scanned or photographed pattern piece into the software.

- Cropping: Remove any excess background or unwanted edges around the pattern piece. This helps to focus on the actual pattern.

- Adjusting Brightness and Contrast: Enhance the visibility of the pattern lines. Often, increasing contrast will make the lines stand out more clearly against the background.

- Using the Eraser Tool: Carefully erase any stray marks, smudges, or unwanted shadows that are not part of the original pattern. Be precise to avoid erasing actual pattern lines.

- Filling Background Areas: If there are any gaps or uneven white spaces within the pattern, the fill tool can be used to create a uniform background.

- Sharpening (Optional): A slight sharpening can sometimes improve the definition of the pattern lines, but use this feature sparingly to avoid introducing digital artifacts.

These steps are fundamental to preparing your image for accurate tracing, whether you plan to do it manually within the same software or import it into a more specialized program.

Tracing for Clean Vector Paths

Once your raster image (composed of pixels) is clean, the next step is to convert it into a vector image (composed of mathematical paths). This is achieved by tracing over the existing lines. While basic image editors offer tracing tools, they are often limited. For more precise vectorization, digital art software or vector graphics editors are recommended. These programs allow you to draw new paths that precisely follow the Artikel of your pattern pieces.The process of tracing over existing lines in digital art software to create clean vector paths typically involves:

- Importing the Cleaned Image: Bring your prepared raster image into your chosen digital art or vector software.

- Layering: Place the image on a lower layer and create a new, transparent layer above it. This allows you to trace without altering the original image.

- Selecting the Pen Tool (or equivalent): This is the primary tool for creating vector paths. It allows you to place anchor points and draw lines between them.

- Placing Anchor Points: Click along the edge of your pattern piece to place anchor points. For curves, you will create Bezier curves by dragging the handles of the anchor points. Aim for the fewest anchor points necessary to accurately define the shape.

- Drawing the Paths: Connect the anchor points to create smooth, clean lines that precisely follow the pattern’s edges. Pay close attention to corners and curves.

- Adjusting Paths: Once traced, you can refine the paths by moving anchor points or adjusting curve handles to ensure perfect accuracy.

- Saving as a Vector File: Export your traced pattern as a vector file format such as SVG, AI, or DXF, which are compatible with most pattern-making software and cutting machines.

This method ensures that your digitized pattern is scalable without losing quality and can be easily edited or manipulated.

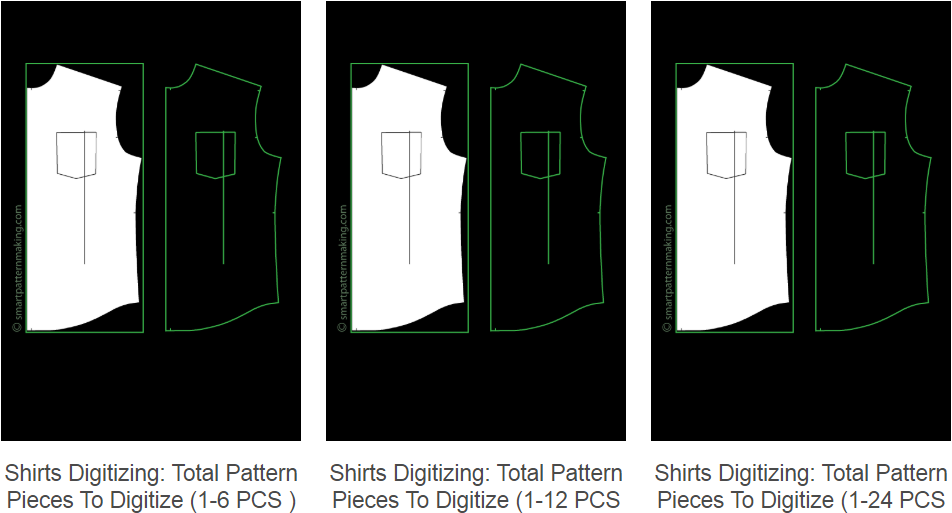

Specialized Pattern Digitization Software

For those who digitize patterns frequently or require advanced features, specialized pattern digitization software offers a streamlined and more efficient workflow. These programs are designed with the specific needs of pattern makers in mind, often incorporating tools for grading, seam allowances, and pattern manipulation. While these can be a significant investment, they offer substantial advantages in terms of speed, accuracy, and functionality.A typical workflow using specialized pattern digitization software would look something like this:

- Importing or Scanning: The software often has direct integration for scanning or allows for easy import of cleaned raster images.

- Automatic or Assisted Tracing: Many specialized programs feature advanced algorithms that can automatically trace raster images with remarkable accuracy, or provide highly intuitive tools for manual tracing that are faster than general vector editors.

- Defining Seam Allowances: A key advantage is the ability to easily add or modify seam allowances with precise control. This is often a single-click operation or a parameter adjustment.

- Adding Notches and Markings: Specialized tools allow for the quick and accurate placement of pattern markings like notches, dots, and grainlines.

- Pattern Grading: If you need to create different sizes of your pattern, these software packages excel at grading, allowing you to input size variations and automatically generate all required sizes.

- Piece Manipulation and Layout: Features for mirroring, rotating, and combining pattern pieces are standard, along with tools for optimizing fabric layout (marker making) to minimize waste.

- Exporting in Industry Standard Formats: These programs can export to a wide range of industry-standard formats (e.g., Gerber, Lectra, DXF) for use in digital cutting machines or for professional pattern services.

The primary advantage of specialized software lies in its integrated features that automate many of the repetitive and time-consuming tasks associated with pattern making, leading to increased productivity and professional-quality results.

The transition from a physical pattern to a digital format opens up a world of possibilities for customization, reproduction, and efficient production.

Converting Scans/Photos into Usable Digital Patterns

Once your physical pattern pieces have been successfully scanned or photographed, the next crucial step is to transform these raw digital images into precise, usable digital patterns. This process involves refining the image quality, cleaning up any imperfections, and ensuring the dimensional accuracy of your pattern pieces within your chosen software. These adjustments are vital for creating accurate digital patterns that will translate perfectly into physical garments.This stage focuses on enhancing the clarity and accuracy of your digitized pattern pieces.

By making strategic adjustments to the image, you can ensure that all lines are crisp and measurements are precise, laying the groundwork for successful pattern manipulation and garment creation.

Image Adjustment for Clarity

Digital images of patterns can sometimes appear washed out or too dark, making it difficult to discern fine details. Adjusting basic image properties like brightness, contrast, and sharpness is essential for creating clean, readable digital pattern pieces. These adjustments help to define the lines of your pattern and remove any ambiguity.To achieve optimal clarity:

- Brightness: Increase brightness to ensure the white background is clean and the pattern lines are clearly visible. Avoid over-brightening, which can cause some lines to disappear.

- Contrast: Enhance contrast to make the pattern lines stand out distinctly from the background. A good contrast level ensures that faint pencil marks or subtle curves are easily discernible.

- Sharpness: Apply a slight sharpening filter to define edges and make any blurred lines crisp. Be cautious not to over-sharpen, as this can introduce artifacts or a “halo” effect around the lines.

Removing Background Noise and Imperfections

Physical patterns can have marks, smudges, or creases that are captured during the digitization process. These unwanted elements can interfere with pattern editing and tracing. Most graphic editing software offers tools to clean up these imperfections.The process of removing unwanted marks typically involves:

- Using a “clone stamp” or “healing brush” tool to sample adjacent clean areas of the background and paint over the unwanted marks.

- Employing an eraser tool with a soft edge to gently remove small smudges or stray marks without damaging the pattern lines.

- Carefully selecting and deleting small, isolated specks of dust or lint that may have been present on the scanner bed or camera lens.

Accurate Scaling of Digital Pattern Pieces

Ensuring that your digital pattern pieces are the exact same size as your original physical pattern is paramount for garment fit. Most pattern digitizing software allows you to scale images based on known measurements.The procedure for accurate scaling involves:

- Identify a Known Measurement: Locate a specific measurement on your physical pattern that you can reliably measure, such as the length of a straight edge (e.g., a side seam) or a marked grainline.

- Measure in Software: Use the software’s measurement tool to measure the corresponding line on your digitized image.

- Calculate Scaling Factor: Compare the software’s measured length to the known physical measurement. The scaling factor is calculated as (Physical Measurement / Software Measurement).

- Apply Scaling: Input this scaling factor into the software’s scaling function to resize the entire pattern piece accurately. Many programs will prompt you to confirm the scaling operation.

Accurate scaling is the foundation of a well-fitting garment. Always double-check your measurements before and after scaling.

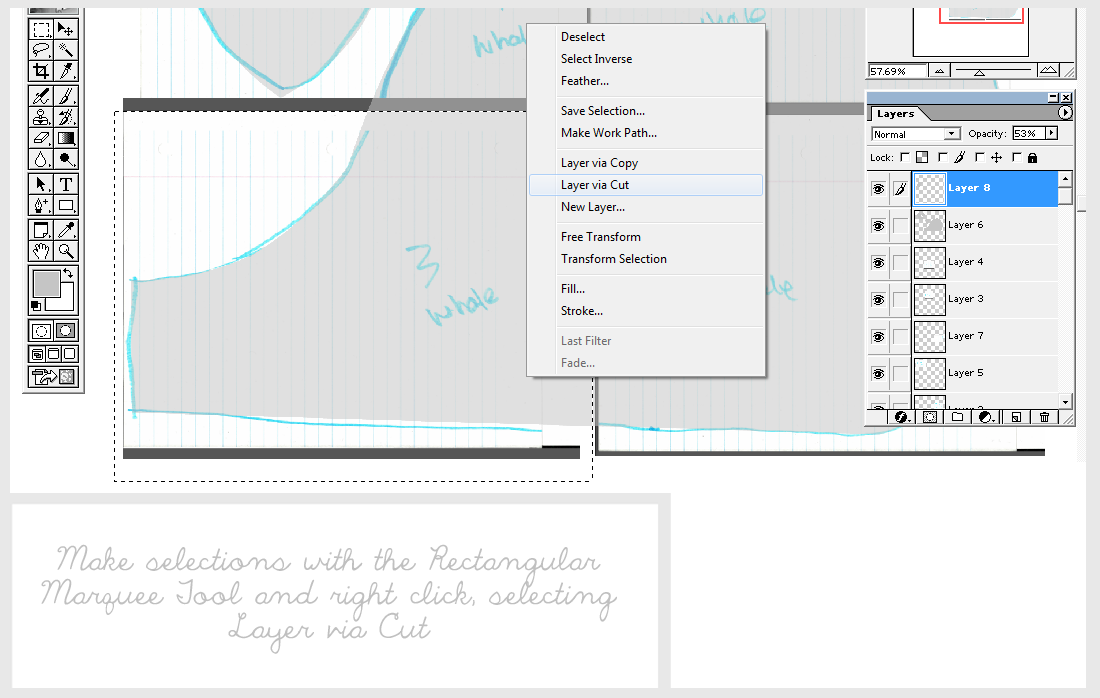

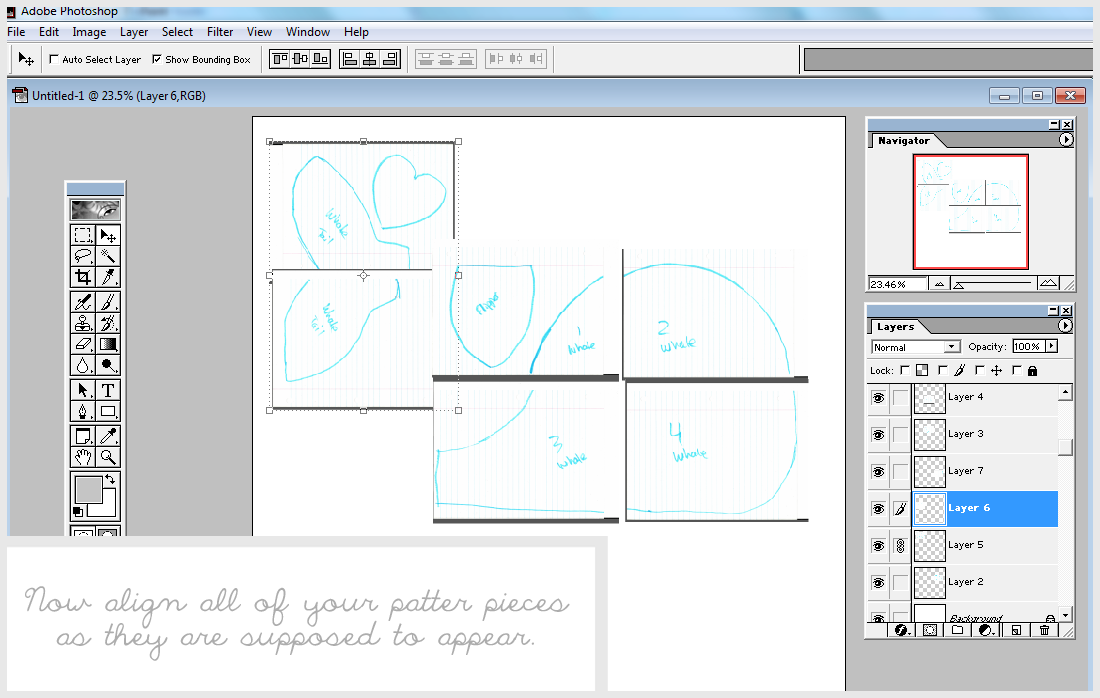

Separating Individual Pattern Pieces

If you have scanned or photographed multiple pattern pieces together on a single sheet, you will need to separate them into individual digital files. This is crucial for managing and editing each piece independently.A systematic approach to separating pattern pieces includes:

- Artikel Selection: Use the selection tools in your software (e.g., lasso tool, pen tool) to carefully trace the outer edges of each individual pattern piece.

- Layer Management: If your software supports layers, it is highly recommended to place each selected pattern piece on its own layer. This provides flexibility for editing and manipulation.

- Cutting and Pasting: Once a pattern piece is selected, you can cut it from the main image and paste it into a new document or onto its designated layer.

- Saving Individual Files: Save each separated pattern piece as a new file (e.g., JPEG, PNG, or a vector format if your software supports it) to ensure it can be easily accessed and used later.

Creating Digital Pattern Files for Use

Once you have successfully digitized your physical pattern pieces, the next crucial step is to transform these digital representations into usable pattern files. This involves saving them in appropriate formats, adding essential markings, and organizing them effectively for future projects. This process ensures that your digitized patterns are not only preserved but are also ready for printing and assembly, whether for personal use or for sharing with others.The goal is to create digital files that are accurate, easy to print, and contain all the necessary information for sewing.

This involves selecting the right file formats, incorporating details like seam allowances and grainlines, and establishing a clear system for managing your digital pattern library.

Saving Digitized Pattern Pieces for Printing

To ensure your digitized pattern pieces can be printed accurately at home or at a copy shop, it’s essential to save them in formats that maintain their dimensions and are widely compatible. Vector-based formats are generally preferred for their scalability and precision, preventing pixelation when enlarged or reduced.Commonly used file formats for printable patterns include:

- PDF (Portable Document Format): This is the most popular format for printable patterns. PDFs preserve formatting and layout, ensuring that your pattern prints at the correct scale. Most design software can export to PDF, and it’s universally viewable with free readers. When saving as a PDF, ensure you select a “print quality” or “high quality” setting.

- SVG (Scalable Vector Graphics): While often used for web graphics, SVGs are vector-based and can be excellent for patterns. They maintain sharp lines and can be scaled without losing quality. Some specialized pattern-making software might export directly to SVG.

- AI (Adobe Illustrator Artwork) or EPS (Encapsulated PostScript): These are professional vector graphics formats. If you are using advanced design software, these formats offer maximum flexibility for editing and scaling. However, they require compatible software to open and print.

When saving, pay attention to the print settings within your software. Ensure that “actual size” or “100% scale” is selected, and that any scaling options like “fit to page” are turned off to avoid distortion. It’s also a good practice to print a small test section (like a 1-inch square) to verify the scale before printing the entire pattern.

Adding Seam Allowances and Pattern Markings

Creating a usable digital pattern involves more than just the Artikel of your fabric pieces. Essential elements like seam allowances and other markings are critical for accurate sewing and assembly. These additions ensure that your digital pattern functions just like a professionally drafted paper pattern.Seam allowances are the areas around the edges of pattern pieces that are used for stitching.

They are typically addedafter* the main pattern shape is digitized. Many pattern-making software programs have dedicated tools for automatically adding seam allowances of a specified width. If your software doesn’t have this feature, you can manually draw them, ensuring consistency.Other vital markings to include are:

- Grainline: A long arrow indicating the direction of the fabric’s grain, which should be parallel to the selvage. This is crucial for ensuring the garment hangs correctly.

- Notches: Small marks or triangles along the edges of pattern pieces that help you align them correctly during sewing.

- Darts and Pleats: Lines and shapes indicating where to fold and stitch darts or pleats.

- Buttonholes and Button Placement: Marks indicating the size and location of buttonholes and corresponding button placements.

- Text Labels: Clear labels for each pattern piece (e.g., “Front Bodice,” “Sleeve”), including size information and the number of times each piece should be cut.

- Fold Lines: Dashed lines indicating where to fold fabric, often used for center front or center back pieces.

When adding these elements, use different line styles or colors to distinguish them from the cutting line. For example, a solid line for the cutting edge, a dashed line for seam allowances, and a different color for grainlines or dart lines. This visual clarity is paramount for ease of use.

Organizing and Naming Digital Pattern Files

A well-organized digital pattern library is essential for efficient workflow and easy retrieval of your creations. Establishing a consistent naming convention and folder structure from the outset will save you significant time and frustration in the long run.Consider the following strategies for organizing your digital pattern files:

- Folder Structure: Create a hierarchical folder system. You might have top-level folders for “My Patterns,” “Commercial Patterns,” or “Patterns to Test.” Within these, you can create subfolders for garment types (e.g., “Dresses,” “Tops,” “Pants”), by designer, or by season.

- Naming Convention: A clear naming convention should be descriptive and include key information. A good format might be:

[Garment Type]_[Style Name]_[Size]_[Version/Date].pdf. For example:Dress_AlineMidi_SizeM_v1_20231027.pdf. Including the date can be helpful for tracking revisions. - Metadata: Some file management systems allow you to add metadata (tags, s, descriptions) to your files. This can be incredibly useful for searching for specific patterns later.

Regularly review and tidy up your digital pattern files. Delete duplicates or outdated versions. Consider backing up your entire pattern library to an external hard drive or cloud storage to prevent data loss.

Checklist of Essential Elements for a Final Digital Pattern File

Before you consider your digitized pattern file complete and ready for use or sharing, it’s wise to run through a checklist to ensure all necessary components are present and accurate. This step helps prevent common errors and ensures a professional-quality output.Here is a checklist of essential elements to include in a final digital pattern file:

- Accurate Pattern Pieces: All digitized pieces are present and correctly shaped.

- Correct Seam Allowances: Seam allowances of the specified width are added consistently to all edges.

- Grainline Arrows: Each piece has a clearly marked grainline.

- All Necessary Notches: Matching notches are present on pieces that need to be joined.

- Size and Piece Labels: Each piece is clearly labeled with its name, size, and cut count (e.g., “Cut 2 on fold”).

- Pattern Key/Legend: A small section or separate document explaining all markings and line types used in the pattern.

- Scale Verification: A scale ruler or a sample 1-inch or 2.54cm square is included on the printout for verification.

- Printing Instructions: Notes on how to print the pattern (e.g., “Print at 100% scale,” “Do not scale”).

- Finished Garment Measurements (Optional but Recommended): Information about the finished garment’s bust, waist, hip, and length measurements for the specific size.

- Layout Diagram (Optional but Helpful): A visual guide showing how to arrange pattern pieces on fabric for optimal layout and minimal waste.

Advanced Techniques and Considerations

Once you have a basic digital pattern, several advanced techniques can significantly enhance its usability, precision, and scalability. Moving beyond simple image conversion, these methods leverage specialized software to create robust digital assets ready for a variety of applications. This section delves into these powerful techniques, focusing on how to maximize the value of your digitized patterns.The transition to advanced digital pattern making involves embracing tools that offer precision and flexibility.

Vector graphics software, in particular, is instrumental in this process, allowing for patterns that can be resized infinitely without any loss of quality, a crucial advantage for creating patterns that cater to a range of body measurements or project dimensions.

Benefits of Vector Graphics Software for Pattern Digitization

Vector graphics software offers a distinct advantage over raster-based (pixel) image editors for pattern digitization due to its fundamental approach to creating and manipulating images. Instead of relying on a grid of pixels, vector graphics are composed of mathematical equations that define points, lines, and curves. This mathematical foundation translates directly into significant benefits for pattern digitization.

- Scalability and Precision: Vector graphics can be scaled to any size without losing resolution or becoming pixelated. This means a digitized pattern can be printed at full scale for a large garment or reduced for a miniature sample with perfect clarity. The mathematical definitions ensure that lines remain sharp and curves are smooth regardless of the output size.

- Editability and Accuracy: Because each line and curve is a distinct object defined by mathematical points, they can be precisely edited. This allows for meticulous adjustments to seam allowances, dart placements, and grading between sizes with unparalleled accuracy.

- File Size Efficiency: Vector files are often smaller than comparable high-resolution raster images, making them easier to store and share.

- Integration with Other Software: Vector files are the standard format for many design and manufacturing software, facilitating seamless integration into workflows for pattern grading, marker making, and even direct output to digital cutting machines.

Creating Adjustable Digital Patterns for Different Sizes

A key benefit of using vector graphics software is the ability to create patterns that can be easily adjusted for different sizes, a process known as grading. This eliminates the need to redraw each size from scratch. The core principle involves establishing a baseline pattern and then applying consistent mathematical increments or decrements to key measurements to generate new sizes.To achieve this, you will typically define specific points on your pattern that correspond to important measurements (e.g., bust point, waistline, shoulder width).

In vector software, these points can be assigned numerical values. Grading involves creating rules that dictate how these points move relative to each other for each size increase or decrease. For example, a common grading rule for the bust might involve adding 0.5 inches for every size up. The software then applies these rules to all designated points, automatically generating the new pattern pieces for each size.For example, if you have a basic bodice pattern digitized in vector software, you can set up grading rules for the chest, waist, and hip measurements.

You might define that for each larger size, the chest increases by 1 inch, the waist by 0.75 inches, and the hip by 1.25 inches. You would also define how shoulder width, armhole depth, and other critical dimensions change proportionally. Advanced software can even manage complex curves and shapes, ensuring that the integrity of the pattern is maintained across all sizes.

Preparing Digitized Patterns for Digital Cutting Machines

Digital cutting machines, such as those used in industrial garment manufacturing or for intricate craft projects, require digital pattern files in specific vector formats. The precision and scalability offered by vector graphics are essential for these machines to accurately cut fabric or other materials. Preparing your digitized patterns involves ensuring they meet the technical requirements of the cutting machine’s software.The process typically involves:

- Ensuring Clean Vector Paths: All lines and curves in your digitized pattern must be clean, closed paths without overlapping segments or extraneous points. Any imperfections can lead to cutting errors.

- Defining Seam Allowances: Seam allowances need to be accurately represented as part of the digital pattern. Some software allows you to define seam allowances as a separate layer or as an offset from the cutting line, ensuring they are consistently applied.

- Exporting in Compatible Formats: Digital cutting machines often accept standard vector file formats such as DXF (Drawing Exchange Format), DWG (AutoCAD Drawing), AI (Adobe Illustrator), or SVG (Scalable Vector Graphics). It’s crucial to consult the cutting machine manufacturer’s specifications for the preferred or required format.

- Setting Up Cutting Layers and Tools: In some advanced workflows, you might need to define different layers for cutting, perforating, or scoring lines, and specify which cutting tool should be used for each.

For instance, if you are preparing a pattern for a fabric cutting machine, you would export your vector file as a DXF. The machine’s software would then interpret these paths to guide the laser or blade for precise cutting. If the pattern includes notches or drill marks, these are also translated into precise coordinates for the machine.

Considerations for Specific Sewing or Crafting Applications

The way you prepare and utilize a digitized pattern can vary significantly depending on its intended application. Different sewing and crafting disciplines have unique requirements for pattern precision, material handling, and final product aesthetics.For apparel sewing, key considerations include:

- Seam Allowances: Standard seam allowances (e.g., 1/2 inch, 5/8 inch) must be consistently applied and clearly indicated.

- Grainlines: Accurate grainlines are essential for fabric drape and fit. These should be clearly marked on each pattern piece.

- Notches and Markings: Notches, dots, and other markings for matching pattern pieces need to be precisely placed and easily visible in the digital file.

- Ease: The amount of ease built into a pattern for comfort and movement is a critical design element that needs to be preserved or adjusted as needed during grading.

For quilting or appliqué, considerations might shift towards:

- Precise Edge Definitions: Seams are often sewn with a specific, small seam allowance (e.g., 1/4 inch), and the cutting lines must be exact.

- Complex Shapes: Intricate shapes and sharp points require vector paths that can be rendered perfectly by cutting machines or rotary cutters.

- Color and Fabric Planning: While not directly part of the pattern’s geometry, the digital file might be used in conjunction with software that helps plan fabric placement and color schemes.

For paper crafting or model making, the focus might be on:

- Scoring Lines: Patterns often include fold lines that need to be distinguished from cut lines, often indicated by dashed or dotted lines.

- Tab and Slot Placement: For 3D constructions, the precise placement and size of tabs and slots for assembly are critical.

- Material Thickness: The thickness of the material being cut can influence the required kerf (the width of the material removed by the cutting tool), which might need to be accounted for in the digital file.

Conclusive Thoughts

By following these steps, you will have successfully transformed your physical patterns into versatile digital assets. This process not only preserves your original designs but also opens up a world of possibilities for scaling, sharing, and integrating them into various crafting and sewing applications. Embrace the precision and flexibility that digital patterns offer, and enjoy the enhanced creative potential they bring to your projects.