As How to Sew Darts to Add Shape to Clothing takes center stage, this opening passage beckons readers into a world crafted with good knowledge, ensuring a reading experience that is both absorbing and distinctly original.

This comprehensive guide delves into the art and science of sewing darts, a fundamental technique in garment construction that transforms flat fabric into beautifully shaped clothing. We will explore the historical significance, various types, precise measurement and marking, effective sewing techniques, common troubleshooting, and advanced applications of darts, culminating in visual examples that showcase their transformative power.

Understanding the Purpose of Darts in Garments

Darts are a fundamental element in garment construction, serving as the primary tool for transforming flat fabric into a three-dimensional shape that conforms to the human body. Without darts, most clothing would hang loosely and shapelessly, failing to flatter the wearer’s form. Their precise placement and execution are key to achieving a well-fitting and aesthetically pleasing garment.Darts are essentially folded and stitched seams that taper to a point.

This manipulation of the fabric allows for controlled shaping, creating curves and contours where needed. They provide ease and accommodate the body’s natural curves, such as the bust, waist, and hips, ensuring comfort and a polished appearance.

Historical Significance of Darts

The use of darts in garment construction can be traced back to ancient times, though their sophistication has evolved significantly. Early forms of clothing, such as togas and tunics, relied heavily on draping and simple folds. As tailoring techniques advanced, particularly during the Renaissance and into the Victorian era, the development of fitted garments became more prevalent. This era saw a rise in the understanding of anatomy and the desire for clothing that accentuated the human form.

The dart emerged as a crucial technique to achieve these fitted silhouettes, allowing for the creation of structured bodices, tailored waistlines, and sculpted sleeves that were characteristic of the fashion of the time. The precision and artistry involved in dart manipulation became a hallmark of skilled tailors.

How Darts Manipulate Fabric

Darts work by removing excess fabric in a controlled manner, thereby shaping the material to fit the body’s contours. When a dart is sewn, the fabric is folded along a line, and the seam is stitched from the wider end towards the point. This process effectively reduces the circumference of the fabric in that specific area, creating a sculpted effect.

For instance, a bust dart on a bodice starts at the bust point and tapers towards the side seam or center front, allowing the fabric to curve around the bust without creating unwanted fullness or drag lines. Similarly, waist darts on a skirt or dress taper from the side seam towards the natural waist, cinching the garment to create a flattering hourglass shape.

Common Garment Types Benefiting from Dart Manipulation

A wide array of garments benefit from the strategic use of darts to achieve proper fit and desirable shaping. These essential components are not limited to formal wear but are integral to everyday clothing as well.

- Bodices and Tops: Darts are crucial for shaping bodices to fit the bust, waist, and hips. Bust darts, waist darts, and sometimes shoulder darts are used to create a smooth, fitted silhouette that follows the body’s curves.

- Dresses: Similar to bodices, dresses utilize darts extensively to shape the torso and skirt sections. Princess seams, which can be seen as a form of elongated dart, also contribute significantly to shaping.

- Skirts: Waist darts are a staple in skirt construction, tapering from the side seams or center back to define the waist and allow the skirt to drape smoothly over the hips.

- Trousers and Pants: Darts are used at the waistline and sometimes at the knee or thigh area to accommodate the shape of the legs and create a comfortable, well-fitting pant.

- Jackets and Coats: Tailored outerwear relies heavily on darts to create structure and shape, particularly around the bust, waist, and shoulders, to achieve a sophisticated and fitted look.

Identifying Common Dart Types

Understanding the different types of darts and their applications is key to successfully adding shape to garments. Each type serves a specific purpose in manipulating the fabric to achieve desired contours.

| Dart Type | Description | Primary Application |

|---|---|---|

| Single-Pointed Dart | A triangular fold of fabric that tapers to a single point. | Waist shaping, bust shaping, and accommodating shoulder curves. |

| Double-Pointed Dart (Fish-Eye Dart) | A dart that tapers to a point at both ends, typically sewn from the center outwards. | Used for more complex shaping, often in the bust area, to create a rounded effect without a prominent seam line. |

| Curved Dart | A dart where the stitching line is curved, allowing for a more natural fit around rounded areas. | Often used for bust darts to better follow the curve of the breast. |

| French Dart | A single-pointed dart that originates from the side seam and angles towards the bust point. | Commonly used in women’s wear to shape the bust and waist. |

Types of Darts and Their Applications

Darts are fundamental to garment construction, serving as folded and stitched seams that create shape and dimension. Understanding the various types of darts and their specific applications allows sewers to expertly tailor clothing to the human form, achieving flattering silhouettes and comfortable fits. Each dart type possesses unique characteristics that make it suitable for particular areas of a garment and different fabric weights.

Single-Pointed Darts

Single-pointed darts are the most common type, characterized by a single fold that tapers to a point. They are typically used to shape garments around curves such as the bust, waist, and hips. The construction involves marking a line from the seam allowance to the apex of the dart, folding the fabric along the center line of the dart, and stitching from the raw edge to the point.

This creates a triangular or diamond shape that effectively removes excess fabric and conforms the garment to the body.

Double-Pointed Darts

Double-pointed darts, also known as fish-eye darts, are formed with two points that meet in the middle. They are constructed by stitching from both ends towards a central apex. This type of dart is particularly useful for creating a smooth, rounded shape, especially in areas where a single-pointed dart might create an unwanted crease or bulk. They are frequently employed in tailored jackets, bodices, and sleeves to achieve a more refined and sculpted fit, offering a sophisticated solution for complex shaping.

Bust Darts versus Waist Darts

Bust darts and waist darts are distinct in their placement and primary function, though both aim to contour fabric to the body. Bust darts are designed to accommodate the fullness of the bust, typically originating from the side seam, waist seam, or neckline and pointing towards the apex of the bust. They are crucial for achieving a good fit in the upper torso of women’s garments.

Waist darts, on the other hand, are primarily used to cinch in the fabric at the waistline, creating a more defined silhouette. They usually run from the side seam or from the center front/back towards the natural waist. While both darts remove excess fabric, bust darts are oriented to the curve of the breast, whereas waist darts are focused on reducing circumference at the narrowest part of the torso.

French Darts

French darts are a variation of single-pointed darts that originate from the side seam and curve diagonally upwards towards the bust apex. They are often used in blouses, dresses, and tailored garments to provide subtle shaping and a flattering fit without the visual prominence of traditional bust darts. The gentle, diagonal line of a French dart can contribute to a more streamlined and elegant aesthetic, enhancing the overall design of the garment by offering a less obvious yet effective method of contouring.

Darts for Different Fabric Weights

The choice of dart style and construction can be influenced by the weight and drape of the fabric being used.

- Lightweight Fabrics (e.g., silk chiffon, voile, lawn): These fabrics benefit from darts that are as unobtrusive as possible. Single-pointed darts, especially French darts, are ideal as they can be sewn precisely and pressed flat, minimizing bulk. Double-pointed darts can also be used if a more rounded shape is desired, but care must be taken to ensure the points are sharp and the stitching is fine.

- Medium-Weight Fabrics (e.g., cotton poplin, linen blends, quilting cotton): Most dart types are suitable for medium-weight fabrics. Single-pointed darts are a staple for shaping the waist and bust. Double-pointed darts work well for creating more structured shapes in bodices and jackets.

- Heavyweight Fabrics (e.g., denim, wool suiting, canvas): For heavier fabrics, darts need to be substantial enough to create the desired shape but also manageable to avoid excessive bulk. Single-pointed darts are commonly used, and it is often beneficial to press them towards the center front or back to reduce visual disruption. Double-pointed darts can be used, but the stitching needs to be strong, and the fabric may require easing at the point to prevent stiffness.

In some very heavy fabrics, multiple smaller darts might be used instead of one large dart to distribute the shaping more evenly.

Measuring and Marking Darts Accurately

Accurate dart measurement and marking are fundamental to achieving a well-fitting and aesthetically pleasing garment. Darts are the primary method for incorporating shaping into flat fabric, transforming it into a three-dimensional form that conforms to the body’s curves. Precision at this stage ensures that the garment will lie smoothly, without pulling or puckering, and that the intended silhouette is successfully realized.The process begins with understanding the specific dart placements indicated on your sewing pattern.

These placements are designed to accommodate the body’s natural contours, such as the bust, waist, and hips. Careful measurement and transfer of these lines are crucial, as even minor inaccuracies can lead to significant fitting issues. This section will guide you through the essential steps to ensure your darts are both precise and symmetrical.

Taking Body Measurements for Dart Placement

To ensure darts are placed correctly for a custom fit, it’s essential to take accurate body measurements. These measurements are typically taken directly from the pattern, but understanding how they relate to your body is key. For instance, bust darts are designed to accommodate the fullest part of the bust, while waist darts shape the garment to the natural waistline.

Hip darts provide contouring around the hip area.When working from a commercial pattern, the dart measurements are already incorporated. However, if you are drafting your own pattern or making significant alterations, you’ll need to measure specific body points. These often include the full bust circumference, the distance from the waist to the apex of the bust, and the waist and hip circumferences.

Always use a flexible measuring tape and keep it parallel to the floor for consistent results.

Transferring Dart Lines from Pattern to Fabric

Once your pattern pieces are prepared and laid out on the fabric, the next critical step is accurately transferring the dart lines. This ensures that when you sew the dart, you are following the intended design lines that will create the garment’s shape. There are several reliable methods for this transfer, each suited to different fabric types and personal preferences.Consider the fabric’s weight and texture when choosing your marking tool.

For lighter fabrics, tailor’s chalk, a fabric pen that disappears with heat or water, or even a fine-tipped pencil can be effective. For darker or heavier fabrics, a contrasting color of tailor’s chalk or a white fabric pen is often necessary. Always test your chosen marking tool on a fabric scrap to ensure it is visible and easily removable without damaging the fabric.

Methods for Marking Dart Points Precisely

The termination point of a dart, often referred to as the “dart point” or “apex,” is one of the most critical areas for achieving a smooth finish. If the dart is not sewn to an exact point, it can create a small hole or a visible bubble in the fabric. Precision here is paramount for a professional look.There are several effective techniques for marking dart points:

- Notches: Many patterns include notches at the dart points. You can snip a tiny notch into the seam allowance or transfer these notches to the fabric with your marking tool.

- Transfer Paper and Wheel: Use tailor’s transfer paper (also known as dressmaker’s carbon paper) and a tracing wheel. Place the transfer paper between the pattern and the fabric, and run the tracing wheel along the dart lines and the point.

- Tailor’s Tacks: This traditional method involves creating small loops of thread at the dart points on the pattern. When you transfer these to the fabric, you’ll have a small cluster of threads indicating the point.

- Direct Measurement: Measure the exact distance from the edge of the fabric or a known seam line to the dart point as indicated on the pattern and mark it directly on the fabric.

Ensuring Dart Symmetry on a Garment

Symmetry is essential for a balanced and flattering garment. Darts that are not symmetrical on opposing sides of a garment will be visually apparent and can throw off the overall fit and appearance. This is particularly important for front and back bodices, skirts, and trousers where paired darts are common.When marking darts on symmetrical pattern pieces, such as the left and right front bodice, ensure that the measurements and markings are identical.

It’s often helpful to mark one dart completely, sew it, and then use that sewn dart as a guide for marking and sewing the second dart. Alternatively, you can mark both darts before sewing, carefully double-checking all measurements against the pattern and the fabric.

Checklist for Accurate Dart Measurement and Marking

To ensure that every dart you sew is as accurate as possible, use this checklist before you begin cutting and sewing. This systematic approach will help prevent common errors and lead to a much more professional finish.

- Pattern Verification: Confirm that you are using the correct pattern pieces and that all dart lines are clearly visible and correctly placed on the pattern.

- Fabric Preparation: Ensure your fabric is pre-shrunk and pressed smooth. Any wrinkles can lead to inaccurate measurements.

- Measurement Tool: Use a flexible, accurate measuring tape or ruler.

- Marking Tool Test: Test your chosen marking tool on a fabric scrap to ensure visibility and removability.

- Transferring Lines: Carefully trace all dart legs and the termination point from the pattern to the fabric, using your chosen transfer method.

- Dart Point Precision: Mark the dart point(s) using a reliable method (notches, transfer paper, tailor’s tacks, or direct measurement).

- Symmetry Check: For paired darts, double-check that markings on both sides are identical.

- Grainline Alignment: Ensure that the dart lines are oriented correctly with the fabric grainline as indicated on the pattern.

- Seam Allowance: Be mindful of the seam allowance when marking. Dart lines are typically drawn within the seam allowance to guide the stitch line.

- Final Inspection: Before sewing, visually inspect all marked darts to ensure they match the pattern and appear symmetrical.

Sewing Techniques for Various Dart Types

Now that we understand the purpose, types, and accurate marking of darts, let’s delve into the practical application: sewing them. Mastering these techniques will ensure your garments fit beautifully and look professionally finished. This section will guide you through the sewing process for different dart types, emphasizing best practices for a smooth and precise outcome.Sewing darts is a fundamental skill in garment construction.

The approach can vary slightly depending on the dart’s shape and the fabric type. By following these detailed steps and tips, you’ll be able to confidently sew all types of darts, enhancing the fit and aesthetic of your handmade clothing.

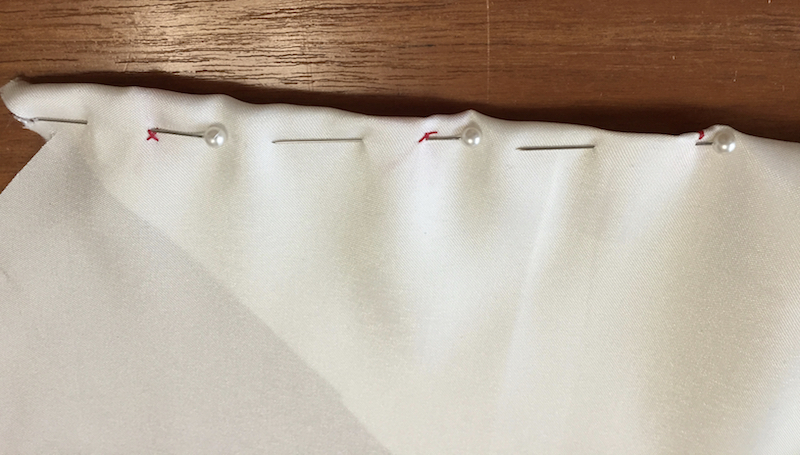

Sewing a Single-Pointed Dart

Single-pointed darts are the most common type, used to shape garments around curves like the bust, waist, or hip. Their simplicity makes them an excellent starting point for learning dart construction.To sew a single-pointed dart, follow these steps:

- Ensure your fabric is pressed well, and the dart markings are clearly visible.

- Fold the fabric so that the two lines of the dart are perfectly aligned, right sides together. The point of the dart should meet the marked single point on the fabric.

- Begin stitching at the raw edge of the fabric, precisely on the marked seam line.

- Stitch towards the dart point, gradually tapering your stitch to a single point at the apex.

- When you reach the dart point, instead of backstitching, continue stitching off the fabric edge for a few stitches, creating a small “tail” of thread. This prevents the dart from unraveling and creates a neat finish.

- Trim the thread tail, leaving it about 1 to 2 inches long.

- Press the dart according to the pattern instructions, usually towards the center front or back, or towards the nearest seam. For bust darts, it’s common to press them downwards.

Sewing a Double-Pointed Dart

Double-pointed darts, also known as fish-eye darts, are used to add fullness and shape in areas where both ends of the dart need to be contained within the garment, such as at the bust or shoulders. They offer a more subtle shaping than single-pointed darts.The procedure for sewing a double-pointed dart is as follows:

- With the fabric right sides together, align the two seam lines of the dart, ensuring the center point is marked accurately.

- Begin stitching at one of the raw edges, on the marked seam line, heading towards the center point.

- As you approach the center, gradually taper your stitches to a single point, just as you would for a single-pointed dart.

- Continue stitching past the center point, again tapering your stitches to a single point at the other marked end.

- Stitch off the fabric edge at the second end, creating a thread tail.

- Trim the thread tails, leaving them about 1 to 2 inches long.

- Press the dart. Typically, both halves of a double-pointed dart are pressed towards the center of the garment (e.g., towards the center front or center back).

Best Practices for Sewing Bust Darts to Avoid Puckering

Bust darts are crucial for achieving a well-fitted bodice, but they can be prone to puckering if not sewn carefully. Puckering occurs when the fabric bunches up or folds unevenly, creating an unsightly ripple.To ensure smooth and pucker-free bust darts:

- Accurate Marking: Double-check your dart markings. Any inaccuracies will be amplified when sewing.

- Stitching Direction: Always stitch from the raw edge towards the bust point. This allows the fabric to ease smoothly into the point.

- Tapering Stitches: As you approach the bust point, gradually reduce your stitch length to a very fine stitch or even hand-stitch the last few stitches. This creates a sharp, neat point without bulk.

- Thread Tail: Leave a generous thread tail (1-2 inches) at the point and do not backstitch. Tie off the threads securely by hand if necessary.

- Pressing: Press the dart flat, usually downwards, after stitching. Use a pressing cloth to protect the fabric, especially if it’s delicate. For a smoother finish, you can press the dart over a tailor’s ham or a rolled-up towel to support the curved shape.

- Gentle Handling: Avoid stretching or pulling the fabric as you sew. Let the machine feed the fabric, guiding it gently.

Finishing the Ends of Darts for a Clean Look

The way you finish the ends of your darts significantly impacts the garment’s overall professional appearance. A clean finish prevents unraveling and adds a polished touch.Here’s how to achieve a clean dart end:

- Thread Tail Method: As described for single and double-pointed darts, stitch off the fabric edge to create a thread tail. After stitching, tie the two thread tails together securely with a knot. This is a simple and effective method for most woven fabrics.

- Backstitching (with caution): While generally discouraged at the dart point to avoid bulk, a very short and discreet backstitch can be used at the

-raw edge* of the dart if the pattern or fabric requires it for extra security. However, avoid backstitching at the apex. - Hand-Stitching: For a truly invisible finish, especially on fine fabrics or at the dart point, you can hand-stitch the last few stitches or tie off the thread tails by hand.

- Trimming: Once the threads are secured, trim them, leaving a small tail of about 1 to 2 inches.

Guide to Sewing Darts on Different Fabric Types

The type of fabric you are working with will influence your dart sewing approach. Some fabrics are more forgiving, while others require extra care to achieve a smooth finish.Here’s a guide for sewing darts on various fabric types:

- Lightweight Wovens (e.g., cotton lawn, voile, silk charmeuse): These fabrics are prone to showing every stitch and can fray easily. Use a fine needle and thread. Stitch slowly and precisely. Pressing is crucial; use a pressing cloth and a medium-low heat setting. Finish dart ends with the thread tail method and tie off securely.

- Medium-Weight Wovens (e.g., quilting cotton, linen blends, poplin): These fabrics are generally easier to work with. You can use a standard needle and thread. Stitch with confidence, and press darts firmly. The thread tail method is usually sufficient for finishing.

- Heavy-Weight Wovens (e.g., denim, canvas, tweed): These fabrics can create bulky darts. Use a sturdy needle and a slightly longer stitch length if necessary. Press darts open or to one side, using a press cloth and high heat. For very thick fabrics, you might consider grading the seam allowances of the dart to reduce bulk before pressing.

- Knits (e.g., jersey, interlock): Darts on knits are less common as knits have inherent stretch. When they are used, they are often sewn with a stretch stitch or a serger. Stitch carefully to avoid stretching the fabric. Pressing on knits should be done with caution and often from the wrong side to avoid stretching or creating a shiny impression.

- Delicate Fabrics (e.g., chiffon, georgette): These require the utmost care. Use a microtex needle and fine thread. Consider using a French seam or a Hong Kong finish on the dart allowance for a very clean internal finish, though this is more advanced. For a simpler approach, stitch with extreme care and press very gently with a pressing cloth on a low heat setting.

Troubleshooting Common Dart Sewing Issues

While sewing darts is a fundamental skill for adding shape and definition to garments, occasional challenges can arise. Understanding these common issues and their solutions will help you achieve professional-looking results and refine your sewing technique. This section addresses frequent problems and provides practical strategies for resolution.Sewing darts can sometimes lead to unexpected outcomes, but with a systematic approach, these can be effectively managed.

By identifying the root cause of an issue, you can apply the appropriate fix to ensure your darts lie smoothly and contribute positively to the garment’s overall fit and appearance.

Puckering at the Dart Point

Puckering at the dart point is a common frustration that can detract from the neatness of a garment. This issue typically occurs due to a few specific reasons related to fabric tension, needle choice, or thread.The primary causes of puckering at the dart point include:

- Fabric Bunching: When the fabric layers are not held smoothly as you sew, they can bunch up at the point where the dart stitches converge. This is often exacerbated by pulling or stretching the fabric during the sewing process.

- Incorrect Needle Size: Using a needle that is too large for the fabric weight can create larger holes, allowing the fabric to push through and bunch. Conversely, a dull needle can snag the fabric, leading to puckering.

- Thread Tension Issues: If the upper or bobbin thread tension is too tight, it can pull the fabric layers together excessively, causing them to pucker.

- Stitch Length: Very short stitch lengths can sometimes create a dense line of stitching that pulls the fabric, especially on delicate materials.

To resolve puckering at the dart point:

- Ensure you are using the correct needle size and type for your fabric. A sharp, appropriate needle is crucial.

- Maintain consistent, gentle pressure on the fabric, avoiding any pulling or stretching as you sew.

- Check and adjust your machine’s thread tension. Often, slightly loosening the tension can help.

- If using a very short stitch length, consider increasing it slightly, particularly for fine fabrics.

- When you reach the dart point, pivot the fabric carefully to sew off the point, rather than stopping abruptly and snipping the threads.

Dart Not Lying Flat

A dart that doesn’t lie flat can disrupt the intended silhouette and create an unsightly bulge. This often happens when the dart hasn’t been pressed correctly or if there are excess fabric or threads hindering a smooth finish.Methods to fix a dart that is not lying flat include:

- Proper Pressing: After sewing, press the dart according to the pattern instructions (usually towards the center front or back, or towards the nearest seam). Use a pressing cloth for delicate fabrics. Ensure you are pressing, not ironing, to avoid stretching the fabric.

- Trimming Excess Fabric: If the dart is bulky, trim the seam allowance of the dart to about 1/4 inch (0.6 cm) after pressing. This reduces bulk and helps it lie flatter.

- Clipping the Dart Point: For single-pointed darts, a small snip into the seam allowance (not through the stitching) at the very tip can help the dart lie flatter. Be extremely careful not to cut into the stitches.

- Understitching: For darts that press towards a seam, understitching can be beneficial. This involves sewing a line of stitches within the seam allowance, very close to the seam line, on the side that the dart is pressed towards. This helps to keep the dart and the seam from rolling out.

Dart Too Long or Too Short

A dart that is too long or too short will affect the fit of the garment, either creating excess fabric or causing a pull. Correcting these issues depends on whether the dart has already been sewn and pressed.Methods for correcting a dart that is too long or too short:

- If Unsewn: If you discover the dart is the wrong length before sewing, simply re-mark the dart according to the correct measurements.

- If Sewn and Too Long: Carefully unpick the stitching from the dart’s end point to the tip. Re-mark the dart to the correct length, ensuring you use the original seam allowance. Press the dart again after re-sewing.

- If Sewn and Too Short: This is a more challenging fix. If the garment is already constructed, you may need to carefully unpick the dart stitching and then re-mark and sew a new dart, extending further. This might involve slightly adjusting the surrounding seam lines to accommodate the change. If the difference is minor, sometimes a slight adjustment during pressing or a strategically placed dart tuck can help disguise the issue without full unpicking.

- If the Issue is Fit-Related (Not Marking Error): If the dart seems too long or short after sewing and it’s causing a fit problem, it might indicate an issue with the pattern itself or how it was interpreted. In such cases, it might require a more significant alteration, potentially involving adding or removing fabric from the seam allowances or adjusting the pattern piece.

Skipped Stitches When Sewing Darts

Skipped stitches can create weak points in your darts and look unprofessional. This problem is usually related to the sewing machine’s setup or maintenance.Advice on how to avoid skipped stitches when sewing darts:

- Needle Condition: Always use a sharp, new needle. Bent or dull needles are a primary cause of skipped stitches.

- Correct Needle Type: Ensure the needle type matches your fabric (e.g., ballpoint for knits, sharp for wovens).

- Thread Quality: Use good quality thread that is appropriate for your fabric. Old or inferior thread can break or tangle, leading to skipped stitches.

- Machine Maintenance: Regularly clean and oil your sewing machine. Lint buildup can interfere with the thread path.

- Thread Path: Double-check that the thread is correctly seated in all the guides and tension discs. Re-threading the machine can often resolve this issue.

- Bobbin Winding: Ensure the bobbin is wound evenly and is correctly inserted into the bobbin case.

Troubleshooting Table for Common Dart Sewing Problems

This table provides a quick reference for identifying and resolving common dart sewing issues.

| Problem | Potential Causes | Solutions |

|---|---|---|

| Puckering at Dart Point | Fabric bunching, incorrect needle, thread tension too tight, short stitch length. | Hold fabric smoothly, use correct needle, adjust tension, try longer stitch length, pivot carefully at point. |

| Dart Not Lying Flat | Improper pressing, excess fabric, bulky seam allowance. | Press correctly, trim dart seam allowance, clip dart point, consider understitching. |

| Dart Too Long/Short | Incorrect marking before sewing, inaccurate pattern. | Re-mark and re-sew if unsewn. Unpick and re-sew if sewn. Adjust pattern if necessary. |

| Skipped Stitches | Dull/bent needle, wrong needle type, poor thread quality, machine lint, incorrect thread path. | Use sharp, correct needle type, good quality thread. Clean machine, re-thread carefully, check bobbin. |

Advanced Dart Techniques and Variations

Beyond the foundational understanding of darts, several advanced techniques and variations can elevate garment construction, offering enhanced fit, stylistic expression, and creative problem-solving. These methods allow sewers to refine their skills and achieve professional-level results, transforming simple garments into tailored masterpieces.Exploring these advanced techniques unlocks a new dimension in dart manipulation, enabling sewers to tackle complex fitting challenges and infuse garments with unique design elements.

By mastering these variations, you can significantly improve the drape, silhouette, and overall aesthetic of your sewing projects.

Easing Fabric Within a Dart

Easing fabric within a dart is a crucial technique for managing excess fullness, particularly in curved areas like the bust or shoulder. This process involves strategically manipulating the fabric as you sew to distribute any slight discrepancies in length or circumference smoothly, preventing puckering or distortion.

- Gentle Stretching: As you sew the dart, a slight, even stretch of the fabric on the side that is slightly longer can help it conform to the shorter side. This is especially useful when sewing a dart where the seam allowance of one side is fractionally longer than the other.

- Slight Gathering: In instances of more noticeable fullness, very fine, almost imperceptible gathering can be introduced as you sew. This is achieved by gently easing the longer edge of the fabric into the shorter edge, allowing small pleats to form within the seam allowance, which are then pressed flat.

- Pre-Basting and Steaming: For stubborn areas, basting the dart first and then carefully steaming it can help the fabric relax and conform. Once the steam has set the shape, you can then sew the dart permanently.

- Bias Cutting: When working with fabrics that have a strong bias stretch, understanding how the fabric behaves is key. Sometimes, a slight bias stretch can naturally accommodate minor fullness differences without explicit easing techniques.

Darts as Stylistic Design Elements

Darts are not solely functional; they are powerful tools for creating visual interest and shaping garments in unique ways. Their placement, length, and curvature can dramatically alter the silhouette and add sophisticated design details.

- Contour Darts: These are curved darts, often used in place of straight darts, to create a more sculpted and form-fitting silhouette, especially around the bust and hips. They follow the natural curves of the body more closely, resulting in a smoother, more anatomical fit.

- Princess Darts: While technically a type of contour dart, princess seams are often referred to separately. They are long, curved seams that run from the shoulder or armhole down to the hem, effectively replacing traditional bust and waist darts and offering excellent shaping capabilities.

- Decorative Darts: Darts can be intentionally exaggerated or placed in unconventional locations to serve as a design feature. For example, multiple, closely spaced darts on a bodice or skirt can create a textured, pleated effect.

- Yoke Darts: Darts can be incorporated into yokes to add subtle shaping and volume, particularly in blouses and shirts. These darts can release fullness from the yoke into the main body of the garment.

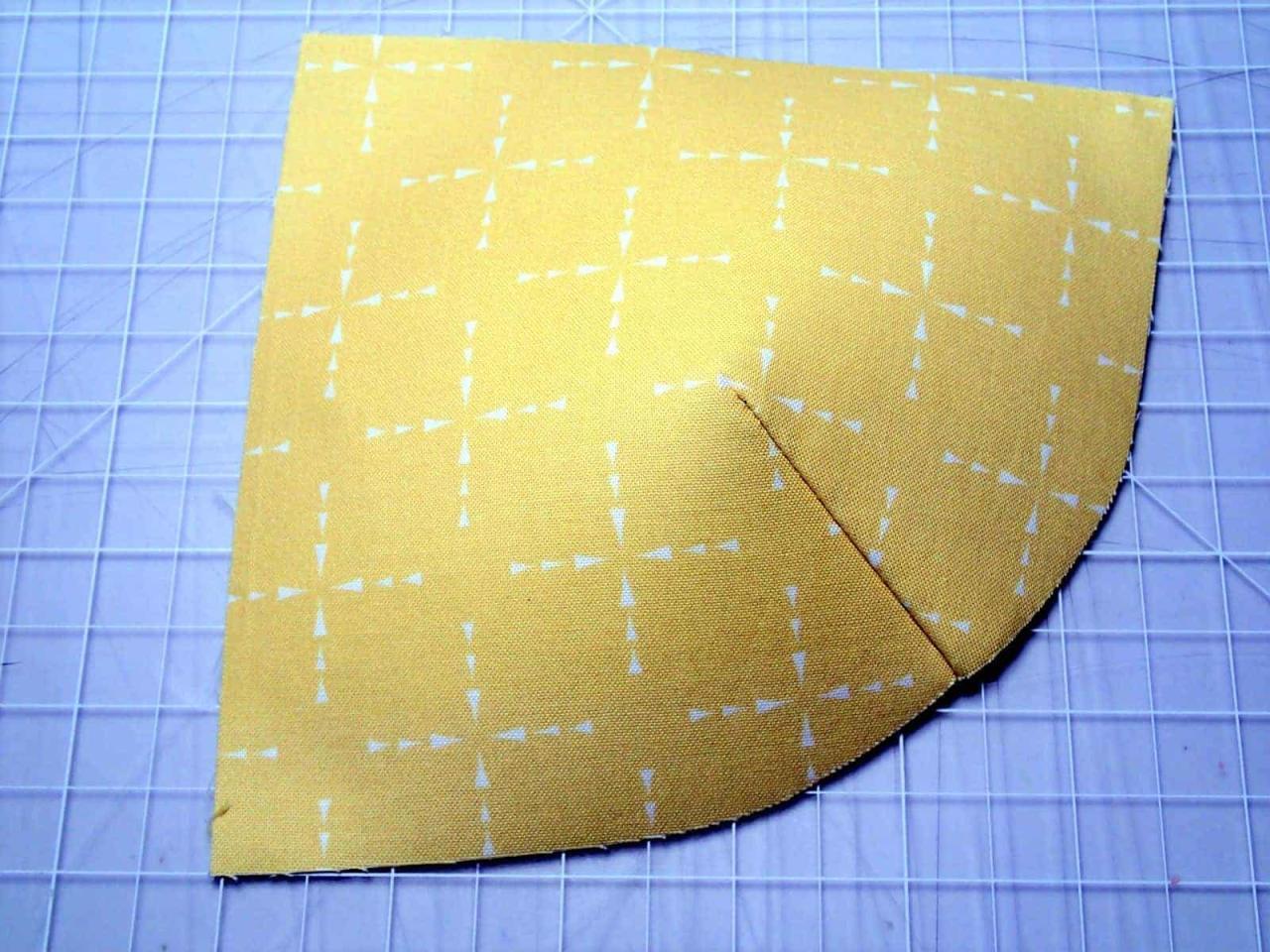

Methods for Creating Curved Darts

Creating curved darts requires precision and a slightly different approach than sewing straight darts. The goal is to maintain a smooth, consistent curve throughout the dart’s length, ensuring a flattering fit.

- Accurate Marking: The first step is to meticulously mark the curved dart lines onto the fabric. Use a tailor’s chalk or a fabric marker that is easily removed. Ensure the curve is smooth and symmetrical if it’s a pair of darts.

- Sewing with a Gentle Hand: As you sew, guide the fabric smoothly along the marked curve. Avoid pulling or stretching the fabric. Instead, allow the fabric to feed through the machine naturally, following the drawn line.

- Gradual Pivot: When approaching the apex of a curved dart, pivot the fabric very gradually. If the curve is sharp, you may need to stop with the needle down and slightly adjust the fabric’s angle before continuing.

- Pressing with a Tailor’s Ham: After sewing, pressing a curved dart is best done over a tailor’s ham or a curved pressing pillow. This allows the dart to retain its shape without flattening unnecessarily, ensuring a rounded, sculpted appearance.

Incorporating Darts into Set-In Sleeves

Darts are essential for achieving a well-fitting set-in sleeve, as they help to shape the sleeve cap to match the armhole curve and manage the fabric’s fullness.

- Sleeve Cap Darts: These are typically two or three small darts sewn into the sleeve cap. They help to ease the fullness of the sleeve cap into the armhole, preventing unwanted gathers or drag lines. The apex of these darts usually points towards the shoulder seam.

- Elbow Darts: For fitted sleeves, an elbow dart is often incorporated into the underside of the sleeve. This dart is curved and positioned to allow for natural arm movement, preventing the sleeve from pulling or feeling restrictive. It typically runs from the elbow point downwards.

- Apex Placement: The placement of the apex of the sleeve cap darts is critical. If placed too far forward or backward, it can cause the sleeve to twist or hang incorrectly. Generally, they are distributed evenly around the top curve of the sleeve cap.

Impact of Different Dart Apex Placements on Garment Fit

The precise location of a dart’s apex has a significant impact on how a garment fits and drapes. Even slight variations can alter the intended silhouette and comfort.

- Bust Darts: The apex of a bust dart should ideally align with the fullest part of the bust. If the apex is too low, it can create a droopy appearance. If it’s too high, it can cause the fabric to pull upwards and create an unnatural shape. The apex placement determines where the dart “ends” and where the shaping is most concentrated.

- Waist Darts: For waist darts, the apex should point towards the natural waistline. If the apex is placed too high or too low, it can make the waist appear distorted or create unflattering bulges.

- Shoulder Darts: The apex of a shoulder dart, often found in the back of blouses or jackets, should be placed to release fullness smoothly towards the neckline or shoulder seam. Incorrect placement can lead to drag lines or a lack of smooth transition.

- Stylistic Considerations: While fit is paramount, apex placement can also be used for stylistic effect. For example, elongating a dart or placing its apex slightly off the natural body curve can create a unique design element.

The precision of dart apex placement is fundamental to achieving both a flattering fit and a well-executed design.

Creating Visual Examples of Darts in Clothing

Visualizing how darts transform flat fabric into sculpted garments is key to understanding their impact. By examining specific garment types, we can appreciate the subtle yet significant ways darts shape clothing to fit the human form. This section provides descriptive examples to help you envision these transformations.

Bodice Silhouette Enhancement with Waist Darts

Imagine a standard rectangular piece of fabric intended to form the front of a bodice. Without darts, this fabric would hang loosely, creating a shapeless silhouette. When waist darts are introduced, typically one or two on each side of the front and back bodice pieces, they are stitched to a point at the natural waistline. This process removes excess fabric, drawing the material inward and upward.

The result is a garment that hugs the torso, defining the waist and creating a more feminine and fitted shape. The visual effect is a smooth, contoured line from the bust to the hip, eliminating any boxy appearance and providing a flattering silhouette that accentuates the wearer’s natural curves.

Bust Accommodation and Enhancement with Bust Darts

Consider a simple T-shirt pattern. To make it fit a female form, bust darts are essential. A common type is the single-pointed bust dart, which originates from the side seam or the armhole and tapers to a point just below the bust apex. When sewn, this dart creates a triangular fold of fabric that projects outward. This projection perfectly accommodates the natural curve of the bust, preventing the fabric from pulling or stretching across this area.

Visually, this results in a rounded, well-defined bustline, rather than a flattened or distorted one. The dart essentially shapes the fabric to mirror the three-dimensional form of the bust, leading to a more comfortable and aesthetically pleasing fit that enhances the overall appearance of the garment.

Hem Flare Creation with a Single-Pointed Skirt Dart

Picture a basic A-line skirt pattern. If this pattern were cut and sewn without any shaping, the hem might hang straight down, lacking movement. A single-pointed dart placed strategically at the hem, often on the side seams or center front/back, can alter this. This dart is typically sewn from the hem upwards, tapering to a point a few inches above the hemline.

By stitching this dart, a small amount of fabric is effectively removed from the seam allowance at the hem. This subtle removal causes the fabric at the hem to subtly angle outwards. The visual outcome is a gentle flare at the skirt’s hem, adding a touch of elegance and allowing for easier movement without the need for a fuller skirt pattern.

Seat Contouring with Angled Trousers Darts

Envision the back of a pair of trousers. The seat area is curved, and flat fabric needs to be shaped to accommodate this. Angled darts at the back of trousers, often originating from the waistband and angling downwards towards the seat curve, are crucial for this. These darts are typically sewn to a point that sits within the fullest part of the seat.

When stitched, they create a three-dimensional pocket of fabric that molds to the rounded shape of the buttocks. Visually, this eliminates pulling and sagging at the back of the trousers, creating a smooth, sculpted fit that follows the natural contours of the body. The result is a more tailored and flattering appearance for the seat area.

Ending Remarks

In conclusion, mastering the art of sewing darts is an essential skill for any aspiring or experienced seamster. By understanding their purpose, exploring different types, employing accurate measurement and sewing techniques, and knowing how to troubleshoot common issues, you can elevate your garment construction to new heights, creating well-fitted and aesthetically pleasing clothing. The ability to strategically place and sew darts allows for unparalleled control over silhouette and fit, turning simple fabric into wearable art.