As How to Sew a Lapped Zipper takes center stage, this opening passage beckons readers into a world crafted with good knowledge, ensuring a reading experience that is both absorbing and distinctly original.

This comprehensive guide delves into the art of installing a lapped zipper, a classic technique that adds a polished and professional finish to garments. We will explore its unique characteristics, understand its advantages, and meticulously walk through each step, from preparation to the final touches, ensuring a successful and beautiful outcome for your sewing projects.

Understanding Lapped Zippers

A lapped zipper is a common and versatile fastener used in garment construction, known for its neat and professional appearance. It is designed to be almost entirely concealed within the seam, offering a clean finish that is particularly desirable in dresses, skirts, and trousers. Understanding its characteristics and proper installation is key to achieving a polished final product.The fundamental concept of a lapped zipper involves one side of the zipper tape being sewn flat against the seam allowance, with the other side folded over it, creating a flap that covers the zipper teeth.

This creates a smooth, uninterrupted surface on the exterior of the garment.

Visual Characteristics of a Lapped Zipper

The defining visual characteristic of a lapped zipper is its near invisibility from the right side of the garment. Unlike exposed zippers or even centered zippers where the teeth might be partially visible, a lapped zipper is designed so that the fabric of the garment forms a neat overlap covering the entire zipper mechanism. The stitching that secures the zipper is typically placed very close to the edge of this overlap, further concealing the zipper tape and teeth.

This creates a clean, sleek line that integrates seamlessly with the garment’s design.

Applications of Lapped Zippers

Lapped zippers are frequently chosen for their subtle integration into various garment types. They are especially popular in:

- Dresses: Providing a discreet closure for side seams or back seams without disrupting the garment’s silhouette.

- Skirts: Offering a clean finish for the back or side closures of pencil skirts, A-line skirts, and more.

- Trousers: Often used in the side seams of tailored trousers or as a fly closure, though a fly zipper is a specific type of lapped zipper.

- Formal wear: Where a refined and understated closure is paramount.

Advantages of Using Lapped Zippers

The lapped zipper offers several distinct advantages for sewing projects, making it a preferred choice for many seamstresses and designers.

- Aesthetic Appeal: The primary advantage is the clean, almost invisible finish it provides, enhancing the overall look of the garment.

- Durability: When installed correctly, a lapped zipper is very secure and can withstand regular use.

- Professional Finish: It imparts a high-quality, professional look that is often associated with ready-to-wear garments.

- Versatility: It can be used on a wide range of fabrics, from delicate silks to sturdy denims.

Essential Tools and Materials for Lapped Zippers

Successfully installing a lapped zipper requires specific tools and materials to ensure accuracy and a professional outcome.

Before beginning, ensure you have the following readily available:

- Zipper: A zipper of appropriate length for your project. It is advisable to purchase a zipper that is slightly longer than needed, as it can be shortened if necessary.

- Sewing Machine: Equipped with a zipper foot. A zipper foot is crucial for stitching close to the zipper teeth.

- Thread: Matching thread to your fabric and zipper.

- Pins or Clips: To hold the zipper and fabric in place before sewing.

- Fabric: The garment or project where the zipper will be installed.

- Iron and Ironing Board: For pressing seams and the zipper flap, which is a critical step in achieving a neat finish.

- Seam Ripper: In case of any mistakes.

Preparing for Lapped Zipper Installation

Proper preparation of your fabric is paramount to achieving a professional and durable lapped zipper. This phase involves precise marking, careful pressing, and strategic reinforcement to ensure the zipper lies flat and the fabric around it remains strong. Neglecting these steps can lead to puckering, unevenness, and potential tearing, diminishing the overall quality of your garment.This section will guide you through the essential preparatory steps, ensuring a smooth and successful lapped zipper installation.

We will cover the accurate marking of the zipper opening, the importance of pressing fabric edges, techniques for reinforcing stress points, and common mistakes to sidestep.

Marking the Zipper Opening

Accurate marking of the zipper opening is the foundation for a perfectly placed lapped zipper. This ensures that the zipper is centered and the overlap is consistent.The procedure for accurately marking the zipper opening on fabric is as follows:

- Determine the desired zipper length and mark the top and bottom points of the zipper insertion area on the right side of the fabric. This is typically done by measuring from the neckline or waistline, depending on the garment.

- On the seam allowance of one of the fabric pieces that will enclose the zipper, mark the zipper stop point. This is where the zipper will end at the top. This mark should align with the top of the zipper teeth.

- Measure and mark the width of the zipper opening. For a lapped zipper, this is usually the width of the zipper teeth plus a small amount for ease. A common measurement is 1/2 inch (1.25 cm) from the edge of the fabric. This line represents the stitching line for the zipper tape.

- Transfer these markings to the corresponding fabric piece, ensuring symmetry.

Pressing and Preparing Fabric Edges

Pressing the fabric edges correctly before inserting the zipper is crucial for creating a neat and flat finish. This step helps to control the fabric and ensures the zipper tape lies smoothly against the garment.The proper method for pressing and preparing fabric edges for zipper insertion involves:

- Press the seam allowance of the zipper opening to the wrong side of the fabric. This creates a crisp fold that will serve as a guide for stitching.

- On the fabric piece that will form the overlap, press the seam allowance to the wrong side, aligning the folded edge with the marked zipper opening line. This creates the visible lap of the zipper.

- Ensure that the pressed edges are sharp and straight. Use a pressing cloth if necessary to protect delicate fabrics.

Reinforcing Fabric at Zipper Ends

The ends of a zipper, particularly the top and bottom, are subject to stress. Reinforcing these areas prevents tearing and ensures the longevity of the garment.Techniques for reinforcing the fabric at the zipper ends include:

- Bar Tacks: Before stitching the zipper in place, sew several tight, short stitches back and forth across the top and bottom of the zipper opening on the seam allowance. This creates a strong reinforcement that mimics a bar tack and significantly reduces the risk of tearing.

- Interfacing: For lighter fabrics, consider applying a small piece of lightweight interfacing to the wrong side of the fabric at the zipper ends. This adds stability and strength without adding bulk. Cut a small rectangle of interfacing and fuse or stitch it to the fabric before marking the zipper opening.

- Heavy Duty Thread: When sewing the initial seam allowance or when applying bar tacks, use a strong thread that matches your fabric to ensure durability.

Common Pitfalls in Fabric Preparation

Several common mistakes can undermine the success of a lapped zipper installation if not carefully avoided during the fabric preparation phase.Common pitfalls to avoid during the fabric preparation phase include:

- Inaccurate Marking: Failing to mark the zipper opening precisely can lead to a crooked zipper or an uneven overlap. Always double-check your measurements.

- Insufficient Pressing: Skipping or inadequately pressing the seam allowances will result in a bulky and uneven zipper application. Crisp folds are essential for a clean finish.

- Neglecting Reinforcement: Not reinforcing the zipper ends is a frequent oversight that can lead to fabric tearing around the zipper, especially with frequent wear and washing.

- Stretching Fabric: Be mindful not to stretch the fabric while marking or pressing, as this can distort the opening and affect the final appearance of the zipper.

- Ignoring Grainline: Ensure that your fabric is cut on the correct grainline. Deviations can cause the fabric to lie unevenly around the zipper.

Attaching the Lapped Zipper

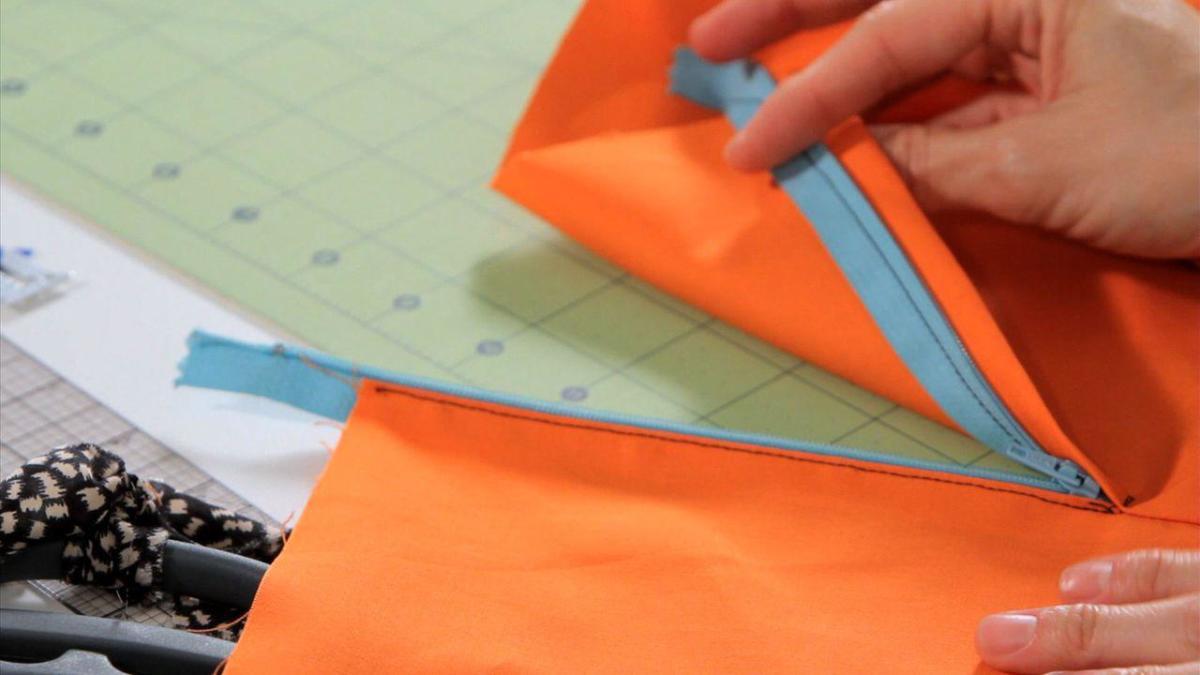

With the zipper tape and fabric edges prepared, the next crucial step is to securely attach the zipper to your garment. This process requires precision to ensure the characteristic neat overlap of a lapped zipper and a smooth, professional finish. We will now detail the steps involved in this attachment, from initial pinning to final stitching.

Pinning the Zipper Tape to Fabric Edges

Accurate placement of the zipper tape is paramount for a successful lapped zipper installation. This initial pinning step sets the foundation for all subsequent sewing.To begin, lay the fabric piece with the zipper opening flat, right side up. Place the zipper face down onto the seam line, aligning one edge of the zipper tape with the raw edge of the fabric.

Ensure the zipper teeth are positioned directly over the seam allowance line you previously marked. Pin the zipper tape securely to the fabric, placing pins perpendicular to the edge, about every 2-3 inches. Repeat this process for the other side of the zipper opening, ensuring the zipper is centered and the teeth are aligned.

Basting the Zipper in Place

Before committing to permanent stitching, basting the zipper provides an opportunity to check the alignment and ensure a smooth fit. This temporary stitching helps hold the zipper firmly in position.Several methods can be employed for basting:

- Hand Basting: Using a long, running stitch with a contrasting thread, hand-baste along the edge of the zipper tape, close to the teeth. This allows for easy removal of the basting stitches later.

- Machine Basting: Set your sewing machine to a long stitch length (around 4mm) and a straight stitch. Sew close to the edge of the zipper tape, as you would for hand basting. This method is quicker but requires careful attention to avoid sewing through the zipper teeth.

- Wash-Away Tape: For a very secure temporary hold, you can use double-sided wash-away tape specifically designed for fabric. Apply the tape along the seam allowance and press the zipper tape onto it.

Stitching the First Side of the Lapped Zipper

The first side of the lapped zipper requires careful stitching to establish the correct seam allowance and ensure the zipper is integrated seamlessly.Using a zipper foot on your sewing machine, begin stitching approximately one inch from the top of the zipper. Sew along the edge of the zipper tape, staying within the marked seam allowance. It is crucial to stitch directly on top of your seam line, ensuring the zipper teeth are encased within the seam allowance.

Backstitch at the beginning and end of your stitching to secure the seam. The goal here is to stitch through the zipper tape and the fabric layer only, not through the zipper teeth themselves.

Folding and Pressing the Seam Allowance for the Lap

Creating the characteristic lap of this zipper type involves precise folding and pressing of the seam allowances. This step defines the visible overlap.Once the first side of the zipper is stitched, press the seam allowance containing the zipper tape away from the garment’s center front or opening. Next, fold the opposite seam allowance over the zipper tape, encasing it completely.

The width of this fold should align with your initial seam allowance measurement, creating a clean, even lap. Press this fold firmly to create a crisp crease. This fold will cover the stitched zipper tape and create the neat overlap.

Stitching the Second Side of the Lapped Zipper

Stitching the second side secures the lap and completes the visible zipper installation, demanding attention to detail for a professional appearance.With the lap folded and pressed, you will now stitch along the folded edge to secure it in place. Using your zipper foot, stitch close to the folded edge of the lap, again staying within your marked seam allowance. Start your stitching at the bottom of the zipper and work your way up, ensuring you catch the folded seam allowance and the underlying zipper tape.

Backstitch at the beginning and end. For an extra professional finish, you can consider stitching a second line of stitching very close to the zipper teeth, further securing the lap and providing a clean, defined line.

Trimming Excess Zipper Tape

After the zipper is securely stitched, any excess zipper tape can be trimmed to create a tidy finish.Carefully trim away any excess zipper tape extending beyond the top or bottom of the garment opening. It is advisable to leave a small amount of tape (about half an inch) at the top and bottom for reinforcement and to prevent the zipper pull from coming off.

Trim the tape as close to the stitching line as possible without cutting through the stitches. This final step ensures a clean and professional look to your lapped zipper installation.

Finishing and Perfecting the Lapped Zipper

Now that the lapped zipper is attached, the focus shifts to ensuring a polished and professional final appearance. This stage involves refining the details to make the zipper not only functional but also an attractive element of your garment. Achieving a clean lap, smooth operation, and proper securing of the zipper ends are key to a successful outcome.A well-executed lapped zipper enhances the overall quality of your sewing project.

It demonstrates attention to detail and contributes to the garment’s longevity and wearability. Let’s explore the techniques that elevate a basic zipper installation to a professional standard.

Achieving a Clean and Professional Zipper Lap

The characteristic of a lapped zipper is a single fold of fabric that covers the zipper teeth, creating a neat and streamlined look. To achieve this, precise folding and stitching are essential. The underlap should be pressed firmly away from the zipper teeth, and the top lap should be folded over to conceal the zipper tape. The edge of this top lap should be stitched close to the folded edge, creating a clean, straight line that runs parallel to the zipper.To ensure a crisp lap, consider these techniques:

- Accurate Folding: After the initial basting or stitching of the zipper, carefully press the fabric that forms the lap. The fold line should be sharp and consistent.

- Edge Stitching Precision: When topstitching the lap, use a consistent seam allowance from the folded edge. A walking foot on your sewing machine can help feed the fabric evenly and prevent shifting.

- Understitching (Optional but Recommended): For an even cleaner finish, understitch the seam allowance of the underlap to the zipper tape. This helps the lap lie flat and prevents it from rolling to the outside.

- Pressing Throughout: Continuous pressing at each step, from initial pressing of the lap fold to the final pressing of the finished zipper, is crucial for a professional look.

Ensuring Smooth Zipper Pull Movement

A zipper that snags or is difficult to operate detracts from the garment’s overall appeal and functionality. Ensuring the zipper pull moves freely is a critical finishing step. This involves checking for any obstructions, ensuring proper tension, and lubricating the teeth if necessary.The smooth operation of the zipper pull is a testament to careful installation and finishing. Here’s how to ensure it:

- Check for Fabric Obstructions: Carefully examine the zipper tape and the surrounding fabric to ensure no threads or fabric edges are caught in the zipper teeth.

- Zipper Tape Alignment: Verify that the zipper tape is not twisted or puckered, as this can impede the slider’s movement.

- Zipper Slider Tension: The slider should move with moderate resistance, not too tight that it requires force, nor too loose that it feels flimsy. If the slider feels stiff, a small amount of zipper lubricant (like beeswax or a graphite pencil rubbed on the teeth) can help.

- Testing the Full Range: Zip the zipper up and down several times, paying attention to any points where it feels stiff or catches. Address these areas immediately.

Troubleshooting Common Lapped Zipper Issues

Even with careful preparation, issues like puckering or uneven stitching can arise. Identifying and rectifying these problems promptly will lead to a superior finish. Early detection and the application of appropriate techniques can salvage a potentially flawed installation.Common challenges and their solutions include:

- Puckering: Puckering often occurs when the fabric is stretched during stitching or when the machine tension is too high. To fix minor puckering, try gently steaming the area (without direct iron contact) to relax the fibers. For more significant puckering, you may need to carefully unpick the stitching and re-stitch, ensuring even fabric feed and appropriate machine tension. Using a longer stitch length can also help prevent puckering on delicate fabrics.

- Uneven Stitching: Inconsistent stitch lines can result from an unsteady hand or a sewing machine that isn’t feeding fabric evenly. Ensure your presser foot is appropriate for the fabric and that you are guiding the fabric gently, not pushing or pulling. A walking foot is highly recommended for even topstitching on tricky fabrics. If the stitching is significantly uneven, unpicking and re-stitching with more care is the best solution.

- Zipper Teeth Showing: If the zipper teeth are visible after the lap is folded and stitched, it indicates that the lap was not folded wide enough or the topstitching was placed too far from the folded edge. Carefully unpick the topstitching and re-stitch closer to the folded edge.

Methods for Securing the Bottom of the Lapped Zipper

The bottom of the zipper requires secure fastening to prevent it from pulling apart during wear. Several methods can be employed, each offering a different level of security and aesthetic. The choice of method often depends on the fabric weight, garment type, and desired finish.Different approaches to securing the zipper bottom include:

- Bar Tacks: A strong and durable method, bar tacks are short, dense stitches made by a sewing machine or by hand. They are typically placed at the very bottom of the zipper, extending slightly onto the fabric for reinforcement. This is ideal for garments that experience a lot of stress, such as trousers or skirts.

- Reinforcing Stitch: A simple box stitch or a few reinforced straight stitches can also secure the bottom. This involves stitching back and forth several times across the bottom end of the zipper tape, ensuring it’s firmly attached to the garment fabric.

- Hand Stitching (Blind Stitch): For a nearly invisible finish, the bottom of the zipper can be secured with a strong hand stitch, such as a whipstitch or a small catchstitch, taking care to catch only a few threads of the garment fabric. This is a good option for delicate fabrics or when a completely seamless look is desired.

- Securing to the Underlap: In some cases, the bottom of the zipper tape can be stitched to the underlap fabric as part of the seam finishing, effectively locking it in place.

Lapped Zipper Quality Control Checklist

To ensure your lapped zipper installation meets a high standard, use this checklist to review your work before considering the project complete. This systematic approach helps catch any overlooked details and guarantees a professional and functional finish.Before deeming your lapped zipper installation complete, confirm the following:

- The zipper lap lies flat and smooth without puckering or lifting.

- The topstitching on the lap is straight, even, and consistent in width.

- The zipper pull operates smoothly without snagging or catching.

- The zipper teeth are completely concealed by the fabric lap.

- The bottom of the zipper is securely fastened to prevent it from pulling away.

- The overall appearance of the zipper is neat and complements the garment.

- There are no visible loose threads or unfinished edges around the zipper area.

- The length of the zipper opening is as intended and functions correctly.

Advanced Lapped Zipper Techniques

While mastering the basic lapped zipper is a significant achievement, exploring advanced techniques allows for greater versatility and a more professional finish in your sewing projects. This section delves into adapting the lapped zipper for various materials, tackling challenging applications like curved seams, and incorporating different zipper types for aesthetic and functional purposes. We will also cover refined methods for concealing zipper ends and creating decorative effects.Adapting lapped zipper installation to different fabric weights and types is crucial for achieving a polished and durable result.

The principles remain the same, but the execution requires careful consideration of needle choice, thread weight, and seam finishing. For instance, working with delicate fabrics like silk or chiffon necessitates lighter needles and threads to prevent snagging or distortion, while heavier materials such as denim or canvas can accommodate sturdier tools.

Adapting Lapped Zipper Installation for Fabric Variations

The key to successfully installing a lapped zipper on diverse fabrics lies in understanding how each material behaves under the needle and with the tension of the zipper. Adjusting your sewing machine settings and choosing appropriate notions are paramount.

- Lightweight Fabrics (e.g., silk, chiffon, voile): Use a fine, sharp needle (e.g., size 60/8 or 70/10). Opt for a fine polyester or silk thread. Consider using a very lightweight interfacing on the zipper tape and the fabric under the zipper to prevent stretching and puckering. A walking foot can be beneficial for even feeding.

- Medium-Weight Fabrics (e.g., cotton, linen, quilting cotton): A universal needle (e.g., size 70/10 or 80/12) is generally suitable. All-purpose polyester thread works well. Standard interfacing is usually sufficient.

- Heavyweight Fabrics (e.g., denim, canvas, upholstery fabric): Employ a heavier needle (e.g., size 90/14 or 100/16). A strong polyester or heavy-duty thread is recommended. Consider using a heavier weight interfacing, or even a fusible interlining, for added stability.

- Knit Fabrics: While a lapped zipper is less common on very stretchy knits, it can be adapted for more stable knits. Use a ballpoint or stretch needle to avoid damaging the fabric fibers. Ensure you stabilize the seam allowance with a non-stretch interfacing or a strip of twill tape to prevent the zipper from stretching out the knit.

Installing a Lapped Zipper on Curved Seams

Installing a lapped zipper on a curved seam presents a unique challenge, requiring precision and careful manipulation of the fabric. The goal is to ensure the zipper tape lies smoothly along the curve without creating pleats or pulling.The most effective method involves pre-shaping the zipper tape and the fabric. Begin by gently easing the fabric along the seam line. For the zipper tape, you can sometimes achieve a slight curve by clipping the edge of the tape at intervals, being careful not to cut through the stitching.

However, a more controlled approach for pronounced curves involves using a method similar to setting in a sleeve.

- Prepare the Curve: Sew a staystitch line on the seam allowance of the fabric where the zipper will be installed. This prevents stretching.

- Pre-shape the Zipper Tape: For subtle curves, you may be able to gently press the zipper tape into a curve. For sharper curves, you might need to create small, shallow darts or pleats on the zipper tape itself, ensuring they are placed on the side that will be enclosed within the lap.

- Baste the Zipper: Carefully baste the zipper to the fabric, aligning the zipper teeth with the seam line. Work slowly, easing the fabric and the zipper tape together. Use plenty of pins to secure the zipper in place.

- Stitch with Care: When stitching, use a zipper foot. Stitch slowly, guiding the fabric and zipper tape to follow the curve smoothly. You may need to pivot at points of significant curvature.

- Trim and Finish: Once stitched, carefully trim any excess seam allowance and finish the raw edges as appropriate for your fabric.

It is often beneficial to practice this technique on scrap fabric first to gain confidence and refine your approach.

Considerations for Invisible or Metallic Lapped Zippers

While the standard metal or plastic coil zipper is common for lapped installations, using invisible or metallic zippers can offer distinct aesthetic and functional advantages.

- Invisible Zippers: These zippers are designed to be nearly hidden. For a lapped zipper effect with an invisible zipper, the technique is slightly modified. Instead of the zipper tape being exposed, the teeth are carefully positioned to be concealed beneath the lapped fabric. This requires precise placement and often a special invisible zipper foot. The lap itself will be sewn over the concealed zipper teeth, creating a very clean and seamless look.

This is particularly effective in garments where a smooth, uninterrupted line is desired.

- Metallic Zippers: Metallic zippers, with their distinct sheen, can add a decorative element to a lapped zipper. They are often used in fashion garments or accessories. When installing a metallic zipper as a lapped zipper, consider the weight and stiffness of the zipper. Heavier metallic zippers might require a stronger needle and thread, similar to working with heavyweight fabrics. The metallic finish can also be prone to scratching, so careful handling during installation is advised.

Ensure the lap fabric is positioned to showcase the metallic sheen without obscuring it entirely, depending on the desired effect.

Strategies for Concealing Zipper Ends

A truly professional lapped zipper finish involves skillfully concealing the zipper ends, both at the top and the bottom. This prevents fraying, provides a neat appearance, and enhances the garment’s durability.

Concealing the top zipper end typically involves folding the end of the zipper tape back onto itself and securing it with a few hand stitches or by stitching it down within the seam allowance of the waistband or facing. Another common method is to create a small fabric tab or facing that encases the top of the zipper. For the bottom zipper end, especially in skirts or dresses, it’s often integrated into the hem construction.

This can be achieved by folding the zipper tape up and securing it to the underside of the hem, or by incorporating it into a faced hem where the facing is stitched to the zipper tape.

Guide for Creating a Decorative Lapped Zipper Effect

A decorative lapped zipper moves beyond pure function to become a design feature. This can be achieved through various methods, transforming a standard zipper into an embellishment.

To create a decorative lapped zipper effect, consider the following approaches:

- Contrast Stitching: Use a contrasting thread color to stitch the lap. This highlights the zipper’s presence and adds a graphic element. For example, on a dark denim skirt, bright red topstitching along the zipper lap would be a bold statement.

- Decorative Topstitching: Beyond simple contrast stitching, employ decorative stitch settings on your sewing machine, such as a zigzag or a special embroidery stitch, to embellish the edge of the lap over the zipper.

- Exposed Zipper Tape with Embellishment: In some fashion contexts, the zipper tape itself is intentionally left partially exposed and then embellished. This could involve embroidery directly onto the visible zipper tape, or the application of beads, sequins, or studs along the edge of the tape. For a lapped effect, the lap would be narrower, allowing a portion of the decorated tape to be visible.

- Fabric Contrast in the Lap: Use a different fabric for the lapped section than for the main garment. This could be a contrasting color, texture, or even a print. For instance, a leather lap over a fabric zipper on a jacket would create a luxurious and distinct look.

- Multiple Lapped Zippers: Incorporate multiple, closely spaced lapped zippers as a design element, perhaps running parallel to each other down the front of a dress or the side of a skirt.

When aiming for a decorative effect, always consider how the chosen method will integrate with the overall design of the garment and ensure the embellishments do not interfere with the zipper’s functionality.

Summary

Mastering the lapped zipper installation opens up a realm of refined garment construction. By following these detailed steps, you will confidently achieve a neat, durable, and aesthetically pleasing zipper that enhances the overall quality of your creations. This guide equips you with the knowledge to tackle this technique with precision and style, leaving you with a beautifully finished garment and the satisfaction of a job well done.