How to Sew Smocking with Your Machine offers a comprehensive guide to mastering this intricate textile art using modern sewing technology. This exploration delves into the foundational principles, essential tools, and step-by-step procedures required to achieve beautiful smocking effects with your sewing machine.

We will navigate through understanding various smocking techniques suitable for machine execution, preparing your sewing machine and fabric, and executing basic to advanced smocking stitches. Furthermore, the guide addresses common troubleshooting issues, fabric and design considerations, and the seamless integration of machine-smocked elements into garment construction, promising a rewarding journey for crafters of all levels.

Understanding Smocking Techniques for Machine Sewing

Smocking, a decorative and functional technique used to gather fabric, has a rich history that has evolved significantly with the advent of modern sewing technology. While traditionally a hand-sewing art form, its principles have been adapted for machine execution, making it more accessible and efficient for contemporary sewers. Understanding these fundamental principles is key to successfully replicating smocking effects with your sewing machine.Machine smocking leverages specific stitches and settings to create the characteristic fullness and decorative patterns of traditional smocking.

The core concept remains the same: gathering fabric to create volume and then securing these gathers with decorative stitches that form patterns. The machine offers precision and speed, allowing for consistent results and intricate designs that might be time-consuming to achieve by hand.

Fundamental Principles of Machine Smocking

The essence of smocking, whether by hand or machine, lies in the controlled gathering of fabric. For machine smocking, this is primarily achieved through two methods: pre-gathering the fabric and then embellishing it with decorative stitches, or using specialized machine stitches that simultaneously gather and decorate. The tension of the thread and the stitch density are crucial factors in achieving the desired look and feel.

Properly balanced tension ensures that the fabric gathers evenly without puckering or breaking.

Types of Smocking Stitches Achievable with a Sewing Machine

Modern sewing machines, especially those with embroidery capabilities, can replicate many traditional smocking stitches and introduce new, machine-specific decorative effects. The key is to understand how different stitches function to gather and adorn the fabric.

The following are common types of smocking stitches and techniques that can be achieved with a sewing machine:

- Cable Stitch: This is a foundational stitch that mimics the hand-sewn cable stitch. On a machine, it’s often created using a zigzag stitch with specific settings for width and length, or by using specialized embroidery machine stitches. It creates a raised, rope-like effect.

- Wave Stitch: Similar to the cable stitch in its gathered appearance, the wave stitch creates a softer, undulating pattern. Machine embroidery units or carefully programmed zigzag stitches can produce this effect.

- Honeycomb Stitch: This stitch is a hallmark of true smocking. While traditionally created by hand, some advanced sewing machines and embroidery software can simulate this stitch by creating a dense, interlocking pattern that forms small, hexagonal-like shapes, effectively gathering the fabric.

- Surface Embroidery Stitches: Beyond the primary smocking stitches, machines can be used to add surface embroidery details over pre-gathered fabric. This includes stitches like satin stitch, stem stitch, and various decorative fill stitches to enhance the smocked areas.

- Specialized Smocking Feet and Accessories: Many sewing machines come with or can be fitted with specialized feet, such as smocking feet or pleaters, which help to evenly gather multiple rows of fabric simultaneously, preparing it for decorative stitching.

Historical Context and Evolution of Smocking to Machine Methods

Smocking originated centuries ago as a practical method to control voluminous fabric, particularly in garments worn by men, women, and children. It allowed for ease of movement and breathability, and its decorative appeal quickly made it a favored embellishment. Historically, smocking was exclusively a hand-sewing technique, requiring considerable skill and time. The transition to machine methods began with the invention of the sewing machine itself, which revolutionized garment production.

Early attempts focused on creating gathering stitches and then embellishing them by hand.The development of more sophisticated sewing machines, particularly those with multiple stitch options and later, embroidery capabilities, marked a significant leap. These machines allowed for the automation of both the gathering and decorative stitching processes. The advent of computerized embroidery machines has further expanded the possibilities, enabling the creation of complex smocking patterns with remarkable precision and speed, democratizing a technique once reserved for skilled artisans.

Common Smocking Patterns Suitable for Machine Replication

While the possibilities are vast with modern machines, certain smocking patterns lend themselves particularly well to machine execution due to their repetitive nature and defined stitch structures. These patterns are often found in historical smocking examples and have been adapted for digital designs.

The following smocking patterns are commonly replicated using sewing machines:

- Traditional Geometric Patterns: These include designs like rows of cable stitches alternating with plain fabric, or repeating wave patterns. Their symmetrical and structured nature makes them ideal for machine programming.

- Floral and Leaf Motifs: Many smocking patterns incorporate simplified floral or leaf shapes. These can be achieved using a combination of basic stitches and more intricate embroidery stitches on machines with design capabilities.

- Diamond and Trellis Designs: These patterns, often created by intersecting rows of stitches, can be accurately reproduced by machines, especially those with stitch editing functions.

- Modern Abstract Designs: With the flexibility of computerized embroidery, entirely new abstract patterns can be created, pushing the boundaries of traditional smocking aesthetics. These might involve textured fills, unique stitch combinations, and asymmetrical arrangements.

Essential Tools and Machine Preparations for Smocking

To achieve beautiful and consistent smocking results with your sewing machine, having the right tools and properly preparing your machine is paramount. This section will guide you through the necessary attachments, machine settings, and fabric preparations to ensure your smocking project is a success.Proper machine setup and the selection of appropriate tools significantly impact the quality and appearance of your smocking.

Taking the time to gather the right accessories and configure your machine correctly will prevent frustration and lead to professional-looking results.

Sewing Machine Attachments and Accessories for Smocking

Several specialized attachments and accessories can greatly enhance the smocking process on a conventional sewing machine. These tools are designed to help create the gathers and decorative stitches characteristic of smocking.The following list details essential items:

- Gathering Foot: This foot is designed to automatically gather fabric as you sew, making it ideal for creating the dense pleats needed for smocking. Some gathering feet can be adjusted to control the amount of gathering.

- Smocking Plate or Smocking Disc: These are specifically designed plates that attach to the bobbin case area of some sewing machines. They work with a special twin needle to create parallel rows of decorative stitches that pull the fabric into pleats.

- Twin Needle: Essential for use with smocking plates, a twin needle creates two parallel stitches on the top side of the fabric, while a single bobbin thread catches both stitches on the underside, forming the pleats.

- Piping Foot or Zipper Foot: While not exclusively for smocking, these feet can be helpful for sewing along the edges of smocked areas or for attaching smocked panels.

- Edge Stitch Foot: Useful for stitching close to an edge, which can be beneficial when finishing smocked areas or attaching trims.

Sewing Machine Setup for Smocking Techniques

Setting up your sewing machine correctly is crucial for achieving the desired smocking effect. This involves adjusting tension, stitch selection, and understanding how different techniques require different configurations.The following provides guidance on machine setup:

- Tension Adjustment: For most smocking techniques, especially those using a smocking plate and twin needle, the upper thread tension often needs to be slightly loosened. This allows the bobbin thread to pull the fabric into neat pleats without puckering. It is advisable to test tension on scrap fabric of the same type as your project.

- Stitch Selection: When using a smocking plate, the machine will typically be set to a straight stitch. The width and length of the stitch are determined by the plate itself and the machine’s capabilities. For gathering foot methods, a standard straight stitch is used, with stitch length adjusted for desired gather density.

- Twin Needle Usage: Ensure your machine is capable of using a twin needle and that you have threaded both upper threads correctly. The bobbin thread will work as usual. The machine’s manual will provide specific instructions for twin needle setup.

- Gathering Foot Usage: The gathering foot is attached like a regular presser foot. Adjust the stitch length and the gathering tension (if your machine has this feature) to control how much the fabric is gathered. Experimentation is key to finding the perfect balance.

Needle and Thread Choices for Neat Smocking Stitches

The selection of the right needle and thread is fundamental to achieving professional-looking smocking stitches. The combination impacts the stitch appearance, fabric integrity, and overall neatness of the work.Consider the following for optimal needle and thread choices:

- Needle Type: For smocking with a twin needle and smocking plate, a universal needle or a specific twin needle designed for your machine is recommended. The size of the needle should correspond to the fabric weight; a finer needle (e.g., 70/10 or 80/12) is generally suitable for lighter to medium-weight fabrics.

- Thread Type: High-quality all-purpose polyester thread is generally suitable for both the upper threads and the bobbin. For decorative smocking stitches, you might consider using a slightly finer thread for the upper threads to create a more delicate look, while a slightly stronger thread can be used for the bobbin to ensure durability of the gathers.

- Thread Weight: The weight of the thread should be proportionate to the fabric and the needle size. Using a thread that is too thick can cause skipped stitches or distort the fabric, while a thread that is too fine might break easily.

- Color Matching: For most smocking, the bobbin thread is not visible on the right side of the fabric. However, the upper threads should match your fabric for a cohesive look. If you are intentionally using contrasting threads for decorative effect, ensure they are complementary.

Fabric Preparation for Smocking

Properly preparing your fabric before you begin smocking is a critical step that ensures your stitches lie flat, your gathers are even, and your finished garment has a professional appearance. This involves pre-treatment and accurate marking.The following steps are essential for fabric preparation:

- Pre-washing: Always pre-wash your fabric according to its care instructions. This removes any sizing, dyes, or chemicals and accounts for any shrinkage that might occur. This prevents your finished smocking from distorting after the first wash.

- Ironing: After washing and drying, press your fabric thoroughly to create a smooth surface for marking and sewing. A well-pressed fabric makes accurate marking and stitching much easier.

- Marking Techniques: For smocking, precise marking is essential for creating even rows of stitches.

- Transferring Patterns: If your smocking pattern involves specific designs or motifs, transfer these onto the fabric using tailor’s chalk, a fabric pen that disappears, or a tracing wheel and paper.

- Marking Pleat Lines: For techniques that require uniform pleats, you can mark the lines where your smocking stitches will be sewn. This can be done by folding the fabric and pressing a crease, or by drawing lines with a disappearing fabric marker at regular intervals. The spacing of these marks will determine the density of your smocking.

- Using a Gridded Fabric: Some lightweight cottons and linens have a natural weave that can be used as a guide for marking or even for smocking directly along the threads, ensuring perfect spacing.

- Stabilization (Optional): For very lightweight or slippery fabrics, a lightweight interfacing or stabilizer might be applied to the wrong side of the fabric in the smocking area to provide extra body and prevent stretching or distortion during the smocking process.

Step-by-Step Machine Smocking Procedures

Now that we have a solid understanding of smocking techniques and are prepared with the right tools and machine settings, it’s time to delve into the practical application of machine smocking. This section will guide you through the fundamental stitches and processes involved in creating beautiful smocked designs using your sewing machine, ensuring even fabric manipulation and accurate pattern transfer for a professional finish.The core of machine smocking lies in creating precise stitches that gather and shape the fabric.

We will explore the techniques for achieving common smocking stitches, ensuring that your fabric is gathered uniformly to create the desired fullness and design.

Creating Basic Machine Smocking Stitches

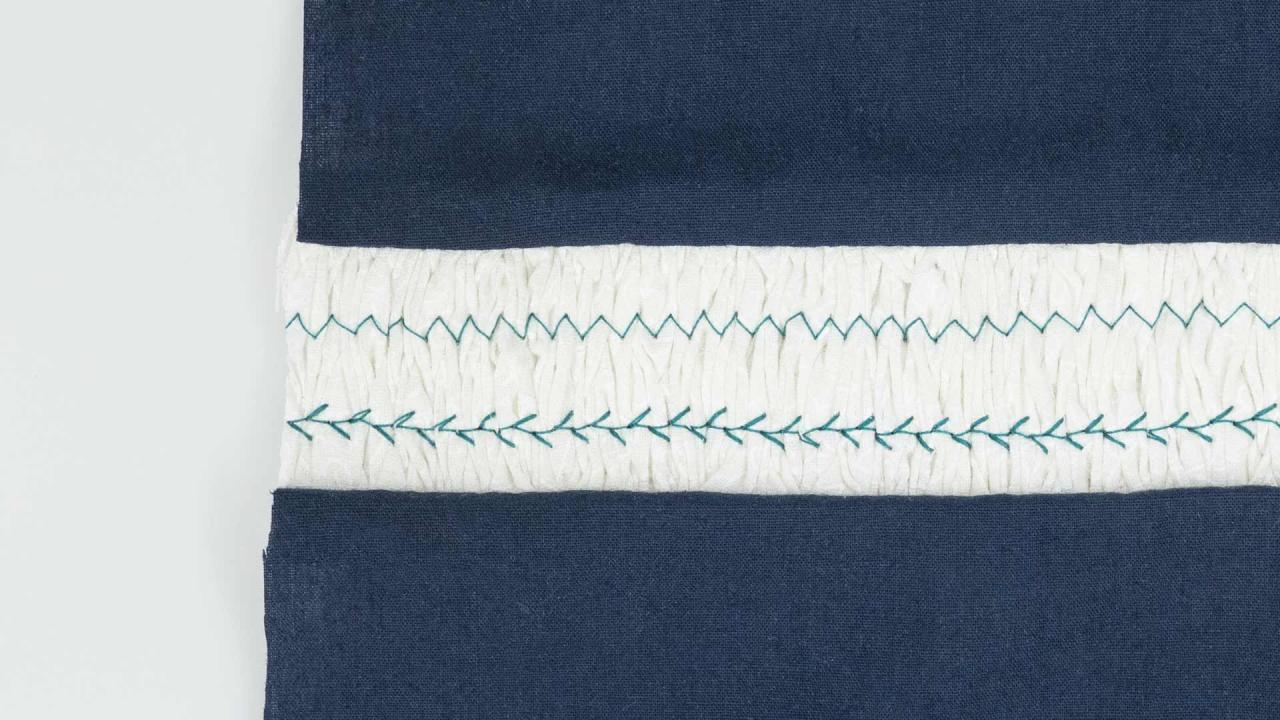

Machine smocking offers efficient ways to replicate traditional hand-smocked patterns. We will focus on two fundamental stitches: the cable stitch, which creates a series of parallel, decorative lines, and the honeycomb stitch, which forms a lattice-like pattern by joining stitches in a staggered arrangement.To demonstrate the cable stitch, begin by setting your machine to a zigzag stitch. Adjust the stitch width to approximately 2.5-3mm and the stitch length to about 1.5-2mm.

Place your fabric right side up, with the pre-gathered threads or elastic in place. Guide the fabric under the presser foot, ensuring the needle penetrates the fabric on one side of the gathering thread or elastic. As you sew, the zigzag stitch will wrap around the gathering element, creating a neat, raised line. For a consistent cable effect, maintain an even tension and guide the fabric smoothly.The honeycomb stitch requires a slightly different approach, often involving two distinct stitch types or careful manual manipulation.

A common machine method involves using a narrow zigzag stitch. First, sew a row of straight stitches or a very short zigzag stitch along the top edge of your fabric to create a stable gathering line. Then, set your machine to a wider zigzag stitch, perhaps 4-5mm wide, and a short stitch length, around 1-1.5mm. Carefully sew a stitch into the fabric, then manually advance the fabric a very small amount (about 1/8 inch or 3mm) and sew another stitch, aiming to catch the edge of the previous stitch.

This creates a small, diamond-like shape. By repeating this, staggering the stitches slightly in subsequent rows, you build the characteristic honeycomb pattern. It’s crucial to practice this on scrap fabric to achieve consistent spacing and tension.

Techniques for Gathering Fabric Evenly for Smocking

Achieving even gathers is paramount for successful smocking, as it directly impacts the final appearance and fit of your garment. Machine methods can significantly speed up this process while maintaining accuracy.There are several effective methods for gathering fabric evenly with a sewing machine:

- Using a Gathering Foot: This specialized foot is designed to gather fabric as you sew. It typically has slots that allow the fabric to feed through and be gathered automatically. You sew a straight stitch, and the foot gathers the fabric behind the needle. Experiment with different stitch lengths and tensions to find the perfect gathering effect.

- Using Elastic Thread: Wind a bobbin with elastic thread and use a regular stitch on your machine. Sew parallel lines of stitching on the wrong side of your fabric. As you sew, the elastic thread will contract, gathering the fabric. Ensure you maintain consistent spacing between your rows of stitching.

- The Two-Row Straight Stitch Method: Sew two parallel lines of long straight stitches (the longest stitch length your machine offers) within your seam allowance on the wrong side of the fabric. Leave long thread tails at the beginning and end of each row. Gently pull the bobbin threads of both rows simultaneously to gather the fabric to your desired width. Distribute the gathers evenly by nudging them along the threads.

Regardless of the method chosen, it is essential to test your gathering technique on a swatch of your fabric to ensure the desired fullness and evenness before applying it to your project.

Methods for Working with Smocking Patterns and Transferring Them to Fabric

Accurate pattern transfer is the foundation of well-executed smocking. Whether you are following a commercial pattern or creating your own design, precise placement of the smocking stitches is key.Here are the common methods for working with smocking patterns and transferring them to fabric for machine sewing:

- Pattern Paper and Marking Tools: Many smocking patterns are printed on specialized paper with dots or lines indicating where stitches should be placed. You can lay this pattern paper directly onto your fabric and trace the markings using a water-soluble or air-erasable fabric pen. Ensure the pattern is perfectly aligned with the grain of the fabric.

- Transfer Paper and Wheel: For simpler patterns or when the pattern paper is not reusable, you can use carbon transfer paper designed for fabric. Place the transfer paper between the pattern and your fabric, then use a tracing wheel to firmly trace over the pattern lines. This will leave a faint mark on the fabric.

- Iron-On Transfer Pens/Pencils: Some patterns or custom designs can be drawn onto a special transfer paper with iron-on pens or pencils. Once drawn, you iron the paper onto your fabric, transferring the design. This method is excellent for intricate or freehand designs.

- Doodling/Freehand: For experienced sewers or when following a very simple design, you can mark stitch lines directly onto the fabric using a ruler and fabric marker. This requires a keen eye for symmetry and spacing.

When transferring patterns, always double-check your measurements and alignment. It is often helpful to mark the center point of your pattern and your fabric to ensure symmetrical placement.

Workflow for Completing a Smocked Panel on a Garment

Creating a smocked panel as part of a garment involves a logical sequence of steps to ensure a seamless integration of the smocking with the rest of the project. Following a structured workflow will lead to a more professional and aesthetically pleasing result.A typical workflow for completing a smocked panel on a garment using a sewing machine would be as follows:

- Prepare the Smocking Panel Area: Identify the area on your garment that will be smocked. This might be the yoke of a dress, the front of a blouse, or cuffs. Ensure this area is properly interfaced if required by the pattern for stability.

- Transfer the Smocking Pattern: Accurately transfer your chosen smocking pattern onto the designated fabric area of the garment, following the methods described previously. Mark all stitch points or lines clearly.

- Pre-Gather the Fabric (if applicable): If your smocking design requires gathering (e.g., for cable or honeycomb stitches), perform the gathering process on the smocked panel area using your chosen machine technique. Gather the fabric to the width specified by your pattern or design.

- Sew the Smocking Stitches: Using your sewing machine and appropriate stitch settings, carefully sew the smocking stitches over the transferred pattern. Work methodically, ensuring each stitch is placed accurately and that tension is consistent. For honeycomb smocking, you may need to sew in multiple rows, working from top to bottom or bottom to top as per the pattern.

- Secure and Finish the Smocking: Once all smocking stitches are completed, gently knot or secure any loose threads on the wrong side of the fabric. Trim excess threads. For some smocking techniques, a final pressing might be required, being careful not to flatten the smocking texture.

- Integrate the Smocked Panel: Attach the completed smocked panel to the rest of your garment according to your sewing pattern instructions. This might involve sewing side seams, attaching it to a bodice, or completing other construction steps.

- Final Pressing: Give the entire garment a final press, paying attention to the smocked area to ensure it lies flat and the design is crisp.

Troubleshooting Common Machine Smocking Issues

As you become more proficient with machine smocking, you may encounter a few common challenges. Addressing these issues promptly and effectively will ensure your smocking projects maintain a professional and polished appearance. This section focuses on identifying these recurring problems and providing practical solutions to keep your sewing experience smooth and enjoyable.Understanding the root cause of an issue is the first step towards a successful resolution.

Many smocking problems stem from a few key areas: tension, stitch length, thread quality, and machine preparation. By carefully examining these elements, you can often diagnose and correct most smocking difficulties.

Uneven Stitches and Puckering

Uneven stitches and puckering are perhaps the most frequent frustrations in machine smocking. Puckering, in particular, occurs when the fabric bunches up between the smocking stitches, creating an undesirable gathered effect. This can happen due to a few interconnected factors, including incorrect tension settings, the wrong type of needle or thread, or an improperly prepared sewing machine.To address uneven stitches and puckering:

- Adjust Thread Tension: Start by checking your machine’s upper and bobbin thread tension. For smocking, a slightly looser upper tension and a balanced bobbin tension often yield the best results. If the stitches are too tight on the top, the fabric will pull and pucker. Experiment with small adjustments, testing on a scrap piece of fabric first.

- Select the Right Needle and Thread: A sharp, fine-point needle (such as a universal or microtex needle in a size 70/10 or 80/12) is crucial. A dull or too-large needle can create larger holes and lead to puckering. Use good quality, all-purpose polyester thread. Avoid heavy or textured threads for smocking as they can snag and break, contributing to unevenness.

- Stabilize the Fabric: For very fine or slippery fabrics, consider using a temporary stabilizer on the wrong side of the fabric. This can be a lightweight tear-away stabilizer or even a very thin fusible interfacing, which can be removed after smocking.

- Maintain Consistent Fabric Feed: Ensure the fabric is feeding evenly through the machine. Avoid pulling or pushing the fabric as you sew. Allow the feed dogs to do their work.

Thread Breakage During Smocking

Thread breakage can be incredibly disruptive, especially when working on intricate smocking patterns. This issue often indicates a problem with the thread path, the needle, or the tension. It’s essential to identify the exact point where the thread is breaking to pinpoint the cause.Preventing and resolving thread breakage involves:

- Inspect the Thread Path: Ensure the thread is correctly threaded through all the guides, tension discs, and the presser foot. Sometimes a burr on a metal guide or a snagged thread in the bobbin area can cause breakage.

- Check the Needle: As mentioned earlier, a damaged or dull needle can cause thread breakage. Replace the needle frequently, especially when working with different fabric types or after extended sewing sessions. Ensure the needle is inserted correctly and securely.

- Review Tension Settings: If the tension is too tight, it can put excessive stress on the thread, leading to breakage. Conversely, if the tension is too loose, the stitches might be uneven, and the thread could snag.

- Use Quality Thread: Inexpensive or old thread can be brittle and prone to breaking. Invest in good quality sewing thread that is appropriate for your fabric and project.

- Clean Your Machine: Lint buildup in the bobbin case or tension discs can interfere with smooth thread flow. Regularly clean your sewing machine, especially the bobbin area.

Maintaining Consistent Tension and Stitch Length

Achieving professional-looking smocking relies heavily on maintaining consistent tension and stitch length throughout your project. Inconsistency in these areas can result in a lumpy, uneven, and unprofessional finish.To ensure consistent results:

- Test on Scraps: Before starting on your actual project, always test your stitch length and tension settings on a scrap piece of the same fabric. Make several stitches and examine the front and back to ensure they look balanced and the fabric is not puckering.

- Understand Your Machine’s Settings: Familiarize yourself with your sewing machine’s stitch length dial and tension adjustments. For smocking, a shorter stitch length is generally preferred to create defined pleats. The exact setting will vary depending on your machine and fabric.

- Regularly Monitor Tension: Periodically check your stitches as you sew. If you notice a change in stitch appearance, stop and readjust your tension. This is especially important when changing thread types or fabrics.

- Even Fabric Handling: As you sew, guide the fabric smoothly without pulling or pushing. This consistent feed ensures that the stitches are evenly spaced and the fabric is not distorted.

Preventative Measures for Common Smocking Errors

Proactive steps are often the most effective way to avoid smocking errors. By preparing your machine and materials properly, you can significantly reduce the likelihood of encountering problems.Key preventative measures include:

- Proper Machine Setup: Ensure your machine is clean, oiled, and has a new, appropriate needle inserted correctly. Check that the bobbin is wound evenly and inserted properly.

- Fabric Preparation: Pre-wash your fabric to account for any shrinkage. Press your fabric smooth before starting to ensure an even sewing surface.

- Accurate Pattern Transfer: If your smocking pattern requires marking, use a method that is visible but easily removable and won’t damage the fabric. Precise markings help ensure even stitch placement.

- Thread Selection: Always use a good quality thread that is compatible with your fabric. Consider using a slightly thinner thread for the bobbin than for the top thread if you’re having trouble with tension balance.

- Practice First: If you are new to smocking or using a new technique, practice on a similar fabric scrap. This allows you to get a feel for the stitch, tension, and fabric handling before committing to your final project.

Fabric and Design Considerations for Machine Smocking

Selecting the right fabric and thoughtfully considering your design are crucial for achieving beautiful and successful machine-smocked projects. The interaction between fabric type, weight, and fiber content significantly influences how the smocking stitches lay, the overall drape of the garment, and the final aesthetic. Understanding these elements will empower you to make informed choices that enhance your smocking creations.

Optimal Fabrics for Machine Smocking

Certain fabric types are inherently better suited for machine smocking due to their weave, weight, and fiber composition. These fabrics allow the smocking stitches to gather evenly, create well-defined pleats, and maintain their shape without becoming overly stiff or distorted.

- Lightweight to Mid-weight Cottons: Cotton lawn, voile, quilting cotton, and chambray are excellent choices. They are breathable, easy to press, and hold a smocked design beautifully. Their natural fibers respond well to the tension of the sewing machine.

- Linen Blends: A blend of linen and cotton or rayon can offer a lovely drape and a slightly more textured appearance to smocking. Pure linen can sometimes be a bit too stiff for intricate smocking, but blends often strike a good balance.

- Rayon and Viscose: These fabrics offer a beautiful drape and a silky feel, making them ideal for more elegant smocked garments like blouses or dresses. They require careful handling due to their tendency to shift.

- Silk Blends: For high-end projects, silk blends can provide a luxurious sheen and a soft hand. Ensure the silk content isn’t too fine, as it might be difficult to control during the smocking process.

Impact of Fabric Weight and Fiber on Smocking Appearance

The physical properties of a fabric directly translate into the visual outcome of your machine smocking. Understanding this relationship helps in predicting how your chosen fabric will behave with smocking stitches.

- Lightweight Fabrics: These fabrics will produce a more delicate and airy smocked effect. The gathers will be finer, and the overall garment will have a softer drape. Be mindful of potential sheerness and consider a lining or a more opaque fabric choice for the underlying layers.

- Mid-weight Fabrics: Mid-weight fabrics, such as quilting cottons, offer a good balance. They allow for well-defined smocking stitches without appearing too bulky or stiff. This weight is versatile for a wide range of garments, from children’s wear to home decor items.

- Heavyweight Fabrics: While possible, heavyweight fabrics like denim or canvas are generally not ideal for traditional smocking. The stitches may become lost in the fabric’s thickness, and the resulting smocking can appear stiff and lack fluidity. If using heavier materials, consider simpler smocking patterns or decorative stitching that doesn’t rely on extensive gathering.

- Natural Fibers (Cotton, Linen, Silk): These fibers tend to breathe well and hold shape, making them excellent for smocking. They press crisply and provide a stable base for the stitches.

- Synthetic Fibers (Polyester Blends): Polyester blends can offer durability and wrinkle resistance. However, they may not have the same breathability or natural drape as pure fibers. Ensure the blend has a soft hand and doesn’t feel overly slick, which can make stitching more challenging.

Thread Selection for Machine Smocking

The thread you choose plays a significant role in both the appearance and durability of your smocked designs. It should complement the fabric and the intended aesthetic of the project.

- Matching Thread: For a subtle and integrated look, use a thread color that closely matches your fabric. This allows the smocking pattern itself to be the focus, creating a sophisticated and understated effect.

- Contrasting Thread: A contrasting thread color can highlight the smocking stitches and add a bold, decorative element. This is particularly effective on solid-colored fabrics and can be used to create graphic designs within the smocking. Ensure the contrast is intentional and complements the overall color scheme of the garment.

- Thread Types:

- All-Purpose Polyester Thread: This is a reliable and versatile choice for most machine smocking projects. It’s strong, durable, and comes in a vast array of colors.

- Cotton Thread: For 100% cotton fabrics, using a cotton thread can create a more cohesive and natural feel. It might not be as strong as polyester but offers a beautiful finish on cotton garments.

- Silk Thread: For luxurious silk projects, a silk thread can be the perfect match, offering a subtle sheen and excellent compatibility.

- Specialty Threads: Consider metallic threads for a touch of sparkle or variegated threads for unique color transitions within your smocking. Test these on a scrap of fabric first to ensure they feed smoothly through your machine.

Matching Smocking Patterns with Garment Styles and Fabrics

The art of smocking is enhanced by thoughtfully pairing specific patterns with appropriate garment styles and fabric choices. This ensures a harmonious and aesthetically pleasing final product.

| Smocking Pattern Type | Recommended Fabric Types | Suitable Garment Styles | Design Considerations |

|---|---|---|---|

| Traditional Cable Stitch | Lightweight to mid-weight cottons (lawn, voile, quilting cotton) | Children’s dresses, blouses, christening gowns | Creates a dense, textured look. Best for areas where significant gathering is desired, like the yoke of a dress. |

| Honeycomb Smocking | Lightweight to mid-weight cottons, linen blends | Blouses, skirts, decorative panels on garments | Produces a delicate, airy, and slightly elastic effect. Works well on softer fabrics that can hold the small, puckered stitches. |

| Wavy or Diamond Smocking | Mid-weight cottons, rayon, silk blends | Dresses, tops, home decor items (pillows) | Offers a more graphic and geometric appearance. Can be used to create bold patterns or subtle textural elements depending on stitch density. |

| Freeform or Abstract Smocking | Wide range, including rayons, silks, and even some lighter denims for avant-garde looks | Unique fashion pieces, accents on jackets, skirts | Allows for creative freedom. The fabric choice will heavily influence the final texture and drape of the abstract design. |

Integrating Machine Smocking into Garment Construction

Machine smocking, with its ability to create beautiful textures and volume, can elevate simple garments into statement pieces. This section focuses on the practical aspects of incorporating these decorative and functional elements into your apparel projects, ensuring a polished and professional finish. We will explore how to seamlessly blend smocked sections with the rest of your garment, from initial planning to the final seam.Integrating machine-smocked panels into garment construction involves careful planning and precise execution.

The smocked area often serves as a focal point, so its placement and integration are crucial for the overall design aesthetic. Whether you are creating a smocked bodice for a dress, a decorative yoke for a blouse, or an elasticated smocked cuff, understanding how to attach and finish these sections will lead to professional-looking results.

Attaching Smocked Panels to Garment Pieces

Seamlessly attaching smocked sections requires attention to detail to ensure the fabric lies flat and the smocking remains undisturbed. The method of attachment will depend on whether the smocked panel is a separate piece being joined or if the smocking is being applied directly to a larger garment section.To achieve a smooth transition between smocked and non-smocked areas, consider the following methods:

- Joining Separate Panels: When a smocked panel is a distinct piece (e.g., a smocked bodice insert), it can be attached to the main garment fabric using standard seam allowances. Press the seam allowances of both the smocked panel and the garment piece away from the seam line. For a cleaner finish on the inside, you might consider enclosing the raw edges of the smocking with a facing or a bias binding, especially if the smocking is very open.

- Applying Smocking Directly to a Garment Section: If you are smocking a portion of a larger piece, such as the upper chest of a blouse or the yoke of a dress, it is essential to mark your smocking area clearly. Once smocked, the excess fabric within the smocking pleats can be trimmed from the wrong side, leaving a small, neat allowance. This trimmed edge can then be interfaced or finished with a lightweight fabric to prevent fraying and provide stability.

- French Seams for Smocked Yokes: For a particularly neat finish, especially on lightweight fabrics, consider using French seams when attaching a smocked yoke to the main body of a garment. This encloses the raw edges entirely within the seam, creating a very clean and professional look on both the inside and outside of the garment.

- Using Interfacing: In some cases, a lightweight fusible interfacing applied to the wrong side of the garment fabric in the area where the smocking will be attached can provide extra stability and prevent stretching, especially if the fabric is delicate or prone to distortion.

Finishing Edges and Seams Around Smocked Areas

The finishing of edges and seams surrounding machine-smocked areas is paramount to the longevity and aesthetic appeal of the garment. Proper finishing prevents fraying, reduces bulk, and creates a professional boundary between the smocked and non-smocked portions.Effective techniques for finishing edges and seams include:

- Trimming and Pressing: After smocking, carefully trim the excess fabric from the wrong side of the smocked panel, leaving a consistent seam allowance. Pressing the seam allowances flat, either towards the smocked panel or away from it, depending on the design, is crucial for a smooth finish.

- Bias Binding: Applying a bias binding to the raw edge of a smocked panel offers a clean and decorative finish. This is particularly effective for curved edges or when you want to add a contrasting color or texture.

- Facing: A facing can be used to enclose the raw edges of a smocked panel, especially at necklines or armholes. This creates a smooth interior finish and adds structure.

- Serging: For a quick and durable finish, particularly on knits or stable wovens, serging the raw edges of the smocked panel before joining it to the garment can be an efficient method. Ensure your serger settings are appropriate for the fabric to avoid stretching or damaging the smocking.

- Hemming: If the smocked section forms the hem of a garment (e.g., a smocked skirt or sleeve), ensure the hem allowance is generous enough to accommodate the smocking and is finished neatly, perhaps with a rolled hem or a narrow double-folded hem.

Project Plan: Smocked Bodice Sundress

This project plan Artikels the creation of a charming sundress featuring a machine-smocked bodice as its central design element. The smocking will provide fullness and decorative texture to the upper part of the dress.

Materials:

- Lightweight cotton or linen blend fabric (e.g., chambray, voile, lawn) for the main dress

- Coordinating thread

- Sewing machine with smocking capability (e.g., gathering foot, smocking plate, or specialized smocking foot)

- Standard sewing machine feet (zipper foot, presser foot)

- Rotary cutter, mat, and ruler

- Fabric scissors

- Pins

- Iron and ironing board

- Measuring tape

- Pattern for a simple sundress (or drafted measurements)

Steps:

- Pattern Preparation: Select a simple sundress pattern. If the pattern does not include a smocked bodice, you will need to adapt it. Measure the desired smocked width and height for your bodice. You will need to cut two bodice pieces (front and back) from your main fabric, allowing extra fabric for the smocking. For example, if your desired finished bodice width is 12 inches, you might cut your fabric pieces to 24 inches wide to allow for the gathering effect of the smocking.

The length will depend on your pattern and desired smocking depth.

- Fabric Cutting: Cut all pattern pieces according to your chosen pattern, including the bodice front and back, skirt panels, and any straps or facings.

- Bodice Smocking:

- Mark the smocking area on the wrong side of each bodice piece. This area will be where the smocking stitches are applied.

- Using your machine’s smocking technique (gathering foot, smocking plate, or other method), carefully smock the marked area on both bodice front and back pieces. Ensure even tension and consistent stitch length for a beautiful, uniform effect.

- Once smocking is complete, carefully trim the excess fabric from the wrong side of the smocked area, leaving a small, neat seam allowance (e.g., 1/2 inch). Press this seam allowance flat.

- Bodice Assembly:

- With right sides together, pin and sew the smocked bodice front to the smocked bodice back at the side seams.

- Finish the raw edges of these side seams using your preferred method (e.g., serging, zigzag stitch).

- Skirt Attachment:

- Gather the top edge of the skirt panels according to your pattern instructions, or if using a gathered skirt, sew multiple rows of gathering stitches.

- With right sides together, pin the gathered top edge of the skirt to the bottom edge of the smocked bodice. Distribute the gathers evenly.

- Sew the skirt to the bodice, securing the gathers.

- Finish the seam allowance. For a neat finish, consider enclosing this seam with a facing or a bias binding.

- Straps/Sleeves: Attach straps or sleeves according to your pattern. If the sleeves are to be smocked, repeat the smocking process as done for the bodice.

- Hemming: Hem the skirt of the dress according to your pattern.

- Final Pressing: Give the entire dress a final press, paying attention to the seams and the smocked bodice to ensure a crisp and professional finish.

Ultimate Conclusion

In conclusion, mastering how to sew smocking with your machine opens a world of creative possibilities, transforming ordinary fabrics into exquisitely detailed creations. By understanding the techniques, preparing your tools, and following systematic procedures, you can confidently tackle everything from simple gathers to complex smocked panels, enhancing garments and textile art with unique texture and visual appeal.