How to Create and Sew Pleats sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail and brimming with originality from the outset. This comprehensive guide delves into the art of pleating, a fundamental yet often intricate sewing technique that can elevate any garment or textile project. From understanding the distinct characteristics of various pleat types to mastering the precise methods for their creation and application, we embark on a journey to transform flat fabric into dynamic, structured designs.

We will explore the essential tools and materials required, ensuring you are well-equipped for success. The process begins with meticulous fabric preparation, moving through the critical steps of accurate marking and measuring, and culminating in the detailed techniques for forming and sewing different pleat styles. Furthermore, this guide addresses common challenges and offers practical solutions, alongside insights into advanced pleating applications that can inspire your creativity.

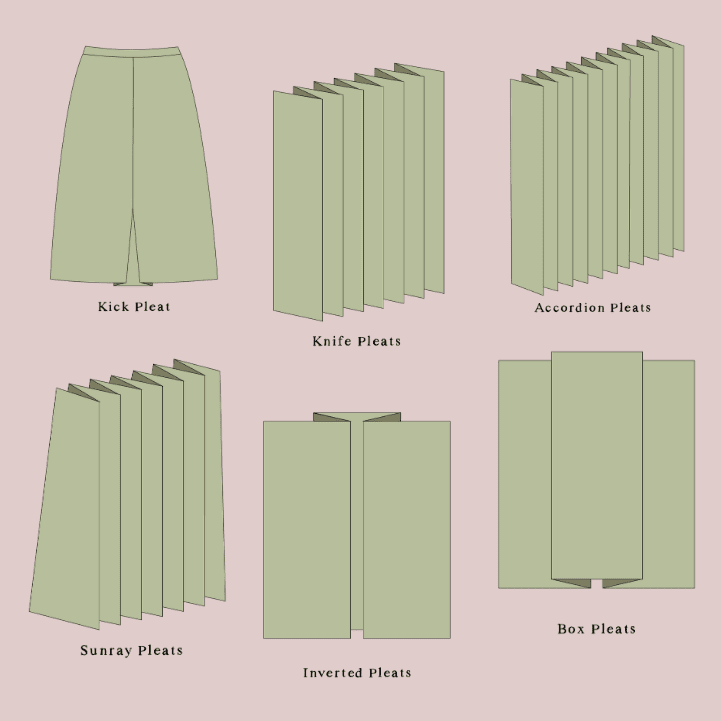

Understanding Pleat Types

Pleating is a fundamental technique in garment construction that adds volume, structure, and decorative flair to fabric. Different pleat types offer distinct visual effects and functional properties, making the choice of pleat crucial for achieving the desired aesthetic and fit. Understanding the characteristics of each pleat style will empower you to select the most appropriate one for your sewing projects.The formation and visual outcome of pleats are determined by how the fabric is folded and secured.

Each type of pleat has a unique way of manipulating the fabric to create depth and shape, influencing the drape and overall silhouette of the finished garment.

Knife Pleats

Knife pleats are characterized by their clean, sharp lines and directional flow. They are formed by folding the fabric in one direction, with each pleat lying flat against the next. This creates a sleek and streamlined appearance, often used for skirts, kilts, and blouses where a smooth, elongated silhouette is desired. The process involves creating a series of parallel folds, each one the same width and pressed in the same direction, resulting in a continuous cascade of fabric.The suitability of fabrics for knife pleats depends on their ability to hold a sharp crease.

- Lightweight to medium-weight fabrics: Cotton, linen, silk, and polyester blends work well. These fabrics have enough body to maintain crisp folds without becoming too bulky.

- Stiffer fabrics: Wool and some synthetic blends can also be used for more structured knife pleats, especially in tailored garments.

- Avoid very drapey or slippery fabrics: While possible, achieving sharp, consistent knife pleats in fabrics like rayon challis or charmeuse can be challenging due to their tendency to shift and not hold a crisp fold.

Box Pleats

Box pleats are created by folding two pleats away from each other, meeting in the center to form a raised ridge. This results in a symmetrical, box-like appearance that adds volume and a more structured, often slightly more voluminous, look compared to knife pleats. Box pleats are frequently used in skirts, dresses, and historical costumes where a fuller silhouette is desired.

Visually, they create two folds that appear to form a box on the right side of the fabric, with the underside of the pleats lying flat.The choice of fabric for box pleats is important for achieving the desired fullness and structure.

- Medium to heavyweight fabrics: Cotton twill, denim, corduroy, and heavier linen blends are excellent choices. These fabrics have the necessary body to support the structure of the box pleat and maintain its shape.

- Fabrics with some stiffness: Wool and suiting fabrics are also well-suited for creating crisp and defined box pleats.

- Fabrics that can hold a crease: The ability of the fabric to be pressed and hold a sharp crease is essential for the visual impact of a box pleat.

Accordion Pleats

Accordion pleats are distinguished by their uniform, narrow folds that resemble the bellows of an accordion. These pleats are created by pressing the fabric in alternating directions, creating a series of sharp, V-shaped creases that allow the fabric to expand and contract. This dynamic characteristic makes accordion pleats ideal for garments that require movement and flow, such as flowing skirts, decorative cuffs, and avant-garde designs.

The visual effect is one of continuous, rhythmic lines.Accordion pleats are best suited for fabrics that can be permanently or semi-permanently set with heat and steam.

- Synthetic fabrics: Polyester and nylon are highly suitable as they respond well to heat setting, allowing accordion pleats to retain their shape.

- Lightweight to medium-weight fabrics with a good drape: Silk, rayon, and some cotton blends can be used, though the longevity of the pleats may vary.

- Fabrics that can withstand heat: The pleating process for accordion pleats often involves heat, so fabrics that can tolerate this are preferred.

- Avoid very thick or bulky fabrics: These can make the pleating process difficult and result in an overly stiff and less visually appealing accordion effect.

Essential Tools and Materials

To successfully create and sew pleats, having the right tools and selecting appropriate materials are fundamental. These elements not only simplify the process but also significantly contribute to the precision and professional finish of your pleated garments. This section will guide you through the essential sewing tools and fabric types that are most conducive to achieving beautiful pleats.Understanding the purpose of each tool and the characteristics of different fabrics will empower you to make informed decisions throughout your pleating project.

This knowledge is key to transforming a flat piece of fabric into a structured and elegant design element.

Sewing Tools for Pleat Creation

A well-equipped sewing kit is crucial for accurate pleat formation. Each tool plays a specific role in measuring, marking, holding, and stitching the fabric to achieve crisp and defined pleats. Investing in quality tools will enhance your efficiency and the final aesthetic of your work.

- Sewing Machine: Essential for stitching pleats securely. A machine with adjustable stitch length and tension control is beneficial for different fabric weights.

- Iron and Ironing Board: Absolutely vital for pressing pleats into place. A good quality iron with steam functionality and a sturdy ironing board will ensure sharp creases.

- Fabric Scissors: Sharp scissors are necessary for precise cutting of fabric, ensuring clean edges that are important for accurate pleat alignment.

- Pins: Used to hold fabric layers together and to mark pleat lines. Fine, sharp pins are preferred to avoid damaging delicate fabrics.

- Seam Ripper: A small but indispensable tool for correcting any mistakes, allowing for precise removal of stitches without harming the fabric.

- Tailor’s Chalk or Fabric Marker: Used for marking pleat lines directly onto the fabric. Choose a marker that is easily removable or fades with heat or water, depending on your fabric.

- Thread: Select thread that matches your fabric in color and is of appropriate weight and fiber content for durability and appearance.

- Needles: Both hand-sewing needles and machine needles are required. Ensure you use the correct type and size of needle for your fabric to prevent snags or skipped stitches.

Recommended Fabric Types for Pleating

The choice of fabric is paramount when creating pleats, as certain materials hold a crease better and drape more elegantly. The weight, weave, and fiber content of the fabric will influence how the pleats form and how they behave when worn.

- Woven Fabrics: These are generally ideal for pleating. Fabrics with a good amount of body and a crisp finish will hold sharp pleats well. Examples include:

- Cotton: Particularly poplin, broadcloth, and quilting cottons, which offer good structure.

- Linen: Offers a natural crispness, though it can wrinkle easily.

- Wool: Suiting weights and worsted wools are excellent for structured pleats in tailored garments.

- Polyester Blends: Many synthetic blends offer excellent wrinkle resistance and crease retention, making them a practical choice.

- Silk: Heavier silks like dupioni or brocade can hold pleats beautifully, while lighter silks might require interfacing for defined pleats.

- Fabrics to Approach with Caution:

- Very lightweight or drapey fabrics (e.g., chiffon, georgette): These may not hold sharp pleats and can be challenging to work with, often requiring interfacing or specialized techniques.

- Knit fabrics: Most knit fabrics are too stretchy and do not hold a pressed crease, making them unsuitable for traditional pleating techniques.

Function of Measuring and Marking Implements

Precision in measuring and marking is the bedrock of successful pleat creation. Without accurate guides, achieving symmetrical and evenly spaced pleats becomes nearly impossible, leading to an uneven and unprofessional appearance. These tools ensure that every pleat is identical, contributing to the overall harmony of the design.Measuring tools provide the dimensions for each pleat, including its depth and width, as well as the spacing between pleats.

Marking implements then transfer these precise measurements onto the fabric, creating visible lines that guide the sewer.

- Measuring Tape: A flexible tape measure is essential for accurately measuring fabric lengths, widths, and the dimensions of individual pleats. It is used to determine the total amount of fabric needed for the desired fullness of the pleats.

- Rulers (e.g., Quilting Ruler, Straight Ruler): Straight rulers, especially those with clear markings, are invaluable for drawing straight lines for pleat guidelines and for ensuring consistent pleat depth. They are particularly useful for marking long, straight pleats.

- Tailor’s Square or L-Square: These tools are helpful for drawing perpendicular lines and for ensuring that pleats are sewn at a perfect 90-degree angle to the edge of the fabric, which is crucial for many pleat types.

- Tailor’s Chalk, Fabric Pencils, or Disappearing Ink Markers: These are used to transfer the measured pleat lines onto the fabric. The choice of marking tool depends on the fabric type and how visible the markings need to be. For delicate fabrics, a fine-tipped disappearing ink marker or a very light tailor’s chalk is recommended.

- Awl: In some instances, a fine awl can be used to make tiny marks on the fabric at the corners of pleats, especially when working with very fine fabrics or when extreme precision is needed.

Preparing Fabric for Pleating

Before you can begin the satisfying process of creating pleats, it’s crucial to prepare your fabric meticulously. This foundational step ensures that your pleats will be crisp, even, and visually appealing, setting the stage for a professional-looking finished garment or project. Proper preparation minimizes the risk of shrinkage or distortion after your pleats are formed, saving you time and frustration.The initial stages of fabric preparation involve ensuring the material is clean and free from any residual sizing or impurities that could interfere with the marking and pressing of pleats.

Following this, creating a perfectly squared fabric edge is paramount for accurate pleat formation, and understanding the grainline is essential for the structural integrity of your pleated design.

Pre-Washing and Pressing Fabric

Pre-washing your fabric is a vital step that simulates the effects of laundering, preventing any unexpected shrinkage or color bleeding after your garment is completed. This is particularly important for natural fibers like cotton and linen, which are prone to significant shrinkage. For delicate fabrics, consider hand-washing or using a gentle cycle.Once washed, the fabric needs to be thoroughly pressed.

This process not only removes wrinkles but also helps to stabilize the fabric, making it easier to mark and manipulate for pleating. A well-pressed fabric provides a smooth, even surface, which is essential for precise pleat formation.

- Washing: Follow the care instructions for your specific fabric. For most fabrics, a warm water wash is suitable.

- Drying: Air-dry fabrics when possible to minimize heat exposure and potential damage. If using a dryer, opt for a low heat setting.

- Pressing: Use an iron appropriate for your fabric type. For cottons and linens, a medium to high heat setting with steam is effective. For synthetics or delicate fabrics, use a lower heat setting and consider a pressing cloth to protect the material. Press the fabric until it is completely smooth and flat.

Squaring Off Fabric Edges

To ensure your pleats are perfectly aligned and symmetrical, it is essential to have square fabric edges. A square edge means that the weft threads (crosswise) are perpendicular to the warp threads (lengthwise). This prevents any distortion or bias in your pleat lines.You can achieve square edges by carefully examining the cut edge of your fabric. If the edge appears uneven or slightly curved, you can use a sharp pair of fabric scissors or a rotary cutter to trim it.

To square off your fabric edges, follow these steps:

- Inspect the cut edge: Look for any stray threads or unevenness.

- Locate a thread: If possible, gently pull a single weft thread from the selvage edge (the finished edge of the fabric). This will create a small opening.

- Cut along the opening: Use sharp scissors or a rotary cutter to cut along the line created by pulling the thread. This will result in a straight, clean edge.

- Repeat for all edges: Ensure all four edges of your fabric are squared off to create a perfect rectangle or square.

Importance of Grainline

The grainline refers to the direction of the threads in woven fabric. The lengthwise grain runs parallel to the selvages, and the crosswise grain runs perpendicular to the selvages. Understanding and respecting the grainline is fundamental to successful sewing, especially when creating pleats.Fabric cut on the straight grain will hang properly and maintain its shape. Cutting fabric off-grain can lead to garments that twist, hang unevenly, or do not drape as intended.

For pleating, accurate cutting on the grainline ensures that the folds of the pleats will fall correctly and maintain their intended sharpness and dimension.

Cutting fabric on the straight grain ensures that your pleats will drape beautifully and hold their intended shape.

When marking and cutting your fabric for pleating:

- Identify the grainline: The lengthwise grain is usually the strongest and has the least stretch. The crosswise grain will have slightly more give.

- Align patterns: If using a pattern, ensure the grainline indicated on the pattern piece aligns with the lengthwise grain of your fabric.

- Marking pleats: When marking your pleat lines, always do so parallel to the lengthwise grain unless the design specifically calls for otherwise. This ensures consistency and proper drape.

- Cutting: Cut precisely along your marked lines, ensuring your scissors or rotary cutter follow the grainline without deviation.

Marking and Measuring Pleats

Accurate marking and measuring are foundational to achieving professional-looking pleats. This stage ensures that each fold is precisely placed, contributing to the overall symmetry and intended drape of the garment or textile. Without meticulous attention to detail here, even the best sewing skills can be undermined by uneven pleats.This section will guide you through the essential steps for marking and measuring pleats, including calculating fabric requirements and establishing a consistent system for your markings.

Calculating Fabric Width for Pleats

Determining the total fabric width needed is a critical first step, as pleats require significantly more fabric than a flat piece. The amount of extra fabric depends on the type of pleat, its depth, and how much fabric is folded back.To calculate the total fabric width, you need to consider the desired finished width and the amount of fabric allocated for each pleat.

For many common pleats, like knife pleats or box pleats, a standard ratio is often used.

Total Fabric Width = Finished Width + (Number of Pleats

Fabric per Pleat)

The “Fabric per Pleat” is the amount of fabric that will be folded and enclosed within the pleat. For instance, in a simple knife pleat where the fabric is folded back on itself, the fabric per pleat is twice the pleat depth. For a box pleat, which involves two folds, it’s typically three times the pleat depth.Let’s consider an example: If you want a finished skirt width of 40 inches and plan to use knife pleats that are 2 inches deep, and you want 10 pleats, the calculation would be:Fabric per Pleat (for knife pleat) = 2

- Pleat Depth = 2

- 2 inches = 4 inches.

Total Fabric Width = 40 inches + (10 pleats

4 inches/pleat) = 40 inches + 40 inches = 80 inches.

Therefore, you would need 80 inches of fabric width for this skirt.

Marking Pleat Allowances

Precisely marking the fold lines and the edge of each pleat is paramount for consistent results. This process involves transferring measurements from your pattern or design to the fabric.The marking process typically involves two key lines for each pleat: the fold line and the stitching line (or the edge of the finished pleat). The distance between these lines determines the pleat depth.Here are the step-by-step instructions for accurately measuring and marking pleat allowances:

- Determine Pleat Depth and Spacing: Based on your design, decide on the desired depth of each pleat and the spacing between them. This will have been calculated in the previous step for the total fabric width.

- Mark the Center of Each Pleat: Using your measuring tape and chalk or a fabric marker, mark the exact center of each pleat. This is often referred to as the “center fold line.” Ensure these marks are equidistant across the fabric. For example, if you have 10 pleats and a total fabric width of 80 inches, and a finished width of 40 inches, you have 40 inches of excess fabric to distribute.

If each pleat requires 4 inches of fabric (2 inches folded back twice), you’d mark these centers every 4 inches within the excess fabric sections.

- Mark the Fold Lines: From the center fold line, measure out half of the pleat depth in both directions and mark these as your fold lines. For a 2-inch deep knife pleat, you would measure 1 inch from the center fold line in each direction and mark these lines.

- Mark the Stitching Lines (or Pleat Edges): Measure from the center fold line outwards by the full pleat depth (which is equivalent to the distance from the center to the fold line plus the amount folded back). Mark these lines. For a 2-inch deep knife pleat, you’ll mark lines 2 inches away from the center fold line in each direction. These lines represent where the pleat will be pressed or stitched down.

- Verify Measurements: Before proceeding, double-check all your markings to ensure they are accurate and consistent across the entire fabric width. Measure the distance between the stitching lines to confirm the finished pleat width.

Organizing a System for Consistent Pleat Lines

Maintaining consistency across all pleats is crucial for a professional finish. A systematic approach to marking will prevent errors and ensure symmetry.A reliable method for marking consistent pleat lines involves creating a template or using a specialized ruler. This ensures that each pleat is marked identically.

- Using a Pleating Template: For complex or repetitive pleating, you can create a template. This could be a piece of cardstock or stiff paper with notches cut out to represent the pleat depth and spacing. You lay this template on the fabric and trace the lines.

- Employing a Quilting Ruler and Fabric Marker: A quilting ruler with clear markings is excellent for this task. You can use it in conjunction with a fabric marker or chalk. Place the ruler on the fabric, align it with your previously marked center lines, and mark the fold and stitching lines at the correct distances.

- Batch Marking: If you have a large piece of fabric, consider marking a section at a time. For example, mark the first few pleats, then use those as a guide for the next section, ensuring the spacing remains uniform.

- Visual Alignment: When marking, always align your measuring tool with the selvage edge or a pre-marked straight line on the fabric to maintain parallelism. This prevents pleats from becoming skewed.

- Reinforcing Marks: For delicate fabrics or if the markings might fade, consider using a temporary basting stitch along the marked lines to ensure they remain visible throughout the pleating process.

Creating Different Pleat Styles (Methods and Procedures)

Understanding the distinct methods for creating various pleat styles is fundamental to achieving professional and aesthetically pleasing results in your sewing projects. Each pleat type requires specific folding, pressing, and securing techniques to maintain its shape and structure. This section will guide you through the creation of three common pleat styles: knife, box, and accordion pleats, detailing their procedures and comparing their complexity.To ensure your pleats are precisely formed and lay flat, meticulous marking and careful pressing are essential.

Before diving into the folding, always ensure your fabric is properly prepared and marked according to your pattern or design.

Knife Pleat Creation

The knife pleat is characterized by its simple, unidirectional folds, creating a sleek and sharp appearance. It is a foundational pleat often used in skirts, blouses, and historical costuming.The technique for folding and pressing a knife pleat involves creating a series of evenly spaced, parallel folds, all facing in the same direction.

- Measure and Mark: Ensure your fabric is marked with the precise width of each pleat and the space between them. For a knife pleat, the space between pleats is typically the same width as the pleat itself, or half the width of the pleat, depending on the desired fullness.

- Fold the Fabric: Take the marked edge of the fabric and fold it over to meet the next marked line, creating a single, sharp fold. All folds should be in the same direction.

- Press the Fold: Using a warm iron and a pressing cloth (if necessary for your fabric type), press the fold firmly. Ensure the crease is sharp and lies flat against the fabric.

- Repeat and Secure: Continue this process for all marked pleats, ensuring each fold is aligned with the previous one. Temporarily secure each pleat with a few hand stitches or a small piece of fusible web just below the fold line to hold it in place while you proceed.

Box Pleat Creation

A box pleat is a more structured and voluminous pleat, formed by two knife pleats folded away from each other, creating a central channel or “box.” This pleat is commonly used in skirts, dresses, and decorative elements where a fuller, more architectural look is desired.Demonstrating the method for creating a box pleat requires careful attention to centering the fold to achieve symmetry.

- Measure and Mark: For a box pleat, you will typically mark three lines: the width of the pleat, the width of the space between pleats, and then the width of the second pleat. The space between the two pleat edges is usually twice the width of the pleat itself. For example, if your pleat is 2 inches wide, you might mark lines at 2 inches, 4 inches, and 2 inches again.

- Fold the Fabric: Fold the fabric along the first and third marked lines so that these edges meet in the center, creating the box. The two folded edges will lie on top of each other.

- Press the Folds: Press the two outer folds firmly, ensuring they are sharp and lie flat. The central channel will naturally form as a result of these opposing folds.

- Secure the Pleat: Baste or tack the pleats in place along the bottom edge, just above where the folds meet, to keep the box pleat from unfolding.

Accordion Pleat Creation

Accordion pleats are characterized by their consistent, zigzagging folds, resembling the bellows of an accordion. They create a fluid and dynamic drape, often seen in skirts, scarves, and decorative trims.Detailing the process for forming an accordion pleat focuses on achieving and maintaining even spacing for a uniform appearance.

- Measure and Mark: Accordion pleats require precise measurements for both the pleat width and the spacing. The pleats are typically the same width as the space between them, creating a symmetrical zigzag. For instance, if you want 1-inch pleats, you would mark every inch.

- Fold the Fabric: Begin by folding the fabric in half along the first marked line. Then, fold the fabric back on itself along the next marked line, creating a zigzag. Continue this back-and-forth folding, ensuring each fold is precisely aligned with the previous one.

- Pressing and Setting: Accordion pleats are often set using heat. For synthetic fabrics, a hot iron can be used. For natural fibers, steaming or a steam iron can be effective. Press each fold carefully, maintaining the zigzag pattern. Some methods involve sandwiching the pleated fabric between two layers of interfacing or fabric and pressing with high heat to set the pleats permanently.

- Temporary Securing: Once folded, accordion pleats can be temporarily secured using a technique called “basting” or “tacking.” This involves sewing a long, loose stitch by hand or machine along the raw edge of the fabric, just below the last fold. This keeps the pleats aligned until they are permanently stitched into the garment.

Comparison of Pleat Creation Methods

The time investment and complexity of each pleat creation method vary significantly, influencing the choice of pleat for a particular project.

| Pleat Type | Time Investment | Complexity | Description |

|---|---|---|---|

| Knife Pleat | Moderate | Low | Simple, unidirectional folds. Requires consistent marking and pressing. |

| Box Pleat | Moderate to High | Moderate | Involves creating two opposing folds. Requires precise centering and careful pressing to maintain the central channel. |

| Accordion Pleat | High | High | Requires meticulous, repetitive folding and often heat setting. Precision in spacing is crucial for a professional finish. |

Procedure for Temporarily Securing Pleats

Before permanently stitching your pleats, it is crucial to secure them to maintain their shape and alignment. This temporary securing allows for easier handling and precise insertion into a garment.The following procedure Artikels methods for temporarily securing pleats before permanent stitching:

- Hand Basting: Using a long needle and contrasting thread, sew a long, loose running stitch along the raw edge of the fabric, just below the deepest fold of each pleat. This is a versatile method suitable for all fabric types and pleat styles.

- Machine Basting: Set your sewing machine to a long stitch length and a straight stitch. Sew a line of stitches along the raw edge of the fabric, securing all pleats. This method is faster than hand basting but can be less precise for very delicate fabrics.

- Fusible Web or Tape: For some fabrics, a lightweight fusible web or hemming tape can be applied along the raw edge. Following the product instructions, press the fusible material to adhere the pleats in place. This method provides a firm hold but can alter the drape of very fine fabrics.

- Staples (for heavy fabrics or specific techniques): In some heavy-duty or specialized applications, small, discreet staples might be used to temporarily hold pleats. This is not recommended for most garment construction due to potential fabric damage.

Sewing Pleats into Garments

Now that your pleats are meticulously marked and your fabric is prepared, the next crucial step is to bring them to life through sewing. This phase requires precision and care to ensure that the carefully created folds lie flat and maintain their intended shape throughout the garment’s construction and wear. This section will guide you through the best practices for stitching pleats, securing them, and achieving a polished, professional finish.

Stitching Along Marked Pleat Lines

Successfully sewing pleats begins with accurate stitching directly on your marked lines. This ensures that the pleats are permanently set in their folded position.

- Follow the Markings Precisely: Use your marked lines as a guide, stitching as close to the fold as possible without encroaching on the folded fabric itself. A seam allowance of 1/8 inch (0.3 cm) to 1/4 inch (0.6 cm) from the fold is generally recommended, depending on the fabric weight and desired aesthetic.

- Use a Walking Foot: For slippery or thick fabrics, a walking foot (also known as an even-feed foot) on your sewing machine is invaluable. It helps to feed the multiple layers of fabric evenly, preventing shifting and puckering as you stitch.

- Backstitch at the Beginning and End: Secure your stitching at the start and end of each pleat line with a few backstitches. This prevents the stitching from unraveling.

- Consider a Shorter Stitch Length: For very fine fabrics or delicate pleats, a slightly shorter stitch length can provide a more secure and refined finish.

Maintaining Pleat Integrity While Sewing

Sewing through multiple layers of fabric can be challenging. Employing specific techniques will help maintain the sharp, defined edges of your pleats.

The key to maintaining pleat integrity is to keep the fabric layers aligned and flat as they enter the sewing machine. This prevents the layers from shifting or bunching up, which can distort the pleat’s shape and create an uneven stitch line.

- Pinning and Basting: After marking, carefully fold and pin your pleats. For added security, consider basting the pleats in place along the stitching line before machine sewing. This temporary stitch will hold the pleats perfectly in position.

- Gentle Guidance: As you sew, use your free hand to gently guide the fabric, ensuring it stays flat and aligned. Avoid pulling or stretching the fabric.

- Sewing Direction: For some pleat types, sewing in a specific direction (e.g., from the hem upwards or from the waist downwards) can help the fabric feed more smoothly and prevent distortion. Experiment on a scrap piece of fabric to determine the best direction for your specific pleat.

Pressing Pleats for a Professional Finish

Pressing is as crucial as stitching in achieving well-defined, professional-looking pleats. It sets the folds permanently and gives the garment a crisp appearance.

Pressing should be done with care, using the appropriate heat and steam settings for your fabric type. The goal is to create sharp creases that lie flat and remain in place.

- Press as You Go: It’s best to press each pleat as you complete its stitching, rather than waiting until the entire garment is assembled. This makes the process more manageable and ensures each pleat is perfectly pressed.

- Use a Pressing Cloth: Always use a pressing cloth between the iron and your fabric, especially for delicate fabrics like silk or synthetics, or when pressing dark colors that can show scorch marks. A pressing cloth also helps to distribute heat evenly and prevent shine.

- Press from the Fold: When pressing, start at the fold and press downwards. For knife pleats, press them all in the same direction. For box or inverted pleats, ensure they are pressed to lie flat in their intended configuration.

- Steam and Gentle Pressure: Utilize steam if your fabric allows, as it helps to set the folds more effectively. Apply firm but gentle pressure with the iron. Avoid excessive pressure, which can flatten the pleat too much or create unwanted creases.

- Allow to Cool: Let the pressed pleats cool completely before moving the fabric. This allows the fibers to set and helps the pleats retain their shape.

Tacking or Securing Pleats

To ensure pleats remain in their correct position, especially at the top of the garment or along the hem, they are often tacked or secured.

Tacking provides structural support to the pleats, preventing them from opening up unexpectedly and maintaining the garment’s intended silhouette. The method of tacking depends on where the pleat is located and the desired aesthetic.

- Top Tacking: At the waistline or top edge of a skirt or dress, pleats are typically tacked to keep them aligned with the waistband or bodice. This can be done with a few hand stitches or by machine stitching across the top of the pleat within the seam allowance.

- Hem Tacking: For skirts and dresses, tacking pleats near the hem can help them hang correctly and prevent them from flipping outwards. This is usually done with small, invisible hand stitches.

- Interfacing: In some cases, interfacing can be applied to the upper portion of the pleat (on the wrong side of the fabric) to provide extra stability and help the pleats hold their shape.

Seam Finishing Techniques for Pleated Areas

The way you finish the seams in areas with pleats can significantly impact the garment’s durability and appearance. Since pleats often involve multiple layers of fabric, clean finishes are essential.

Choosing the right seam finishing technique ensures that the raw edges within the pleated areas are enclosed or neatly trimmed, preventing fraying and providing a professional look on both the inside and outside of the garment.

- French Seams: For lightweight fabrics, French seams are an excellent option as they enclose the raw edges completely, creating a very neat finish. This is particularly effective for pleats that are sewn together at the side seams.

- Serged Edges: A serger (overlocker) can provide a quick and durable finish by trimming and overcasting the raw edges simultaneously. This is a good choice for sturdier fabrics and for areas that will experience a lot of stress.

- Bound Seams: Binding the raw edges with bias tape offers a clean and decorative finish, especially suitable for areas where the inside of the garment will be visible or for adding a touch of detail.

- Pinked Edges: For fabrics that do not fray excessively, pinking the raw edges with pinking shears can be a simple and effective method to reduce fraying.

- Facing: In some designs, the upper edge of a pleated skirt might be finished with a facing, which is a separate piece of fabric sewn to the raw edge and then turned to the inside, providing a clean and structured finish.

Troubleshooting Common Pleating Issues

While the process of creating and sewing pleats can be incredibly rewarding, it’s not uncommon to encounter a few bumps along the way. Addressing these common issues promptly will ensure your finished garments have a professional and polished look. This section will guide you through identifying and resolving frequent pleating challenges, from unevenness to lost shape, and achieving those coveted crisp pleats.

Unevenness and Puckering

Uneven pleats or puckering can detract from the beauty of your garment. These issues often arise from inconsistencies in marking, cutting, or sewing. A careful approach and attention to detail are key to preventing and correcting them.

Causes and Solutions for Unevenness and Puckering

Several factors can lead to uneven pleats and puckering:

- Inaccurate Marking: If your initial markings for the pleat folds are not precise, the resulting pleats will naturally be uneven. Ensure you are using a reliable measuring tool and marking every fold accurately. For critical pleats, consider using tailor’s chalk or a washable fabric pen for clear, temporary marks.

- Uneven Fabric Feed: When sewing, if the fabric is not fed evenly under the presser foot, it can cause stretching or bunching, leading to puckering. Ensure both layers of fabric are guided smoothly and consistently. Some sewing machines have a walking foot or even feed that can help with difficult fabrics.

- Incorrect Stitch Length: A stitch length that is too short can cause the fabric to bunch up, while a stitch length that is too long might not secure the pleats firmly enough, allowing them to shift. Experiment with stitch lengths on a scrap piece of fabric to find the optimal setting for your chosen material. Generally, a medium stitch length (around 2-2.5mm) is suitable for most pleating tasks.

- Presser Foot Pressure: If the presser foot pressure is too high, it can stretch the fabric as you sew, causing puckering. Conversely, too little pressure might not keep the fabric stable. Consult your sewing machine’s manual for instructions on adjusting presser foot pressure, if possible.

- Thread Tension: Improper thread tension can also contribute to puckering. If the upper thread tension is too tight, it can pull the fabric. If the bobbin tension is too tight, it can create a rippled effect. Always test your tension on a scrap of the same fabric before starting your project.

Fabric Bunching or Stretching During Pleating

Managing fabric during the pleating process is crucial. If the fabric bunches or stretches, the integrity of your pleats will be compromised. Understanding the mechanics of fabric handling will help you maintain control.

Strategies for Controlling Fabric Movement

To prevent fabric bunching or stretching, consider the following:

- Accurate Measuring and Marking: As mentioned, precise markings are fundamental. Double-check all measurements before cutting and marking.

- Stabilizing the Fabric: For very slippery or stretchy fabrics, consider using a temporary stabilizer like a lightweight fusible interfacing on the wrong side of the fabric. This adds body and makes it easier to handle. Ensure the stabilizer is compatible with your fabric and can be easily removed if necessary.

- Using a Walking Foot: A walking foot is designed to feed the top and bottom layers of fabric evenly, significantly reducing the chances of stretching or bunching, especially with multiple layers or challenging fabrics.

- Gentle Guidance: Avoid pulling or pushing the fabric as it goes through the sewing machine. Instead, gently guide it with your hands, allowing the machine’s feed dogs to do the work.

- Basting: For complex pleats or when working with delicate fabrics, basting the pleats in place before machine sewing can provide extra security and prevent shifting. You can hand-baste or use a long machine stitch.

Fixing Pleats That Have Lost Their Shape

Even with careful sewing, sometimes pleats can lose their crispness or definition after the garment has been worn or washed. Fortunately, most of these issues can be rectified with proper pressing.

Re-establishing Pleat Definition

To restore the shape of your pleats:

- Proper Pressing Techniques: The key to sharp pleats is consistent and correct pressing. Use a good quality iron and a pressing cloth to protect the fabric. Press each pleat firmly, ensuring it lies flat and in the correct direction.

- Steaming: For fabrics that respond well to steam, using a steam iron can help set the pleats and give them a sharper edge. Always test steam on a scrap first.

- Pinning and Pressing: After washing or if pleats have flattened, you can re-pin them precisely along their original fold lines. Then, carefully press them into shape. For permanent pleats, especially in wool or synthetic blends, a tailor’s ham or seam roll can be invaluable for pressing curves and ensuring the pleat is pressed evenly.

- Interfacing: In some cases, if pleats consistently lose their shape, it might indicate that the fabric itself lacks the necessary body. In future projects, consider using a slightly heavier weight fabric or incorporating a lightweight interfacing on the wrong side of the fabric to provide more structure.

Achieving Sharp, Crisp Pleats on Various Fabric Weights

The desired crispness of a pleat can vary depending on the fabric type and the intended style. Achieving sharp pleats requires adapting your techniques to the specific characteristics of the material you are working with.

Tailoring Techniques for Crisp Pleats

The following strategies are effective for achieving sharp pleats across different fabric weights:

- Lightweight Fabrics (e.g., chiffon, silk, lawn): These fabrics require a delicate touch. Use fine pins to avoid leaving marks. Pressing should be done with moderate heat and a pressing cloth. Consider using a temporary spray starch to give these fabrics a bit more body for sharper folds. Basting is highly recommended to hold the pleats in place before sewing.

- Medium-Weight Fabrics (e.g., cotton, linen, rayon): These fabrics are generally more forgiving. Accurate marking and sewing are still important, but they tend to hold a crease well. A walking foot can be beneficial. Pressing with medium to high heat and a pressing cloth will yield excellent results.

- Heavyweight Fabrics (e.g., denim, wool, upholstery fabric): These fabrics can hold a very sharp crease. Ensure your sewing machine needle and thread are appropriate for the fabric weight. Use a heavy-duty presser foot if necessary. When pressing, use high heat and a pressing cloth, and consider using a clapper to set the crease firmly. For very thick fabrics, it might be beneficial to pre-press the fold lines before stitching to create a more defined edge.

The secret to perfectly crisp pleats lies in a combination of precise preparation, careful sewing, and meticulous pressing tailored to the fabric’s properties.

Advanced Pleating Techniques and Applications

Beyond the foundational pleats, there exists a world of sophisticated pleating techniques that can elevate garments and home decor to new levels of artistry and texture. These advanced methods allow for intricate detailing, unique silhouettes, and specialized applications that go beyond simple decorative elements. By understanding and mastering these techniques, you can unlock a new dimension in your sewing projects.This section delves into some of these advanced pleating methods, exploring their creation, application, and the distinctive aesthetic they bring.

We will also consider how these techniques can be integrated into pattern modifications and used in diverse textile applications.

Inverted Pleats and Their Decorative Uses

Inverted pleats, also known as cartridge pleats or box pleats when pressed flat in opposite directions, offer a clean and structured finish. Unlike outward-facing pleats, the inverted pleat folds fabric inwards, creating a smooth surface on the right side of the garment while adding fullness and a subtle ripple effect. This technique is particularly effective for creating a more tailored and sophisticated look, especially in skirts and the bodices of dresses.The decorative potential of inverted pleats lies in their ability to create depth and subtle visual interest without adding bulk.

They can be used to:

- Define waistlines with a smooth, fitted appearance.

- Create gentle fullness in A-line skirts or the bottom of bodices.

- Achieve a minimalist yet elegant aesthetic.

- Be strategically placed for architectural design elements.

Micro-Pleats for Specific Garment Designs

Micro-pleats are characterized by their extremely fine and numerous folds, creating a delicate, often ethereal texture. These pleats are typically achieved through specialized techniques or by using lightweight, fluid fabrics that lend themselves to such fine manipulation. The process often involves precise measuring and careful pressing to ensure uniformity across a large area.Creating micro-pleats requires patience and attention to detail.

Common methods include:

- Hand-Pleating: This involves meticulously folding and pressing small sections of fabric, often with the aid of a pleating board or ruler.

- Machine-Pleating: Some industrial machines are designed specifically for creating micro-pleats, though this is less common for home sewers.

- Fabric Treatment: Certain heat-settable fabrics can be permanently pleated using specialized tools or professional services.

Micro-pleats are frequently employed in contemporary fashion for:

- Creating flowing sleeves with a delicate texture.

- Adding a whimsical, almost feathery effect to the hem of skirts or dresses.

- Designing intricate collars or cuffs.

- Achieving a sheer, layered look in blouses and overlays.

Incorporating Pleats into Skirts, Dresses, and Other Apparel

Pleats are incredibly versatile and can be integrated into a wide range of apparel to enhance design, add fullness, and create flattering silhouettes. The type of pleat and its placement significantly influence the final garment.For skirts, pleats are a classic choice for adding movement and volume.

- Knife Pleats: These can be used to create a full, flowing skirt or a more structured, A-line silhouette depending on the fabric and spacing.

- Box Pleats: Offer a structured fullness that can be very flattering, especially at the waist.

- Inverted Pleats: Provide a smooth, tailored look with controlled fullness.

In dresses, pleats can be used in various ways:

- Bodice: Pleats at the neckline or waist can create shape and definition.

- Skirt: As with standalone skirts, pleats can add volume and flair to the skirt portion of a dress.

- Sleeves: Puff sleeves or bishop sleeves often incorporate pleats at the shoulder or cuff for volume and style.

Beyond skirts and dresses, pleats can be found in:

- Blouses: Adding subtle fullness to the front or sleeves.

- Trousers: Often seen as single or double pleats at the waistband for a more traditional or relaxed fit.

- Jackets and Coats: Used for shaping, adding volume to the hem, or as decorative detailing.

Use of Pleats in Home Decor Items

The textural and structural qualities of pleats extend beautifully into the realm of home decor, offering both aesthetic appeal and functional benefits.In curtains, pleats are not just decorative but also functional:

- Enhance Drape: Pleats allow fabric to hang in graceful folds, creating a luxurious and finished look.

- Control Light and Privacy: The way pleats gather fabric can influence how light filters through and the level of privacy offered.

- Add Volume: More pleats create a fuller, more opulent appearance for the curtains. Common heading types like pinch pleats or goblet pleats are specifically designed to create beautiful folds.

For cushions, pleats can add a sophisticated touch:

- Decorative Edging: Small, neatly pressed pleats can form a decorative border around the edge of a cushion cover.

- Textural Panels: Larger, more prominent pleats can be incorporated into the main surface of the cushion for a striking visual effect.

- Unique Shapes: Experimenting with different pleating techniques can result in cushions with unusual and artistic forms.

Design a Basic Pattern Modification to Incorporate a Single, Prominent Pleat

Incorporating a single, prominent pleat into a basic pattern can dramatically alter its silhouette and add a focal point to the garment. This is a relatively straightforward modification that can be applied to skirts, dresses, or even the front of a top. Let’s consider modifying a simple A-line skirt pattern to include a single, large box pleat at the center front.The modification process involves creating extra fabric allowance on the pattern piece to accommodate the fold of the pleat.

- Prepare the Pattern: Start with your basic A-line skirt pattern piece for the front.

- Determine Pleat Depth: Decide on the desired depth of your box pleat. A common depth might be 3 to 4 inches.

- Calculate Fabric Allowance: For a box pleat, you need to add twice the desired depth to the center front edge of your pattern piece. For example, if you want a 3-inch deep box pleat, you will add 6 inches (3 inches for each side of the fold) to the center front.

- Mark the Pleat Lines: On the pattern piece, measure from the center front edge outwards by the desired pleat depth (e.g., 3 inches). Draw a line parallel to the center front edge at this point. This marks the fold line of the pleat. Repeat this on the other side of the center front, also measuring out the pleat depth.

- Adjust the Center Front: The original center front line of the pattern piece will now become the fold line for the center of the pleat. You will need to extend the pattern piece at the center front by the total allowance calculated in step 3. The original center front line should be clearly marked as the “fold line” or “center pleat line.”

- Redraw the Hemline: Ensure the hemline is adjusted to match the new, wider front pattern piece.

- Cutting Instructions: When cutting your fabric, you will place the “fold line” of your modified pattern piece on the fold of the fabric. This ensures the pleat is created from a single piece of fabric.

This modification will result in a skirt with a smooth, flat front panel that opens into a deep, structured box pleat, adding both visual interest and subtle fullness.

Visualizing Pleat Formation (Descriptive)

Understanding how pleats look as they are formed and when sewn into a garment is key to achieving the desired aesthetic and drape. This section will visually guide you through the appearance of different pleat types, highlighting their unique characteristics and the interplay of light and shadow that defines their dimensionality.

Knife Pleat Formation

A knife pleat is characterized by its sharp, clean lines and directional flow. As fabric is folded over itself in a single, uniform direction, it creates a sleek, narrow band. The appearance is one of disciplined structure, where the folded edge is pressed firmly, resulting in a crisp, almost architectural line that runs parallel to the fabric’s grain. This unidirectional fold gives garments a streamlined and elegant look, with each pleat lying flat against the one beneath it.

The visual effect is one of continuous, unbroken lines that guide the eye along the garment.

Box Pleat Formation

The box pleat offers a more voluminous and structured appearance compared to the knife pleat. Its formation involves a central fold that is turned away from the main fabric, with two outer folds meeting at the seam. Visually, this creates a distinct raised section on the right side of the fabric, resembling a box. The central fold is hidden on the wrong side, while the two outer folds create a clean, symmetrical division.

This method adds significant fullness and a structured silhouette, making it ideal for skirts, dresses, and decorative elements where a defined shape is desired.

Accordion Pleat Formation

Accordion pleats are instantly recognizable by their repetitive, fan-like structure. Created by folding the fabric back and forth in equal, narrow sections, they resemble the bellows of an accordion. This technique results in a dense arrangement of pleats that can expand and contract, creating a dynamic visual effect. The fabric appears to ripple and flow, offering substantial volume and a rich texture.

The consistent, repeating pattern gives garments a playful yet sophisticated feel, often seen in vintage-inspired designs and flowing skirts.

The Play of Light and Shadow on Pleats

The dimensionality of different pleat types is dramatically accentuated by the interplay of light and shadow. Sharp, defined pleats like knife pleats cast subtle, clean shadows that emphasize their crisp edges and directional lines. Box pleats create deeper shadows within their central folds, highlighting the raised, architectural quality of the pleat. Accordion pleats, with their numerous folds, generate a complex pattern of light and shadow that adds depth and movement, giving the fabric a textured, almost three-dimensional appearance.

The way light catches the raised surfaces and recedes into the folds is crucial to appreciating the visual impact of each pleat style.

Closing Summary

In essence, mastering the art of pleating unlocks a world of design possibilities, allowing for the creation of garments and decor with captivating texture, volume, and refined aesthetics. By understanding the nuances of different pleat types, utilizing the correct tools, and applying careful techniques, you can confidently tackle any pleating project. We hope this exploration has provided you with the knowledge and inspiration to confidently bring your pleated visions to life, transforming fabric into statements of style and craftsmanship.