Embarking on any sewing project begins with a foundational step: the precise cutting of fabric. This meticulous process is not merely about following lines; it’s about understanding the very nature of textiles and employing the right techniques to ensure your creations drape beautifully and fit perfectly. Mastering accurate fabric cutting is a cornerstone of successful sewing, transforming raw material into the beginnings of a masterpiece.

This guide delves into the essential elements of achieving precision when cutting fabric for your sewing endeavors. We will explore the critical role of fabric grain, the indispensable tools that facilitate accuracy, and the preparatory steps that set the stage for flawless cuts. Furthermore, we will navigate the nuances of cutting various fabric types and leverage pattern markings to your advantage, ensuring every piece is prepared with the utmost care and attention to detail.

Understanding Fabric Grain and Its Importance

Accurate fabric cutting is foundational to successful sewing. A crucial element often overlooked by beginners, but vital for experienced sewers, is understanding and correctly identifying fabric grain. This knowledge directly influences how your finished garment will hang, move, and wear over time.Fabric grain refers to the direction of the threads in woven fabric. These threads are interlaced at right angles, creating a stable structure.

Understanding this structure is paramount because cutting fabric against the grain can lead to distorted seams, uneven hems, and garments that stretch or sag in unexpected ways.

Fabric Grain: Warp and Weft Threads

Woven fabrics are constructed from two sets of threads: the warp and the weft. The warp threads run lengthwise along the fabric bolt, parallel to the selvage (the finished edge of the fabric). The weft threads run crosswise, perpendicular to the warp threads and the selvage. The interaction of these threads dictates the fabric’s stability and stretch.The warp threads are generally stronger and under more tension during weaving, making them less prone to stretching.

Therefore, the grainline, which aligns with the warp threads, is considered the “straight grain.” The weft threads, running across the width, have more inherent give and stretch. Cutting with the grainline ensures that the fabric’s natural drape and stability are maintained in the finished project.

Identifying Fabric Grain

Correctly identifying the grainline is essential for accurate cutting. Fortunately, there are several reliable methods to determine it, applicable to most woven fabrics.

- The Selvage Method: This is the easiest and most reliable method. The selvage is the tightly woven, finished edge of the fabric that runs parallel to the warp threads. Aligning your cutting lines with the selvage ensures you are cutting along the straight grain.

- The Tear Method: For some fabrics, especially natural fibers like cotton and linen, a gentle tear can reveal the grain. Fold the fabric and give a sharp, controlled tug. The fabric will often tear more cleanly along the weft threads, indicating the direction of the crossgrain. The straight grain will resist tearing as much. This method is not suitable for all fabrics, particularly knits or those with synthetic blends, as it can cause damage.

- The Selvage Edge Observation: If the selvage is not present (e.g., if it has been cut off), look for the direction of the woven threads. The warp threads often appear straighter and more parallel than the weft threads, which may have a slight waviness due to being interlaced.

- The Stretch Test: Gently pull the fabric in both directions (lengthwise and crosswise). The direction with less stretch is typically the straight grain (warp), while the direction with more stretch is the crossgrain (weft). This is particularly useful for fabrics that are somewhat stretchy in both directions.

- The Fold Test: Fold the fabric in half lengthwise, bringing the selvages together. The fold should be straight and crisp. If you fold it crosswise, the fold might not lie as flat or could be slightly curved, indicating the direction of less stability.

Marking the Grainline

Once you have identified the grainline, it is crucial to mark it accurately on your fabric before cutting. This ensures that your pattern pieces are placed and cut correctly.

The grainline is typically indicated on commercial sewing patterns by a long, dashed line with arrows at each end. This line must be parallel to the selvage or the straight grain of the fabric.

There are several effective ways to mark the grainline:

- Chalk or Fabric Pen: Using tailor’s chalk or a washable fabric pen, draw a line parallel to the selvage along the length of your fabric. Ensure this line extends through the area where your pattern piece will be placed.

- Thread Tracing: For very fine or delicate fabrics where chalk might be too harsh, you can use a contrasting thread to “trace” the grainline. Use a long basting stitch to mark a line parallel to the selvage. This method is precise and easily removed after cutting.

- Pinning to the Grainline: When laying out your pattern pieces, ensure the pattern’s grainline marking is parallel to the selvage. You can also use pins to mark the grainline on the fabric itself, running them parallel to the selvage at regular intervals.

- Visual Alignment: In many cases, especially with experienced sewers, the grainline can be visually aligned by ensuring the pattern piece’s grainline marking is parallel to the selvage. However, for critical projects or less experienced sewers, marking it directly is highly recommended.

Essential Tools for Accurate Fabric Cutting

Achieving precise cuts is foundational to successful sewing. The right tools, used correctly, will transform your fabric from a raw material into perfectly shaped pieces ready for assembly. This section will guide you through the essential cutting implements and how to maintain them for optimal performance.Selecting the appropriate cutting tool depends on the fabric type, the complexity of the pattern, and your personal preference.

Each tool has its strengths and weaknesses, and understanding these will help you make informed decisions for every project.

Primary Cutting Tools

The success of your sewing projects hinges on the accuracy of your cuts, and this accuracy is directly influenced by the quality and suitability of your cutting tools. Having the right implements at hand ensures clean, precise edges that align perfectly during assembly.The primary cutting tools used in sewing are designed for specific tasks and fabric types, each offering unique advantages.

- Rotary Cutters: These tools feature a circular blade that rotates as it is pushed across the fabric. They are excellent for making long, straight cuts and are particularly effective on multiple layers of fabric when used with a cutting mat. The blade requires regular sharpening or replacement to maintain its cutting efficiency.

- Fabric Scissors: Dedicated fabric scissors are designed with longer blades and a specific handle design that allows them to cut through fabric without snagging or distorting the material. They are ideal for intricate cuts, curves, and trimming seam allowances. It is crucial to use these scissors

-only* for fabric and never for paper or other materials, as this will dull the blades quickly. - Marking Tools: These are essential for transferring pattern lines and markings onto the fabric before cutting. Common marking tools include chalk pencils, tailor’s chalk, fabric pens (which may disappear over time or with washing), and washable markers. The choice of marking tool depends on the fabric color and type, ensuring visibility without permanently damaging the material.

Rotary Cutter vs. Fabric Scissors

The choice between a rotary cutter and fabric scissors often comes down to the specific task and fabric at hand. Both tools, when used correctly, can yield excellent results, but they excel in different scenarios.

- Rotary Cutters:

- Advantages: Excellent for long, straight cuts, efficient for cutting multiple layers simultaneously, allows for faster cutting on large pattern pieces, and can reduce fabric shifting.

- Disadvantages: Requires a cutting mat, can be less precise for intricate curves or small pieces, blades dull and need replacement, and poses a higher risk of accidental cuts if not handled with extreme care.

- Fabric Scissors:

- Advantages: Superior for intricate curves and small, detailed pattern pieces, no additional mat required, generally safer to handle than rotary cutters, and offer precise control for trimming.

- Disadvantages: Can be slower for long, straight cuts, may cause fabric distortion if not held correctly, and are less efficient for cutting through multiple layers of thick fabric.

For example, when cutting out a quilt top with many straight edges and multiple layers of cotton fabric, a rotary cutter and mat combination will likely be faster and more efficient. Conversely, when sewing a garment with delicate silk or intricate lace details, sharp fabric scissors will provide the necessary precision and control.

Maintaining Cutting Tools

The longevity and precision of your cutting tools are directly related to their maintenance. Regularly caring for your rotary cutters and scissors ensures they perform optimally and prevents frustration from dull blades or damaged fabric.Proper maintenance involves a few key practices:

- Sharpening: Rotary cutter blades should be replaced when they begin to drag or tear the fabric. Some craft stores offer blade sharpening services, or you can purchase a blade sharpener designed for rotary cutters. Fabric scissors can be sharpened using a sharpening stone or by taking them to a professional sharpener. A simple test for sharpness is to see if they can cleanly cut through a single strand of thread.

- Cleaning: After each use, wipe down your cutting tools to remove any fabric fibers or dust. For rotary cutters, ensure the blade housing is free of debris. For scissors, a damp cloth followed by a dry one can remove residue.

- Storage: Store cutting tools safely and separately to prevent damage. Rotary cutters should have their blades retracted or covered. Fabric scissors should be stored in a protective sheath or a dedicated sewing box to prevent their blades from being nicked or dulled by contact with other items.

- Dedicated Use: As mentioned, it is paramount to use fabric scissors

-only* for fabric. Using them for paper, cardboard, or other household tasks will rapidly dull their blades, leading to inaccurate cuts and potential fabric damage.

Selecting the Right Cutting Tool

Choosing the correct cutting tool is crucial for achieving professional-looking results. The type of fabric and the complexity of the sewing project are the primary factors to consider.Consider the following guide when making your selection:

| Fabric Type | Recommended Cutting Tool(s) | Reasoning |

|---|---|---|

| Lightweight Cottons, Linens | Fabric Scissors, Rotary Cutter | Both are effective. Scissors offer precision for garment pieces; rotary cutters are efficient for straight edges and multiple layers, common in quilting. |

| Silks, Satins, Delicate Fabrics | Sharp Fabric Scissors | Requires extreme precision to avoid snagging or stretching. Sharp scissors allow for clean, controlled cuts. |

| Denim, Canvas, Upholstery Fabrics | Rotary Cutter (with fresh blade), Heavy-Duty Fabric Scissors | Thicker fabrics benefit from the efficiency of a rotary cutter. Heavy-duty scissors are necessary for clean cuts without excessive hand strain. |

| Knits, Stretch Fabrics | Rotary Cutter (with a specific rotary blade for knits), Sharp Fabric Scissors | A rotary cutter can minimize stretching. However, very sharp scissors with a serrated edge can also provide a good grip on stretchy materials. |

| Multiple Layers of Fabric (e.g., Quilting) | Rotary Cutter and Mat | Ideal for efficiency and accuracy when cutting many identical pieces or through several layers at once. |

| Intricate Patterns, Small Pieces | Sharp Fabric Scissors | Offers the best control and maneuverability for detailed shapes and small components. |

Preparing Fabric for Cutting

Before a single cut is made, properly preparing your fabric is paramount for achieving accurate sewing results. This crucial step ensures that your final garment or project will fit as intended and maintain its shape over time. Neglecting fabric preparation can lead to frustrating issues like uneven seams and a disappointing finished product, all due to unforeseen shrinkage or persistent wrinkles.This section will guide you through the essential preparatory stages: pre-washing and ironing, squaring up your fabric edges, and securely pinning patterns.

By dedicating time to these initial steps, you lay a solid foundation for precise cutting and, consequently, successful sewing.

Pre-Washing and Ironing Fabric

Pre-washing your fabric is a vital step that simulates the first wash cycle your finished project will experience. This process accounts for any potential shrinkage that may occur, preventing your completed garment from becoming too small or misshapen after its initial cleaning. Different fabric types have varying shrinkage rates, so understanding this is key.Ironing, after pre-washing and drying, removes all wrinkles and creases.

A smooth, flat surface is essential for accurate pattern placement and cutting. Wrinkles can distort the fabric, leading to inaccurate measurements and cuts.Here’s a detailed approach to pre-washing and ironing:

- Pre-Washing: Wash your fabric in the same manner you intend to wash the finished garment. For example, if your project will be machine-washed and dried, do the same with the fabric. Use the recommended water temperature and detergent. If you plan to dry clean, it’s still advisable to pre-wash, as some dry cleaning processes can also cause minor shrinkage.

- Drying: Allow the fabric to dry completely. You can air dry it or tumble dry it according to your planned care instructions.

- Ironing: Once dry, lay the fabric flat on your ironing board. Use a hot iron with steam (if appropriate for the fabric type) to press out all wrinkles. Work systematically, section by section, ensuring the fabric is completely smooth before proceeding to the next step. For very large pieces of fabric, you might need to iron in sections.

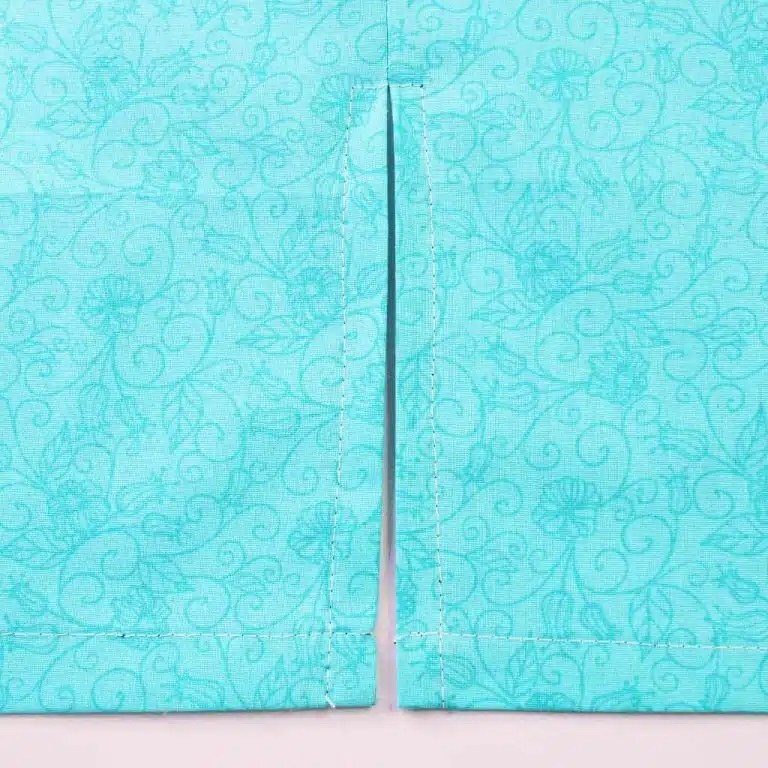

Squaring Up Fabric Edges

Squaring up your fabric is the process of ensuring that the cut edges of your fabric are perfectly perpendicular to the selvages and the grainline. This creates a stable and predictable starting point for laying out patterns and making precise cuts. If the edges are already uneven or biased, it becomes incredibly difficult to cut accurately, as the fabric can stretch or distort unpredictably.There are several methods to achieve squared edges, but they all aim to create a true right angle.Here is a step-by-step procedure for squaring up fabric edges:

- Inspect the Selvages: Examine the selvage edges of your fabric. Sometimes, these edges can be slightly wavy or uneven due to the manufacturing process.

- Locate a Straight Edge: Find a point along the selvage where the fabric appears to be cut the straightest. This will be your starting point.

- Create a Perpendicular Cut: Using a rotary cutter and a long ruler, or sharp fabric shears and a T-square, make a cut perpendicular to the selvage at your chosen straight point. This cut should create a 90-degree angle with the selvage. If you are using shears, you may need to carefully snip into the selvage first to get your ruler or T-square positioned correctly.

- Trim the Excess: Once you have established a straight, perpendicular edge, you can then trim the opposite edge of the fabric to match this squared-off side. Ensure the fabric is laid out flat and smooth for this step.

Pinning Patterns to Fabric

Securely pinning your pattern pieces to the fabric is the final, critical step before cutting. This prevents any movement or shifting of the pattern during the cutting process, which is essential for accuracy. Shifting can lead to pieces that are too large, too small, or misaligned with the grainline.The placement and density of your pins are important. Aim for a balance that holds the pattern firmly without distorting the fabric.Here is a step-by-step procedure for pinning patterns to fabric:

- Align Pattern to Grainline: Before pinning, ensure your pattern piece is correctly aligned with the fabric’s grainline, as discussed previously. This is crucial for the drape and fit of your garment.

- Start Pinning at Key Points: Begin pinning at important intersections, such as corners of darts, notches, and the center front or back lines. These points are critical for accuracy.

- Distribute Pins Evenly: Once the key points are secured, distribute pins evenly around the entire perimeter of the pattern piece. Aim for pins to be approximately 4-6 inches apart, depending on the fabric type and the size of the pattern piece.

- Use Plenty of Pins: Don’t be stingy with pins. More pins are generally better than too few, especially on slippery or stretchy fabrics. Ensure pins are placed perpendicular to the cutting edge of the pattern to avoid snagging your fabric or rotary cutter.

- Check for Puckering: As you pin, gently smooth the fabric between pins to ensure there is no puckering or stretching underneath the pattern.

“Accuracy in cutting begins with meticulous preparation. Every step, from pre-washing to precise pinning, builds the foundation for a flawless sewing project.”

Cutting Techniques for Different Fabric Types

Accurate fabric cutting is paramount for successful sewing, and the techniques employed must adapt to the unique characteristics of various fabric types. Understanding these differences ensures that your cuts are precise, your seams lie flat, and your finished garment drapes beautifully. This section will explore specialized cutting methods tailored for woven, knit, slippery, delicate, and thick fabrics, as well as the art of cutting on the bias.

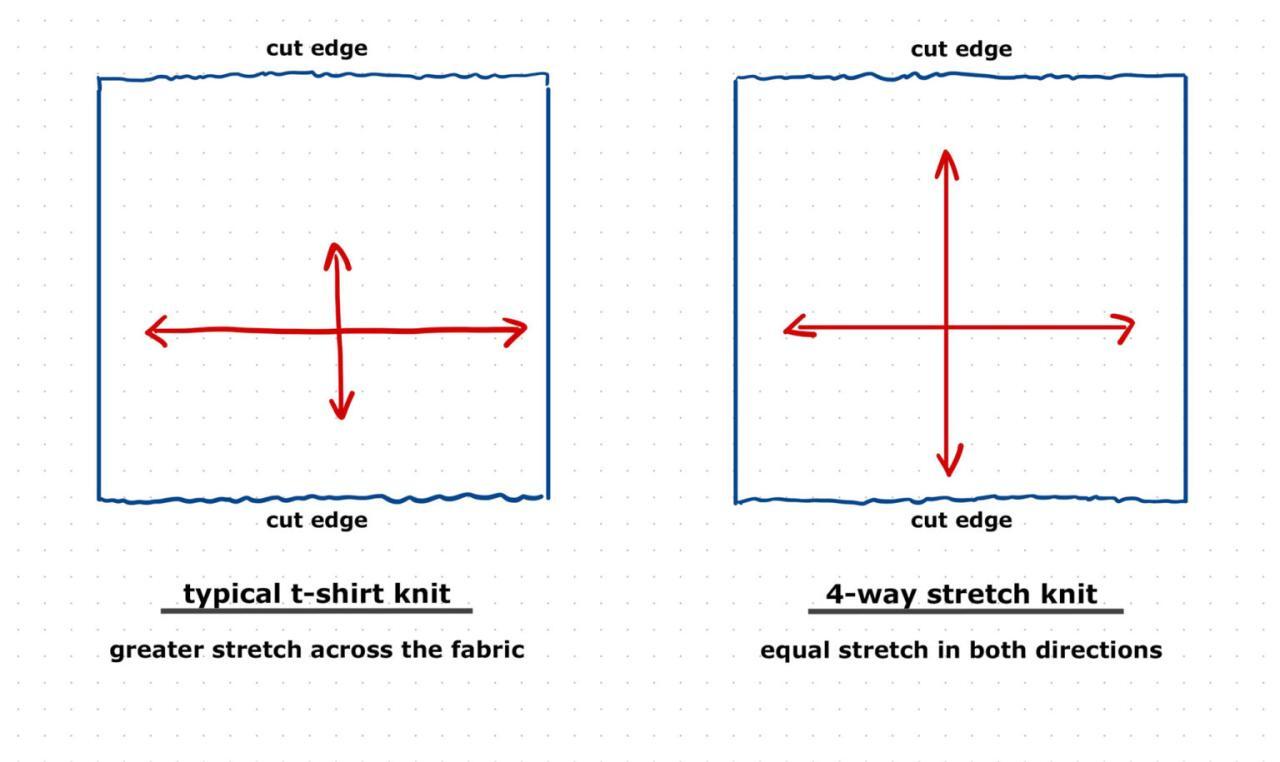

Woven Versus Knit Fabric Cutting

Woven fabrics, characterized by their interlaced warp and weft threads, offer stability and minimal stretch. Knit fabrics, on the other hand, are constructed with interlocking loops, providing inherent stretch and drape. These fundamental differences necessitate distinct cutting approaches to prevent distortion and ensure accurate pattern placement.Woven fabrics are generally more forgiving and can be cut with standard rotary cutters or shears.

The key is to ensure the fabric is laid flat and doesn’t shift. For knit fabrics, however, extra care is needed due to their tendency to stretch and curl.Here are the primary distinctions and techniques:

- Woven Fabrics:

- Stability: They maintain their shape well once cut.

- Cutting Tools: Sharp fabric shears or a rotary cutter with a self-healing mat are ideal.

- Technique: Lay the fabric flat, ensuring grainlines are perfectly aligned. Pinning is often recommended to prevent shifting. Cut smoothly and deliberately.

- Knit Fabrics:

- Stretch and Curl: Prone to stretching, distorting, and edge curling.

- Cutting Tools: A very sharp rotary cutter is often preferred to minimize pulling and stretching. Gingher or high-quality shears can also be used, but require more careful handling. A pinking shears can help reduce fraying on some knits.

- Technique: Use weights instead of pins where possible to avoid creating holes that can stretch. If pinning, use very fine, sharp pins placed within the seam allowance. Cut with a single, decisive motion to avoid multiple passes that can distort the fabric. Consider using a stabilizer spray on the edges of very stretchy knits before cutting to help them lie flat.

Cutting Slippery or Delicate Fabrics

Fabrics like silk, satin, chiffon, and georgette present unique challenges due to their smooth surfaces and tendency to shift, slide, and fray easily. Special attention to preparation and cutting technique is crucial to avoid uneven edges and distorted pieces.The primary goal when cutting these fabrics is to minimize movement and prevent snagging.Consider these methods for successful cutting:

- Preparation:

- Pre-washing: If the fabric is washable, pre-washing and drying it according to its care instructions will help pre-shrink it and make it slightly less slippery.

- Stabilization: For very sheer or slippery fabrics, a temporary stabilizer spray or a thin layer of starch can be applied to the wrong side to provide a bit more grip.

- Ironing: Ensure the fabric is well-pressed and smooth before laying it out.

- Cutting Tools:

- Rotary Cutter: A sharp rotary cutter is often the best choice as it minimizes fabric manipulation.

- Sharp Shears: If using shears, ensure they are extremely sharp and specifically designated for fabric to avoid snagging.

- Cutting Mat: A self-healing mat is essential for rotary cutting.

- Technique:

- Weights: Use pattern weights generously to hold the pattern and fabric in place. Avoid pins as much as possible, as they can create holes and distort the fabric.

- Cutting Surface: A non-slip cutting mat or a layer of felt beneath the fabric can help prevent it from sliding.

- Cutting Motion: Cut slowly and deliberately, with a single, smooth stroke. Avoid sawing motions.

- One Layer at a Time: For very slippery fabrics, it is often best to cut one layer of fabric at a time rather than cutting through multiple layers.

Cutting Thick or Textured Fabrics

Denim, canvas, corduroy, velvet, and other thick or textured fabrics require robust tools and specific techniques to achieve clean, accurate cuts. Their bulk can make it difficult to see cut lines, and their textures can hide shifting.The challenge with these fabrics lies in their density and the potential for their pile or texture to interfere with the cutting process.Here’s how to manage these fabrics:

- Preparation:

- Pre-washing: Always pre-wash and dry thick fabrics as they can shrink significantly.

- Pressing: Press the fabric thoroughly, paying attention to nap direction for fabrics like velvet.

- Pattern Placement: Ensure your pattern pieces are placed with sufficient spacing, as thick fabrics take up more room.

- Cutting Tools:

- Heavy-Duty Shears: Invest in a good pair of heavy-duty fabric shears. They should be sharp and strong enough to cut through multiple layers without effort.

- Rotary Cutter: A sharp, heavy-duty rotary cutter can also be effective, especially for multiple layers, but ensure your mat can handle the pressure.

- Rotary Blade Sharpness: Regularly change your rotary blades; a dull blade will struggle and fray thick fabrics.

- Technique:

- Clear Visibility: Use a bright light and consider using a ruler with clear markings. Some sewers find it helpful to trace pattern lines with chalk or a washable marker before cutting.

- Support the Fabric: When cutting, support the fabric to prevent it from drooping or shifting under its own weight, especially when cutting long pieces.

- Cutting Through Pile: For fabrics like velvet, cut with the nap running in the same direction. Cut on the wrong side if possible to avoid crushing the pile. Use a very sharp rotary cutter or shears.

- Multiple Layers: If cutting multiple layers, ensure they are stacked evenly and securely pinned or weighted to prevent slippage.

Cutting Bias Grain

Cutting fabric on the bias means cutting at a 45-degree angle to the selvage and the lengthwise grain. This technique is used to create garments that drape softly, have a fluid movement, and allow for curved seams. Fabrics cut on the bias stretch more than those cut on the grain.Understanding the bias is crucial for achieving specific design elements and fit.Follow these steps for accurate bias cutting:

- Identify the Grainlines: First, determine the lengthwise and crosswise grainlines of your fabric.

- Fold the Fabric: Fold the fabric diagonally, bringing one selvage edge to meet the other. This creates a fold line that runs along the bias. The fabric will likely form a triangle or a diamond shape.

- Align the Pattern Piece: Lay your pattern piece on the fabric so that the “cut on bias” line on the pattern is aligned with the folded edge of the fabric. Ensure the grainline marking on the pattern is parallel to the folded edge.

- Pin Securely: Pin the pattern piece to the fabric. Because the fabric is more likely to shift on the bias, use plenty of pins, especially around the edges.

- Cut with Precision: Cut slowly and carefully along the edges of the pattern. Maintain a consistent distance from the pattern edge.

- Marking and Handling: Bias-cut pieces are more prone to stretching out of shape. Handle them gently and consider marking them with clips or temporary labels to indicate the grain direction and to avoid stretching them while sewing.

“The bias is the diagonal grain of the fabric, offering maximum stretch and drape, essential for flowing designs and curved seams.”

Utilizing Patterns for Precise Cutting

Incorporating sewing patterns is a fundamental step towards achieving accurate garment construction. Patterns provide the blueprint for your project, and understanding how to read and use them effectively is crucial for translating your design vision into a well-fitting garment. This section will guide you through the intricacies of pattern markings and their application to fabric for precise cutting.

Reading and Interpreting Pattern Markings

Sewing patterns are rich with information designed to guide you through the cutting and construction process. Familiarizing yourself with these symbols is key to avoiding errors and ensuring your fabric is cut correctly.

- Grainline Arrows: These long, straight arrows indicate the direction of the fabric grain. They are typically parallel to the selvage edge. It is vital to align these arrows with the fabric’s lengthwise grain for proper drape and to prevent stretching or distortion.

- Cutting Lines: These are the outermost lines on a pattern piece and represent the actual cutting edge. They are usually solid lines.

- Seam Lines: These lines are typically dashed or dotted and indicate where you will stitch the fabric pieces together. The distance between the cutting line and the seam line is your seam allowance.

- Notches: Small triangles or squares that extend outward from the cutting line. Notches are used to match corresponding pieces during sewing. For example, shoulder seams often have notches to align them with the back bodice.

- Dots and Circles: These markings can indicate placement points for pockets, darts, buttonholes, or other design elements.

- Fold Lines: A line with arrows pointing in opposite directions, indicating that the pattern piece should be placed on a fold of the fabric.

Efficient Pattern Layout for Accuracy and Waste Reduction

The way you arrange pattern pieces on your fabric significantly impacts both accuracy and fabric conservation. A well-planned layout minimizes waste and ensures that critical pattern markings, like the grainline, are correctly placed.Before laying out your pattern pieces, it is essential to consider the fabric’s characteristics, such as its width and any directional prints or nap. Always refer to the pattern envelope for layout suggestions, as these are optimized for the specific pattern and fabric width.When laying out pattern pieces, follow these steps:

- Prepare Your Fabric: Ensure your fabric is pre-washed and pressed to remove any wrinkles or shrinkage.

- Fold Fabric (if necessary): Fold your fabric according to the pattern’s layout diagram, paying attention to whether it requires a single layer or a double fold.

- Place Large Pieces First: Begin by positioning the largest pattern pieces on the fabric, as these often dictate the placement of smaller pieces.

- Align Grainline Arrows: Crucially, ensure that all grainline arrows on the pattern pieces are parallel to the selvage edge of the fabric, or as indicated by the layout.

- Consider Directional Prints/Nap: If your fabric has a nap (like velvet) or a directional print (like a floral with flowers all facing one way), all pattern pieces must be laid out in the same direction.

- Fit Smaller Pieces: Once the larger pieces are in place, strategically fit the smaller pieces into the remaining spaces, aiming to minimize gaps and fabric waste.

- Pin Securely: Pin the pattern pieces to the fabric along the cutting lines and at key points, ensuring they do not shift during cutting.

Accurate Cutting of Pattern Pieces

Once your pattern pieces are laid out correctly, the next step is to cut them out with precision. This involves carefully following the marked lines and maintaining a steady hand.To ensure accuracy when cutting out pattern pieces:

- Use Sharp Tools: Employ sharp fabric shears or a rotary cutter with a sharp blade. Dull tools can lead to jagged edges and inaccurate cuts.

- Cut on the Cutting Line: Focus on cutting precisely along the outermost solid line of the pattern piece, which is the cutting line.

- Maintain a Steady Hand: Cut with smooth, continuous strokes. Avoid stopping and starting frequently, which can cause unevenness.

- Turn the Fabric, Not the Scissors: For intricate curves or corners, it is often easier to pivot the fabric rather than trying to maneuver the scissors awkwardly.

- Cut Through One Layer at a Time (if applicable): If you are cutting a single layer of fabric, be mindful of keeping the pattern piece flat and cutting through only that layer.

Precise Cutting of Notches and Pattern Indicators

Notches, dots, and other pattern indicators are vital for accurate garment assembly. Cutting these precisely ensures that your seams will match up correctly and your design elements will be placed accurately.Methods for cutting notches and other pattern indicators precisely include:

- Notches:

- Slits: Cut small, outward-facing slits from the edge of the fabric up to the notch marking. These are typically about 1/8 to 1/4 inch long.

- Triangles: For thicker fabrics, you can cut small V-shaped notches that extend outward from the edge.

- Snipping: Alternatively, you can snip a small triangular piece of fabric from the seam allowance at the notch point.

- Dots and Circles:

- Tailor’s Tacks: For precise placement of dots, use tailor’s tacks. These are small loops of thread that mark the exact point.

- Chalk or Water-Soluble Pen: Mark dots and circles with tailor’s chalk or a water-soluble pen, ensuring the marking is clearly visible.

- Small Snips: For very small dots, a tiny snip into the seam allowance can also be effective, but be cautious not to cut too deep.

It is essential to cut these indicators within the seam allowance, ensuring they do not interfere with the finished garment’s appearance or structural integrity.

Advanced Cutting Strategies and Tips

Beyond the foundational techniques, several advanced strategies can significantly enhance your fabric cutting accuracy and efficiency, especially for complex projects or when working with larger quantities of material. These methods leverage specific tools and workflow optimizations to minimize errors and save valuable time.

Cutting Multiple Layers of Fabric Simultaneously

Cutting multiple layers of fabric at once can be a tremendous time-saver, particularly for projects requiring many identical pieces, such as quilting, garment construction with linings, or creating multiple samples. However, this technique demands extra precision to ensure all layers align perfectly and are cut cleanly. The key is to maintain absolute stability of the fabric stack and use sharp tools.Before cutting multiple layers, it is crucial to ensure they are perfectly aligned.

A common method involves laying out the fabric smoothly, one layer on top of the other, and then carefully smoothing out any wrinkles or shifting between the layers. Pins can be strategically placed along the edges, but care must be taken not to create bulk that would affect the accuracy of the cut. For extremely precise work, a rotary cutter and a long, clear ruler are indispensable.

The ruler should be placed firmly on top of the fabric stack, and the rotary cutter guided along its edge with consistent pressure.

Utilizing Cutting Mats and Rulers for Straight and Accurate Cuts with a Rotary Cutter

The synergy between a cutting mat and a ruler is fundamental for achieving straight and accurate cuts when using a rotary cutter. A self-healing cutting mat provides a protective surface for your workspace and your rotary blade, preventing damage to both. Its grid lines offer visual guides for aligning fabric and measuring, though precise cuts often rely more heavily on a dedicated ruler.When using a rotary cutter with a ruler, the ruler acts as a guide for the blade.

It is essential to select a ruler with clear markings and a non-slip backing to prevent it from shifting during the cutting process. Place the ruler firmly along the intended cutting line, ensuring it is perfectly straight and aligned with the fabric. Apply even pressure with the rotary cutter, rolling it along the edge of the ruler. A slight angle on the rotary cutter can sometimes help ensure a clean cut through all layers.

For very thick fabrics or multiple layers, multiple passes with the rotary cutter might be necessary, always maintaining the ruler’s position.

Checklist of Common Cutting Errors and How to Avoid Them

Identifying and proactively addressing common cutting errors is crucial for a successful sewing project. These mistakes, while seemingly minor, can lead to significant issues in garment fit or project assembly.

- Uneven or Wavy Edges: This often results from a dull rotary blade, insufficient pressure, or the fabric shifting during the cut. Ensure your rotary blade is sharp and replace it regularly. Apply consistent, firm pressure.

- Inaccurate Measurements: Human error in reading rulers or marking lines is common. Double-check all measurements before cutting. Use a clear, high-quality ruler with precise markings.

- Fabric Shifting: This is particularly problematic when cutting multiple layers. Use weights or a sufficient number of pins to keep the fabric layers stable. Smooth out the fabric carefully before each cut.

- Cutting Against the Grain: This leads to fabric that drapes or stretches incorrectly. Always pay close attention to grainlines marked on patterns and align them accurately with the fabric grain.

- Not Cutting Exactly on the Line: Whether it’s a pattern line or a marked line, deviating from it will affect accuracy. Practice cutting precisely on the intended line.

- Using a Dull Blade: A dull blade will snag, tear, or create fuzzy edges, leading to inaccurate cuts. Invest in good quality blades and replace them frequently.

Workflow for Organizing Cut Fabric Pieces for a Sewing Project

An organized approach to managing your cut fabric pieces is essential for a smooth and efficient sewing process. Proper organization prevents lost pieces, reduces confusion, and ensures you have everything you need before you start stitching.The workflow for organizing cut fabric pieces typically begins immediately after cutting. For smaller projects, laying out all the cut pieces and identifying them by name or number (as indicated on the pattern pieces) is a good start.

For larger or more complex projects, a more structured system is beneficial.

- Labeling: As each piece is cut, immediately label it with its corresponding pattern piece letter or number. This can be done with a fabric marker, a temporary chalk pencil, or by attaching small paper tags.

- Grouping by Pattern Piece: If a pattern has multiple identical pieces (e.g., sleeves, cuffs), keep them together.

- Bagging or Bundling: For intricate projects or when working over several days, consider placing cut pieces for specific sections into labeled zip-top bags or bundling them with a rubber band. For instance, all pieces for the bodice could go in one bag, and all pieces for the skirt in another.

- Layout and Visual Check: Before storing, lay out all the cut pieces for a specific section or the entire project. This allows for a visual check to ensure no pieces are missing and that all cuts appear correct.

- Storage: Store the organized fabric pieces in a designated area, such as a shelf or a box, to keep them safe and easily accessible.

This systematic approach ensures that when you are ready to sew, all your components are accounted for and clearly identified, allowing you to proceed with confidence and precision.

Final Conclusion

By diligently applying the principles of understanding fabric grain, utilizing the correct tools, preparing your materials, and employing specific cutting techniques for different textiles and patterns, you will undoubtedly elevate the quality of your sewing projects. This comprehensive approach to accurate fabric cutting not only enhances the final garment’s appearance and fit but also contributes to a more enjoyable and efficient sewing experience.

Embrace these strategies, and watch your sewing skills reach new heights with every precisely cut piece.