How to Deal with a Jammed Sewing Machine sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail with formal and friendly language style and brimming with originality from the outset.

This comprehensive guide delves into the common causes of sewing machine jams and provides practical, step-by-step solutions to get your machine running smoothly again. From identifying the initial signs of trouble to understanding specific troubleshooting scenarios and essential maintenance practices, we aim to empower you with the knowledge to overcome these frustrating interruptions with confidence.

Identifying the Jam

A jammed sewing machine can halt your creative flow and cause frustration. Recognizing the signs of a jam early is crucial for a swift and effective resolution. This section will guide you through the common indicators of a jam, the initial steps to take before attempting any repairs, and the frequent culprits behind such issues.Understanding what a jam looks and feels like is the first step to overcoming it.

A jammed machine typically exhibits resistance when you try to operate it manually or when the motor struggles to move. This resistance is usually accompanied by unusual noises or a complete cessation of movement.

Common Jam Indicators

Several tell-tale signs suggest your sewing machine has encountered a jam. Paying close attention to these symptoms will help you diagnose the problem accurately.

- Resistance to Handwheel Movement: When you attempt to turn the handwheel manually, it feels unusually stiff or completely stuck.

- Thread Bunching or Snagging: You observe a significant knot or clump of thread, often underneath the presser foot or within the bobbin area.

- Skipped Stitches: The machine continues to run, but the stitches are inconsistent, uneven, or missing altogether.

- Unusual Noises: Grinding, clicking, or straining sounds emanate from the machine, which are not part of its normal operation.

- Motor Strain or Stalling: The sewing machine motor sounds like it’s working very hard, or it stops abruptly during operation.

- Thread Breaking Frequently: The upper thread or bobbin thread breaks repeatedly, often at the same point in the stitching cycle.

Initial Steps Before Repair

Before diving into complex troubleshooting, it’s essential to take a few precautionary steps. These actions can sometimes resolve minor jams and prevent further damage to your machine.

- Stop Immediately: As soon as you notice any of the jam indicators, stop the machine. Continuing to run a jammed machine can cause more significant damage.

- Raise the Presser Foot: Lift the presser foot to release tension on the upper thread and needle.

- Remove Fabric: Gently pull the fabric out from under the presser foot. If it’s stuck, carefully cut the fabric close to the needle.

- Check the Needle: Inspect the needle for any bends, burrs, or breaks. A damaged needle can cause thread to snag and lead to a jam. If the needle appears damaged, replace it.

- Thread Removal: Carefully remove any visible tangled thread from around the needle, presser foot, and feed dogs. Use tweezers for precision if needed.

Potential Causes of Sewing Machine Jams

Sewing machine jams are often caused by a combination of factors related to threading, tension, or mechanical issues. Identifying the root cause is key to preventing future occurrences.

| Cause | Explanation |

|---|---|

| Improper Threading | The upper thread or bobbin thread not being threaded correctly is a primary cause. This can happen if the thread is not guided through all the tension discs, the presser foot is down during threading, or the bobbin is inserted incorrectly. |

| Incorrect Tension Settings | When the upper thread tension is too tight or too loose relative to the bobbin tension, it can cause the threads to knot and jam. Similarly, if the bobbin tension is not set correctly, it can lead to looping and tangling. |

| Using the Wrong Needle or Thread | Using a needle that is too fine for the fabric or thread, or a thread that is too thick, can cause the needle to snag or break, leading to a jam. Using a dull or bent needle can also contribute to thread issues. |

| Fabric Caught in Mechanism | Small pieces of fabric, lint, or stray threads can accumulate in the bobbin case, feed dogs, or under the needle plate, creating obstructions that cause jams. |

| Skipping the Bobbin Winding Process | If the bobbin is not wound evenly or is wound too loosely, it can lead to thread issues and jams during sewing. |

| Needle Position | Attempting to sew when the needle is not in its highest position can sometimes cause the needle to hit the presser foot or the throat plate, resulting in a jam. |

“A well-threaded machine with balanced tension is the foundation of smooth sewing.”

Basic Troubleshooting Steps

Once a jam has been identified, it is crucial to address it systematically to prevent further damage to your sewing machine. These basic troubleshooting steps will guide you through clearing common thread obstructions and ensuring your machine is ready to sew again. A calm and methodical approach is key to resolving these issues efficiently.Addressing a jammed sewing machine requires a step-by-step approach to identify and resolve the underlying cause.

The following sections detail essential troubleshooting techniques to help you get your machine back in working order.

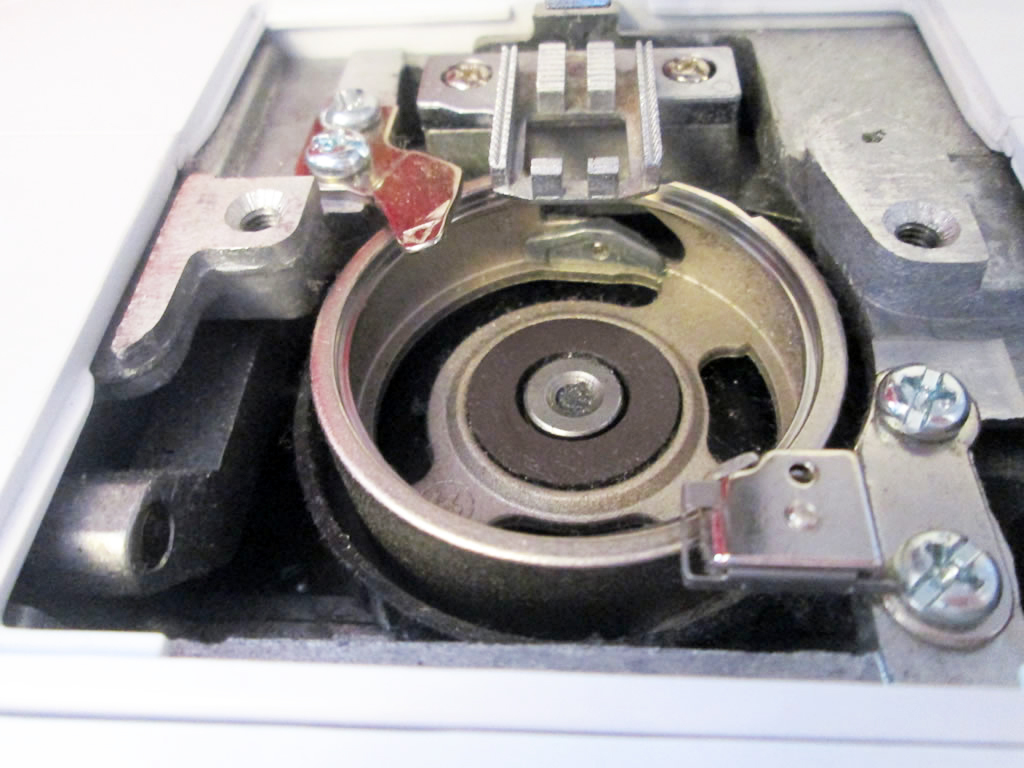

Clearing a Thread Jam in the Bobbin Area

The bobbin area is a frequent site for thread jams, often caused by uneven feeding or a loose thread. It is important to approach this area with care to avoid bending or breaking delicate parts.Follow these steps to clear a thread jam in the bobbin area:

- Turn off and unplug your sewing machine. This is a critical safety measure.

- Remove the needle.

- Open the bobbin case area. This usually involves removing the needle plate and the bobbin case itself. Refer to your sewing machine’s manual if you are unsure how to access this area.

- Carefully remove any visible tangled thread. Use tweezers or small scissors to gently pull out the threads. Avoid yanking, as this could damage the machine.

- Check the bobbin case for any nicks or burrs that might be catching the thread. If you find any, they may need to be smoothed out or the bobbin case may need to be replaced.

- Clean the bobbin area thoroughly. Use a small brush or a can of compressed air to remove any lint or small thread fragments.

- Reinsert the bobbin case and the needle plate.

- Thread the machine again, ensuring the thread is correctly seated in all the tension discs and guides.

- Manually turn the handwheel towards you a few times to ensure the thread is feeding smoothly before resuming sewing.

Removing Tangled Thread from the Needle and Upper Tension Discs

Thread can become entangled around the needle bar or within the upper tension discs, disrupting the smooth flow of thread. This requires a delicate touch to untangle without causing damage.To remove tangled thread from the needle and upper tension discs:

- Ensure the machine is powered off and unplugged.

- Gently lower the presser foot. This can sometimes help to loosen threads caught around the needle.

- Using tweezers, carefully try to unwind any thread wrapped around the needle or the presser foot shank.

- For the upper tension discs, slowly turn the handwheel towards you while observing the thread. If you can see a loop or a snag, try to gently pull it free with tweezers as the handwheel turns.

- If the thread is tightly wound, you may need to loosen the upper tension dial completely to help release the tension on the thread.

- After removing the tangled thread, re-thread the machine completely, ensuring the thread passes through the tension discs correctly.

- Test sew on a scrap piece of fabric to confirm the issue is resolved.

Checking and Cleaning the Feed Dogs

The feed dogs are responsible for moving the fabric under the needle. If they are clogged with lint or fabric debris, they can cause skipped stitches or fabric feed issues, which can lead to jams.The process for checking and cleaning the feed dogs involves:

- Turn off and unplug the sewing machine.

- Remove the needle plate.

- Locate the feed dogs, which are typically small, toothed metal pieces that move up and down and forward and backward.

- Use a small brush, a lint brush, or a can of compressed air to remove any accumulated lint, thread fragments, or fabric bits from around and between the feed dogs.

- Ensure the feed dogs can move freely. Gently push them with your finger to feel for any resistance.

- If your machine has adjustable feed dogs, ensure they are set to the appropriate height for your sewing task. Consult your manual for instructions on adjusting them.

- Reattach the needle plate.

Inspecting the Presser Foot and Needle Plate for Obstructions

Obstructions under the presser foot or on the needle plate can interfere with fabric movement and thread path, leading to jams. A thorough inspection is necessary to clear any hindrances.To inspect the presser foot and needle plate for obstructions:

- With the machine unplugged, lift the presser foot to its highest position.

- Visually examine the underside of the presser foot for any trapped threads or fabric.

- Remove the needle plate.

- Carefully inspect the area around the needle hole on the needle plate. Look for any small pieces of thread, fabric, or other debris that might be lodged there.

- Use a small brush, tweezers, or compressed air to remove any obstructions found on the needle plate or in the area directly beneath it.

- Ensure the needle is straight and properly inserted into the needle clamp. A bent needle can cause significant jamming issues.

- Reassemble the needle plate and lower the presser foot.

Addressing Specific Jam Scenarios

While basic troubleshooting often resolves common sewing machine jams, certain specific situations require tailored approaches. Understanding these scenarios and their solutions can save you time and prevent further damage to your machine. This section will guide you through resolving jams caused by broken needles, incorrect thread tension, and issues with the handwheel or motor.

Broken Needle Jams

A broken needle is a frequent culprit for jams, often lodging itself within the fabric, the needle plate, or even the bobbin area. When a needle breaks, it’s crucial to stop the machine immediately to avoid potential damage to the feed dogs or the bobbin case. After stopping, carefully remove any loose fabric fragments. Then, with the presser foot lifted, gently try to rotate the handwheel backward to see if the remaining needle piece can be dislodged.

If the needle fragment is visible and accessible, you might be able to carefully extract it with needle-nose pliers. If the fragment is lodged deeper, it may be necessary to remove the needle plate to gain better access. Always inspect the needle plate and the bobbin area for any bent or damaged parts after a needle breaks.

Incorrect Thread Tension Issues

Improper thread tension is a very common cause of stitching problems, including jams. If the top thread tension is too tight, it can cause skipped stitches and pull the bobbin thread through to the top, creating a messy, loopy stitch that can snag and jam. Conversely, if the top thread tension is too loose, the bobbin thread can loop on the underside of the fabric, also leading to jams.

The bobbin tension can also be a factor; if it’s too tight, it can resist the top thread, causing similar issues.To resolve tension-related jams, start by re-threading both the top thread and the bobbin. Ensure the thread is correctly seated in all the tension discs and guides. Adjust the top thread tension dial, typically starting from a medium setting (e.g., 4 on a 0-9 scale) and adjusting incrementally.

For the bobbin, most machines have a small screw on the bobbin case. Tightening this screw increases tension, while loosening it decreases it. It is generally recommended to adjust the top tension first.

A balanced stitch typically has both the top and bobbin threads meeting evenly within the fabric layers, with neither thread visibly dominating the other.

Handwheel or Motor Jamming

A jammed handwheel or motor indicates a more significant obstruction or mechanical issue within the machine. If the handwheel refuses to turn, it suggests that something is physically preventing the internal mechanisms from moving. This could be a tangled thread or lint buildup in the bobbin area, a jammed needle bar, or a problem with the drive belt.If the motor seems to be running but the needle isn’t moving, the issue is likely with the drive mechanism connecting the motor to the sewing head.

This could be a broken or slipped drive belt. In such cases, it’s often best to consult your sewing machine’s manual or seek professional servicing. Attempting to force the handwheel when it’s jammed can cause more severe damage.

Common Mistakes Leading to Jams and Prevention

Many sewing machine jams stem from simple oversights or incorrect usage. Being aware of these common pitfalls can significantly reduce the occurrence of jams.Here is a list of common mistakes and how to avoid them:

- Using the wrong needle: Always use the correct type and size of needle for your fabric and thread. For instance, using a ballpoint needle on woven fabric can cause skipped stitches, while a sharp needle on knits can snag. Ensure the needle is inserted correctly, with the flat side facing the back.

- Incorrect threading: Re-thread the machine entirely if you suspect a threading error. Ensure the presser foot is up when threading the top thread to allow the thread to seat properly in the tension discs.

- Thread tangles: Check for thread nests or tangles in the bobbin area and under the needle plate regularly. This often happens when the machine is started without holding the thread tails, or when the top thread is not pulled through the tension discs.

- Fabric handling: Do not force or pull the fabric through the machine. Let the feed dogs do the work. If the fabric is not feeding evenly, check the presser foot pressure and the feed dog height settings.

- Ignoring maintenance: Regular cleaning and oiling are essential. Lint and dust buildup can impede the smooth operation of moving parts, leading to jams.

- Using old or poor-quality thread: Old, frayed, or low-quality thread can break easily and cause tangles.

- Starting without holding thread tails: Always hold both the top thread and bobbin thread tails to the back of the presser foot when you begin sewing. This prevents the bobbin thread from getting pulled up and tangled.

By diligently following these preventative measures, you can enjoy a smoother and more consistent sewing experience, minimizing the frustration of dealing with jammed sewing machines.

Tools and Maintenance for Prevention

Preventing sewing machine jams is far more efficient than dealing with them. A proactive approach, involving the right tools and a consistent maintenance routine, can significantly reduce the occurrence of these frustrating issues. This section will guide you through the essential tools for unjamming and Artikel a comprehensive maintenance schedule to keep your machine running smoothly.A well-maintained sewing machine is less prone to jams.

This involves regular cleaning, proper lubrication, and attention to the details of thread and needle care. By incorporating these practices into your sewing habits, you can enjoy a more seamless and enjoyable crafting experience.

Essential Unjamming Tools

Having the right tools readily available can make a significant difference when a jam does occur. These items are designed to help you gently and effectively remove tangled thread without damaging your machine.

- Tweezers: Fine-tipped tweezers are invaluable for grasping and pulling out small, stubborn pieces of thread from tight spaces within the bobbin area or feed dogs.

- Small Screwdriver Set: A set of small, precision screwdrivers, often included with sewing machines, is necessary for removing needle plates or other components to access deeply lodged thread.

- Seam Ripper: While primarily used for altering stitches, a seam ripper’s sharp point can be useful for carefully cutting through tangled thread in accessible areas.

- Brush: A small, stiff-bristled brush, such as a cleaning brush specifically designed for sewing machines or even a clean toothbrush, is excellent for sweeping away lint and small thread fragments.

- Needle-Nose Pliers: For larger, more stubborn tangles, needle-nose pliers offer a firmer grip to pull out thread without breaking it into smaller, more difficult pieces.

Routine Maintenance Schedule for Jam Prevention

Establishing a regular maintenance routine is crucial for preventing future jams and ensuring the longevity of your sewing machine. This schedule Artikels key tasks and their recommended frequency.

Daily or After Each Use

These simple tasks, performed consistently, can prevent the buildup of lint and thread that often leads to jams.

- Remove Lint and Debris: After each sewing session, use a brush to clear away lint and thread scraps from the bobbin area, feed dogs, and needle plate.

- Check for Loose Threads: Visually inspect the machine for any loose threads that might have become caught.

Weekly or Every Few Hours of Sewing

More thorough cleaning and checks should be performed regularly to maintain optimal performance.

- Clean the Bobbin Case and Area: Carefully remove the bobbin and bobbin case and clean any accumulated lint or dust from these components and the surrounding area.

- Wipe Down Exterior: Use a soft, dry cloth to wipe down the exterior of the machine.

Monthly or As Needed

These tasks address deeper cleaning and lubrication, which are vital for internal mechanism health.

- Lubricate Moving Parts: Refer to your sewing machine manual for specific lubrication points. Apply a small amount of sewing machine oil to the designated areas to ensure smooth operation. Over-oiling can attract lint, so use sparingly.

- Clean the Feed Dogs: Use a brush and possibly a mild cleaning solution (as per your manual) to thoroughly clean the feed dogs, ensuring they can move freely.

- Inspect the Needle: Check the needle for any signs of bending, dullness, or burrs. A damaged needle can cause skipped stitches and jams. Replace as needed.

Annually or Bi-Annually

For optimal performance and to catch potential issues early, consider professional servicing.

- Professional Servicing: Schedule a professional tune-up with a qualified sewing machine technician. They can perform a deep clean, comprehensive lubrication, and identify any potential mechanical issues before they lead to major problems.

Proper Thread Selection and Handling for Jam Prevention

The type and condition of your thread play a significant role in preventing sewing machine jams. Using the correct thread and handling it properly ensures it feeds smoothly through the machine.

- Use Quality Threads: Opt for high-quality sewing threads. Inexpensive or old threads can be brittle, fuzzy, or have uneven thickness, all of which can cause tangles and breaks. Brands like Gütermann, Coats & Clark, or Mettler are generally reliable.

- Match Thread to Fabric and Needle: Ensure your thread weight is appropriate for the fabric you are using and the needle size. A thread that is too thick for a fine fabric or a small needle will cause tension issues and jams.

- Wind Bobbins Correctly: Wind bobbins evenly and without slack. An unevenly wound bobbin can cause the thread to snag or unwind improperly, leading to jams in the bobbin area.

- Store Threads Properly: Keep threads away from direct sunlight and dust. Old, frayed, or dusty threads are more likely to break or cause issues.

- Check Thread Spool: Ensure the thread is feeding off the spool smoothly. Sometimes, a knot or a loose end on the spool itself can cause problems.

Simple Cleaning Process for Internal Mechanisms

Regular cleaning of your sewing machine’s internal mechanisms is essential for preventing lint buildup and ensuring smooth operation, thereby minimizing the risk of jams.

Step-by-Step Cleaning Guide:

- Power Off and Unplug: Always ensure your sewing machine is turned off and unplugged from the power source before beginning any cleaning or maintenance.

- Remove Needle Plate: Carefully unscrew and remove the needle plate. This typically requires a small screwdriver. Keep the screws in a safe place.

- Clean the Bobbin Area: Remove the bobbin case and bobbin. Use a small brush to sweep out all lint, thread scraps, and dust from the bobbin race and the surrounding area. Pay close attention to the feed dogs.

- Clean the Feed Dogs: The feed dogs are the small, toothed bars that move the fabric. Lint can easily get trapped here. Use your brush to meticulously clean between and around the feed dogs. A toothpick can be used carefully to dislodge stubborn debris, but avoid scratching the metal.

- Clean the Needle Bar Area: With the needle plate removed, you can often access the area around the needle bar. Use your brush to remove any lint that may have accumulated here.

- Wipe Down Components: Use a clean, dry lint-free cloth to wipe down the removed needle plate and bobbin case.

- Reassemble: Carefully reassemble the needle plate and bobbin case, ensuring all screws are tightened appropriately but not excessively.

- Test Run: Before resuming regular sewing, perform a short test run with a scrap piece of fabric to ensure everything is functioning correctly and no new noises or issues have arisen.

“A clean machine is a happy machine, and a happy machine rarely jams.”

When to Seek Professional Help

While many sewing machine jams can be resolved with basic troubleshooting, there are instances where it is best to consult a professional. Attempting to fix complex issues without the necessary knowledge or tools can inadvertently cause further damage to your machine, leading to more expensive repairs. Recognizing when your skills have reached their limit is a sign of good judgment and can save you time and money in the long run.Understanding the nature of the jam and being able to articulate it clearly will greatly assist a repair technician in diagnosing and fixing the problem efficiently.

This preparedness can also help you make an informed decision about whether a repair is economically viable compared to purchasing a new machine.

Situations Requiring Expert Intervention

Certain sewing machine malfunctions indicate deeper mechanical problems that are beyond the scope of typical home repairs. These issues often involve internal components or require specialized tools and knowledge to address safely and effectively.

- Persistent Thread Jams: If you have followed all basic troubleshooting steps and the thread continues to jam repeatedly, especially in the bobbin area or under the needle plate, it suggests a misalignment or a worn component within the thread path.

- Broken Needles and Bent Components: A series of broken needles or evidence of bent parts, such as the needle bar or presser foot bar, often signifies that the machine has experienced a significant impact or internal stress, requiring a technician to inspect for underlying damage.

- Unusual Noises: Grinding, clicking, or loud clunking sounds that do not cease after basic checks can point to issues with the motor, gears, or other internal mechanisms that need professional assessment.

- Skipped Stitches or Uneven Tension After Extensive Adjustments: If you have meticulously adjusted tension settings, changed needles, and tried different threads without resolving persistent skipped stitches or uneven stitch quality, the problem might lie with the timing or internal stitch formation mechanism.

- Sewing Machine Not Moving: When the handwheel turns but the needle does not move, or the machine makes a whirring sound without any mechanical action, it suggests a problem with the drive belt, motor, or internal linkages.

- Electronic Malfunctions: For computerized sewing machines, error codes on the display, unresponsive buttons, or a complete lack of power that isn’t related to the power cord or outlet usually indicate an issue with the circuit board or software, necessitating professional diagnosis.

Describing the Jam Problem to a Repair Technician

Providing a clear and detailed description of the jam will significantly help a repair technician diagnose the issue accurately and efficiently. The more information you can offer, the quicker they can pinpoint the problem and estimate the repair.

- When did the jam occur? Note if it happened suddenly during normal operation, after a specific task (like sewing through thick fabric), or after a period of disuse.

- What type of fabric and thread were you using? Mention the material (e.g., cotton, denim, silk) and the thread weight and type (e.g., all-purpose polyester, cotton).

- What were you sewing? Briefly describe the project or the specific action you were performing when the jam happened.

- What steps have you already taken? List the troubleshooting methods you’ve already attempted, such as re-threading, changing the needle, checking the bobbin, cleaning the machine, etc.

- Describe the symptoms precisely: Is the thread tangled around the bobbin, caught under the needle plate, or does the machine refuse to move? Are there any unusual noises?

- Provide machine details: Have the make and model of your sewing machine readily available.

Cost-Effectiveness of DIY Fixes Versus Professional Repair

Deciding whether to attempt a DIY fix or seek professional repair involves weighing the potential costs and risks. For minor issues, DIY solutions are often cost-effective and empowering. However, for more complex problems, professional repair can be more economical and less risky.

For simple jams, such as thread nests in the bobbin area or a needle hitting the presser foot, the cost of DIY solutions is minimal, primarily involving your time and possibly the cost of a new needle or thread. The risk of further damage is also low if basic precautions are taken.

Conversely, persistent jams, internal mechanical issues, or problems with electronic components can escalate in cost if attempted DIY repairs go awry. A technician’s diagnostic fee might range from $50 to $100, with repairs for common issues like timing adjustments or motor problems potentially costing between $100 and $300. However, attempting to fix these yourself without expertise could lead to damage costing upwards of $500 or more, potentially rendering the machine irreparable.

For instance, a user trying to force a jammed needle bar might break a more critical internal gear, turning a $200 repair into a $700 one or a complete write-off.

The decision between DIY and professional repair hinges on the complexity of the issue, your comfort level with mechanical tasks, and the potential cost of exacerbating the problem.

It is generally cost-effective to attempt simple, visible fixes yourself. However, when the jam involves internal mechanisms, unusual noises, or repeated failures after basic troubleshooting, investing in professional expertise is often the more prudent and economical choice, preventing more significant expenses down the line.

Wrap-Up

Navigating a jammed sewing machine can initially feel daunting, but by understanding the common culprits and employing the straightforward techniques Artikeld, you can effectively resolve most issues. Remember that regular maintenance and proper usage are your best allies in preventing future jams, ensuring your creative endeavors flow uninterrupted. Should persistent problems arise, knowing when to seek professional assistance is a wise and cost-effective step, preserving both your machine and your passion for sewing.