Embarking on your sewing journey or looking to refine your skills? Mastering the art of how to insert a bobbin into your machine is a fundamental step that unlocks a world of creative possibilities. This guide will demystify the process, transforming what might seem like a small detail into a cornerstone of your sewing success.

Understanding the bobbin and its crucial role in sewing machine operation is the first step toward achieving beautiful, consistent stitches. From its basic purpose to the different types and materials used, we will explore the essential knowledge needed before you even begin. Preparing your machine safely and efficiently, including identifying the bobbin area and clearing out old thread, sets the stage for a smooth insertion process.

We will then delve into the standard bobbin winding technique, ensuring you achieve an evenly wound bobbin for optimal performance. Finally, we will guide you through the specific procedures for inserting a wound bobbin into both top-loading and front-loading (drop-in) systems, followed by the critical step of threading the upper thread to meet the bobbin thread, and conclude with troubleshooting common issues to ensure your sewing endeavors are always successful.

Understanding the Bobbin and Its Role

The bobbin is a crucial, yet often overlooked, component of any sewing machine. It serves as the reservoir for the lower thread, which is essential for creating a complete stitch. Without a properly inserted and functioning bobbin, your sewing machine would be unable to form the characteristic interlocking stitches that hold fabric together. It works in conjunction with the needle thread to produce a secure and durable seam.The fundamental purpose of a bobbin in sewing machine operation is to supply the lower thread that forms the underside of a stitch.

As the needle, carrying the upper thread, passes through the fabric, the bobbin case rotates around the bobbin, catching the upper thread and looping it around the lower thread. This interaction creates a balanced stitch, ensuring that both the top and bottom threads are securely intertwined.

Types of Bobbins

Sewing machines utilize various types of bobbins, each designed to fit specific machine models and bobbin cases. Understanding these differences is important for ensuring compatibility and optimal machine performance.

- Class 15 Bobbins: These are the most common type, characterized by their slightly wider and shorter profile. They are often made of plastic or metal and are found in many domestic sewing machines.

- Class 100/66 Bobbins: These are a smaller, more compact bobbin, often used in lighter-duty machines. They are typically made of plastic.

- Class 77 Bobbins: These are a larger, industrial-style bobbin, designed to hold more thread and are commonly found in heavy-duty and commercial sewing machines. They can be made of plastic or metal.

- Rotary Hook Bobbins: Many modern machines use bobbins designed specifically for rotary hook mechanisms. These bobbins often have a flat side or a notch to ensure proper engagement with the rotating hook.

Bobbin Materials

Bobbins are manufactured from a variety of materials, with the choice often dictated by the sewing machine’s design, intended use, and cost considerations.

- Plastic: This is the most prevalent material for bobbins in domestic sewing machines. Plastic bobbins are lightweight, inexpensive to produce, and generally do not damage the bobbin case. They are available in various colors, which can sometimes be helpful for organizing different thread colors.

- Metal: Metal bobbins, typically made of brass or aluminum, are often found in older machines or in industrial machines where durability and weight are more critical. They are generally more robust than plastic bobbins and can be more precise in their fit. However, a metal bobbin can potentially damage a bobbin case if it becomes warped or if the machine is not properly maintained.

Interacting Sewing Machine Components

Several key components within a sewing machine are specifically designed to interact with the bobbin, ensuring its correct placement and function.

- Bobbin Case: This component houses the bobbin and is responsible for guiding the lower thread. It typically has a small spring or tension mechanism that controls the release of the lower thread. The bobbin case is usually removable and can be cleaned or replaced if damaged.

- Bobbin Winder Spindle: This is the part of the machine that holds the bobbin while it is being wound with thread. It typically engages with the bobbin and spins it at a controlled speed.

- Bobbin Tension Mechanism: This is an integrated part of the bobbin case or the machine’s shuttle mechanism. It applies a slight resistance to the lower thread, ensuring that the tension between the upper and lower threads is balanced for a consistent stitch.

- Shuttle Hook (Rotary or Oscillating): This is the primary component that works with the bobbin case. In rotary hook systems, the shuttle hook rotates around the bobbin case, catching the loop of the upper thread and pulling it around the bobbin. In oscillating hook systems, the hook moves back and forth to perform the same function.

Preparing Your Machine for Bobbin Insertion

Before you can successfully insert a bobbin, it’s crucial to ensure your sewing machine is in a safe and ready state. This preparation step not only prevents accidental starts but also makes the bobbin insertion process smoother and more efficient. Taking a moment to properly prepare your machine will contribute to a more enjoyable sewing experience.The process of preparing your sewing machine for bobbin insertion involves a few key actions to guarantee safety and accessibility.

By following these steps, you’ll create an optimal environment for this fundamental sewing task.

Ensuring Machine Safety

It is paramount to ensure your sewing machine is powered off and disconnected from its power source before commencing any maintenance, including bobbin insertion. This is a critical safety measure to prevent accidental activation of the machine, which could lead to injury.The following steps will guide you in safely preparing your machine:

- Locate the main power switch, typically found on the side or back of the machine.

- Flip the switch to the ‘Off’ position.

- Unplug the power cord from the electrical outlet.

- If your machine has a foot pedal, disconnect it from the machine.

Identifying the Bobbin Area

The location of the bobbin and its case can vary slightly depending on the type and model of your sewing machine. Familiarizing yourself with your machine’s specific design will make the process intuitive.Sewing machines generally fall into two main categories regarding bobbin placement:

- Front-loading or Top-loading Bobbin: In these machines, the bobbin is typically housed in a removable or flip-open compartment located directly beneath the needle plate. You will usually lift a small cover or swing open a section to access it.

- Front-inserting Bobbin: Some older or more basic models might have a bobbin case that inserts into a compartment at the front of the machine, often below the stitch plate.

To confirm the location on your specific model, consult your sewing machine’s user manual. The manual will provide clear diagrams and instructions tailored to your machine.

Removing Existing Thread or Bobbin

Before inserting a new bobbin, it is essential to clear the bobbin area of any previous thread or bobbin. This prevents tangles and ensures the new bobbin can be seated correctly, allowing for smooth thread feeding.Follow these steps to clear the bobbin area:

- Gently pull out any loose thread that might be hanging from the needle or the bobbin area.

- If a bobbin is already in place, carefully lift it out of its case.

- If there is a bobbin case, ensure it is completely empty of thread.

- If the thread has become tangled, you may need to use small scissors or a seam ripper to carefully cut away the obstruction. Be cautious not to damage any parts of the machine.

Common Mistakes to Avoid

When preparing your sewing machine for bobbin insertion, several common oversights can lead to frustration or issues with your stitching. Being aware of these pitfalls can help you avoid them.Here are some common mistakes to be mindful of:

- Forgetting to power off the machine: This is the most critical safety error and must be avoided at all costs. Always ensure the machine is unplugged before attempting any bobbin-related tasks.

- Not removing all old thread: Leaving even a small piece of old thread can cause the machine to skip stitches or jam.

- Forcing the bobbin or bobbin case: If the bobbin or case doesn’t fit easily, do not force it. Recheck that you have the correct bobbin size and that the area is clear.

- Incorrectly seating the bobbin case: If your machine uses a removable bobbin case, ensure it is inserted in the correct orientation. Many have a small notch or tab that must align with a corresponding groove in the machine.

- Not consulting the manual: While many machines are similar, specific designs can differ. Relying on your machine’s manual is the most accurate way to prepare it.

The Standard Bobbin Winding Process

Winding a bobbin correctly is a fundamental skill for any sewer, ensuring a consistent thread supply for smooth and even stitching. A properly wound bobbin prevents skipped stitches, thread breakage, and an uneven stitch quality. This section will guide you through the essential steps of winding a bobbin, from preparing your machine to achieving a perfectly wound spool.Understanding the bobbin winding mechanism on your sewing machine is key to a successful outcome.

Most machines have a dedicated bobbin winder spindle, often located on the top or front of the machine, and a tension disc or guide through which the thread passes. The process is designed to be straightforward, but paying attention to a few details can make a significant difference in your sewing experience.

Steps for Winding Thread onto an Empty Bobbin

To ensure a smooth and consistent thread supply, the winding process must be followed carefully. This involves setting up the thread and guiding it through the machine’s winding mechanism.

- Begin by placing an empty bobbin onto the bobbin winder spindle. Most spindles have a small notch or groove to help secure the bobbin in place.

- Thread the sewing machine as if you were preparing to sew, but instead of guiding the thread through the needle, bring it up and over to the bobbin winder.

- Pass the thread through the tension disc on the bobbin winder. This disc provides the necessary tension to wind the thread evenly.

- Guide the thread through the small hole in the side of the empty bobbin. You may need to use a needle or a pin to help push the thread through.

- Hold the tail end of the thread firmly.

- Engage the bobbin winder mechanism according to your sewing machine’s manual. This usually involves pushing the bobbin winder spindle to the right or left, or engaging a lever.

- Manually wind the thread around the bobbin a few times to secure the tail.

- Once the tail is secured, trim any excess thread, leaving a short tail extending from the bobbin.

- Begin the automatic winding process. The machine will wind thread onto the bobbin until it is full or until you stop it.

Securing the Thread End on the Bobbin Winder Spindle

Properly securing the thread end before starting the winding process is crucial for preventing unraveling and ensuring a neat bobbin. A loose thread end can lead to tangles and an uneven wind.

Before you begin the automatic winding, it is essential to secure the thread tail. After manually winding the thread a few times around the bobbin to create a base, you should trim the excess thread, leaving a short tail (about 1-2 inches) that extends from the bobbin itself. This short tail acts as an anchor and prevents the wound thread from slipping off the bobbin.

Some sewing machines also have a small notch on the bobbin winder spindle designed to hold the thread end in place. Ensure the thread is firmly seated in this notch if your machine has one.

Tips for Achieving an Evenly Wound Bobbin

An evenly wound bobbin is paramount for optimal sewing machine performance. Uneven winding can cause tension issues, thread jams, and inconsistent stitch quality, leading to frustration and wasted time.

- Consistent Tension: Ensure the thread passes through the bobbin winder’s tension discs correctly. If the thread feels too loose or too tight as it winds, adjust the tension slightly.

- Smooth Thread Path: Verify that the thread is not catching on any rough edges of the machine or the thread spool. A clean and unobstructed path is vital.

- Correct Thread Spool Placement: Place the thread spool on its holder so that the thread unwinds smoothly without snagging or twisting. Some machines have vertical spool pins, while others use horizontal ones; follow your manual’s guidance.

- Gentle Guidance: While the machine does the winding, a gentle hand guiding the thread from the spool to the winder can help prevent loops and tangles, especially at the beginning.

- Stopping at the Right Time: Do not overfill the bobbin. Overfilling can cause the thread to snag or unwind prematurely.

Indicators of a Fully Wound Bobbin

Sewing machines typically provide clear signals when the bobbin is nearing completion or is fully wound. Recognizing these indicators helps you stop the winding process at the appropriate time, preventing overfilling.

Most sewing machines are equipped with an automatic stop mechanism. As the bobbin fills, the winding spindle often shifts slightly or engages a lever that disengages the motor once the bobbin reaches its maximum capacity. You might hear a subtle change in the machine’s sound or feel a slight resistance when the winding is complete. Some older or simpler machines may require you to manually monitor the winding and stop it by disengaging the bobbin winder.

Always refer to your sewing machine’s manual for specific indicators and procedures.

A Simple Setup for Winding a Bobbin

For beginners, a straightforward setup is key to mastering the bobbin winding process. This simplified approach focuses on the essential components and actions needed for a successful wind.

To create a basic bobbin winding setup, you will need the following:

- Your sewing machine with its bobbin winder spindle and tension disc.

- An empty bobbin that fits your machine.

- A spool of thread.

- A pair of sharp scissors.

Begin by placing the empty bobbin onto the spindle and threading the machine as you would for sewing, but directing the thread towards the bobbin winder. Guide the thread through the tension disc and then through the small hole in the bobbin. Hold the thread tail and manually wind it around the bobbin a few times to secure it. Trim the excess thread, leaving a short tail.

Then, engage the bobbin winder and let the machine do the work. Keep an eye on the bobbin as it fills, and disengage the winder when it appears full or when your machine automatically stops.

Inserting a Wound Bobbin into the Machine (Top Loading)

Now that your bobbin is wound and ready, the next crucial step is to correctly insert it into your sewing machine’s top-loading bobbin case. This process is designed to ensure smooth thread delivery and prevent common sewing issues like skipped stitches or thread tangles. Taking a moment to understand the mechanics of top-loading systems will make this task straightforward and efficient.In a top-loading bobbin system, the bobbin is housed in a removable bobbin case or directly within a specially designed shuttle area that is easily accessible from the top of the machine.

This design offers a clear view of the bobbin and makes it simpler to thread and re-thread. The key to success lies in understanding the direction the thread should unwind and how it engages with the machine’s feed mechanism.

Bobbin Placement and Thread Direction

The correct placement of the wound bobbin is paramount for proper stitch formation. Most top-loading bobbin systems are designed for the thread to unwind in a specific direction to feed the upper thread correctly. When you look at the bobbin as it sits in its case, the thread should generally unwind counter-clockwise, coming off the top of the bobbin. This allows the thread to pass through the tension discs and the machine’s threading path smoothly.To confirm this, gently pull on the thread tail.

It should feed off the bobbin without snagging or excessive resistance. If the thread is wound too loosely or is catching on the bobbin itself, it may unwind incorrectly, leading to sewing problems.

Engaging the Bobbin with the Machine

Once the bobbin is in place, it needs to be properly engaged with the machine’s shuttle mechanism. For machines with a removable bobbin case, the case itself is inserted into the shuttle area. The bobbin is placed inside this case, ensuring the thread unwinds in the correct direction. The case is then clicked or slid into its designated slot.For machines where the bobbin loads directly into the shuttle area without a separate case, you will place the bobbin into the designated cavity.

In both scenarios, a small notch or groove on the bobbin case or in the shuttle area is designed to catch the thread tail. After placing the bobbin, you will typically guide the thread tail into this notch or under a small clip. This secures the bobbin and ensures the thread is ready to be picked up by the needle.

Checklist for Successful Top-Loading Bobbin Insertion

A systematic approach ensures that the bobbin is inserted correctly every time. Following these steps will help you achieve a properly seated bobbin, ready for sewing.

- Ensure the machine is powered off and the needle is in its highest position.

- Open the bobbin cover or access panel for the top-loading bobbin area.

- If using a removable bobbin case, ensure it is clean and free of lint.

- Place the wound bobbin into the bobbin case or the designated shuttle area.

- Verify that the thread unwinds from the bobbin in the correct direction (typically counter-clockwise).

- Gently pull the thread tail to ensure it feeds smoothly.

- If using a bobbin case, insert it into the shuttle mechanism until it clicks or seats firmly.

- If loading directly into the shuttle, place the bobbin and guide the thread tail into the designated notch or under the clip.

- Close the bobbin cover or access panel.

- When you bring the needle down and then up manually (by turning the handwheel towards you), the bobbin thread should be caught and brought up with the needle thread.

Visual Cues for Correct Bobbin Seating

Observing certain visual cues can confirm that your bobbin is correctly seated in a top-loading system. These indicators are designed to provide immediate feedback on the bobbin’s status.

The bobbin should sit snugly within its housing, without wobbling or appearing loose.

The thread tail should be held securely in its designated groove or under its clip, preventing it from being pulled back into the bobbin housing.

After seating the bobbin and closing the cover, when you manually turn the handwheel to bring the needle down and then up, the bobbin thread should be smoothly pulled up through the machine’s throat plate, creating the first loop for the upper thread to catch.

If you notice any resistance, looseness, or if the bobbin thread doesn’t appear when you manually operate the machine, it indicates that the bobbin has not been seated correctly, and you should re-check the insertion steps.

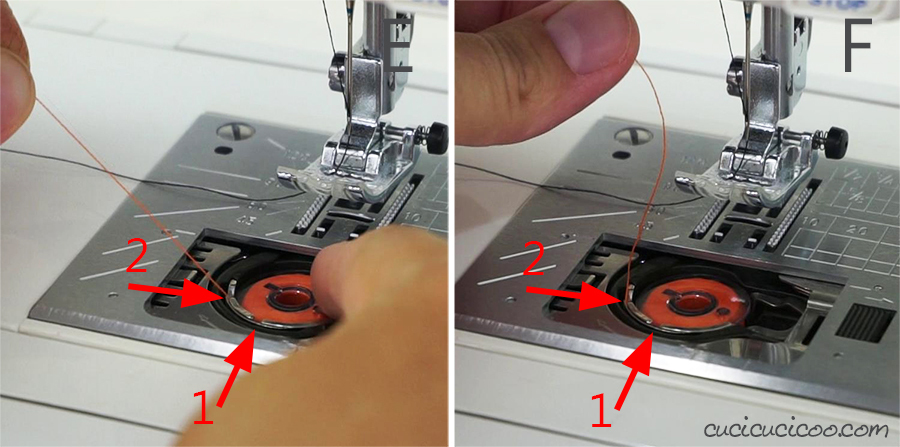

Inserting a Wound Bobbin into the Machine (Front Loading/Drop-in)

The front-loading or drop-in bobbin system is a popular design found in many modern sewing machines, prized for its convenience and ease of use. Unlike top-loading systems, the bobbin is accessed from the front of the machine, often through a small hinged door or a removable plate. This design allows for a clear view of the bobbin as it’s being inserted and is generally considered more intuitive for beginners.This section will guide you through the precise steps of inserting a wound bobbin into a front-loading or drop-in bobbin system.

We will cover how to correctly position the bobbin, thread it through the machine’s designated path, and ensure it’s securely in place so your machine can smoothly pick up the bobbin thread.

Placing the Wound Bobbin

The initial step involves carefully placing the wound bobbin into its designated housing. It’s crucial to orient the bobbin correctly, as this will affect how the thread is released and picked up by the machine.

To place the wound bobbin:

- Open the bobbin cover or plate located at the front of your sewing machine.

- Identify the bobbin case or housing. It’s typically a small, circular area where the bobbin will sit.

- Gently place the wound bobbin into the bobbin case. Ensure the bobbin is seated correctly and can spin freely.

Guiding the Bobbin Thread

Once the bobbin is in place, the next critical step is to guide the bobbin thread through the specific path designed by the manufacturer. This path is essential for the machine’s upper thread to engage with the bobbin thread and create a stitch.

Follow these steps to guide the bobbin thread:

- Observe the markings or grooves around the bobbin case. These are your guide for the thread.

- The thread typically needs to be pulled from the bobbin in a specific direction, often counter-clockwise, and then passed through a small notch or slit in the bobbin case.

- Continue guiding the thread towards the needle area, often through a small tension spring or guide, as indicated by your machine’s manual.

Ensuring Bobbin Security

A securely inserted bobbin is paramount for successful sewing. If the bobbin is loose or not properly seated, it can lead to skipped stitches, thread tangles, or the machine failing to pick up the bobbin thread altogether.

To ensure the bobbin is securely in place:

- After guiding the thread, gently tug on the thread to confirm the bobbin doesn’t pop out of its case.

- The bobbin should feel snug within its housing, with no excessive wobble.

- If your machine has a cover or plate, ensure it is closed or reattached securely.

Positioning the Thread for Pickup

The correct positioning of the bobbin thread is vital for the machine’s needle to successfully “grab” it and form a stitch. This involves ensuring the thread is fed smoothly and without tension that would prevent the needle from catching it.

The thread must be positioned correctly for the machine to pick it up by adhering to these points:

- The thread should be taut enough to be caught by the needle but not so tight that it resists movement.

- The thread should exit the bobbin case area cleanly, without any kinks or snags.

- This often means the thread needs to be pulled in a particular direction through the tension mechanism before it reaches the needle.

Visualizing a Correctly Inserted Drop-in Bobbin

A correctly inserted drop-in bobbin system presents a neat and orderly appearance. When viewed from above, you should see the bobbin sitting snugly in its case, with the thread emerging smoothly and ready to be guided upwards.

A correctly inserted drop-in bobbin should appear as follows:

- The bobbin is centered within its housing, with no part of it protruding unnaturally.

- The thread is visible emerging from the bobbin and passing through any designated guides or tension springs, leading towards the needle.

- The area around the bobbin case is clear of any loose threads or obstructions.

The smooth operation of your sewing machine relies heavily on the precise insertion and threading of the bobbin.

Threading the Upper Thread Through the Bobbin System

This crucial step connects the upper thread to the bobbin thread, allowing your sewing machine to create stitches. It’s a moment where the two threads must work in harmony to produce a beautiful seam. Successfully completing this process ensures your machine is ready to sew.The interaction between the upper thread and the bobbin thread is fundamental to sewing machine operation.

When threaded correctly, the upper thread will loop around the bobbin thread at the needle plate, forming a secure stitch. This section will guide you through the process of bringing the bobbin thread up to meet the upper thread, a vital maneuver for any sewer.

Bringing the Bobbin Thread Up

This is a pivotal moment where the lower thread is coaxed to the surface to meet the upper thread. This action is typically performed using the machine’s handwheel, a manual control that allows for precise movements.The handwheel is your key to controlling the needle’s vertical motion. By turning it towards you, you manually lower and then raise the needle. This movement is what will “catch” the bobbin thread and pull it up through the needle plate.To successfully bring the bobbin thread up, follow these steps:

- Ensure the presser foot is in theup* position. This provides clearance for the needle and thread.

- Hold the end of the upper thread loosely in your left hand.

- Turn the handwheel towards you, slowly lowering the needle into the needle plate.

- Continue turning the handwheel until the needle reaches its lowest point and begins to ascend.

- As the needle rises, you will see a small loop of the upper thread form around the needle.

- As the needle continues to rise, this loop will enlarge and snag the bobbin thread.

- Continue turning the handwheel until the bobbin thread is pulled up through the hole in the needle plate, forming a visible loop.

- Once a loop of bobbin thread is visible, gently pull it upwards and out from under the presser foot.

Identifying Successful Bobbin Thread Emergence

Recognizing that the bobbin thread has successfully emerged is straightforward. You will visually confirm its presence.You know the bobbin thread has successfully emerged when you can see a distinct loop of thread coming up through the needle plate, separate from the upper thread. This loop will be accessible to be pulled clear.

Common Issues and Resolutions for Bringing the Bobbin Thread Up

Occasionally, the bobbin thread may not come up on the first attempt. Several common issues can prevent this, but they are usually easily rectified.Common problems and their solutions include:

- Bobbin not wound correctly: If the bobbin thread is tangled or unevenly wound, it may not feed properly. Re-wind the bobbin, ensuring the thread is smooth and secure.

- Thread not caught by the needle: The needle may not have been lowered and raised sufficiently to catch the bobbin thread. Ensure you turn the handwheel through a full lowering and raising cycle.

- Needle threaded incorrectly: An improperly threaded needle will not create the loop needed to catch the bobbin thread. Re-thread the upper thread, making sure it passes through all guides and the needle eye correctly.

- Presser foot not in the up position: The presser foot can obstruct the needle’s ability to catch the bobbin thread. Always ensure the presser foot is raised before starting this process.

- Lint or debris in the bobbin case/area: Accumulated lint can prevent the bobbin thread from being pulled up. Clean the bobbin case and the surrounding area according to your machine’s manual.

Sequence for Threading Both Upper and Lower Threads

Successfully threading both the upper and lower threads involves a specific order of operations to ensure proper stitch formation. This sequence ensures that the machine is primed for sewing.The recommended sequence for threading your sewing machine is as follows:

- Ensure the sewing machine is turned off or unplugged for safety.

- Thread the upper thread according to the machine’s manual, passing it through all tension discs, guides, and the needle eye.

- Ensure the presser foot is in the

up* position.

- Hold the end of the upper thread loosely.

- Turn the handwheel towards you to lower and then raise the needle, catching the bobbin thread and pulling it up through the needle plate.

- Gently pull the bobbin thread loop completely out from under the presser foot.

- Place both the upper thread and the bobbin thread ends behind the presser foot and to the side, keeping them out of the way of the needle.

Troubleshooting Common Bobbin Insertion Problems

Even with the best intentions and clear instructions, occasional hiccups can occur when inserting a bobbin. Understanding these common issues and their solutions will help you get back to sewing smoothly in no time. This section will guide you through diagnosing and resolving problems that might arise during bobbin insertion.When a bobbin doesn’t insert correctly, it can stem from several factors related to the bobbin itself, the machine’s bobbin case, or the thread.

Identifying the root cause is the first step toward a swift resolution.

Reasons for Incorrect Bobbin Insertion

Several factors can contribute to a bobbin not seating or functioning properly within your sewing machine. These often relate to the physical characteristics of the bobbin or the bobbin area of the machine.

- Bobbin Size and Type: Using a bobbin that is not the correct size or type for your specific sewing machine is a frequent cause of insertion issues. Different machines are designed for specific bobbin dimensions and materials (e.g., plastic, metal).

- Damaged Bobbin: A bent, chipped, or otherwise damaged bobbin can prevent it from fitting correctly into the bobbin case or spinning freely.

- Incorrect Bobbin Winding: If the bobbin is wound unevenly, too loosely, or too tightly, it can cause thread jams or prevent proper engagement with the machine’s mechanisms.

- Dirt and Lint Buildup: Accumulations of lint and thread debris in the bobbin area, including the bobbin case and shuttle hook, can obstruct the bobbin’s movement and proper seating.

- Misaligned Bobbin Case: In machines with removable bobbin cases, an incorrectly seated or misaligned bobbin case will prevent the bobbin from functioning.

- Obstructions in the Bobbin Area: Foreign objects or tangled threads within the bobbin housing can physically prevent the bobbin from being inserted or operating correctly.

Diagnosing Thread Jams Related to Bobbin Placement

Thread jams originating from the bobbin area often manifest as the machine stopping mid-stitch, pulling loops of thread to the top side, or making unusual noises. Careful observation and systematic checking are key to diagnosing these issues.When a thread jam occurs, it’s crucial to stop the machine immediately to prevent further damage. The symptoms can be quite telling about the nature of the problem.

- Observe the Needle Plate Area: Look for visible thread nests or tangled threads around the needle plate and under the presser foot. This often indicates a jam originating from the bobbin system.

- Check for Resistance: Gently try to turn the handwheel. If it feels stiff or won’t turn, there’s likely a significant jam.

- Inspect the Bobbin Area: Open the bobbin cover and carefully remove the bobbin case (if applicable) and the bobbin. Examine them for any tangled threads or obstructions.

- Listen for Unusual Noises: Grinding, clicking, or loud thumping sounds during operation can signal that the bobbin is not moving freely or is catching on something.

- Examine the Upper Thread Path: While the issue may stem from the bobbin, sometimes the upper thread tension or threading can cause problems that mimic bobbin issues. Ensure the upper thread is correctly threaded and the tension is set appropriately.

Solutions for Bobbin Spinning Freely or Not Engaging

A bobbin that spins freely without catching the upper thread, or one that doesn’t seem to engage with the machine’s mechanism, indicates a problem with how the thread is being picked up or how the bobbin is seated.The primary goal here is to ensure the bobbin is held securely and that its thread can be properly caught by the rotating hook mechanism.

- Re-seat the Bobbin: Remove the bobbin and re-insert it, ensuring it is seated correctly according to your machine’s manual. For drop-in bobbins, ensure it’s fully settled in its compartment. For machines with a bobbin case, make sure the bobbin case is properly inserted and locked into place.

- Check Bobbin Thread Tension: For machines with a separate bobbin case tension adjustment, ensure it’s not too loose. The thread should pull with a slight resistance.

- Verify Bobbin Thread Direction: Confirm that the bobbin thread is feeding off the bobbin in the correct direction. Most machines require the thread to unwind counter-clockwise from the top. Refer to your manual for the exact requirement.

- Ensure Bobbin is Fully Wound: A bobbin that is nearly empty or wound very unevenly might not engage properly. Rewind the bobbin if necessary.

- Clean the Bobbin Area: Thoroughly clean the bobbin case, shuttle hook, and surrounding areas of lint and debris. A clean area allows for smooth operation.

Impact of Incorrect Bobbin Insertion on Stitch Quality

The bobbin plays a crucial role in forming stitches, and its incorrect insertion can lead to a variety of aesthetic and structural problems in your sewing. The bobbin thread forms the underside of your stitches, and any disruption here will be visible.

The bobbin’s proper function is essential for creating balanced, consistent stitches. Any issue with its placement or thread delivery will directly impact the appearance and integrity of the sewn fabric.

Incorrect bobbin insertion can result in:

- Looped or Skipped Stitches: This occurs when the bobbin thread is not properly caught by the upper thread, leading to loose loops on the underside or skipped stitches altogether.

- Uneven Tension: The stitch may appear tight on one side and loose on the other, or the fabric may pucker, indicating an imbalance caused by improper bobbin thread tension or delivery.

- Thread Breakage: A jam or snag caused by an improperly inserted bobbin can lead to frequent upper or bobbin thread breakage.

- Balled Thread Underneath: If the bobbin is spinning freely or not engaging correctly, the upper thread can pull the bobbin thread into a messy knot or ball underneath the fabric.

- Poor Stitch Formation: Ultimately, the overall appearance of the stitch will be compromised, appearing weak, messy, or inconsistent.

Best Practices for Maintaining the Bobbin Area

Proactive maintenance of the bobbin area is the most effective way to prevent future problems and ensure consistent, high-quality sewing. Regular cleaning and attention to detail will save you time and frustration.Establishing a routine for checking and cleaning the bobbin area will significantly reduce the likelihood of encountering insertion issues and thread jams.

- Regular Cleaning: After each sewing session, or at least daily for frequent users, remove the bobbin and bobbin case (if applicable) and use a small brush or compressed air to remove lint and debris from the bobbin area, shuttle hook, and feed dogs.

- Inspect Bins and Bobbins: Before inserting a bobbin, quickly inspect it for damage or uneven winding. Ensure you are using the correct type and size of bobbin for your machine.

- Proper Bobbin Winding: Always wind bobbins evenly and to capacity. Over- or under-winding can lead to thread issues.

- Correct Threading: Double-check that both the upper thread and bobbin thread are correctly threaded through their respective paths before starting to sew.

- Periodic Oiling: Refer to your sewing machine manual for specific instructions on lubricating the bobbin area or shuttle hook if your machine requires it.

- Address Issues Promptly: If you notice any unusual sounds, resistance, or poor stitch quality, stop sewing and address the bobbin area immediately rather than continuing and potentially causing more damage.

Closure

Successfully inserting a bobbin is more than just a mechanical step; it’s about building confidence and ensuring the foundation for every stitch you create. By understanding the nuances of bobbin types, proper winding, and the distinct insertion methods for various machine designs, you are now well-equipped to tackle any sewing project with precision. Remember, a correctly inserted bobbin is key to achieving professional-looking results, so embrace this skill and let your creativity flow!