How to Select the Right Stitch on Your Machine sets the stage for this enthralling narrative, offering readers a glimpse into a story that is rich in detail with formal and friendly language style and brimming with originality from the outset.

Embarking on any sewing project, whether you’re a seasoned artisan or just beginning your creative journey, hinges on a fundamental understanding of your sewing machine’s capabilities. The diverse array of stitches available is not merely for aesthetic variation; each stitch serves a specific purpose, impacting the durability, finish, and overall success of your creation. This guide will navigate you through the intricacies of identifying and utilizing the perfect stitch for every fabric and project, ensuring your sewing endeavors are both efficient and beautifully executed.

Understanding Your Sewing Machine’s Stitch Options

Selecting the right stitch on your sewing machine is fundamental to achieving professional-looking and durable results. Modern sewing machines offer a variety of stitches, each designed for specific purposes. Understanding these options empowers you to make informed decisions, enhancing both the appearance and integrity of your sewing projects. This section will guide you through the common stitch types, their functionalities, and how to identify them on your machine.Navigating the stitch options on your sewing machine can initially seem complex, but by understanding the purpose and appearance of each stitch, you can confidently select the best one for your needs.

Most machines categorize their stitches, making it easier to locate the appropriate setting.

Common Stitch Types and Their Functions

Sewing machines typically come equipped with a core set of stitches that form the foundation of most sewing tasks. Familiarizing yourself with these basic stitches will enable you to tackle a wide range of projects, from simple mending to garment construction and decorative embellishments.

- Straight Stitch: This is the most fundamental stitch and is used for almost all construction seams. It creates a single, continuous line of stitching. The length of the straight stitch is adjustable, with shorter stitches being stronger and suitable for areas that will experience stress, while longer stitches are good for gathering or basting.

- Zigzag Stitch: The zigzag stitch is a versatile stitch that moves back and forth as it stitches, creating a V-shaped pattern. It is commonly used for finishing raw edges to prevent fraying, for sewing stretchy fabrics where some give is needed, for decorative purposes, and for attaching elastic. The width and length of the zigzag stitch can usually be adjusted.

- Decorative Stitches: These are specialized stitches designed for embellishment. They often mimic hand embroidery or create unique patterns. Examples include satin stitches, blanket stitches, heirloom stitches, and various geometric or floral designs. Their primary use is for adding visual interest to projects, such as on cuffs, collars, or home decor items.

Identifying Stitch Types on Your Machine

Locating and selecting the desired stitch on your sewing machine is typically straightforward once you understand the labeling conventions. Most machines employ clear symbols or names on their control panels or digital displays.The control panel or display on your sewing machine is your primary interface for stitch selection. Take a moment to familiarize yourself with its layout.

- Control Dials/Buttons: Many machines have physical dials or buttons, often with corresponding symbols, to select stitch types. You might see a dial labeled “Stitch Select” or “Stitch Pattern.”

- Digital Displays: More advanced machines feature digital screens that show stitch names or icons. These often have up and down arrows or a selection wheel to cycle through the available stitches.

- Stitch Chart: Most sewing machine manuals include a stitch chart that visually displays each available stitch, its corresponding number or symbol, and a brief description of its use. Keep your manual handy for reference.

- Common Symbols: Look for a straight line icon for the straight stitch, and a zigzag line icon for the zigzag stitch. Decorative stitches are usually represented by more intricate patterns or specific names.

Comparison of Basic Stitch Settings and Their Impact on Fabric

The settings for stitch length and width significantly influence how a stitch behaves on different fabrics, affecting both its strength and appearance. Adjusting these parameters allows you to tailor the stitch to the specific material you are working with.Understanding the relationship between stitch settings and fabric type is crucial for preventing issues like skipped stitches, puckering, or fabric damage.

| Stitch Type | Typical Setting Range (Length/Width) | Impact on Fabric | Primary Use Case |

|---|---|---|---|

| Straight Stitch | Length: 1.0 mm (strong) to 4.0 mm (loose/basting) | Short lengths create strong seams that are less likely to break. Longer lengths can be used for gathering or temporary stitching without damaging the fabric. | Construction seams, topstitching, hemming. |

| Zigzag Stitch | Width: 0.5 mm (narrow) to 5.0 mm (wide) | Narrow widths provide a dense finish for preventing fraying on lighter fabrics. Wider widths are suitable for stretch fabrics or decorative applications. | Finishing raw edges, sewing knits, appliqué, buttonholes. |

| Satin Stitch (a type of decorative stitch) | Length: Very short (e.g., 0.1-0.5 mm), Width: Adjustable | Close, short stitches create a solid, smooth fill effect. Too long a stitch will result in gaps and a weak, uneven appearance. | Filling in letters, motifs, or small design areas. |

For instance, when sewing a fine silk, a shorter straight stitch (around 1.5-2.0 mm) will provide a secure seam without tearing the delicate fibers. Conversely, when basting a heavy denim, a longer stitch (3.5-4.0 mm) will allow for easy removal later. For stretchy athletic wear, a medium to wide zigzag stitch with a moderate length (e.g., width 2.0-3.0 mm, length 1.5-2.0 mm) offers both durability and flexibility.

Identifying the Right Stitch for Your Fabric Type

Selecting the appropriate stitch for your fabric is paramount to achieving professional-looking and durable results in your sewing projects. Different fabrics possess unique characteristics such as weight, texture, and elasticity, all of which influence how they behave under the sewing machine’s needle and thread. Understanding these fabric properties will guide you in making informed stitch choices, preventing common issues like skipped stitches, puckering, or fabric damage.The interaction between your sewing machine’s stitch and the fabric is a delicate balance.

A stitch that is too tight or too coarse can tear delicate materials, while a stitch that is too loose might not provide adequate strength for heavier fabrics. Similarly, stretchy fabrics require special consideration to maintain their flexibility. This section will delve into how to match your stitch selections with the specific demands of various fabric types.

Stitches for Delicate Fabrics

Delicate fabrics such as silk, chiffon, organza, and fine cottons require a gentle touch and stitches that do not strain or damage the fibers. The goal is to create a seam that is strong enough to hold but subtle enough not to detract from the fabric’s inherent beauty and drape. Overly aggressive stitches can lead to runs, tears, or an unsightly puckered appearance.For these fine materials, a shorter stitch length is generally recommended.

This distributes the stress over a greater number of stitches, making the seam more resilient without pulling or distorting the fabric.

- Straight Stitch: A standard straight stitch with a slightly shorter stitch length (e.g., 1.5-2.0 mm) is often suitable. Ensure your needle is appropriate for the fabric type, opting for fine, sharp needles to prevent snagging.

- Narrow Rolled Hem Stitch: Many sewing machines offer a specific rolled hem stitch, which creates a very narrow, clean hem. This is ideal for the edges of scarves, handkerchiefs, and lightweight garments made from silks or chiffons.

- Zigzag Stitch (Narrow and Short): A very narrow and short zigzag stitch can be used as a seam finish to prevent fraying on fabrics that are prone to unraveling. It adds a small amount of flexibility to the seam.

Stitches for Robust Materials

Heavyweight fabrics like denim, canvas, upholstery fabrics, and thick cottons demand stitches that can withstand significant stress and provide robust construction. These materials are often used for durable items such as jeans, bags, and outerwear, where seam strength is a primary concern. The stitches need to be substantial enough to hold the fabric layers together securely without breaking.When sewing robust materials, a slightly longer stitch length might be beneficial to allow the needle to pass through the thick layers more easily, reducing strain on both the needle and the thread.

However, the stitch should still be dense enough to provide strength.

- Straight Stitch: A strong straight stitch with a medium stitch length (e.g., 2.5-3.0 mm) is typically the go-to for durable seams in denim and canvas. Using a heavy-duty needle and strong thread, such as polyester or nylon, is crucial.

- Heavy-Duty Zigzag Stitch: For seams that require extra reinforcement or for finishing raw edges on thick fabrics, a slightly wider and longer zigzag stitch can be effective. This adds strength and prevents fraying.

- Bar Tack Stitch: Many machines have a bar tack stitch, which is excellent for reinforcing stress points like pocket corners or belt loops on heavy fabrics. This stitch creates a dense, short line of stitches that is incredibly strong.

Stitch Adjustments for Stretchy Fabrics

Stretchy fabrics, including knits, jersey, spandex blends, and performance wear, present a unique challenge: they need seams that can stretch with the fabric without breaking or causing the fabric to pucker. A standard straight stitch will likely break when the fabric is stretched, leading to popped seams. Therefore, stitches that incorporate elasticity are essential.The key to sewing stretchy fabrics is to use a stitch that has inherent give.

This allows the seam to move with the fabric.

- Zigzag Stitch (Medium Width and Length): A standard zigzag stitch with a medium width and length (e.g., 1.5-2.0 mm width, 1.0-1.5 mm length) is often referred to as a “stretch stitch.” It allows the seam to expand and contract with the fabric.

- Stretch Stitch (Lightning Bolt Stitch): Many modern sewing machines feature a specific “stretch stitch,” often depicted as a lightning bolt. This stitch is designed to provide excellent elasticity and is ideal for knits and activewear.

- Triple Straight Stitch (Stitch 404): Some machines offer a triple straight stitch, which sews forward, backward, and forward again in the same line. This creates a very strong and slightly elastic seam, suitable for areas that need durability and stretch, though it can be more challenging to work with on very thin knits.

- Overlock/Serger Stitch: While not a standard sewing machine stitch, an overlock or serger machine is specifically designed for knit fabrics. It simultaneously stitches, trims, and finishes the seam, providing a very professional and durable stretch seam. If you frequently work with knits, investing in a serger is highly recommended.

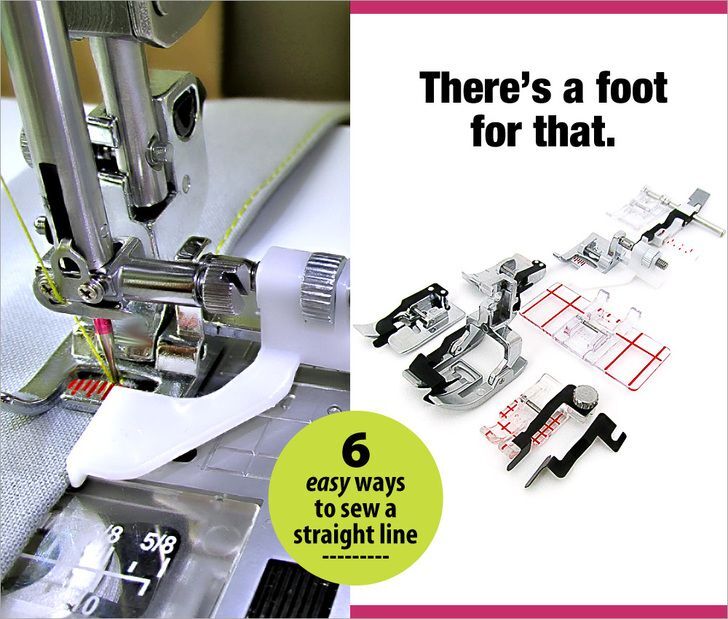

When sewing stretchy fabrics, it is also important to consider using a ballpoint or stretch needle, which is designed to push the fabric fibers aside rather than piercing them, preventing snags and holes. A walking foot or a roller foot can also help to feed multiple layers of stretchy fabric evenly, preventing stretching or distortion during the sewing process.

Matching the Stitch to Your Project’s Needs

Selecting the correct stitch goes beyond simply securing fabric; it’s about aligning the stitch’s function with the intended purpose of your sewing project. Different seams serve distinct roles, from providing structural integrity to adding decorative flair, and your stitch choice should reflect this. Understanding these roles will empower you to make informed decisions that enhance both the appearance and durability of your creations.The fundamental purpose of a seam dictates the type of stitch required.

A construction seam, for instance, needs to be strong and resilient to withstand wear and tear, while a finishing seam aims to prevent fraying and create a neat edge. Embellishment stitches, on the other hand, are purely for aesthetic appeal, adding visual interest and texture.

Durable Seams for Garment Construction

For garments, particularly those that will experience stress and movement, durable seams are paramount. These seams need to hold up to washing, wearing, and stretching without breaking or unraveling.

- Straight Stitch: The workhorse of sewing, the straight stitch is ideal for most construction seams. For added durability, especially on woven fabrics, consider using a slightly shorter stitch length. A stitch length of 2.0-2.5 mm is generally a good starting point for garment construction.

- Zigzag Stitch: A medium-width, short-length zigzag stitch (around 1.0-2.0 mm width and 1.5-2.0 mm length) is excellent for seams that require some stretch, such as those on knit fabrics. It also serves as a good alternative to a serger for finishing seam allowances on wovens, preventing fraying while providing a degree of reinforcement.

- Stretch Stitch: Many machines offer specific stretch stitches, often appearing as a triple straight stitch or a reinforced zigzag. These stitches are designed to stretch with the fabric, making them perfect for activewear, swimwear, and other garments made from elastic materials.

- Overlock Stitch (Serger): While technically a function of a serger, the overlock stitch is the gold standard for durable and professionally finished seams on many garments, especially knits. It simultaneously sews, trims, and finishes the raw edge in one pass.

Decorative Edges and Appliqué

Beyond basic construction, stitches can transform plain edges into decorative elements or secure appliqué pieces with precision and style.

- Satin Stitch: This stitch creates a dense, solid fill effect. It’s ideal for satin stitch appliqué, where it’s used to cover the raw edges of appliqué shapes, creating a smooth, professional finish. It can also be used to create decorative borders and motifs.

- Blanket Stitch: Traditionally used for finishing blankets, the blanket stitch can be adapted for decorative edging on garments and home decor. It can be used to create a scalloped edge or to appliqué shapes, providing both a decorative and functional finish. The spacing and length of the stitch can be adjusted for different looks.

- Decorative Stitches: Most modern sewing machines come equipped with a variety of decorative stitches, such as scallops, leaves, or floral patterns. These can be used to create unique borders, embellish cuffs, collars, or hems, and add a personalized touch to projects.

- Appliqué Stitch: Some machines have a specific appliqué stitch that resembles a small, tight zigzag. This stitch is designed to catch the edge of the appliqué fabric neatly without covering too much of the design, providing a secure and attractive finish.

Preventing Fraying on Edges

Managing fraying is crucial for the longevity and neat appearance of any sewn item. The right stitch can effectively secure raw edges, preventing them from unraveling over time.

- Zigzag Stitch: As mentioned, a well-placed zigzag stitch along the raw edge of a seam allowance is a highly effective method for preventing fraying on woven fabrics. Ensure the stitch straddles the raw edge, with some stitches going off the edge and others catching the fabric.

- Overcast Stitch: Many machines offer an overcast stitch, which is similar to a zigzag but designed specifically to enclose the raw edge. This stitch is particularly useful for lightweight or loosely woven fabrics that are prone to significant fraying.

- French Seams: While not a single stitch, French seams are a construction technique that encloses raw edges within the seam itself. This method results in a very clean and durable finish, ideal for sheer or delicate fabrics where fraying is a concern. The process involves sewing a narrow seam, trimming, turning the fabric, and sewing another seam to encase the raw edges.

- Pinking Shears: While not a stitch, using pinking shears to trim seam allowances before sewing can help reduce fraying. The zigzag cut made by pinking shears shortens the length of individual threads, making them less likely to unravel. This can be used in conjunction with a stitch for maximum protection.

Adjusting Stitch Settings for Optimal Results

Selecting the correct stitch type is a crucial first step, but achieving a truly professional finish requires fine-tuning the settings of your chosen stitch. This involves understanding how adjustments to stitch length, width, and tension can dramatically impact the appearance and durability of your sewing. By mastering these adjustments, you can ensure your stitches not only look good but also perform as intended on a variety of fabrics.The interplay between stitch length, stitch width, and thread tension is fundamental to successful sewing.

Each element influences the other, and finding the right balance is key to creating strong, neat seams. Taking the time to understand these settings and practicing their application will elevate the quality of your sewing projects.

Stitch Length and Width Adjustments

Stitch length dictates the distance between each individual stitch. A shorter stitch length creates a denser, more durable seam, often preferred for high-stress areas or delicate fabrics where you want to prevent fraying. Conversely, a longer stitch length is suitable for temporary seams, basting, or when working with very thick fabrics where a shorter stitch might struggle to penetrate. Stitch width, primarily relevant for decorative stitches like zigzag or satin stitches, controls how wide the stitch pattern spreads.

Adjusting width allows you to create varied decorative effects, from a narrow, precise line to a broad, coverage stitch.Here are the typical impacts of adjusting stitch length and width:

- Shorter Stitch Length: Increases seam strength, reduces fraying, and is ideal for fine fabrics or areas requiring extra durability.

- Longer Stitch Length: Suitable for basting, temporary seams, or very thick materials.

- Narrower Stitch Width (for decorative stitches): Creates a more delicate and refined look.

- Wider Stitch Width (for decorative stitches): Provides more coverage and a bolder visual impact.

Modifying Tension Settings

Thread tension is perhaps the most critical, yet often misunderstood, aspect of stitch adjustment. Proper tension ensures that the needle thread and the bobbin thread interlock correctly between the layers of fabric, creating a balanced stitch. Incorrect tension can lead to a variety of problems, such as loops on the fabric surface, puckering, or weak seams. Different fabric types and thread weights necessitate different tension settings.

For instance, finer fabrics and threads generally require lower tension to prevent tearing, while thicker materials and threads might need slightly higher tension for adequate penetration and seam strength.The goal is to achieve a balanced stitch where the needle thread and bobbin thread meet evenly in the middle of the fabric.

A balanced stitch appears the same on both the top and underside of the fabric, with no visible loops or thread pulling.

When adjusting tension, always remember to modify the needle tension first, as it has a greater impact on the stitch appearance. If the needle thread is looping on the underside, increase the needle tension. If the bobbin thread is looping on the top, decrease the needle tension or increase the bobbin tension (though adjusting bobbin tension is less common and often requires special tools or knowledge).

Procedure for Testing Stitches on a Fabric Scrap

Before committing to your project, it is highly recommended to perform a stitch test on a scrap piece of the same fabric you will be using. This practice allows you to verify that your stitch settings are optimal for that specific material and thread combination without risking damage to your main project.Follow this procedure for effective stitch testing:

- Cut a small scrap of your project fabric, approximately 4×4 inches.

- If you are using a specific thread for your project, use that thread in both the needle and the bobbin for the test.

- Set your machine to the intended stitch type and initial length and width settings.

- Sew a few straight lines and any necessary decorative stitches on the fabric scrap.

- Examine the stitches on both sides of the fabric. Check for evenness, loops, puckering, or thread breakage.

- If adjustments are needed, modify the stitch length, width, or tension settings incrementally.

- Sew another test line after each adjustment and re-examine the results until you achieve a satisfactory stitch.

Troubleshooting Common Stitch Problems

Even with careful setup, stitch problems can occasionally arise. Understanding the common issues and their likely causes will help you quickly diagnose and resolve them, saving you time and frustration.Here is a guide to troubleshooting common stitch problems:

| Problem | Possible Causes | Solutions |

|---|---|---|

| Skipped Stitches | Incorrect needle insertion, bent or dull needle, wrong needle for fabric, incorrect tension, lint in the bobbin area, machine needs cleaning or oiling. | Ensure the needle is inserted correctly with the flat side facing the back. Use the correct needle type and size for your fabric. Clean the bobbin area and the feed dogs. Re-thread the machine, ensuring the presser foot is up when threading the needle. Check if the machine needs professional servicing. |

| Puckering | Tension too high, stitch length too short, fabric not properly supported, using the wrong presser foot. | Reduce needle tension. Increase stitch length. Ensure you are using the correct presser foot for the stitch type and fabric. Gently guide, but do not pull, the fabric as it feeds through the machine. |

| Thread Breaking (Needle Thread) | Tension too high, rough spot on the needle, lint in the tension discs, incorrect threading, knot in the thread. | Reduce needle tension. Check the needle for damage and replace if necessary. Clean the tension discs. Re-thread the machine carefully. Ensure you are using good quality thread without knots. |

| Thread Breaking (Bobbin Thread) | Bobbin wound unevenly, bobbin not seated correctly in the bobbin case, burr on the bobbin case or bobbin. | Rewind the bobbin smoothly. Ensure the bobbin is inserted correctly and the thread is pulled through the tension spring. Check the bobbin case for any rough edges and smooth them if found. |

| Uneven Stitch Appearance | Incorrect tension, inconsistent stitch length, fabric pulling or stretching during sewing. | Adjust needle and bobbin tension for balance. Ensure stitch length is set appropriately. Guide the fabric gently without stretching it. |

Advanced Stitch Techniques and Their Applications

Beyond the fundamental stitches, sewing machines offer a range of advanced techniques that can elevate your projects from simple to sophisticated. These specialized stitches are designed for specific purposes, providing both functional benefits and aesthetic enhancements. Understanding and utilizing these advanced options can significantly expand your sewing capabilities and allow for more professional-looking results. Exploring these advanced stitches opens up a world of creative possibilities, enabling you to tackle a wider variety of sewing tasks with precision and style.

From creating perfectly finished edges to adding decorative flair, these techniques are invaluable tools for any serious sewer.

Buttonhole Stitches

Buttonhole stitches are essential for creating neat, durable openings for buttons on garments and other fabric items. Most modern sewing machines have a dedicated buttonhole function, often an automatic or semi-automatic process that simplifies this formerly intricate task. The stitch itself is a dense, interlocking zig-zag pattern that forms a reinforced edge around the buttonhole opening, preventing fraying and providing structural integrity.

The machine typically stitches four sides of the buttonhole: two parallel lines of straight stitches to define the length, followed by a dense zig-zag stitch on either side to secure the edges, and finally, a few reinforcing straight stitches at each end. The primary purpose of a buttonhole stitch is to create a functional and aesthetically pleasing closure. It ensures that the fabric can withstand repeated stress from buttoning and unbuttoning without tearing or unraveling.

Overlock or Serger Stitches

Overlock or serger stitches are typically performed on a specialized machine called a serger, though some advanced sewing machines incorporate overlock stitch capabilities. These stitches are designed to simultaneously trim excess fabric, stitch the seam, and overcast the raw edges in a single pass. This results in a clean, professional finish that prevents fraying and creates a durable, flexible seam.

The most common overlock stitch involves three or four threads that loop around the raw edge of the fabric, forming a secure and neat finish. The role of overlock stitches in professional finishing is paramount. They are widely used in the garment industry for constructing seams in knit fabrics, as well as for finishing edges of woven fabrics. This technique not only enhances the longevity of the garment by preventing unraveling but also contributes to a polished, ready-to-wear appearance.

Specialty Stitches

Specialty stitches are a category of stitches designed for specific, often decorative or functional, purposes that go beyond basic seams. These stitches add unique qualities to your sewing projects, enhancing both their appearance and utility. Here are some common specialty stitches and their applications:

- Blind Hem Stitch: This stitch is designed to create a nearly invisible hem on garments. It catches only a few threads of the main fabric while securing the hem allowance, making the stitching appear to disappear into the fabric from the right side. It is particularly useful for hemming trousers, skirts, and dresses where a clean, unobtrusive finish is desired.

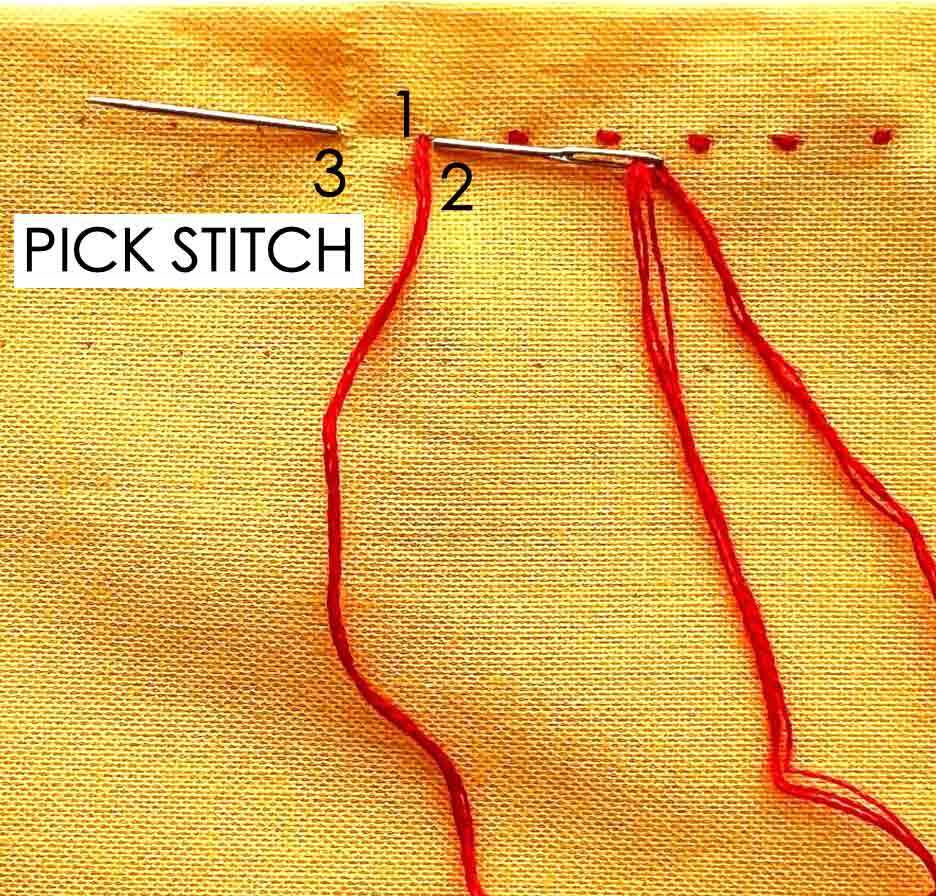

- Quilting Stitches: While a standard straight stitch can be used for quilting, some machines offer specific quilting stitches. These might include a longer stitch length for easier removal if basting is needed, or specialized stitches that mimic hand-quilting stitches for a more traditional aesthetic. They are designed to create durable and decorative lines of stitching through multiple layers of fabric and batting.

- Satin Stitch: This is a dense, short zig-zag stitch that is used to fill in areas for decorative purposes, creating a smooth, solid effect. It is often used in appliqué and embroidery to create solid shapes and designs.

Built-in Embroidery or Decorative Stitches

Many modern sewing machines come equipped with a library of built-in embroidery and decorative stitches. These stitches are pre-programmed patterns that can be selected and stitched directly by the machine, allowing for creative embellishment without the need for a separate embroidery machine. These stitches range from simple geometric patterns and floral motifs to more complex designs. Accessing and utilizing these stitches typically involves navigating through the machine’s stitch selection menu, often displayed on an LCD screen.

Once a stitch is selected, you may have options to adjust its width, length, and even mirror it.

To utilize built-in decorative stitches, ensure you are using the appropriate needle and thread for your fabric type, and select a stitch that complements your project’s design aesthetic.

To use these stitches, you will generally need to:

- Select the desired decorative stitch from the machine’s stitch menu.

- Ensure the correct presser foot is attached; some decorative stitches require a specific foot for optimal performance.

- Adjust the stitch width and length settings as recommended by your machine’s manual or as desired for your project.

- Thread the machine with the appropriate thread color and type.

- Test the stitch on a scrap piece of fabric before stitching on your actual project to ensure you achieve the desired result.

These stitches can be used to add unique borders to projects, create eye-catching embellishments on clothing, or add personalized touches to home décor items.

Visualizing Stitch Performance

Understanding how different stitches appear on fabric is crucial for achieving professional-looking results. This section will guide you through visualizing the aesthetic and functional outcomes of common stitch types, allowing you to make informed decisions for your sewing projects. By observing the top and underside of your fabric, and understanding the mechanics of stitch formation, you can anticipate and achieve the desired effect.Examining stitch performance involves more than just looking at the thread.

It requires an understanding of how the needle and bobbin threads interlock to create a secure and visually appealing seam. This visual inspection helps in diagnosing potential issues and optimizing your machine’s settings for different fabrics and project requirements.

Straight Stitch Appearance

The straight stitch is the most fundamental stitch, forming a single line of thread. Its appearance on the top and underside of the fabric is a direct indicator of correct tension and stitch length.On the top side of the fabric, a well-executed straight stitch appears as a clean, unbroken line of thread, with each stitch evenly spaced and parallel to the previous one.

The needle thread lies smoothly on the surface.The underside of the fabric should mirror the top side. The bobbin thread should be visible as a complementary line of stitching, lying flat against the fabric. Ideally, the bobbin thread should not be pulling the fabric up or creating loops. If the bobbin thread is visible on the top side, it often indicates that the upper tension is too loose or the bobbin tension is too tight.

Conversely, if the needle thread is visible on the underside, the upper tension may be too tight or the bobbin tension too loose. The stitch length should be consistent, with no puckering or skipped stitches.

Zigzag Stitch Coverage and Flexibility

The zigzag stitch, characterized by its back-and-forth motion, offers versatility for various sewing applications, from finishing edges to decorative effects. Its coverage and flexibility are key to its functionality.A standard zigzag stitch creates a series of V-shaped stitches that move from side to side. The width of the zigzag determines how far the needle swings to the left and right, influencing the stitch’s coverage.

A narrow zigzag stitch provides minimal coverage, suitable for reinforcing seams or creating delicate decorative patterns. A wider zigzag stitch offers more substantial coverage, making it ideal for preventing fabric fraying along raw edges or for decorative stitching that needs to stand out.The flexibility of the zigzag stitch comes from its ability to stretch. When sewn on stretch fabrics, the needle and bobbin threads create a stitch that can expand and contract with the fabric, preventing the seam from breaking.

This is particularly important for activewear, knit garments, and other stretchy materials. The stitch density, or the number of stitches per inch, also plays a role in flexibility; a higher stitch density creates a more robust and less stretchy seam.

Buttonhole Stitch Formation

The buttonhole stitch is designed to create a durable and neat casing for buttons, ensuring they are securely attached to the garment. Its formation involves a precise sequence of stitches that form a reinforced loop.The process typically begins with a series of closely spaced straight stitches along the buttonhole’s planned length. This creates a foundation. Following this, the machine switches to a zigzag stitch, often with a narrow width and a slightly longer stitch length.

The needle swings from one side of the initial straight stitches to the other, encasing the raw edge of the fabric. This zigzagging action is repeated multiple times, building up a dense, satin-like stitch that effectively covers the raw edges and creates a strong, raised edge. Finally, the machine often returns to a straight stitch at one or both ends of the buttonhole to further secure the loop and prevent unraveling.

The result is a compact, dense stitch that forms a secure, slightly raised edge around the buttonhole opening.

Blind Hem Stitch Appearance

The blind hem stitch is a specialized stitch that allows for a nearly invisible hem on many types of fabric, providing a professional finish without the visible line of stitching seen with a standard hem.When executed correctly, the blind hem stitch appears as a series of small, discreet stitches on the right side of the fabric. These stitches catch only a few threads of the main fabric, just above the folded hem allowance.

The majority of the stitch is formed by the bobbin thread, which secures the folded hem to the garment’s body. On the underside, the stitch forms a more visible, albeit still relatively small, zigzag or straight stitch that secures the folded edge of the hem. The key to its invisibility is the minimal amount of needle thread that is pulled to the visible surface of the garment, creating a subtle connection that is difficult to discern from a distance.

The stitch length and width are critical; a shorter, narrower stitch is generally preferred for maximum invisibility.

Final Review

Mastering the art of stitch selection is a cornerstone of successful sewing. By understanding the unique characteristics of each stitch, learning how to match them to different fabrics and project requirements, and fine-tuning your machine’s settings, you unlock a new level of precision and creativity. This comprehensive approach empowers you to tackle any sewing challenge with confidence, transforming your ideas into polished, professional-quality finished pieces.

Happy stitching!