Embark on a rewarding journey into the art of garment finishing with our comprehensive guide on How to Sew a Basic Hem on a Dress or Skirt. This essential skill forms the foundation of professional-looking attire, transforming raw edges into polished, durable seams. Whether you’re a novice crafter or looking to refine your techniques, understanding the nuances of hemming is paramount for achieving beautiful and lasting results.

This guide delves into every facet of creating a perfect hem, from understanding its fundamental purpose and selecting the right tools to mastering various sewing techniques suitable for different fabrics. We will explore the preparation steps, the intricacies of both machine and hand stitching, and how to overcome common challenges to ensure your finished hems are smooth, even, and impeccably neat.

Understanding the Basic Hem

The hem is a foundational element in garment construction, serving both a practical and aesthetic purpose. For dresses and skirts, a well-executed hem not only prevents fabric edges from fraying and unraveling but also provides a finished look, adding weight and structure to the garment’s drape. It is the final touch that elevates a piece from a collection of fabric pieces to a wearable item.A basic hem is the simplest and most common method for finishing the bottom edge of a garment.

Its primary function is to create a clean, durable, and visually appealing edge that complements the overall design of the dress or skirt. The type of basic hem chosen can subtly influence the garment’s silhouette and how it moves.

Common Types of Basic Hems

Several types of basic hems are well-suited for dresses and skirts, each offering a slightly different finish and level of ease in execution. Understanding these options allows for a choice that best matches the fabric and desired aesthetic.

- Double Fold Hem: This is perhaps the most prevalent and versatile basic hem. It involves folding the raw edge of the fabric up twice to enclose the raw edge entirely, creating a neat and durable finish. It is suitable for a wide range of fabrics, from lightweight silks to medium-weight cottons.

- Rolled Hem: A finer and more delicate finish, the rolled hem is achieved by rolling the very edge of the fabric and then stitching it down. This is often used on very lightweight or sheer fabrics like chiffon or georgette, where a bulkier hem would be undesirable. It can be done by machine or by hand.

- Narrow Hem: Similar to a rolled hem, a narrow hem is a very small, turned-up edge. It’s a good option for curved hemlines or when a very subtle finish is desired. It can be achieved with a special presser foot on a sewing machine or by carefully folding and stitching by hand.

Essential Tools and Materials

Successfully sewing a basic hem requires a few key tools and materials that ensure precision and a professional finish. Having these readily available will streamline the process.Before beginning, ensure you have the following items prepared for a smooth hemming experience:

- Sewing Machine: While hand-sewing is an option, a sewing machine significantly speeds up the process and can achieve a more consistent stitch.

- Thread: Choose a thread that matches your fabric color. All-purpose polyester thread is a good standard choice for most fabrics.

- Sewing Needles: Use a needle appropriate for your fabric type. A universal needle is suitable for most woven fabrics, while a ballpoint or stretch needle is necessary for knits.

- Fabric Scissors or Rotary Cutter and Mat: For accurately cutting the hem allowance.

- Measuring Tape or Ruler: Essential for precise measurements of the hem allowance.

- Fabric Pins or Clips: To secure the folded hem in place before stitching.

- Iron and Ironing Board: Crucial for pressing the folds, which creates crisp lines and makes stitching much easier and more accurate.

- Seam Ripper: For correcting any mistakes.

- Chalk or Fabric Marker: To mark the hemline and fold lines if needed.

Fabric Type and Hemming Technique

The type of fabric used for a dress or skirt plays a significant role in determining the most appropriate hemming technique. Different fibers and weaves have distinct properties that affect how they drape, fray, and handle being folded and stitched.The interaction between fabric characteristics and hemming methods is critical for achieving a professional and durable garment. Consider these points when selecting your approach:

- Lightweight and Sheer Fabrics (e.g., Chiffon, Silk, Georgette): These fabrics are prone to fraying and can become bulky with double-folded hems. A narrow or rolled hem is often preferred. For machine sewing, a rolled hem presser foot is invaluable. Hand-rolled hems offer a delicate finish but require patience.

- Medium-Weight Woven Fabrics (e.g., Cotton, Linen, Poplin): These are the most versatile fabrics for hemming. A double fold hem is typically the best choice, providing durability and a clean finish without excessive bulk. The width of the double fold can be adjusted based on the fabric’s weight and the desired look.

- Knit Fabrics (e.g., Jersey, Interlock): Knit fabrics stretch, so a hem that can accommodate this stretch is necessary. A double fold hem can work, but it’s important to use a stretch stitch or a twin needle on your sewing machine to prevent the stitches from breaking when the fabric is stretched. A coverstitch machine is ideal for a professional knit hem. Alternatively, a simple turned-up hem secured with a stretch stitch can also be effective.

- Heavyweight Fabrics (e.g., Denim, Wool): These fabrics can handle a wider double fold hem, which can add a nice weight and structure. However, too many layers of heavy fabric can create excessive bulk. Sometimes, a single fold hem with a serged edge is a good alternative to manage bulk while still preventing fraying.

Preparing the Garment for Hemming

Before you can sew a beautiful and even hem, proper preparation of the garment is crucial. This involves ensuring the fabric is clean, pressed, and accurately measured to achieve the desired finished length. Taking these initial steps diligently will prevent frustration and lead to a professional-looking result.The process begins with preparing the raw edge of the fabric that will eventually become your hem.

This ensures that when you fold and press, you are working with a clean and manageable edge, free from wrinkles or distortions that could affect the final outcome.

Initial Garment Preparation

The first step in preparing your dress or skirt for hemming is to ensure the garment is clean and pressed. Washing and drying the garment according to its care instructions will pre-shrink the fabric, preventing any unexpected shrinking after the hem is sewn. A thorough pressing removes any wrinkles or creases that could interfere with accurate measuring and folding. Ensure the garment is laid flat and smooth before proceeding to the next steps.

Measuring and Marking the Hem Length

Accurate measurement is the cornerstone of a well-executed hem. This step determines the final length of your garment, so precision is paramount. You will need a measuring tape and tailor’s chalk or a fabric marker.To measure, hang the garment on a dress form or wear it if it’s a skirt that can be easily managed. If using a dress form, measure from the waist or the point where the hem should begin down to the desired finished length.

If wearing the garment, have a friend assist you in measuring from the waist or designated starting point.

“Measure twice, cut once” is a timeless adage that holds true for hemming. Accuracy in this stage saves significant time and effort later.

When marking, consider the hem allowance you will need for folding. A standard hem allowance for most garments is between 1 to 4 inches, depending on the fabric weight and desired style. For example, a lightweight chiffon skirt might benefit from a narrower double-folded hem, while a heavier denim skirt could accommodate a wider single or double fold.Use tailor’s chalk or a fabric marker to create a line all the way around the garment at your desired finished hem length.

Ensure this line is parallel to the floor for an even hem. If the garment has a side seam, align your measuring tape with the side seam and mark from there, ensuring consistency.

Pressing and Folding the Hem Allowance

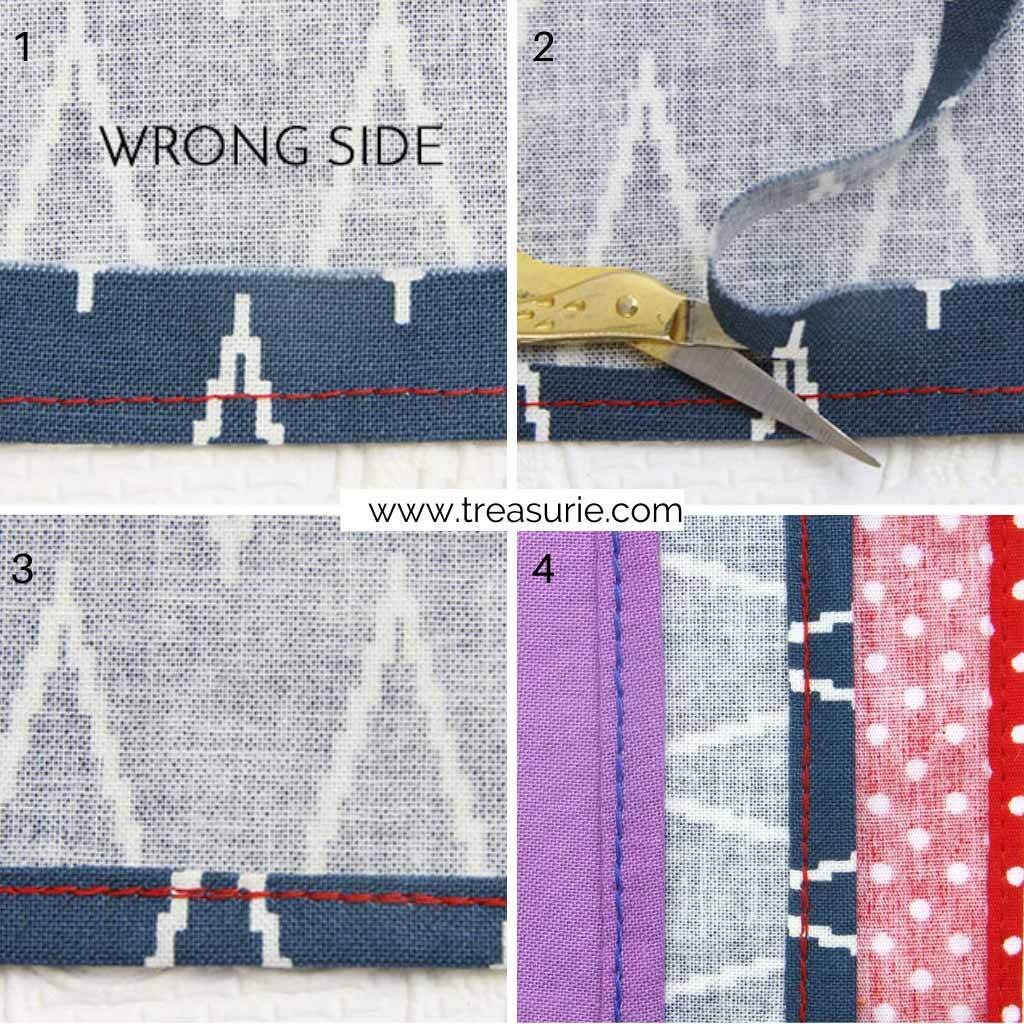

Once the hemline is marked, the next critical step is to press and fold the hem allowance. This creates a crisp guideline for your stitching and ensures a neat finish.Start by folding the raw edge of the fabric inward along your marked chalk line, towards the inside of the garment. Press this fold firmly with your iron. This creates your first fold.Next, depending on your chosen hem type, you will create a second fold.

For a double-folded hem, which is common for most fabrics and provides a clean finish, fold the fabric inward again, enclosing the raw edge. The width of this second fold should match the desired depth of your finished hem. Press this second fold very well.

A well-pressed fold is a visible indicator of professional craftsmanship. It provides a stable edge for sewing and prevents fraying.

For fabrics that tend to fray heavily, like linen or some silks, a wider hem allowance and a neat double fold are particularly beneficial. For very delicate fabrics, you might consider a rolled hem, which involves a much narrower fold, often achieved with a special sewing machine foot.

Pre-Hemming Preparation Checklist

To ensure you haven’t missed any crucial steps, review the following checklist before you begin sewing your hem:

- Garment has been washed and dried to pre-shrink the fabric.

- Garment is thoroughly pressed to remove all wrinkles.

- Desired hem length has been accurately measured and marked with tailor’s chalk or fabric marker.

- Hem allowance has been considered and marked appropriately for the chosen hem style.

- First fold of the hem allowance has been pressed firmly.

- Second fold (if applicable) has been pressed firmly, enclosing the raw edge.

- The entire hemline has been checked for evenness and consistency.

Sewing Techniques for a Basic Hem

Now that your garment is prepared and you have a clear understanding of what a basic hem entails, we can delve into the practical sewing techniques. The method you choose will significantly impact the final look and durability of your hem. This section will guide you through the most common and effective ways to stitch a basic hem, whether you prefer the precision of a sewing machine or the nuanced control of hand-stitching.

Double-Fold Hem Construction

A double-fold hem is the most popular choice for dresses and skirts due to its durability and the exceptionally clean, professional finish it provides. This technique involves folding the fabric edge twice, encasing the raw edge within the folds, which prevents fraying and creates a smooth, substantial hemline.To create a double-fold hem, you will first fold the raw edge of the fabric up by a small amount, typically 1/4 inch to 1/2 inch, and press it firmly in place.

This initial fold helps to manage the raw edge. Next, you will fold this already folded edge up again by a larger amount, usually 1 to 2 inches, depending on the desired hem depth. This second fold completely encloses the raw edge. Press this second fold thoroughly. The goal is to have a neatly folded and pressed hem ready for stitching.

Single-Fold Hem Construction

A single-fold hem is a simpler and quicker option, often used for garments where a less structured hem is acceptable or for fabrics that do not fray excessively. It is also a good choice for curved hemlines where a double fold might be too bulky.The process for a single-fold hem involves folding the raw edge of the fabric up by the desired hem depth and pressing it into place.

For fabrics prone to fraying, it is advisable to finish the raw edge with a serger or a zigzag stitch before making the fold. This prevents the fabric from unraveling. The single fold creates a clean edge that is then ready to be stitched.

Sewing Machine Straight Hem Stitching

Using a sewing machine is an efficient way to achieve a neat and consistent straight hem. The key is to maintain an even seam allowance and stitch line.Before you begin stitching, ensure your sewing machine is set up with an appropriate needle for your fabric type and that you are using a thread that matches your garment. Thread the machine and test the stitch on a scrap piece of fabric to confirm tension and stitch length.The steps for sewing a straight hem with a machine are as follows:

- Align the folded hem edge under the presser foot.

- Position the needle at the beginning of the hemline, close to the edge of the folded fabric.

- Lower the presser foot to secure the fabric.

- Begin sewing, guiding the fabric smoothly to maintain a consistent distance from the folded edge. A seam guide on your machine or painter’s tape can be helpful for accuracy.

- When you reach a corner, stop with the needle down, lift the presser foot, pivot the fabric, lower the presser foot, and continue sewing.

- To finish, backstitch a few stitches at the beginning and end to secure the seam.

Hand-Stitching vs. Machine-Stitching for Hems

Both hand-stitching and machine-stitching have their merits when it comes to hemming. The choice often depends on the fabric, the desired aesthetic, and the time available.

| Method | Advantages | Disadvantages |

|---|---|---|

| Hand-Stitching | Allows for very fine, almost invisible stitches, especially with techniques like the blind hem stitch. Offers precise control over delicate fabrics and intricate curves. Can be done anywhere without the need for electricity. | Significantly more time-consuming than machine stitching. Can be less durable for heavy-wear items if not executed perfectly. Requires practice to achieve consistent results. |

| Machine-Stitching | Much faster and more efficient, especially for straight hems and longer seams. Produces a strong and durable stitch. Ideal for beginners and for garments requiring robust hems. | Can be more visible on certain fabrics, especially if the thread color doesn’t match perfectly. Less ideal for very fine or delicate fabrics where the machine’s pressure might cause damage. Less portable. |

Securing the Hem with Running Stitch or Backstitch

Once your hem is folded and pressed, you will need to secure it with stitches. The running stitch and the backstitch are fundamental hand-stitching techniques suitable for hemming.The running stitch is the simplest hand stitch, characterized by a series of in-and-out stitches. For hemming, it’s best used on fabrics that don’t require extreme durability or where a slightly more visible stitch is acceptable.The backstitch mimics the look of machine stitching and is much stronger and more secure than the running stitch.

It is highly recommended for hems that will experience significant stress or wear.Here is a step-by-step guide for securing a hem using these stitches:

- Thread your needle with a length of thread, no longer than your forearm to prevent tangling, and knot one end.

- For a double-fold hem, insert the needle from the inside of the fold, catching just a few threads of the garment fabric and then the folded hem fabric.

- Running Stitch: Bring the needle up through the garment fabric and then down through the hem fold, creating a small, even stitch. Continue this process along the entire hemline, aiming for consistent stitch length and spacing.

- Backstitch: Bring the needle up through the garment fabric and then down through the hem fold. Bring the needle back up one stitch length behind where you just came out of the garment fabric, and then down into the hem fold at the original stitch’s end point. This creates a continuous line of stitches.

- Ensure your stitches are small and evenly spaced for a neat appearance.

- When you reach the end of the hem, secure the thread with a knot on the inside of the hem.

For a truly invisible hem, consider using a blind hem stitch by hand or a blind hem foot on your sewing machine. This technique involves catching only a few threads of the garment fabric on the right side, making the stitches virtually undetectable.

Finishing Touches and Common Issues

Once your basic hem has been sewn, the final steps involve ensuring its neatness and addressing any potential imperfections. Achieving a smooth, even hemline is the hallmark of a professional finish, and understanding how to resolve common issues will elevate your sewing skills. This section will guide you through techniques for a polished look and provide solutions for typical hemming challenges.

Achieving a Smooth and Even Hemline

A truly professional hem lies flat and hangs gracefully. Several techniques contribute to this polished appearance.

The key to a smooth hem is meticulous preparation and careful execution. Before you even begin sewing, ensure your fabric edge is perfectly straight and your hem allowance is pressed accurately. During the sewing process, maintain consistent tension on your thread and guide the fabric smoothly under the presser foot. Avoid pulling or pushing the fabric, allowing the machine to feed it evenly.

Common Hemming Problems and Their Solutions

Even experienced sewers can encounter minor issues. Recognizing these problems and knowing how to fix them is crucial for a successful outcome.

Puckering

Puckering, where the fabric bunches up around the stitches, can occur for several reasons.

- Thread Tension: If the upper thread tension is too tight or the bobbin tension is too loose, it can pull the fabric, causing puckering. Adjust the upper tension downwards or the bobbin tension upwards.

- Needle Size: Using a needle that is too large for the fabric can create unnecessary holes, leading to puckering. Ensure you are using the appropriate needle size for your fabric type.

- Presser Foot Pressure: Excessive pressure from the presser foot can also cause the fabric to gather. If your machine has adjustable presser foot pressure, try reducing it slightly.

- Fabric Type: Some delicate or stretchy fabrics are more prone to puckering. Using a walking foot or stabilizer can help feed these fabrics more evenly.

Uneven Stitches

Inconsistent stitch length or skipped stitches detract from the professional appearance of a hem.

- Machine Maintenance: Ensure your sewing machine is clean and well-oiled. Lint buildup can interfere with the stitch formation.

- Thread Quality: Using old or poor-quality thread can lead to weak stitches or skipped stitches. Always use good quality, fresh thread.

- Needle Condition: A bent or dull needle can cause skipped stitches. Replace your needle if it appears damaged or has been used extensively.

- Fabric Feeding: If the fabric is not feeding evenly, it can result in uneven stitches. Check that the feed dogs are engaged and functioning correctly.

Stretched or Gaped Hem

This issue is particularly common with knit fabrics or when the hem allowance has been stretched during the preparation or sewing.

- Stabilizers: For stretchy fabrics, consider using a lightweight fusible interfacing or a stabilizer on the wrong side of the hem allowance to prevent stretching.

- Gentle Handling: Avoid stretching the fabric as you press and sew. Use a walking foot for knits to ensure even feeding.

- Seam Ripper Correction: If the hem has already stretched, carefully unpick the stitches in the affected area, re-press the hem allowance to its original shape, and re-sew.

Pressing the Finished Hem

Pressing is a critical step that transforms a sewn hem into a beautifully finished one. It sets the stitches and ensures the hem lays flat.

After sewing, it is essential to press the hem thoroughly. First, press the hem allowance upwards towards the garment to set the seam. Then, carefully press the finished hem downwards, away from the garment. Use the appropriate heat setting for your fabric type and consider using a pressing cloth for delicate fabrics to prevent scorching or shine. A tailor’s ham can be useful for pressing curved hems to maintain their shape.

Visual Representation of a Perfectly Finished Hem

A perfectly finished hem is characterized by its crispness, evenness, and invisibility from the right side of the garment. When viewed from the front, the stitching should be subtle, almost disappearing into the fabric. The hemline itself should be a clean, straight, or gracefully curved line that hangs parallel to the floor. There should be no puckering, no visible threads, and no unevenness in the fabric’s drape.

The pressed edge of the hem should lie flat against the garment, creating a smooth transition and a polished silhouette. From the wrong side, the stitches will be neat and consistent, forming a secure attachment without pulling or distorting the fabric. The folded edge of the hem allowance will be precisely aligned, contributing to the overall clean and professional appearance.

Hemming Different Fabric Types

Sewing a basic hem is a foundational skill, but the beauty of garment construction lies in adapting techniques to suit the unique characteristics of various fabrics. Different materials require specific approaches to achieve a professional and durable finish without compromising the drape or integrity of the garment. This section will guide you through hemming a range of common fabric types, from delicate sheers to robust denims and forgiving knits.Understanding how to adjust your hemming strategy based on fabric weight, texture, and stretch is crucial for sewing success.

By employing the right techniques, needles, threads, and even stabilizers, you can overcome potential challenges and ensure your finished hems look as polished as they feel.

Hemming Lightweight Fabrics Such as Chiffon

Lightweight and sheer fabrics like chiffon, georgette, and organza can be notoriously slippery and prone to fraying, making a neat hem a delicate task. The goal is to create a hem that is almost invisible and does not add bulk or weight to the fabric, thus preserving its natural drape.For chiffon and similar fabrics, a narrow rolled hem is often the most elegant solution.

This technique folds the raw edge over twice to create a very thin, clean edge that minimizes bulk.

- Preparation: Pre-wash and dry the fabric to account for any shrinkage. Carefully press the fabric, using a pressing cloth if necessary, to create crisp folds.

- Technique:

- Fold the raw edge up by about 1/8 inch and press.

- Fold it up again by another 1/8 inch, encasing the raw edge, and press firmly.

- Stitch as close to the inner folded edge as possible. A straight stitch is generally suitable.

- Machine Attachment: A rolled hem presser foot for your sewing machine can be a game-changer for achieving consistent and narrow hems on these delicate fabrics. It guides the fabric edge into a tiny double fold as you sew.

- Hand Sewing: For an even more delicate finish, a tiny hand-stitched hem, such as a blind hem stitch, can be used. This requires patience but results in a virtually invisible hem.

Hemming Heavier Fabrics Such as Denim or Corduroy

Heavier fabrics like denim, corduroy, and canvas require a more robust hemming approach to handle their thickness and durability. The challenge here is to create a hem that lies flat, doesn’t create excessive bulk, and can withstand frequent wear and washing.A double-fold hem is a common and effective method for these materials, providing a clean finish and added strength.

- Preparation: Ensure your sewing machine is equipped with a heavy-duty needle. Press the fabric well to create defined folds.

- Technique:

- Fold the raw edge up by about 1/2 inch and press.

- Fold it up again by another 1 inch to 2 inches (depending on desired hem width and fabric thickness), encasing the raw edge, and press firmly.

- Stitch close to the inner folded edge. You may need to use a longer stitch length and a strong thread.

- Topstitching: For denim, topstitching along the hem edge, mimicking the original construction, adds a professional look and extra durability. Use a contrasting thread color for a classic jeans look.

- Interfacing: In some cases, particularly with very thick denim or canvas, a lightweight fusible interfacing applied to the wrong side of the hem allowance before folding can help the hem lie flatter and prevent it from drooping.

Hemming Stretchy Knits to Prevent Distortion

Knit fabrics, by their very nature, have stretch, which can cause hems to ripple, stretch out, or become distorted during the sewing process. The key is to maintain the fabric’s natural elasticity while securing the hem.Using a stitch that allows for stretch is paramount.

- Stitch Selection:

- Twin Needle: This is an excellent choice for knits. It creates two parallel rows of stitching on the top and a zigzag stitch on the underside, mimicking a coverstitch machine and allowing for stretch.

- Stretch Stitch or Zigzag Stitch: Many sewing machines have a dedicated stretch stitch or a narrow zigzag stitch that provides flexibility.

- Serger/Overlocker: If you have a serger, a 3-thread or 4-thread overlock stitch is ideal for hemming knits, as it finishes the edge and stitches simultaneously with built-in stretch.

- Stabilization: For very lightweight or slinky knits, you might consider using a lightweight fusible interfacing or a strip of lightweight fusible web (like WovenStay Tape) on the wrong side of the hem allowance to provide stability before stitching.

- Technique:

- Fold the hem allowance up once (typically 1 inch to 1.5 inches) and press gently. Avoid stretching the fabric as you press.

- Stitch using your chosen stretch-friendly stitch. Sew from the right side of the fabric for twin needle or topstitched hems.

- Avoid pulling or stretching the fabric as you sew. Let the feed dogs of your machine do the work.

Selecting the Appropriate Needle and Thread for Various Fabric Weights

The right needle and thread combination is fundamental to achieving a clean and strong hem on any fabric. Using the incorrect type can lead to skipped stitches, fabric damage, or weak seams.Here is a guide to help you select the best pairing:

| Fabric Weight | Recommended Needle Type | Recommended Needle Size | Recommended Thread Type |

|---|---|---|---|

| Lightweight (Chiffon, Silk, Organza) | Universal, Microtex, or Sharp | 60/8, 70/10 | All-purpose polyester, Silk thread |

| Medium Weight (Cotton, Linen, Rayon) | Universal | 70/10, 80/12 | All-purpose polyester, Cotton-wrapped polyester |

| Heavyweight (Denim, Corduroy, Canvas) | Jeans/Denim, Heavy Duty | 90/14, 100/16 | Heavy-duty polyester, Upholstery thread |

| Stretchy Knits | Ballpoint, Stretch, or Universal (for twin needle) | 70/10, 80/12 | All-purpose polyester, Stretch thread |

“Always test your stitch and tension on a scrap of the same fabric before hemming your garment. This is the most crucial step to ensure a perfect finish.”

Specific Challenges and Solutions When Hemming Silk or Satin Garments

Silk and satin present unique challenges due to their slippery nature, tendency to fray, and the potential for press marks. Achieving a smooth, undetectable hem requires careful handling and specific techniques.The delicate nature of these fabrics demands precision and a gentle approach.

- Slippage:

- Solution: Use a walking foot on your sewing machine to help feed the layers evenly. Alternatively, pin generously with fine, sharp pins placed perpendicular to the fabric edge. For extreme slippage, a temporary spray adhesive or a very thin layer of double-sided tape can be used to hold the hem in place before stitching.

- Fraying:

- Solution: A narrow rolled hem, as described for chiffon, is ideal. Alternatively, consider a French seam finish for the hem allowance before folding and stitching, or use a serger to finish the raw edge before creating the double-fold hem.

- Press Marks:

- Solution: Always use a press cloth (such as silk organza or a fine cotton) when pressing silk and satin. Press with the iron on a low to medium heat setting, moving the iron continuously rather than letting it rest in one spot. Press the hem allowance from the wrong side.

- Delicate Fabric Damage:

- Solution: Use the finest sharp needles available (Microtex needles are excellent for silk). Ensure your machine’s tension is correctly balanced to avoid puckering. A longer stitch length may also be beneficial to prevent tearing.

Advanced Basic Hem Variations (Optional)

While a standard double-folded hem is a reliable choice, exploring a few advanced variations can elevate the finish of your garments, offering different aesthetic qualities and suitability for various fabric types. These techniques, though requiring a bit more precision, are still within the realm of “basic” in terms of their underlying principles and are achievable with practice.Moving beyond the standard double-fold, several advanced basic hem variations offer distinct visual and functional benefits.

These techniques allow for a more refined and professional appearance, particularly when working with lighter or more delicate fabrics. Understanding when and how to employ these methods can significantly enhance the overall quality of your sewing projects.

Blind Hem Stitch

The blind hem stitch is a sewing machine technique designed to create an almost invisible hem from the right side of the fabric. It’s ideal for trousers, skirts, and dresses where a clean, unblemished finish is desired. The stitch catches only a few threads of the main fabric, making the hemline virtually disappear.To achieve a blind hem:

- Prepare your hem as you would for a standard double-folded hem, but fold the second fold to the inside, pressing it firmly.

- Set your sewing machine to the blind hem stitch setting. This stitch typically looks like a straight stitch followed by a wider zig-zag stitch.

- Position the fabric under the presser foot so that the needle swings over and catches just a few threads of the main fabric on one side, and then swings over to stitch into the folded hem edge on the other.

- Carefully guide the fabric, ensuring the needle consistently catches only a minimal amount of the main fabric.

- Once sewn, press the hem from the right side to complete the invisible finish.

Rolled Hem

A rolled hem is a narrow, tightly turned hem that creates a delicate, slightly rounded edge. It is particularly well-suited for lightweight and sheer fabrics like chiffon, silk, organza, and voile, where a bulkier hem would be undesirable. This technique can be done by hand or by using a rolled hem presser foot on a sewing machine.The process for a machine-rolled hem using a specialized foot is as follows:

- Attach a rolled hem presser foot to your sewing machine. These feet have a small channel that guides the fabric edge.

- Fold the raw edge of the fabric over by about 1/4 inch and press.

- Feed this folded edge into the channel of the rolled hem foot.

- Begin sewing, guiding the fabric so that the raw edge rolls into the channel as you stitch. The foot will automatically fold and enclose the raw edge.

- Sew a straight stitch along the edge, ensuring the fabric feeds smoothly and consistently.

For hand-sewing a rolled hem, you would typically fold the edge twice very narrowly and then use a slip stitch or a blind stitch to secure it, creating a similar effect.

Narrow Hem

A narrow hem is similar to a rolled hem in its slim profile but can be achieved through a slightly different folding and stitching process. It’s often used on sleeves, handkerchiefs, or the edges of collars and cuffs where a subtle, clean finish is required without the pronounced “roll” of a rolled hem.Creating a narrow hem involves precise folding:

- Fold the raw edge of the fabric over by approximately 1/8 to 1/4 inch and press.

- Fold this initial fold over again by the same amount, enclosing the raw edge completely. Press this second fold firmly.

- Stitch close to the inner folded edge, securing the hem.

This method creates a very neat and unobtrusive hemline.

Comparison of Advanced Hem Types

The choice between these advanced basic hem variations depends on the fabric type, the desired aesthetic, and the level of difficulty you are comfortable with.

| Hem Type | Visual Impact | Difficulty Level | Best For |

|---|---|---|---|

| Blind Hem Stitch | Invisible from the right side, clean and professional. | Intermediate (requires precision and practice with machine settings). | Formal wear, trousers, skirts, dresses where a seamless look is paramount. |

| Rolled Hem | Delicate, slightly rounded edge, often with a visible seam on the right side. | Intermediate to Advanced (can be tricky to master by machine or hand). | Lightweight, sheer, and delicate fabrics like silk, chiffon, and organza. |

| Narrow Hem | Slim, flat, and clean edge, very unobtrusive. | Intermediate (requires accurate folding and stitching). | Sleeves, collars, cuffs, handkerchiefs, and areas where minimal bulk is desired. |

Summary

As we conclude our exploration of How to Sew a Basic Hem on a Dress or Skirt, we hope you feel empowered with the knowledge and confidence to tackle any hemming project. From the initial understanding of hem functions to the final, polished finish, each step has been designed to guide you toward creating garments that not only look professional but are also built to last.

Mastering this fundamental technique opens a world of possibilities for garment customization and repair, ensuring your handmade or altered clothing always presents its best self.