As How to Sew a Flat-Felled Seam for Durable Garments takes center stage, this opening passage beckons readers into a world crafted with good knowledge, ensuring a reading experience that is both absorbing and distinctly original.

This comprehensive guide delves into the art of constructing a flat-felled seam, a technique renowned for its exceptional strength and neat finish. We will explore its fundamental purpose, the benefits it offers in terms of garment longevity, and its distinct aesthetic appeal. Understanding the tools and materials required, alongside a step-by-step procedure, will empower you to master this essential sewing skill.

We will also touch upon variations, advanced techniques, and practical applications, demonstrating why the flat-felled seam is a cornerstone of durable and high-quality garment construction.

Understanding the Flat-Felled Seam

The flat-felled seam is a fundamental technique in garment construction, celebrated for its robustness and clean finish. It is not merely a way to join two pieces of fabric; it is a deliberate choice that significantly enhances the longevity and professional appearance of a garment. This seam type is engineered to lie flat against the fabric, offering a smooth surface that minimizes bulk and potential irritation.At its core, the purpose of a flat-felled seam is to create an exceptionally strong and durable join between two fabric panels.

Unlike a standard seam where raw edges are often enclosed within a single fold, a flat-felled seam involves folding both raw edges in the same direction and stitching them down. This process effectively encases the raw edges, preventing fraying and providing a double layer of fabric along the seam line, which is crucial for areas subjected to high stress.

Purpose and Benefits of the Flat-Felled Seam

The primary purpose of a flat-felled seam is to achieve superior durability and a neat, professional aesthetic. Its construction inherently provides significant benefits that make it a preferred choice for many types of garments, especially those designed for active use or requiring exceptional longevity.The key benefits of using a flat-felled seam for durability include:

- Exceptional Strength: The double-layer construction, with two lines of stitching securing the folded edges, makes this seam incredibly resistant to tearing and pulling. This is particularly important for stress points like inseams on trousers, side seams on shirts, and areas on workwear or outdoor gear.

- Fray Resistance: By folding and stitching the raw edges of the fabric within the seam itself, the flat-felled seam effectively encloses and protects them from unraveling. This significantly extends the life of the garment, especially after repeated washing and wear.

- Reduced Bulk: Compared to other durable seam types like a French seam, a flat-felled seam lies very flat against the fabric. This is advantageous for comfort, as it reduces chafing and irritation, and for a clean, professional appearance, especially on garments where a smooth silhouette is desired.

- Smooth Interior Finish: The inside of a flat-felled seam is as neat as the outside, with no raw edges exposed. This contributes to a more comfortable wear and a higher quality finish, preventing snagging on delicate undergarments or skin.

Aesthetic Qualities of the Flat-Felled Seam

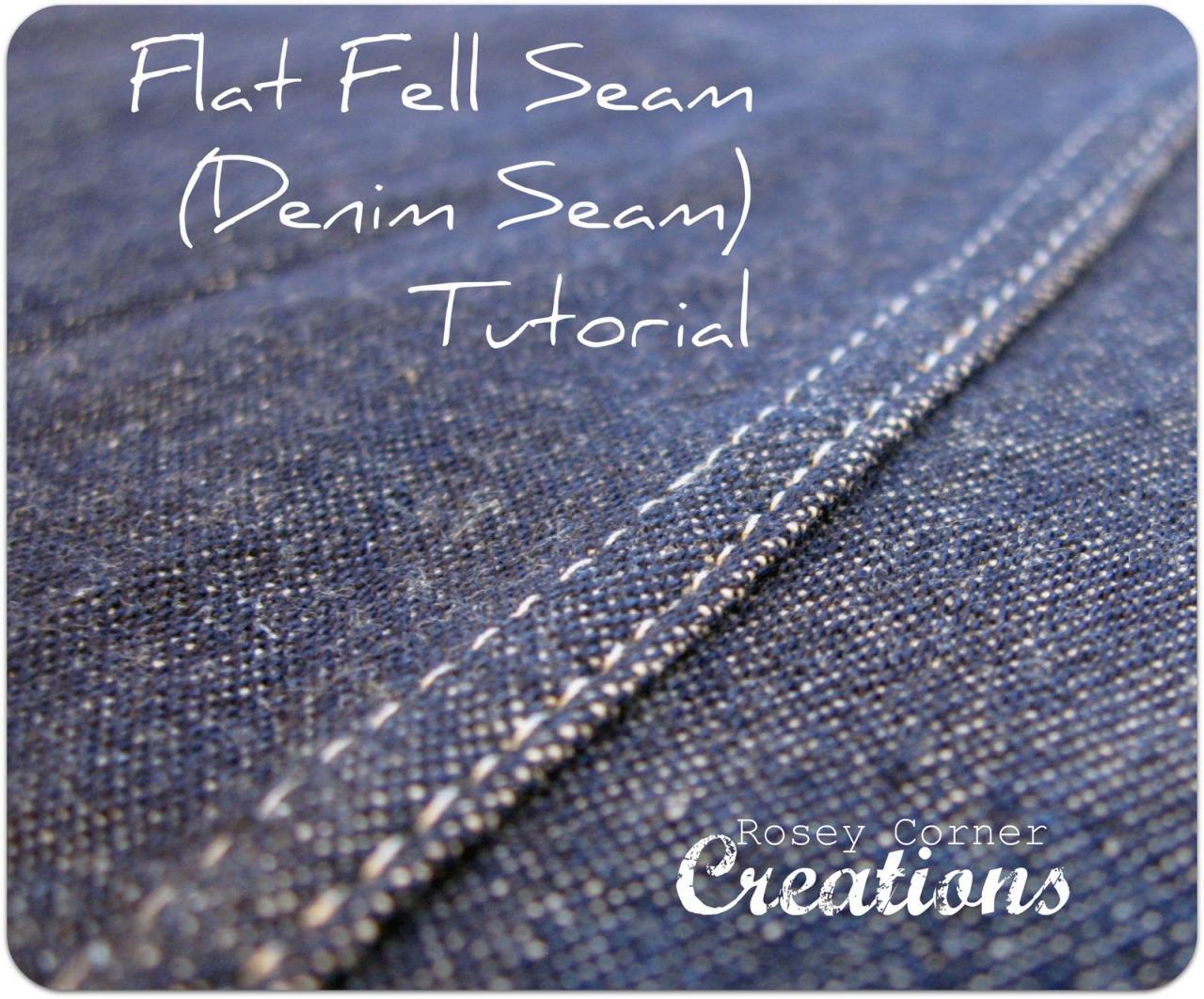

The aesthetic qualities of a flat-felled seam are distinct and contribute to its recognized value in garment construction. It offers a clean, crisp line that can either be a subtle design element or a prominent feature, depending on the fabric and thread choice.When compared to other seam types, the flat-felled seam stands out due to its inherent flatness and the presence of two parallel lines of stitching on the right side of the garment.

- Clean and Streamlined Appearance: The seam lies flat and smooth, creating a streamlined look without the bulk often associated with other durable seams. This makes it ideal for garments where a polished finish is paramount.

- Visible Stitching Detail: The double row of stitching on the exterior can serve as a decorative element, adding a subtle textural contrast and a handmade touch. This is often seen in denim jeans, work shirts, and outdoor apparel, where the stitching becomes a signature design feature.

- Contrast with Other Seams: Unlike a simple plain seam, which has exposed raw edges on the inside and can fray, or a French seam, which encloses raw edges but can create more bulk on the inside, the flat-felled seam offers a unique combination of durability and a flat profile.

Common Garment Types Employing Flat-Felled Seams

The inherent strength and durability of the flat-felled seam make it a staple in the construction of garments that are expected to withstand significant wear and tear. Its presence is often an indicator of quality and longevity.This seam is particularly prevalent in the following types of garments:

- Denim Jeans and Workwear: The classic example. The inseams, outseams, and yokes of jeans and durable work pants are almost universally constructed with flat-felled seams to ensure they can withstand the rigors of daily use and physical labor.

- Outdoor and Activewear: Jackets, trousers, and shirts designed for hiking, camping, or other outdoor activities benefit from the seam’s ability to resist abrasion and prevent fraying in challenging environments.

- Shirts: Particularly casual shirts, button-down shirts, and work shirts. The side seams and often the sleeve seams are flat-felled for added strength and a clean finish.

- Luggage and Bags: The durability of this seam makes it suitable for joining panels in bags and luggage where stress and abrasion are common.

- Upholstery and Home Decor: In some applications, such as durable cushions or awnings, the strength and clean finish of a flat-felled seam are advantageous.

Essential Tools and Materials for a Flat-Felled Seam

Creating durable and professional-looking garments with flat-felled seams requires a specific set of tools and materials. Having the right equipment ensures precision, ease of construction, and a superior finished product that stands up to wear and tear. This section will guide you through the essentials needed for mastering this robust seam technique.The success of a flat-felled seam relies not only on technique but also on the quality of the materials used.

Selecting appropriate fabrics and ensuring your sewing machine is properly set up with the right needle and thread are crucial steps. Furthermore, accurate measurements and consistent seam allowances are paramount, making certain tools indispensable.

Necessary Sewing Tools

To achieve a clean and strong flat-felled seam, several standard sewing tools are essential. These items help in preparing the fabric, guiding the stitching, and ensuring accuracy throughout the process.

- Sewing Machine: A reliable sewing machine capable of consistent stitch formation is fundamental.

- Sharp Fabric Scissors: High-quality scissors are needed for precise fabric cutting, which is critical for even seam allowances.

- Rotary Cutter and Mat: For straighter cuts and faster fabric preparation, especially on long seams.

- Seam Ripper: An indispensable tool for correcting any mistakes and ensuring a neat finish.

- Iron and Ironing Board: Pressing is a vital step in creating a flat-felled seam, ensuring the fabric lies flat and the seam is well-defined.

- Pins: Used to hold fabric layers together accurately before and during sewing.

- Chalk or Fabric Marker: For marking seam allowances and folding lines on the fabric.

Suitable Fabric Types

The flat-felled seam is renowned for its strength and durability, making it ideal for garments that experience significant stress or require longevity. Certain fabric types lend themselves particularly well to this technique, enhancing its inherent advantages.The best fabrics for flat-felled seams are those with a moderate weight and a stable weave. These characteristics prevent the seam from becoming too bulky or distorting during the sewing process.

- Denim: A classic choice for jeans and workwear, denim’s inherent strength and thickness make it a perfect candidate for flat-felled seams, adding to its rugged appeal.

- Canvas: Similar to denim, canvas is a heavy-duty cotton fabric used for bags, outerwear, and durable apparel. It holds its shape well and benefits from the reinforced structure of a flat-felled seam.

- Twill: A sturdy woven fabric with a diagonal ribbed pattern, twill is often used for trousers, skirts, and jackets. Its durability makes it well-suited for this seam type.

- Linen: While linen can be prone to fraying, medium to heavy-weight linens can be used successfully. The key is to ensure the edges are well-finished within the seam.

- Cotton Shirting: For less heavy-duty garments like button-down shirts, medium-weight cotton shirting can also be used, offering a clean and durable finish.

Sewing Machine Needle and Thread Selection

The choice of sewing machine needle and thread plays a significant role in the appearance and strength of any seam, and this is particularly true for flat-felled seams. Using the correct combination ensures smooth stitching and prevents fabric damage.A needle that is too fine can break or skip stitches on heavier fabrics, while a needle that is too thick can create excessive holes, weakening the fabric.

Similarly, the thread must be strong enough to withstand the stress on the seam.

- Sewing Machine Needles: For most fabrics suitable for flat-felled seams, an all-purpose needle ranging from size 80/12 to 100/16 is recommended. For very heavy fabrics like denim or canvas, a denim or microtex needle of a larger size (e.g., 90/14 or 100/16) is often preferred. A sharp point is crucial for piercing the fabric cleanly.

- Thread: A good quality polyester or cotton-wrapped polyester thread is ideal for its strength and durability. For heavy-duty projects, consider using a heavier weight thread, such as an all-purpose polyester thread (Tex 27 or 30) or even a specialized heavy-duty thread. Matching the thread color to the fabric is important for a professional look, but contrasting thread can be used for decorative effect.

Importance of Seam Gauge or Ruler

Precision is a cornerstone of sewing, and for techniques like the flat-felled seam, it is absolutely critical. A seam gauge or ruler is an indispensable tool for ensuring consistent seam allowances and accurate folding, which directly impacts the final appearance and integrity of the seam.The flat-felled seam involves folding and pressing the fabric in specific ways. Without precise measurements, these folds will be uneven, leading to a bulky, unprofessional, and potentially weak seam.

“Accurate measurements and consistent seam allowances are the foundation of a strong and beautiful flat-felled seam.”

- Seam Gauge: This small, sliding ruler is perfect for measuring short distances, typically up to 6 inches. It’s ideal for marking and checking the consistent width of the seam allowance as you sew and press.

- Fabric Ruler: A larger ruler, often made of clear acrylic or metal, is useful for measuring longer seam allowances and for ensuring straight cutting lines.

- Marking Tools: Combined with chalk or a fabric marker, the seam gauge or ruler allows you to accurately mark the initial seam allowance and subsequent folding lines on the fabric.

- Ensuring Consistency: Regularly checking your seam allowance with the gauge as you sew helps prevent variations that can lead to puckering or unevenness.

- Pressing Guides: The markings made with the seam gauge also serve as guides for accurate pressing, ensuring the fabric is folded precisely to create the characteristic flat-felled seam.

Step-by-Step Procedure for Sewing a Flat-Felled Seam

The flat-felled seam is a hallmark of durable and well-constructed garments, offering both strength and a clean aesthetic. This section will guide you through the precise steps to achieve this professional finish, ensuring your sewing projects stand the test of time. From preparing your fabric to the final press, each stage is crucial for a successful outcome.Following these detailed instructions will empower you to confidently create robust and attractive seams that elevate the quality of your sewing.

Whether you’re working on outdoor gear, workwear, or simply want to add extra durability to your everyday clothing, mastering the flat-felled seam is an invaluable skill.

Fabric Edge Preparation

Proper preparation of fabric edges is fundamental to achieving a neat and strong flat-felled seam. This initial step ensures that the fabric lies flat and that the subsequent folds are clean and consistent.Before you begin stitching, consider the following preparation techniques:

- Serging or Zigzagging: For fabrics prone to fraying, it is highly recommended to finish the raw edges of both fabric pieces with a serger or a zigzag stitch. This encases the raw threads and prevents them from unraveling during the sewing process and subsequent wear.

- Trimming Edges: Ensure that the raw edges are trimmed as straight and evenly as possible. This consistency will make the folding process much more manageable and contribute to a uniform seam width.

- Pre-washing Fabric: Always pre-wash your fabric according to its care instructions before cutting and sewing. This accounts for any potential shrinkage, ensuring your finished garment will maintain its size and shape.

Creating the First Fold and Stitching

The foundation of a flat-felled seam lies in the precise creation of its initial fold and the subsequent stitching that secures it. This step involves folding the fabric edges inward and then stitching them down.The process for creating the first fold and stitching is as follows:

- Place Fabric Right Sides Together: Position the two fabric pieces with their right sides facing each other. Align the raw edges that will form the seam.

- Stitch the Seam: Sew the two pieces together with a standard straight stitch, using a seam allowance that is typically twice the desired finished seam width. For example, if you want a 1/4-inch finished seam, you would stitch with a 1/2-inch seam allowance.

- Trim One Edge: After stitching, trim the seam allowance ofone* of the fabric layers to about half its original width. This trimmed edge will be enclosed within the seam. For a 1/2-inch seam allowance, you would trim one layer down to approximately 1/4 inch.

- Press the Seam: Press the seam allowance flat, with the untrimmed edge extending beyond the trimmed edge.

The Second Fold and Securing

Once the initial fold and stitching are complete, the next critical step is to create the second fold, which encloses the raw edges and forms the characteristic flat appearance of the seam. This fold needs to be executed with precision for a professional look.To achieve the second fold and secure it neatly:

- Fold the Untrimmed Edge Over: Take the untrimmed seam allowance and fold it over the trimmed seam allowance, encasing the raw edges. This fold should be exactly the width of the trimmed seam allowance, creating a double-layered edge.

- Press the Fold: Press this second fold firmly in place. This action creates a crisp edge and makes the subsequent stitching much easier and more accurate.

- Stitch Through All Layers: Stitch through all the layers of fabric along the folded edge. This stitching line should be very close to the folded edge, typically about 1/8 inch away, and it will be visible on the right side of the garment. Ensure your stitching is straight and consistent.

Pressing for a Crisp Finish

The role of pressing in creating a professional flat-felled seam cannot be overstated. Strategic pressing at each stage significantly contributes to the seam’s durability, neatness, and overall polished appearance.Effective pressing techniques for a crisp finish include:

- Pressing Open After First Stitch: After the initial seam is stitched and one edge is trimmed, press the seam allowances open, with the untrimmed edge extending over the trimmed edge. This ensures the seam lies flat before the second fold.

- Pressing the Second Fold: As mentioned in the previous step, pressing the second fold firmly is crucial. This crease will guide your final stitching and ensure a sharp, clean line.

- Final Pressing: Once the second stitching is complete, press the entire seam flat. You can choose to press the seam to one side, or if the garment construction allows, press it open. For maximum flatness, some sewers prefer to press the seam flat, then press the top stitching line and the underlying folded edge flat again.

Managing Curves and Corners

Applying a flat-felled seam to curved or cornered areas requires a bit more finesse than on straight edges, but the principles remain the same. Careful clipping and precise folding are key to achieving a smooth and professional finish in these challenging areas.Tips for managing curves and corners with a flat-felled seam:

- Clipping Curves: For outward curves, clip small notches into the seam allowance of the

-trimmed* edge. For inward curves, clip small V-shaped notches. These clips allow the fabric to lie flat without puckering. - Notching Corners: For outward corners, trim the seam allowance diagonally. For inward corners, you may need to make a small snip at the very corner of the seam allowance to allow it to fold smoothly.

- Easing Fabric on Curves: When folding the second layer over on a curve, you may need to gently ease the fabric to help it lie flat. Don’t force it; small adjustments will create a smoother result.

- Stitching Corners: When stitching the second fold on corners, ensure you catch all layers securely. You might need to pivot at the corner point to maintain a neat stitching line. For a very sharp outward corner, you can stitch right up to the point, then turn the fabric to begin stitching the next side.

Variations and Advanced Techniques for Flat-Felled Seams

While the standard flat-felled seam is a workhorse for durable construction, exploring its variations and advanced techniques can significantly enhance garment quality and aesthetic appeal. These methods allow for greater versatility, catering to different fabric types, grainlines, and desired finishes. Understanding these nuances will empower you to tackle a wider range of sewing projects with confidence and precision.This section delves into the subtle yet important differences between common flat-felled seam methods, explores techniques for working with challenging fabric orientations, and introduces a related durable seam finish.

We will also address common pitfalls and provide actionable solutions to ensure your flat-felled seams are always a success.

Single-Fold vs. Double-Fold Flat-Felled Seam Comparison

The fundamental difference between the single-fold and double-fold flat-felled seam lies in the number of fabric folds involved in creating the final seam. Both methods aim to enclose raw edges for durability and a clean finish, but they achieve this through slightly different folding sequences.

- Double-Fold Flat-Felled Seam: This is the most common method discussed in the step-by-step procedure. It involves folding both raw edges of the seam allowance inward, pressing them, and then folding the entire seam allowance in half. This creates two layers of fabric folded within the seam, resulting in a very strong and bulky seam, ideal for heavy-duty garments like jeans and workwear.

The raw edges are completely enclosed.

- Single-Fold Flat-Felled Seam: In this variation, only one raw edge of the seam allowance is folded inward. The other raw edge is then pressed flat against the wrong side of the garment. The entire seam allowance is then folded in half, enclosing the folded edge. This method results in a less bulky seam than the double-fold, making it suitable for lighter to medium-weight fabrics where bulk is undesirable.

One raw edge remains exposed within the fold, but it is typically pressed flat and secured by the stitching.

Sewing a Flat-Felled Seam on a Single Layer of Fabric

While flat-felled seams are typically constructed on two layers of fabric, adapting the technique for a single layer is useful for specific applications, such as creating decorative topstitching or reinforcing an edge on a single piece of material. This technique essentially involves creating a fold and then stitching it down to resemble a flat-felled seam.To sew a flat-felled seam on a single layer of fabric, begin by folding the edge of the fabric to the wrong side by your desired seam allowance width (e.g., 1/2 inch).

Press this fold firmly. Then, fold this creased edge over again, bringing the raw edge to meet the first fold line, creating a double-folded hem or edge. Press this second fold. Topstitch close to the folded edge, securing both layers of the fold. This creates a clean, durable edge that mimics the appearance and strength of a flat-felled seam without requiring two fabric pieces.

Sewing a Flat-Felled Seam on the Bias Grain

Working with fabric on the bias grain presents unique challenges due to its inherent stretch and tendency to distort. Sewing flat-felled seams on the bias requires careful handling and specific adjustments to maintain seam integrity and prevent stretching or puckering.When sewing a flat-felled seam on the bias, it is crucial to:

- Use a Stabilizing Technique: Consider using a lightweight fusible interfacing or a stay tape along the seam line before sewing. This will help to prevent the bias edges from stretching out of shape during the sewing process.

- Gentle Handling: Handle the fabric gently throughout the entire process. Avoid pulling or stretching the fabric as you feed it under the presser foot. Let the machine do the work.

- Appropriate Presser Foot: A walking foot or a roller foot can be beneficial for feeding bias fabrics evenly and preventing slippage.

- Slightly Wider Seam Allowance: You might consider starting with a slightly wider seam allowance than usual. This provides more fabric to work with and can accommodate minor stretching that might occur.

- Test Stitches: Always test your stitch length and tension on a scrap piece of bias fabric before starting on your garment.

The goal is to maintain the natural drape of the bias while ensuring the seam is secure and lies flat.

French Seam as an Alternative Durable Seam Finish

The French seam is another excellent option for creating a durable and aesthetically pleasing seam finish, particularly for sheer or delicate fabrics where raw edges would be visible and unsightly. It achieves a similar goal of enclosing raw edges but with a different construction method and a more refined appearance.A French seam is constructed in two stages:

- First Stitching (Wrong Sides Together): Sew the two fabric pieces together with the right sides facing each other, using a narrow seam allowance (e.g., 1/4 inch). Trim this seam allowance to about 1/8 inch.

- Second Stitching (Right Sides Together): Turn the fabric so the right sides are now facing each other. The first stitched seam will be enclosed within the fold. Press the seam allowance flat. Now, sew a second seam along the same line, enclosing the raw edges from the first seam. This second seam should be slightly wider than the first, ensuring it completely covers the trimmed raw edges.

This process results in a clean, enclosed seam with no raw edges visible on either the right or wrong side of the fabric, making it ideal for fine garments and lingerie.

Troubleshooting Common Flat-Felled Seam Issues

Even with careful attention, encountering issues during flat-felled seam construction is possible. Understanding these common problems and their solutions will help you achieve professional results.Here is a guide to troubleshooting common issues:

- Uneven Topstitching: This often occurs when the fabric is not feeding evenly or the seam allowance is not pressed consistently. Ensure your presser foot is applying even pressure and that your seam allowances are accurately pressed before the second stitching.

- Skipped Stitches: Skipped stitches can be caused by a dull needle, incorrect needle size for the fabric, or lint buildup in the bobbin area. Check your needle, ensure it’s sharp and appropriate for your fabric, and clean your bobbin case.

- Fabric Puckering: Puckering usually indicates that the fabric is being stretched or pulled as it’s sewn. Avoid pulling the fabric; instead, guide it gently. Using a walking foot can significantly help with even fabric feeding and prevent puckering.

- Bulky Seams: If your seams are excessively bulky, you may be using too wide a seam allowance or not pressing the folds adequately. For lighter fabrics, consider the single-fold method or reducing the seam allowance width slightly. Ensure sharp creases are pressed into each fold.

- Raw Edges Peeking Through: This happens when the second fold is not wide enough to fully enclose the first folded edge. When pressing for the second stitching, ensure the folded edge is sufficiently wide to completely cover the raw edge.

By addressing these common issues proactively, you can ensure your flat-felled seams are not only durable but also neat and professional.

Visualizing the Flat-Felled Seam: Illustrative Descriptions

A perfectly executed flat-felled seam is a hallmark of durable and professionally finished garments. Its visual appeal lies in its neatness, strength, and the way it lies flat against the fabric, providing both structure and a clean aesthetic. Understanding its appearance from both sides of the fabric is key to recognizing its quality and the superior construction it represents.This section delves into the distinct visual characteristics of a flat-felled seam, allowing you to identify its presence and appreciate its functional beauty.

We will explore how the fabric edges are ingeniously concealed, creating a smooth finish that is both aesthetically pleasing and incredibly robust.

Right Side Appearance

From the right side of the fabric, a well-sewn flat-felled seam presents a clean, unadorned line. It appears as a single line of stitching, precisely parallel to the cut edge of the fabric. This stitching should be straight, even, and consistently spaced from the folded edge. The seam itself lies flat and unobtrusive, allowing the main fabric of the garment to be the primary visual focus.

There are no raw edges visible, contributing to a polished and professional look.

Wrong Side Appearance

The wrong side of a flat-felled seam reveals the construction that gives it its strength and durability. Here, you will observe two parallel rows of stitching. The first row of stitching secures the two fabric pieces together. The second, wider row of stitching is responsible for enclosing the raw edges of the fabric. This second line of stitching is typically placed about 1/8 inch (3mm) away from the folded edge of the seam allowance.

The seam allowance itself is folded over and pressed flat, creating a smooth, encased finish.

Enclosure of Fabric Edges

The genius of the flat-felled seam lies in its method of enclosing raw fabric edges. After the initial seam is sewn, one of the seam allowances is trimmed slightly shorter than the other. The longer seam allowance is then folded over the trimmed one, encasing it completely. This folded seam allowance is then pressed flat against the main body of the fabric.

Finally, a second line of stitching is sewn through all layers, securing the folded seam allowance and the fabric beneath it. This process effectively hides all raw edges, preventing fraying and creating a smooth, comfortable interior.

Characteristic “Ridged” Appearance

The distinctive “ridged” appearance of a flat-felled seam is a direct result of its construction. On the wrong side, the two parallel lines of stitching, combined with the folded and pressed seam allowance, create a slightly raised or ridged effect. This ridge is not bulky or uncomfortable but rather a testament to the layers of fabric and stitching working together.

The term “ridge” aptly describes the subtle elevation that signifies the seam’s robust structure.

Narrative of Structural Integrity

Imagine a pair of sturdy work trousers or a rugged outdoor jacket. These are garments that endure significant stress and strain during daily wear. The flat-felled seam is the backbone of such durable apparel. Consider the inseam of jeans; it’s a prime example of a flat-felled seam. This seam is subjected to constant pulling and abrasion as you move.

The double stitching, with its fabric edges neatly tucked away, provides an unparalleled resistance to tearing and unraveling. Unlike a simple serged seam or a plain seam, the flat-felled seam’s construction distributes stress across multiple layers of fabric and stitching, significantly enhancing its longevity and preventing blowouts, even under the most demanding conditions. It’s a seam that says, “I’m built to last.”

Practical Applications and Garment Examples

The flat-felled seam is a testament to functional design, celebrated for its strength, durability, and neat appearance. Its application spans a wide array of garments, from rugged workwear to refined fashion pieces, demonstrating its versatility and enduring appeal. Understanding where and why this seam is employed offers valuable insight into garment construction and material choices.This section explores the diverse applications of flat-felled seams, highlighting their integral role in various types of clothing and accessories.

We will examine their presence in garments designed for demanding use, as well as instances where their aesthetic qualities are prioritized.

Garments Featuring Flat-Felled Seams

Flat-felled seams are a hallmark of well-constructed garments, particularly those intended for frequent wear and high stress. Their presence often signals a commitment to durability and a polished finish.

- Workwear: Overalls, coveralls, heavy-duty trousers, work shirts, and utility jackets frequently utilize flat-felled seams for their exceptional strength and resistance to abrasion.

- Outdoor and Activewear: Hiking pants, cargo shorts, technical shirts, swimwear, and some types of active leggings benefit from the smooth, chafe-resistant nature of flat-felled seams, especially in areas prone to friction.

- Casual Wear: Denim jeans, denim jackets, casual shirts (especially those with a more structured feel), and some skirts and shorts incorporate flat-felled seams for both durability and a classic aesthetic.

- Uniforms: Military uniforms, chef uniforms, and other professional attire often feature flat-felled seams for their robustness and neat appearance under demanding conditions.

- Bags and Accessories: Durable tote bags, backpacks, and aprons also commonly employ flat-felled seams to ensure longevity and withstand heavy use.

Flat-Felled Seams in Workwear for Enhanced Durability

In the realm of workwear, durability is paramount. Flat-felled seams are not merely a decorative element but a crucial component that significantly enhances a garment’s lifespan and performance under strenuous conditions. The double-stitched construction, with both rows of stitching encased within the folded fabric, creates a seam that is exceptionally strong and resistant to pulling apart. This makes them ideal for garments that experience constant stress, such as those worn by construction workers, mechanics, or agricultural laborers.

For instance, the side seams and inseams of heavy-duty work pants are often flat-felled to prevent blowouts during bending, squatting, and lifting. Similarly, the armholes and side seams of robust work shirts and jackets are reinforced with this seam type to withstand the rigors of manual labor.

Application in Outdoor Gear and Activewear

The demands placed on outdoor gear and activewear are unique, often involving movement, moisture, and potential abrasion. Flat-felled seams excel in these environments by offering a smooth, low-profile finish that minimizes chafing against the skin, a critical factor for comfort during prolonged activity. In hiking pants, for example, the inseam and side seams are typically flat-felled to prevent irritation during long treks.

For activewear like running shorts or cycling jerseys, the flat-felled seam ensures that the garment moves with the body without causing discomfort. Swimwear also benefits from this seam type, as it provides a secure and comfortable fit that holds up well to water and chlorine. The inherent strength of the flat-felled seam ensures that these garments can withstand the stresses of dynamic movement and repeated washing.

Aesthetic Appeal in Fashion Garments

While celebrated for their durability, flat-felled seams also possess a distinct aesthetic appeal that designers leverage in fashion garments. Their crisp, defined lines can add a subtle yet sophisticated detail that elevates the overall look of a piece. In casual shirts, a well-executed flat-felled seam on the side seams and sleeve seams can lend a tailored and polished appearance. Denim jeans, of course, are a prime example where the flat-felled inseam and outseam are integral to their iconic style, providing a clean finish that complements the rugged nature of the fabric.

For more structured garments like tailored trousers or skirts, flat-felled seams can contribute to a clean, professional silhouette, offering a refined alternative to traditional seam finishes.

Fabric Suitability for Flat-Felled Seams

The choice of fabric significantly influences the ease of sewing and the final appearance of a flat-felled seam. Certain fabrics are inherently more suited to this technique due to their weight, weave, and stability.

| Fabric Type | Suitability for Flat-Felled Seams | Considerations | Example Garments |

|---|---|---|---|

| Denim | Excellent | Can be bulky, use a heavier needle and potentially a walking foot to prevent puckering. Pressing is essential. | Jeans, jackets, overalls, skirts |

| Linen | Good | Pressing is crucial for a crisp finish, especially for the initial fold. Finer linens may require a finer needle. | Shirts, trousers, dresses, skirts |

| Cotton Twill | Excellent | Versatile and durable, holds a crease well. Suitable for a wide range of weights. | Work pants, skirts, jackets, aprons, utility bags |

| Canvas | Very Good | Requires a strong needle and careful pressing due to its thickness. May benefit from a slightly wider seam allowance. | Bags, aprons, durable outerwear, upholstery projects |

| Gabardine | Excellent | A tightly woven twill, it presses beautifully and creates a very clean, durable seam. | Trench coats, tailored trousers, skirts |

| Corduroy | Good | Consider the direction of the nap and press carefully to avoid crushing the pile. Thicker corduroys can be bulky. | Pants, skirts, jackets, vests |

| Wool Blends (medium weight) | Good | Pressing is key; use a pressing cloth and moderate heat. Ensure the wool is pre-shrunk. | Trousers, skirts, jackets, coats |

Closing Summary

In conclusion, mastering the flat-felled seam is a valuable endeavor for any sewist seeking to enhance the durability and professional appearance of their creations. From understanding its core principles and benefits to executing the precise steps and exploring its various applications, this guide has provided a thorough exploration. By incorporating this robust seam finish into your projects, you will undoubtedly elevate the quality and longevity of your handmade garments, ensuring they stand the test of time and wear.