Embark on a journey to master the art of sewing with our comprehensive guide on How to Sew a French Seam for a Clean Finish. This technique, a cornerstone of professional garment construction, offers an elegant solution for achieving impeccable results, particularly with fine or sheer fabrics. We’ll delve into the fundamental principles, explore the myriad benefits, and reveal the projects where this sophisticated seam truly shines, ensuring your creations boast both beauty and durability from the inside out.

This guide will equip you with all the essential knowledge, from understanding the core concept and its advantages to identifying the ideal fabrics and tools. We will meticulously walk through two distinct construction methods, offering clear, step-by-step instructions for each. Furthermore, we’ll address the nuances of handling curves and corners, provide fabric-specific considerations, and offer practical solutions for common troubleshooting scenarios, ensuring you can confidently tackle any sewing project with this refined technique.

Introduction to French Seams

A French seam is a sophisticated and durable seam construction technique that encloses raw edges within the seam itself, resulting in a clean, professional finish on both the inside and outside of a garment. Its primary purpose is to prevent fraying and provide a smooth, comfortable feel against the skin, making it an ideal choice for garments where a high-quality finish is desired.The beauty of a French seam lies in its ability to hide raw edges, offering a more polished and refined appearance compared to standard seam finishes like serging or pinking.

This makes it particularly well-suited for fabrics that tend to fray easily or for garments that are frequently washed or worn.

Advantages of French Seams

French seams offer several distinct advantages, especially when compared to other common seam finishes. They provide superior durability and a clean aesthetic, which is crucial for the longevity and professional look of handmade garments.The key benefits include:

- Fray Prevention: The raw edges of the fabric are completely enclosed, eliminating the possibility of fraying and extending the life of the garment.

- Comfort: By hiding all raw edges, French seams create a smooth interior that is comfortable against the skin, preventing irritation.

- Durability: The double-stitched nature of a French seam makes it exceptionally strong and less prone to seam failure.

- Professional Appearance: The neat, clean finish mimics high-quality ready-to-wear garments, elevating the overall look of handmade items.

Common Sewing Projects for French Seams

French seams are a preferred choice for a variety of sewing projects where a clean and durable finish is paramount. They are particularly beneficial for garments that will be in close contact with the skin or those that require a delicate and refined appearance.Projects that greatly benefit from French seams include:

- Lingerie and Sleepwear: The smooth, chafe-free finish is ideal for intimate apparel.

- Blouses and Shirts: Especially those made from lightweight or sheer fabrics, where a clean interior is visible.

- Dresses: Particularly for delicate fabrics like silk, chiffon, or voile, where a refined finish is desired.

- Children’s Clothing: The durability and comfort are excellent for garments worn by active children.

- Pillowcases and Linens: For a professional and long-lasting finish on home décor items.

Fabric Weights and Types for French Seams

The success of a French seam is highly dependent on the fabric chosen. Certain fabric weights and types lend themselves perfectly to this technique, allowing for ease of manipulation and a beautiful final result.The most suitable fabrics for French seams are typically:

- Lightweight to Medium-Weight Fabrics: Fabrics that are not excessively thick are easier to fold and press neatly for the two-step stitching process.

- Woven Fabrics: French seams are primarily used with woven fabrics, as knits can stretch and distort the seam.

- Fabrics Prone to Fraying: Materials like silk, chiffon, voile, linen, and fine cotton are excellent candidates due to their tendency to unravel.

- Sheer Fabrics: The enclosed seam hides the raw edges, which would be very visible on transparent materials.

Examples of specific fabrics that work wonderfully include silk charmeuse, cotton lawn, rayon challis, and lightweight linen blends. Very heavy or bulky fabrics, such as denim or thick upholstery fabric, can make the double fold of a French seam too cumbersome and create an overly thick seam allowance, which is generally not recommended.

Essential Materials and Tools

To successfully sew a French seam, having the right tools and materials is crucial for achieving that signature clean and professional finish. This section will guide you through the essential items you’ll need, ensuring your sewing project is both efficient and produces beautiful results.The quality and suitability of your sewing machine needle and thread significantly impact the outcome of your French seams.

Using the correct type can prevent skipped stitches, fabric damage, and ensure a strong, neat seam. Precision in measuring seam allowances is also paramount, as French seams rely on specific, accurate measurements for their characteristic enclosed edge. Finally, pressing tools play an indispensable role in setting your seams, making them lie flat and enhancing the overall polished appearance of your garment.

Sewing Machine Needles and Threads

Selecting the appropriate sewing machine needle and thread is fundamental for creating neat and durable French seams. The needle should be sharp and of a size that complements your fabric weight, while the thread should be strong and colorfast.A general guideline for needle and thread selection based on fabric type is as follows:

- For lightweight fabrics (e.g., silk chiffon, voile): Use a fine needle (size 60/8 or 70/10) and a fine, strong thread like silk thread or a high-quality polyester thread.

- For medium-weight fabrics (e.g., cotton lawn, linen, quilting cotton): Opt for a universal needle (size 70/10 or 80/12) and a good quality all-purpose polyester or cotton-polyester blend thread.

- For heavier fabrics (e.g., denim, canvas): A stronger needle (size 90/14 or 100/16) with a durable thread like a heavy-duty polyester or cotton thread is recommended.

The thread should match your fabric as closely as possible to ensure the seam is inconspicuous. For French seams, it’s particularly important that the thread is strong enough to withstand the double stitching without breaking.

Accurate Seam Allowances

Achieving a perfect French seam hinges on the precise measurement and cutting of your fabric. French seams involve two successive seam allowances, and their accuracy directly dictates how well the raw edges are enclosed.

Accurate seam allowances are the cornerstone of a successful French seam; they ensure raw edges are fully concealed, preventing fraying and creating a smooth interior.

When preparing to sew a French seam, always consult your pattern instructions for the recommended seam allowance. If no specific allowance is given for French seams, a standard 5/8 inch (1.5 cm) is often used, divided into two smaller allowances. For instance, if the total seam allowance is 5/8 inch, the first seam will be sewn at 3/8 inch (approx.

1 cm) and the second at 1/4 inch (approx. 0.5 cm).To measure seam allowances precisely:

- Use a good quality measuring tape or a seam gauge.

- Mark the seam allowance line with chalk or a fabric marker before cutting, or rely on the markings on your sewing machine’s throat plate.

- When trimming the first seam allowance, ensure it is trimmed to the exact width required for the second seam allowance to fully enclose it. For example, if the second seam allowance is to be 1/4 inch, trim the first seam allowance to exactly 1/4 inch.

Using a rotary cutter and a self-healing mat with grid lines can also aid in precise cutting and measuring.

Pressing Tools

Pressing is an integral part of the French seam technique, transforming a series of stitched lines into a smooth, professional finish. Proper pressing at each stage of the French seam construction is essential for its success.A standard iron and ironing board are the primary pressing tools. However, for more intricate or delicate fabrics, or for achieving exceptionally crisp seams, additional tools can be beneficial:

- Tailor’s Ham or Sleeve Roll: These curved pressing aids are invaluable for pressing seams on curved areas of a garment, such as armholes or collars, ensuring they lie flat without distortion.

- Pressing Cloth: A lightweight cotton or linen cloth placed between the iron and the fabric can protect delicate materials from scorching or developing a sheen. It also helps to distribute heat evenly.

- Seam Roller or Clapper: A seam roller can be used to flatten seams without the direct heat of an iron, which is useful for very fine or delicate fabrics. A seam clapper, typically made of wood, is used to set a crease firmly after pressing, especially on heavier fabrics, by absorbing steam and heat.

The process typically involves pressing the first seam allowance open, then pressing the two layers of the French seam to one side before trimming. The final pressing involves pressing the entire French seam to one side, ensuring the enclosed raw edges are neatly hidden.

Step-by-Step French Seam Construction (Method 1: Standard)

This section details the standard method for constructing a French seam, a technique that beautifully encloses raw edges for a professional and durable finish. We will guide you through each precise step to ensure a clean and elegant outcome.French seams are particularly well-suited for lightweight to medium-weight fabrics, such as cotton, linen, silk, and rayon. They prevent fraying and create a smooth interior, making them ideal for garments like blouses, dresses, and delicate skirts.

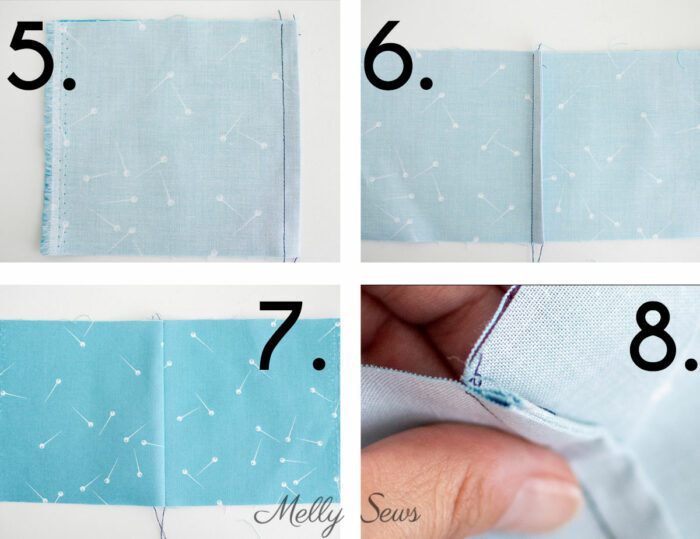

Initial Seam with Wrong Sides Together

The first step in creating a French seam involves sewing the fabric pieces with their wrong sides facing outwards. This initial stitch will be on the “inside” of your final seam.

- Place your fabric pieces with the wrong sides together, aligning the raw edges precisely.

- Using your sewing machine, stitch along the raw edge at a narrow seam allowance, typically 1/4 inch (approximately 6mm). Ensure your stitches are straight and consistent.

Trimming and Pressing the First Seam Allowance

After the initial stitch, it is crucial to trim the seam allowance. This reduction is what allows the raw edges to be fully enclosed in the subsequent step.

- Carefully trim the seam allowance down to approximately 1/8 inch (about 3mm). Use sharp fabric scissors or a rotary cutter for a clean cut. Be cautious not to cut through your stitching.

- Press the trimmed seam allowance flat and to one side. This initial pressing helps to create a neat foundation for the next step.

Enclosing the Raw Edge and Sewing the Second Seam

This is the defining step of the French seam, where the raw edges are neatly tucked away. The fabric is turned so that the right sides are now together, and the previously trimmed seam allowance is enclosed within.

- Turn the fabric so that the right sides are now together, enclosing the trimmed seam allowance within. The folded edge of the first seam should be pressed firmly.

- Align the folded edges of the fabric. You will be stitching again, this time along the original seam line, effectively encasing the raw edges. The new seam allowance should be slightly wider than the first, typically around 3/8 inch (about 1cm), to ensure the first seam’s raw edge is completely covered.

- Sew along this new seam line, ensuring you catch both layers of fabric and the enclosed raw edge.

Pressing the Completed French Seam

The final pressing is essential for achieving a crisp, professional finish that truly showcases the beauty of the French seam.

- Press the completed French seam flat, with the seam running along the edge of the fabric.

- Then, press the seam allowance to one side. For an even cleaner look, you can press the entire seam open as if it were a standard seam, but with the French seam construction, pressing to one side is more common and often results in a flatter finish.

Step-by-Step French Seam Construction (Method 2: Alternative Trim)

While the standard French seam method is excellent, an alternative trimming approach can offer subtle variations in seam bulk and finish. This method involves a slightly different initial trimming measurement, which impacts the final appearance and feel of the seam.This alternative method is particularly useful when working with very fine or delicate fabrics where minimizing bulk is paramount, or when a slightly softer drape is desired.

By adjusting the initial trim, you can fine-tune the seam’s appearance to best suit your project.

Trimming the Initial Seam Allowance

In this variation, the initial trimming measurement is reduced compared to the standard method. Instead of trimming to 1/4 inch, we will trim the first seam allowance to a mere 1/8 inch. This significantly smaller trimmed edge will be enclosed in the subsequent steps.

Enclosing the Raw Edge and Sewing the Second Seam

After trimming the first seam allowance to 1/8 inch, the fabric is turned so that the wrong sides are together, encasing the raw edge. The first seam line should be pressed flat to create a crisp fold. Then, the fabric is pressed again along the folded edge, ensuring the raw edge is completely hidden within the fold. The second seam is then sewn at approximately 3/8 inch from the folded edge.

This measurement, combined with the initial 1/8 inch trim, effectively encloses the raw edge within a 1/2 inch total seam allowance.

Comparing Method 1 and Method 2

The primary difference between Method 1 (standard) and Method 2 (alternative trim) lies in the initial trimming and subsequent seam allowance measurements. Method 1, with its 1/4 inch initial trim and 1/4 inch second seam, results in a slightly more substantial seam. Method 2, with its 1/8 inch initial trim and 3/8 inch second seam, produces a finer, less bulky seam.

Method 1: 1/4 inch (first seam) + 1/4 inch (second seam) = 1/2 inch total seam allowance, with a slightly more pronounced seam bulk.Method 2: 1/8 inch (first seam) + 3/8 inch (second seam) = 1/2 inch total seam allowance, with a finer, less bulky seam.

Visually, Method 2 will appear slightly flatter and less pronounced from the right side of the garment. Tactilely, the seam in Method 2 will feel softer and more pliable, making it ideal for garments that require a gentle drape or for use on very lightweight fabrics.

Pressing the Seam in the Alternative Method

Proper pressing is crucial for both methods, but for Method 2, it’s essential to ensure the initial trimmed edge is perfectly enclosed. After sewing the first seam and trimming to 1/8 inch, press the seam flat with the right sides together. Then, turn the fabric so the wrong sides are together and press the seam allowance firmly to one side.

This creates a sharp crease, ensuring the raw edge is fully concealed before you sew the second seam. After sewing the second seam, press the entire French seam to one side, just as you would with Method 1.

Handling Curves and Corners with French Seams

French seams are celebrated for their neat and durable finish, but achieving this polished look on curved edges and at corners requires specific techniques. These areas present unique challenges that, when addressed correctly, ensure your garment’s interior is as beautiful as its exterior. Understanding these adjustments will elevate your sewing skills and the overall quality of your finished projects.Sewing French seams on curves demands precision to avoid puckering and ensure the seam lies flat.

The key lies in managing the excess fabric and allowing it to ease smoothly around the bend. This section will guide you through the necessary adaptations for a flawless curved French seam.

Curved Edges

When working with curved edges, the primary adjustment for French seams involves careful clipping of the first seam allowance. This allows the fabric to lie flat as it bends, preventing tension that can lead to puckering or distortion of the curve.The process for sewing French seams on curves is as follows:

- With the wrong sides of the fabric together, stitch the first seam at your chosen seam allowance (e.g., 1/4 inch or 6mm).

- Trim this first seam allowance to approximately half its width (e.g., 1/8 inch or 3mm).

- For particularly tight curves, or if you are working with thick fabric, clip small notches into the seam allowance at regular intervals. These notches should be cut towards the stitching line, but not through it. For outward curves, you will clip V-shaped notches. For inward curves, you will make small straight cuts.

- Turn the fabric so the right sides are together, enclosing the raw edges. Press the seam allowance flat.

- Stitch the second seam, enclosing the trimmed first seam allowance. The second seam allowance should be wide enough to fully cover the raw edge of the first seam (e.g., 1/4 inch or 6mm, depending on your initial seam allowance and how much you trimmed).

- Press the finished seam.

External Corners

Creating a neat, sharp point at external corners with French seams involves a specific trimming and turning technique. This ensures the fabric folds cleanly and the point is well-defined without excessive bulk.To achieve a crisp external corner:

- When sewing the first seam allowance (wrong sides together), extend your stitching slightly beyond the corner point, ensuring you have enough fabric to turn.

- Trim the first seam allowance very close to the corner point, clipping diagonally across the corner. Imagine drawing a line from the corner point to the end of your stitching. Cut along this line.

- Turn the fabric to the right sides, enclosing the raw edges. Carefully push out the corner point with a point turner or a blunt tool to ensure it is sharp.

- Press the seam allowance flat.

- Stitch the second seam, enclosing the trimmed first seam allowance.

- Press the finished seam, ensuring the corner remains sharp.

Internal Corners

Managing internal corners with French seams requires careful handling to prevent bulk and ensure a smooth, neat appearance. The technique involves strategic trimming and easing the fabric to lie flat.The approach for internal corners is as follows:

- When sewing the first seam allowance (wrong sides together), stop stitching precisely at the corner point.

- Trim the first seam allowance along the edge leading into the corner, and then trim the seam allowance at the corner itself. For an internal corner, you will clip small V-shaped notches into the seam allowance on the edge leading to the corner, and then trim the seam allowance at the corner diagonally.

- Turn the fabric to the right sides, enclosing the raw edges. The fabric should ease into the corner without significant pulling.

- Press the seam allowance flat.

- Stitch the second seam, enclosing the trimmed first seam allowance.

- Press the finished seam.

Comparative Table: Adjustments for Curves and Corners

To provide a clear overview of the techniques, here is a comparison of the adjustments needed for different edge types when sewing French seams. This table highlights the key differences in clipping and handling the fabric.

| Edge Type | First Seam Allowance Trim | Corner/Curve Handling | Second Seam Allowance |

|---|---|---|---|

| Straight Edge | Trim to 1/4 inch (6mm) | None needed | Enclose trimmed edge, typically 1/4 inch (6mm) |

| External Curve | Trim to 1/4 inch (6mm), clip notches (V-shape for outward curves) | Ease fabric around the curve, press gently | Enclose trimmed edge, ensuring seam lies flat |

| Internal Curve | Trim to 1/4 inch (6mm), clip notches (straight cuts for inward curves) | Ease fabric around the curve, press gently | Enclose trimmed edge, ensuring seam lies flat |

| External Corner | Trim to 1/4 inch (6mm), clip diagonally across the corner point | Push out the corner to create a sharp point | Enclose trimmed edge, ensuring the point remains sharp |

| Internal Corner | Trim to 1/4 inch (6mm), clip notches into the edge leading to the corner and trim diagonally at the corner point | Ease fabric into the corner without pulling | Enclose trimmed edge, ensuring a neat finish without bulk |

Fabric-Specific Considerations for French Seams

French seams are a versatile technique that can elevate the finish of many garments. However, the success of a French seam often depends on understanding how different fabric types behave and adapting the construction method accordingly. This section will explore how to best utilize French seams across a spectrum of fabrics, from the most delicate to the sturdiest.Successfully applying French seams requires a nuanced approach, recognizing that a one-size-fits-all method may not yield the best results.

By considering the unique properties of each fabric, you can ensure a professional and durable finish that enhances both the look and longevity of your sewing projects.

Delicate Fabrics: Silk, Chiffon, and Voile

Working with fine, sheer, or slippery fabrics like silk, chiffon, or voile presents a unique set of challenges when constructing French seams. These materials can easily fray, snag, or distort, making precise stitching and careful handling paramount. The goal is to create a neat, enclosed seam without adding excessive bulk or causing the fabric to pucker.For these delicate materials, a slightly modified approach to the standard French seam is often beneficial.

The key is to manage the small seam allowances and ensure they are fully enclosed to prevent any raw edges from showing or fraying.

- Narrower Seam Allowances: When working with very fine fabrics, you may need to reduce the initial seam allowance for the first stitching. Instead of the standard 1/4 inch, consider starting with 1/8 inch to 3/16 inch. This allows for a smaller second turn, keeping the overall seam width manageable and preventing it from becoming too bulky.

- Precise Trimming: After the first stitching and before turning the seam, carefully trim the raw edge to about half of the initial seam allowance. Use sharp fabric scissors or a rotary cutter for a clean cut. This step is crucial for achieving a smooth second fold.

- Finger Pressing: Instead of a hot iron, which can scorch or damage delicate fibers, gently finger press the seam allowances. This helps to set the folds without the risk of heat damage.

- Stitching Line Accuracy: Ensure your stitching lines are straight and consistent. Even a slight deviation can lead to unevenness in the final enclosed seam, which will be more noticeable on sheer fabrics.

- Using a Walking Foot: For very slippery silks or chiffons, a walking foot can be invaluable. It helps to feed both layers of fabric evenly through the machine, preventing shifting and puckering.

- Basting: Consider hand-basting the seam before machine stitching, especially for the initial enclosure. This provides extra stability and ensures the fabric layers stay aligned.

Heavier Fabrics: Denim, Canvas, and Twill

Heavier fabrics such as denim, canvas, and sturdy twills are generally more forgiving when it comes to French seams due to their inherent stability and less tendency to fray excessively. These materials can handle larger seam allowances and a more robust construction, making them excellent candidates for this seam finish. The challenge here is often managing the bulk that can accumulate with multiple layers of fabric.When applying French seams to these robust materials, the standard method usually works very well.

The goal is to create a strong, neat seam that doesn’t feel overly stiff or bulky, which can be an issue with multiple layers of thick fabric.

- Standard Seam Allowances: The typical 1/4 inch initial seam allowance is usually appropriate for heavier fabrics. This provides enough fabric to work with for the second enclosure.

- Pressing is Key: While finger pressing might not be sufficient for thick fabrics, thorough pressing with an iron is essential. Press each seam allowance open after the first stitching, then press the entire seam to one side before turning. This helps to flatten the fabric and reduce bulk.

- Trimming for Bulk Reduction: After turning and before the second stitching, trim the raw edge of the enclosed seam allowance by about half. This is particularly important for areas like side seams or waistband seams where multiple French seams might meet.

- Topstitching (Optional): For extra durability and a decorative element on fabrics like denim, you can topstitch along the edge of the enclosed seam. Be mindful of needle choice and tension to avoid breaking needles on thick layers.

- Using a Heavy-Duty Needle: Ensure you are using a needle appropriate for the fabric weight. A size 100/16 or 110/18 needle is often recommended for denim and canvas.

Slippery or Unstable Materials

Working with slippery or unstable materials, such as satin, some rayons, or certain synthetics, requires extra care to maintain control and achieve a precise French seam. These fabrics have a tendency to shift, stretch, or slide, making accurate cutting and stitching a significant challenge. The goal is to keep the fabric layers aligned throughout the process.The key to success with these materials lies in minimizing movement and ensuring that the fabric is held securely at all stages of construction.

- Pre-washing and Drying: Always pre-wash and dry your fabric according to its care instructions. This helps to pre-shrink the material and can sometimes make it slightly less slippery.

- Precise Cutting: Use a rotary cutter and mat for the most accurate cutting. If using scissors, ensure they are very sharp and that the fabric is laid flat without any pulling or stretching.

- Stabilizing Techniques: Consider using a temporary stabilizer like a wash-away stabilizer or a thin, lightweight fusible interfacing on the wrong side of the fabric. This can provide extra grip and prevent stretching during sewing. Apply it only to the seam allowance area if possible.

- Use of Pins and Clips: Use plenty of fine, sharp pins or sewing clips to hold the fabric layers together. Place them perpendicular to the seam line so they can be easily removed as you sew.

- Slow and Steady Stitching: Sew slowly and deliberately. Allow the machine to feed the fabric; do not push or pull.

- Paper-Backed Stabilizers: For extremely slippery fabrics, you can try sandwiching the fabric between two layers of tissue paper or specialized sewing paper. Stitch through all layers, then carefully tear away the paper.

Knit Fabrics and French Seams

Knit fabrics, by their very nature, are stretchy and can unravel or distort easily. Applying a traditional French seam to knits presents a significant challenge because the inherent stretch of the fabric can cause the enclosed seam to become distorted, stretched out, and lose its intended shape. Furthermore, the raw edges of knits can roll or curl, making the second turn difficult.While not the most common or ideal seam finish for most knits, there are situations where a French seam might be desired for a very specific aesthetic or for certain types of stable knits.

However, it’s crucial to understand the potential pitfalls and employ specific strategies.

- Fabric Stability is Key: French seams are generally best avoided on highly stretchy or loosely knit fabrics. They are more feasible on very stable knits with minimal stretch, such as ponte or some interlock knits.

- Narrow Seam Allowances: Use very narrow seam allowances for both the initial and final stitching. This minimizes the amount of fabric being enclosed, reducing bulk and the potential for distortion.

- Serger or Zigzag Stitch for Enclosure: After the first stitch, instead of just trimming, consider using a serger or a narrow zigzag stitch along the raw edge of the seam allowance. This helps to prevent the knit from unraveling further and provides a more stable edge to turn.

- Careful Trimming: If you are not using a serger, trim the first seam allowance very precisely. The goal is to have just enough fabric to enclose neatly without adding excessive thickness.

- Gentle Handling and Pressing: Avoid stretching the fabric as you sew. Use a walking foot if possible. Press seams gently with a cool iron or by finger pressing. High heat can damage synthetic fibers common in knits and can also cause them to stretch out of shape.

- Consider Alternative Seam Finishes: For most knit projects, alternative seam finishes like a serged seam, a flat-felled seam, or a binding are generally more appropriate and provide a cleaner, more durable finish that accommodates the fabric’s stretch.

Troubleshooting Common French Seam Issues

While French seams offer a beautiful and durable finish, occasional challenges can arise during their construction. Understanding these common issues and their solutions will help you achieve a consistently professional result. This section addresses prevalent problems and provides practical advice for resolving them.

Puckering in French Seams

Puckering in French seams is often a result of tension issues, incorrect stitch length, or improper fabric handling. When the fabric bunches up along the seam line, it detracts from the clean finish.

Causes and Solutions:

- Excessive Thread Tension: If the upper or lower thread tension is too high, it can pull the fabric together, causing puckering. Adjust your sewing machine’s tension settings to a medium range and test on scrap fabric.

- Stitch Length Too Short: Very short stitches can also create tension that leads to puckering. Use a slightly longer stitch length, typically between 2.0mm and 2.5mm, for French seams.

- Fabric Not Supported: When sewing the initial narrow seam, ensure you are not stretching or pulling the fabric. Gently guide the fabric through the machine without manipulation.

- Incorrect Pressing: Pressing with steam can sometimes exacerbate puckering if the fabric is not laid flat. Ensure you are pressing seams flat before turning and pressing again.

Uneven or Bulky French Seams

An uneven or bulky French seam can occur when the fabric layers are not trimmed consistently, or when the second seam allowance is too wide. This results in a seam that is not as flat or refined as desired.

Causes and Solutions:

- Inconsistent Trimming: Ensure that the first seam allowance is trimmed evenly before turning. Use sharp fabric scissors or a rotary cutter and ruler for precision. A consistent width of approximately 1/4 inch (6mm) is ideal.

- Second Seam Allowance Too Wide: When you turn the seam and stitch the second enclosing seam, if the fabric edge is too far from the folded edge, the second seam allowance will be too wide, leading to bulk. Aim for a second seam allowance that is roughly 3/8 to 1/2 inch (1cm to 1.25cm).

- Fabric Layers Shifting: During the initial stitching, if the fabric layers shift, the enclosed seam will be uneven. Basting the seam allowance before stitching can help prevent this.

Visible Raw Edges

A primary goal of the French seam is to enclose all raw edges. If a raw edge is still peeking out after construction, it indicates an error in the folding or stitching process.

Causes and Solutions:

- Insufficient Fabric in First Seam: The initial narrow seam allowance must be wide enough to fully enclose the raw edge when turned. If the first seam allowance is too narrow (less than 1/4 inch or 6mm), there may not be enough fabric to hide the raw edge.

- Imperfect Turning: Ensure the fabric is turned precisely so that the raw edge is fully caught within the fold before stitching the second seam. Use a point turner or a chopstick to help push out the seam and ensure the raw edge is tucked in.

- Seam Allowance Not Pressed Flat: After turning the fabric for the second seam, pressing the seam flat helps to secure the fold and ensure the raw edge remains enclosed.

French Seams That Are Too Wide or Too Narrow

The width of the French seam impacts its appearance and suitability for different fabrics. A seam that is either too wide or too narrow can compromise the intended aesthetic and strength.

Causes and Solutions:

- Too Wide: If the French seam is too wide, it can appear bulky and disproportionate, especially on lighter fabrics. This usually happens when the second seam allowance is cut too large, or the initial seam allowance was too generous. To correct this, ensure your initial seam allowance is consistently 1/4 inch (6mm) and the second seam allowance is around 3/8 to 1/2 inch (1cm to 1.25cm).

If the seam is already sewn too wide, it may be necessary to unpick and re-sew with narrower allowances.

- Too Narrow: A French seam that is too narrow may not fully enclose the raw edges, leading to fraying and a less durable finish. This typically occurs when the initial seam allowance is too small, or the second seam allowance is too close to the folded edge. Aim for an initial seam allowance of at least 1/4 inch (6mm) and a second seam allowance that provides sufficient coverage.

If the seam is too narrow and fraying, it may be best to carefully unpick and re-stitch with wider seam allowances.

Visualizing the French Seam Process

Understanding the visual progression of a French seam is key to mastering this elegant finishing technique. This section will guide you through what a French seam looks like from both the right and wrong sides of the fabric, detailing its internal structure and the visual cues to observe at each construction stage.

Appearance of a Finished French Seam

From the right side of your garment, a properly constructed French seam is virtually invisible. There are no raw edges exposed, and the seam line appears as a neat, continuous line, as if the fabric pieces were joined without any seam allowance fraying or showing through. This clean finish is the hallmark of a well-executed French seam, making it ideal for delicate fabrics or garments where a polished interior is as important as the exterior.

Internal Structure of a French Seam

The beauty of the French seam lies in its internal construction, where all raw edges are meticulously enclosed. This is achieved in two distinct stitching stages. The first stitch encloses the raw edges within a narrow seam allowance, and the second stitch encases this initial seam, effectively hiding all raw edges from view.

Fabric Appearance at Each Construction Stage

To truly visualize the process, let’s trace the journey of your fabric edges:

- Initial Fabric Edges: Before sewing, you will see the raw, cut edges of your fabric pieces. These are typically uneven and prone to fraying.

- After the First Stitch: When you complete the first, narrower seam (usually 1/4 inch or 6mm), you will see a small, folded-over edge on the wrong side of the fabric. The raw edges are now neatly tucked inside this fold.

- After Turning and Pressing: After turning the fabric so the wrong sides are together and pressing the seam flat, the seam line will appear as a defined ridge on the wrong side. The first seam allowance is now hidden, and the raw edges are contained within this folded section.

- After the Second Stitch: The final seam (typically 1/4 inch or 6mm, depending on your initial seam allowance) is sewn with the right sides of the fabric together, enclosing the previously folded seam allowance. On the wrong side, you will see a neat, double-folded seam. On the right side, the seam appears as a single, clean line with no visible raw edges.

A Visual Narrative of Seam Progression

Imagine two pieces of delicate silk, their raw edges slightly fuzzy. We align them with their wrong sides facing up. The first step is to sew a narrow seam, about 1/4 inch from the raw edge, enclosing those wispy threads. Now, we turn the fabric so the right sides are together, and press this little folded seam flat. It creates a neat ridge on the wrong side, a hidden pocket for our raw edges.

The final act is to sew another seam, again about 1/4 inch, encasing this entire folded structure. When we turn the fabric to the right side, the seam is a clean, uninterrupted line, a testament to the raw edges being perfectly tucked away, leaving a smooth, professional finish. This methodical enclosure transforms a potentially messy raw edge into a beautifully finished seam.

Closing Summary

As we conclude our exploration of How to Sew a French Seam for a Clean Finish, we trust you feel empowered to elevate your sewing projects. By mastering this elegant technique, you’ve gained the ability to create garments with exceptionally neat and durable seams, enhancing both their aesthetic appeal and longevity. Remember, the beauty of a French seam lies in its hidden perfection, a testament to careful craftsmanship that speaks volumes in the final garment.