How to Sew a Perfect Corner is your comprehensive guide to achieving beautifully crisp and professional-looking corners in your sewing projects. Whether you’re a beginner aiming for your first flawless seam or an experienced crafter looking to refine your techniques, this guide delves into every aspect of corner construction.

We will explore the fundamental principles, essential tools, and step-by-step processes required to transform ordinary seams into sharp, defined edges. From understanding fabric behavior to mastering advanced stitching and troubleshooting common issues, this content is designed to equip you with the knowledge and confidence to create impeccable corners every time.

Understanding the Fundamentals of Sewing Corners

Achieving perfectly sharp and neat corners is a hallmark of professional-looking sewing projects. Whether you’re crafting a quilt, a pillowcase, or a garment, understanding the underlying principles and techniques for sewing corners is crucial. This section will delve into the foundational aspects that contribute to flawless corners, from common pitfalls to the tools that make the process manageable.Sewing corners can present several challenges that often lead to less-than-ideal results.

These issues can stem from fabric behavior, technique, or the tools used. By recognizing these common hurdles, we can better prepare to overcome them and achieve the desired crispness.

Common Challenges in Sewing Corners

Several recurring difficulties can arise when sewing corners, impacting the final appearance of a project. These challenges are often related to how the fabric behaves at the point where two seams meet and turn.

- Bulkiness: Excess fabric at the corner can create a thick, rounded, or uneven appearance, especially in thicker fabrics or when multiple layers are involved.

- Point Dropping: The precise point of the corner may become rounded or “dropped” instead of remaining sharp and defined, detracting from the overall neatness.

- Fabric Puckering: Incorrect handling of fabric during the sewing and turning process can lead to puckering or pleating around the corner.

- Uneven Seam Allowance: Inconsistent seam allowances at the corner can result in one side being longer or shorter than the other, leading to an asymmetrical and untidy finish.

- Thread Bunching: If the machine tension is not properly adjusted, or if the needle struggles to navigate the corner’s bulk, thread can bunch up, creating an unsightly knot.

Essential Tools and Materials for Crisp Corners

Having the right tools can significantly simplify the process of sewing and finishing corners, ensuring a professional and precise outcome. These items are designed to help manage fabric, create accurate markings, and execute the necessary steps with ease.A well-equipped sewing kit is fundamental for success. The following items are particularly helpful when focusing on achieving sharp corners:

- Sewing Machine: A reliable sewing machine is the primary tool for creating the seams that form the corner.

- Fabric Scissors: Sharp scissors are essential for trimming excess fabric, which is a critical step in reducing bulk at the corners.

- Seam Ripper: While not for creating corners, a seam ripper is invaluable for correcting any mistakes made during the sewing process, allowing for a fresh start.

- Iron and Ironing Board: Pressing is crucial for setting seams and creasing fabric, making it easier to fold and sew corners accurately.

- Measuring Tools: A ruler or measuring tape is necessary for ensuring consistent seam allowances and marking precise fold lines.

- Marking Tools: Tailor’s chalk, a fabric pen, or a pencil can be used to mark seam lines and fold points, guiding your sewing.

- Turning Tools: A point turner, chopstick, or a knitting needle can be used to gently push out the corner point after turning the fabric right side out, ensuring a sharp definition.

- Rotary Cutter and Mat (Optional): For projects requiring very precise cuts, a rotary cutter and mat can offer accuracy, especially when cutting fabric strips for binding corners.

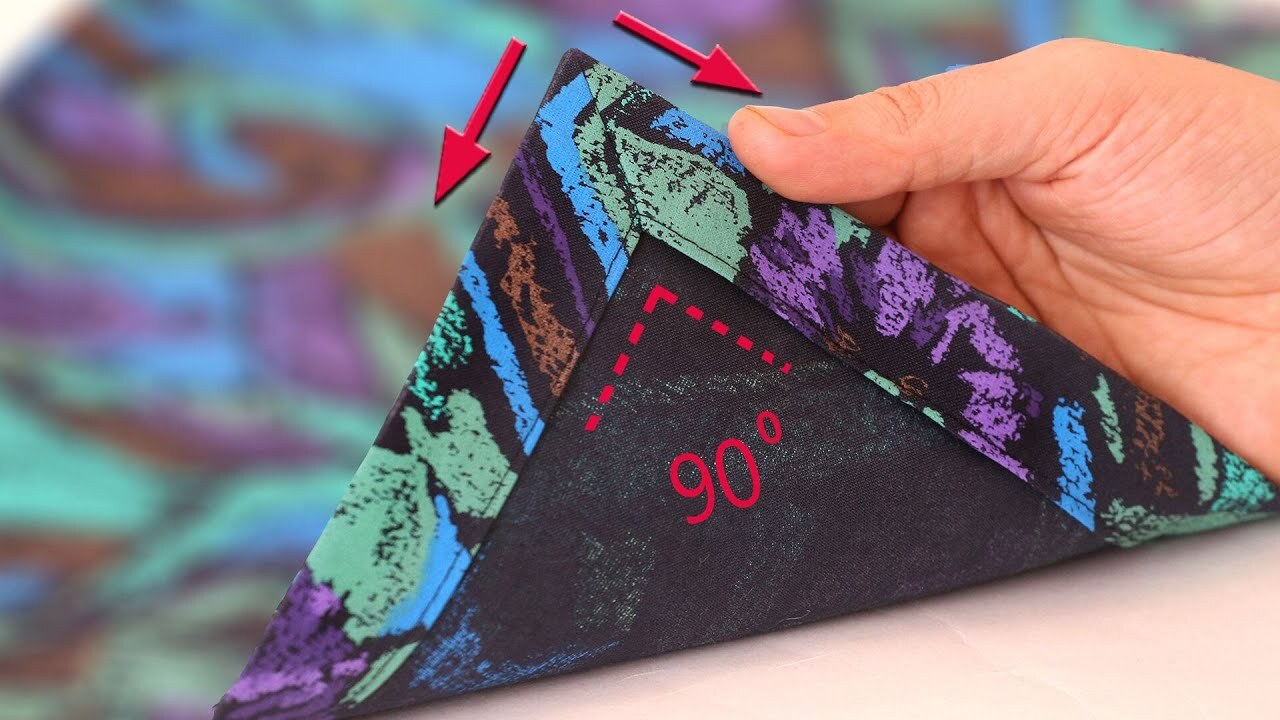

The Basic Concept of Folding and Creasing for Corners

The fundamental principle behind sewing a neat corner lies in how the fabric is managed at the point where two perpendicular seams will meet. This involves strategically folding and creasing the fabric to guide the sewing and ensure a clean turn.The core idea is to prepare the fabric so that when it is sewn and then turned, the corner naturally forms a sharp 90-degree angle.

This is typically achieved by marking and folding the fabric before sewing, or by carefully managing the fabric at the sewing machine.

- Marking the Seam Line: Before sewing, mark the intended seam line on the wrong side of the fabric. This line represents where your stitching will go. For a standard corner, this will be a line perpendicular to the edge.

- Stitching to the Corner Point: Sew along the marked seam line until you reach the exact point where the corner will be formed. This is often the point where the marked seam line intersects the edge of the fabric.

- Backstitching (Optional but Recommended): For added security, backstitch a few stitches at the corner point to reinforce the seam.

- Pivot and Continue Sewing: Leave the needle down in the fabric at the corner point. Lift the presser foot and pivot the fabric 90 degrees. Lower the presser foot and continue sewing along the next seam line. This pivoting action is key to creating the sharp angle.

- Trimming Excess Fabric: After sewing, and before turning, trim the excess fabric at the corner. A common technique is to clip diagonally across the corner, getting close to the stitching but not cutting through it. This reduces bulk.

- Turning and Pressing: Turn the fabric right side out, using a turning tool to gently push out the corner point. Then, press the corner with an iron to set the shape and ensure crispness.

The Importance of Fabric Type and Its Impact on Corner Neatness

The choice of fabric plays a significant role in how easily and neatly corners can be sewn. Different fabric types have varying weights, drapes, and fiber compositions, all of which influence the final outcome of a corner.Understanding your fabric’s properties is essential for adapting your technique. For instance, a very thin, slippery fabric will behave differently than a thick, stable one.

- Lightweight Fabrics (e.g., cotton lawn, silk, rayon): These fabrics are generally easier to work with for sharp corners as they don’t create as much bulk. However, they can be prone to fraying and may require careful handling to prevent stretching or distortion when turning. Trimming the corner seam allowance very close to the stitching is often beneficial.

- Medium-Weight Fabrics (e.g., quilting cotton, linen blends): These offer a good balance of stability and ease of manipulation. They hold a crease well and are less likely to distort, making them ideal for practicing and achieving crisp corners.

- Heavyweight Fabrics (e.g., denim, canvas, upholstery fabric): These fabrics can be challenging due to their thickness. They create significant bulk at the corners, which can lead to rounded or uneven points. Trimming the seam allowance extensively, sometimes to a very narrow width, and using a turning tool with care is crucial. Pre-creasing with an iron can also help manage the bulk.

- Knits (e.g., jersey, interlock): Knits can be tricky for sharp corners because they are stretchy and tend to distort. Achieving a truly sharp 90-degree angle can be difficult. Often, a slightly rounded corner is more practical and aesthetically pleasing with knit fabrics. Stabilizing the fabric with interfacing or using a stretch stitch can help.

- Fabrics with a Napped or Textured Surface (e.g., velvet, corduroy): These fabrics can be difficult to align perfectly when sewing corners, as the nap can shift. Sewing with the fabric in the same direction for both pieces of the corner and pressing carefully after turning is important.

Pre-Sewing Preparations for Perfect Corners

Achieving perfectly crisp corners in your sewing projects is not solely about the stitching itself; it begins long before the needle touches the fabric. Meticulous preparation ensures that your fabric is ready to accept precise markings and that your seams are perfectly aligned for that coveted sharp finish. Investing time in these foundational steps will significantly elevate the professional appearance of your handmade items.These pre-sewing preparations are crucial for setting the stage for success.

They address the physical state of your fabric and the accuracy of your planning, both of which are paramount for creating flawless corners that add a polished touch to any garment or home décor item.

Fabric Readiness Checklist

Before you begin cutting or sewing, a thorough check of your fabric’s readiness will prevent many common issues that lead to imperfect corners. This checklist ensures your material is stable, clean, and properly prepared for accurate handling.

- Pre-washing and Drying: Always pre-wash and dry your fabric according to its care instructions. This step accounts for any shrinkage that might occur after the garment is completed, preventing distorted corners later on.

- Ironing: Ensure your fabric is thoroughly pressed. Wrinkles can distort measurements and create uneven stitching lines, directly impacting corner accuracy.

- Grainline Check: Verify that your fabric is cut on the straight grain. Fabric cut off-grain will not hang or lie correctly, making it impossible to achieve sharp, even corners.

- Thread Removal: Trim any loose threads or selvedges that might interfere with seam allowances or add bulk to the corners.

Marking and Measuring for Accurate Corner Alignment

Precision in marking and measuring is the bedrock of accurate corner construction. These techniques ensure that your cut lines and seam lines converge at the exact points required for a perfect ninety-degree angle.

- Using a Quilting Ruler and Rotary Cutter: For projects requiring extreme precision, a quilting ruler with clear markings and a sharp rotary cutter on a self-healing mat is invaluable. Measure and mark your cut lines carefully, ensuring they are perpendicular to each other.

- Tailor’s Chalk or Water-Soluble Pen: These marking tools are essential for transferring seam lines and corner points onto the fabric. For corners, mark the exact point where the seam will terminate.

- Right-Angle Tools: A right-angle ruler or a carpenter’s square can be used to double-check that your marked lines form a perfect ninety-degree angle before cutting.

- Double-Checking Measurements: Before cutting, re-measure all dimensions, especially those related to corner placement. A slight error here can compound into a noticeable imperfection in the final corner.

Pressing Seams and Corners Before Stitching

Pressing is not just about removing wrinkles; it’s an integral part of shaping the fabric and setting up your seams for success. Proper pressing before and during the sewing process is critical for achieving crisp, defined corners.

- Pressing Seam Allowances Open: For most seams, pressing the seam allowances open before you even start to sew the corner helps to reduce bulk and allows the fabric to lie flat. This is especially important for thicker fabrics.

- Finger Pressing: Before making the final stitch, use your fingers to gently crease the seam allowance at the corner. This provides a visual guide and helps to set the fabric in the correct position for the final press.

- Using a Pressing Ham or Sleeve Board: For curved or complex corners, a pressing ham or sleeve board can help you press the fabric around the curve without creating unwanted pleats or distortions.

- Cooling the Fabric: After pressing, allow the fabric to cool completely before moving it. This helps to set the press and prevents the fabric from stretching or distorting while it is still hot and pliable.

Common Fabric Preparation Mistakes to Avoid

Many sewing enthusiasts overlook the importance of thorough fabric preparation, leading to frustrating results, particularly with corners. Being aware of these common pitfalls can help you avoid them and ensure a smoother sewing experience.

| Mistake | Impact on Corners | How to Avoid |

|---|---|---|

| Skipping pre-washing | Shrinkage after completion can cause corners to pucker or become uneven. | Always pre-wash and dry fabric according to its care label. |

| Sewing on wrinkled fabric | Inaccurate measurements and uneven stitch lines result in misshapen corners. | Press fabric thoroughly before cutting and marking. |

| Cutting fabric off-grain | Fabric will not lie flat, leading to distorted seams and corners that don’t align properly. | Align the fabric selvedge with the ruler’s grainline marking and cut carefully. |

| Overlooking loose threads | Excessive bulk at the seam junction can prevent corners from lying flat and looking sharp. | Trim all loose threads and neatened selvedges before sewing. |

| Improper seam allowance pressing | Bulkiness in seam allowances prevents corners from turning neatly and can lead to a rounded appearance. | Press seam allowances open or to one side as required by the pattern, ensuring they are flat. |

Stitching Techniques for Sharp Corners

Achieving crisp, professional-looking corners is a hallmark of quality sewing. The techniques you employ during the stitching phase are crucial for this, as they directly influence the final appearance and durability of your project. This section delves into the essential stitching methods that will elevate your corner construction.Mastering the art of stitching sharp corners involves understanding the role of different stitch types, strategically managing seam allowances, and executing precise fabric manipulation at the turning point.

By focusing on these elements, you can ensure that every corner you sew is a testament to your skill.

Reinforcing Corners with Stitch Types

The choice of stitch type plays a significant role in how well a corner holds its shape and resists stress. While a standard straight stitch is often sufficient, certain applications benefit from enhanced reinforcement.Here are stitch types suitable for reinforcing corners:

- Backstitch: This is the most common and effective method for securing the beginning and end of any seam, especially at corners. It involves sewing forward and then backward over the same stitches, creating a dense, interlocking pattern that prevents unraveling.

- Reinforcing Stitch (often a shorter stitch length straight stitch): Some sewing machines offer a specific reinforcing stitch, or you can achieve a similar effect by sewing a straight stitch with a slightly shorter stitch length over the corner area twice. This adds extra density to the stitches, making the corner more robust.

- Triple Straight Stitch: This stitch passes over the same line three times, creating a very strong and durable seam. It’s particularly useful for high-stress areas like the corners of bags or home decor items that will undergo frequent handling.

- Zigzag Stitch (Narrow): While not typically used for the main seam of a corner, a very narrow zigzag stitch can be used as a finishing technique around the raw edges of a corner to prevent fraying, especially in fabrics prone to unraveling.

Mitred Corners Versus Square Corners: Stitching Comparisons

The method of stitching a corner is largely dictated by whether you are creating a mitred corner or a square corner. Each has distinct construction processes and stitching considerations.

Mitred Corners

Mitred corners are characterized by a diagonal seam that creates a clean, folded edge, often seen in napkins, placemats, and bindings. The stitching process involves creating a diagonal line that bisects the corner.

- Process: After pressing the fabric to mark the fold lines, you will sew a diagonal seam from the edge of the fabric to the point where the two folded edges meet. The stitching line is typically on the wrong side of the fabric, following the diagonal crease.

- Stitching: A straight stitch is most commonly used. The precision of the stitching line is paramount to achieving a sharp, clean mitre. You are essentially stitching along the diagonal line that will form the miter.

- Trimming: After stitching, the excess fabric beyond the diagonal stitch line is trimmed away, leaving a small seam allowance.

Square Corners

Square corners are formed by sewing straight across the edge and then turning the fabric to sew down the next edge, creating a right angle. These are common in garments, pillowcases, and many sewing projects.

- Process: You sew along one edge of the fabric until you reach the corner point. Then, you pivot the fabric and sew along the next edge.

- Stitching: A straight stitch is the standard. The key here is the pivot at the corner. The seam allowance is maintained consistently along both edges.

- Trimming: Trimming is less about creating a diagonal and more about reducing bulk, as discussed later.

Effective Backstitching at Corner Points

Backstitching is essential for reinforcing corners and preventing seams from coming undone. The goal is to create a secure anchor point.To backstitch effectively at corner points:

- Sew forward to the corner point, stopping with the needle in the fabric.

- Lift the presser foot.

- Pivot the fabric 90 degrees.

- Lower the presser foot.

- Sew backward for a few stitches (typically 3-5 stitches) over the stitches you just made.

- Lift the presser foot.

- Pivot the fabric back to its original direction.

- Lower the presser foot and continue sewing forward.

- Repeat this process at the end of the seam to secure the other side of the corner.

Trimming Seam Allowances to Reduce Bulk at Corners

Excess fabric at corners can create unsightly bulk, making your corners appear rounded or puffy. Trimming the seam allowances effectively is a critical step in achieving sharp, flat corners.Here’s how to trim seam allowances to reduce bulk at corners:

- Square Corners: For square corners, you will typically trim the seam allowance diagonally at the very tip of the corner. Cut from the edge of the fabric towards the stitching line, but be careful not to cut into your stitches. This removes the excess fabric that would otherwise bunch up.

- Mitred Corners: After stitching a mitred corner, you will trim away the excess fabric beyond the diagonal stitching line. You can trim this at an angle, leaving a small seam allowance (e.g., 1/4 inch or 6mm), to reduce bulk and help the mitre lie flat.

- Notching or Clipping (for curves that form corners): If your project involves a curve that meets a straight edge at a corner, you might need to notch (cut a V-shape out) or clip (make small cuts into) the seam allowance on the curved section to allow it to lie flat without puckering.

Pivoting the Fabric at the Corner Point

The pivot is a fundamental technique for sewing square corners. It allows you to change direction precisely without lifting the needle from the fabric.Here’s how to pivot the fabric at the corner point while the needle is down:

When you reach the corner point where you need to change direction, sew up to that exact point. At this precise spot, stop sewing but leave the needle of your sewing machine in the fabric. This is crucial, as the needle acts as a pivot point. With the needle firmly in the fabric, lift the presser foot. Now, you can freely rotate the fabric around the needle.

Carefully turn the fabric exactly 90 degrees so that you are now aligned to sew down the next edge of your project. Once the fabric is positioned correctly, lower the presser foot back down onto the fabric. You can then resume sewing in the new direction.

Advanced Techniques for Flawless Corners

Having mastered the fundamental preparations and stitching techniques, we now delve into advanced methods to elevate your corner sewing from good to exceptional. These techniques are particularly crucial for projects where crisp, defined edges are paramount, such as collars, cuffs, and decorative elements. Achieving a flawless corner often involves a combination of precise cutting, careful manipulation, and the right tools.This section focuses on refining your skills to produce sharp points and minimize bulk, ensuring your finished garments look professionally crafted.

We will explore how to coax fabric into sharp angles and how to execute nearly invisible hand-stitched finishes for ultimate refinement.

Achieving Sharp Points on Collars and Cuffs

Collars and cuffs are prime examples where the sharpness of a corner directly impacts the overall aesthetic and polish of a garment. Achieving a perfectly acute angle requires attention to detail during both the cutting and turning phases.For sharp points on collars and cuffs, it is essential to trim the seam allowance at the very tip of the corner. This can be done by carefully snipping a small triangle of fabric from the seam allowance, ensuring you do not cut into the stitching.

Alternatively, for very acute angles, you can clip diagonally across the corner, from the seam line outwards, creating a small V-shape. This reduces the bulk of the fabric at the point, allowing it to turn out more cleanly. After turning, gently press the seam allowance away from the point to further encourage a sharp definition.

Turning Out Sharp Corners Without Excessive Bulk

Excessive bulk at a corner can prevent it from lying flat and appearing sharp. Several techniques can be employed to mitigate this issue, ensuring a smooth and defined finish.One effective method is to grade the seam allowances. This involves trimming the seam allowances to different widths, typically leaving the seam allowance closest to the outer edge slightly wider than the one underneath.

For example, if you have a quarter-inch seam allowance, you might trim one to an eighth of an inch and the other to a quarter inch. This layering of fabric reduces the overall thickness at the corner. Another approach is to use a lightweight interfacing on the wrong side of the fabric pieces that form the corner. This provides stability and structure without adding significant bulk.

Utilizing a Point Turner for Defined Corners

A point turner is an invaluable tool for achieving crisp, well-defined corners. It allows for precise manipulation of the fabric from the inside, helping to push out the corners and create sharp angles.The procedure for using a point turner is as follows:

- After stitching the corner and trimming excess seam allowance, gently turn the fabric right side out.

- Insert the pointed end of the point turner into the corner from the inside.

- Carefully push the fabric outwards with the point turner, coaxing it into a sharp angle. Avoid forcing the tool, which could create a hole in the fabric.

- Use the flat edge of the point turner to press the corner outwards and help set the seam.

- Repeat for all corners, ensuring each is turned out with equal precision.

Some point turners also have a blunt end, which is useful for pressing seams and edges once the corners are turned.

Hand-Stitching Corners for a Nearly Invisible Finish

For the most refined and professional look, hand-stitching corners can provide a virtually invisible finish, especially on delicate fabrics or visible areas. This technique requires patience and a steady hand.The procedure for hand-stitching corners involves the following steps:

- Prepare the corner as you would for machine sewing, ensuring the seam allowance is trimmed and graded.

- Turn the fabric right side out and gently push out the corner with a point turner.

- Fold the raw edge of the seam allowance inwards, creating a clean, sharp edge.

- Using a fine needle and matching thread, begin a blind stitch or slip stitch along the folded edge.

- Take small, inconspicuous stitches that catch only a thread or two of the fabric on the main body of the project.

- Work your way around the entire folded edge, ensuring the stitches are evenly spaced and as small as possible.

- When you reach the end of the corner, tie off your thread securely on the inside of the seam allowance.

This method creates a seamless appearance, as the stitches are hidden within the fold.

Dealing with Corners on Curved Edges

Corners on curved edges present a unique challenge, as they require a smooth transition rather than a sharp point. The goal here is to avoid puckering and ensure the curve lies flat.For corners on curved edges, it is essential to clip the seam allowance generously.

- On outward curves, make small cuts into the seam allowance, perpendicular to the stitching line, extending almost to the stitching but not through it. These clips allow the fabric to spread open and lay flat.

- On inward curves, make small triangular notches out of the seam allowance. This removes excess fabric and prevents it from bunching up.

After clipping or notching, gently press the seam allowance away from the curve. When turning the fabric, use a rounded tool, like the blunt end of a point turner or a chopstick, to gently ease the curve into shape. Avoid pulling too tightly, which can distort the curve. The aim is to create a smooth, continuous line without any visible stress points.

Troubleshooting Common Corner Issues

Even with careful preparation and stitching, occasional issues can arise when sewing corners. Recognizing these common problems and understanding their solutions is key to achieving that professional, polished finish you desire. This section will guide you through identifying and rectifying these challenges, ensuring your corners are consistently sharp and neat.Addressing unexpected problems is an integral part of the sewing process.

By familiarizing yourself with potential pitfalls, you can approach your projects with greater confidence, knowing you have the strategies to overcome them. Let’s explore some of the most frequent corner concerns and how to resolve them effectively.

Puckering and Rounded Corners

Puckering, where the fabric gathers and creates an unsightly ripple, and rounded corners, which lack the crispness of a sharp angle, are two of the most common frustrations. These issues often stem from tension problems or insufficient precision during the stitching process.

- Puckering Solutions:

- Thread Tension Adjustment: If your machine’s upper or lower thread tension is too tight, it can pull the fabric, causing puckering. Consult your sewing machine manual to learn how to adjust thread tension. Often, a slight loosening of the upper tension is all that’s needed.

- Needle and Thread Compatibility: Ensure your needle size is appropriate for your fabric weight and that your thread is not too thick or too thin. A needle that is too large can create unnecessary holes, while a needle that is too small can break or snag the thread.

- Fabric Handling: Avoid stretching or pulling the fabric as you sew. Gently guide the fabric through the machine, allowing the feed dogs to do the work.

- Stitch Length: For delicate fabrics, a slightly longer stitch length can prevent puckering. Conversely, for very fine fabrics, a shorter stitch length might be necessary, but always test on a scrap first.

- Rounded Corner Correction:

- Precise Pivot: The most common cause of rounded corners is not stopping precisely at the seam allowance mark to pivot. Ensure you stop with the needle down exactly at your designated turning point.

- Trimming Seam Allowances: Before turning the corner, trimming the seam allowance at an angle, or clipping it diagonally (without cutting into the stitching), can help the fabric lie flatter and create a sharper edge.

- Pressing: After turning the fabric right side out, carefully use a pressing cloth and an iron to press the corner flat. Use a point turner or a chopstick to gently push out the corner from the inside.

Overly Bulky Corners

Excess fabric in the seam allowance at the corner can create an undesirable bulkiness, especially when working with thicker materials or multiple layers. This bulk can prevent the corner from lying flat and looking neat.

- Trimming Techniques for Bulk Reduction:

- Diagonal Trim: After stitching the corner, trim the seam allowance diagonally from the corner point towards the stitching, but be very careful not to cut through the stitches. This removes excess fabric without compromising the integrity of the seam.

- Notching: For very thick fabrics or tight corners, you might consider making a small notch in the seam allowance at the very point of the corner. This allows the fabric to spread open slightly, reducing bulk.

- Layer Reduction: If you are working with a pattern that involves multiple fabric layers at the corner, consider if any of these layers can be slightly thinned or reduced at the seam allowance without affecting the overall structure of the item.

- Strategic Fabric Selection: When planning a project where corners are prominent, choosing fabrics with less inherent bulk can significantly help. For instance, a quilting cotton will create less bulk than a heavy denim or upholstery fabric.

Uneven or Misaligned Corners

Sometimes, despite your best efforts, corners can end up uneven or misaligned after stitching. This can be due to shifting fabric during sewing or an inaccurate initial seam allowance.

- Re-stitching and Alignment:

- Unpicking and Re-stitching: The most direct solution is to unpick the stitching of the affected corner and re-stitch it. Before re-stitching, ensure your seam allowance is consistently marked and that you are aligning the fabric edges precisely.

- Using a Seam Gauge: A seam gauge is invaluable for ensuring a consistent seam allowance. Mark your turning point clearly on both pieces of fabric before you begin sewing.

- Stabilizing the Fabric: For slippery or shifting fabrics, consider using a temporary stabilizer, such as a lightweight fusible interfacing or even a piece of tissue paper, under or over the fabric as you stitch. This can help prevent movement.

- Trimming for Symmetry: If the corner is slightly off but the stitching is secure, you can sometimes carefully trim the excess fabric to create a more symmetrical appearance. This should be done with extreme caution to avoid weakening the seam.

Preventing Fraying at Corner Points

Fraying at the sharp points of a corner can detract from the neatness of your finished project. This is particularly common with fabrics that have a tendency to unravel.

- Finishing Techniques for Corner Points:

- Reinforced Stitching: Before trimming the corner seam allowance, you can add a few extra stitches directly on the corner point to reinforce it and prevent fraying.

- Serging or Zigzag Stitch: After trimming the seam allowance diagonally, apply a narrow zigzag stitch or use a serger around the raw edges of the seam allowance. This encases the raw edges and prevents them from unraveling.

- French Seams: For an invisible and fray-proof finish, consider using French seams, especially on lighter-weight fabrics. This technique encloses the raw edges within the seam itself.

- Turning Under and Stitching: For very simple projects or on the wrong side, you can turn the raw edge of the seam allowance under twice to create a narrow hem before stitching.

Reinforcing Corners on Frequently Used Items

Items that undergo frequent handling, washing, or stress, such as tote bags, pillow corners, or garment seams, benefit from extra reinforcement to ensure longevity and durability.

- Methods for Enhanced Corner Strength:

- Bar Tacking: At the point where the corner seam meets another seam, or at stress points, a bar tack (a series of dense, short stitches) can be sewn. Many sewing machines have a specific stitch for this.

- Double Stitching: Consider stitching the corner seam twice, either by following the initial seam line again or by creating a second parallel seam.

- Adding Interfacing or Stabilizer: For items like tote bag corners, adding a small piece of fusible interfacing or a heavier stabilizer to the seam allowance area before stitching can significantly increase strength and prevent stretching or tearing.

- Boxed Corners: For items like bags and pillowcases, creating a boxed corner involves folding and stitching the side and bottom seams together after the initial corner is sewn. This creates a three-dimensional effect and inherently reinforces the corner structure.

- Reinforcement Patches: In high-stress areas, consider sewing a small fabric patch or a piece of webbing to the inside of the corner for added durability.

Visualizing the Process: Step-by-Step Examples

Understanding the theoretical aspects of sewing perfect corners is one thing, but seeing them applied in real-world projects solidifies the learning process. This section provides detailed, step-by-step examples of creating various types of perfect corners, from simple napkin mitered corners to more complex patchwork intersections. By following these visual guides, you’ll gain the confidence to tackle these techniques in your own sewing endeavors.

Sewing a Perfect Mitered Corner on a Napkin

A mitered corner creates a clean, diagonal seam that is both decorative and functional, often seen on napkins, placemats, and tablecloths. This method involves precise folding and pressing to achieve a sharp, professional finish.

- Prepare the Fabric: Start with a square or rectangular piece of fabric for your napkin. Ensure all edges are neatly finished, either by serging or turning and stitching.

- Fold for the Miter: Fold the napkin in half lengthwise, then in half widthwise, bringing all four corners together. Press this fold firmly. This creates a central crease. Unfold the napkin.

- Mark the Miter Line: On one corner, measure from the edge inwards along the pressed crease by the desired seam allowance (e.g., 1/2 inch). Draw a line from this mark to the opposite corner of the fabric. This line represents your miter fold.

- Fold and Press the Miter: Fold the napkin so that the raw edges of two adjacent sides meet along the marked miter line. Press this fold firmly. The corner should now appear as a triangle.

- Stitch the Miter: With the mitered fold in place, stitch along the diagonal line from the raw edge towards the center point of the corner. Backstitch at the beginning and end for security.

- Trim and Turn: Trim the excess fabric from the mitered corner, leaving about a 1/4 inch seam allowance. Turn the napkin right side out, carefully pushing out the mitered corner with a point turner or chopstick.

- Final Press: Press the mitered corner flat. You should have a crisp, diagonal line where the two sides of the napkin meet.

Creating a Sharp, Turned-Out Corner on a Tote Bag Handle

Tote bag handles often require a sturdy and neatly turned corner where they attach to the bag. This method ensures a professional and durable finish.

- Prepare the Handle: Cut your handle fabric to the desired length and width, adding seam allowances to all sides. For example, if you want a 2-inch wide handle, cut it 4 inches wide plus seam allowances.

- Fold and Press: Fold the handle fabric in half lengthwise, wrong sides together, and press to create a center crease. Unfold.

- Turn Edges In: Fold the long raw edges in towards the center crease and press them firmly.

- Fold Again: Fold the handle in half along the original center crease, enclosing the raw edges. Press again. You should now have a handle strip that is the desired width with all raw edges neatly enclosed.

- Stitch the Handle: Topstitch along both long edges of the folded handle, about 1/8 inch from the edge. This secures the handle and adds a decorative element.

- Attaching to the Bag: When attaching the handle to the tote bag, position it as desired. For a sharp, turned-out corner, fold the end of the handle under by the seam allowance amount, creating a clean edge. Pin securely to the bag and stitch in place with a reinforced stitch pattern (e.g., a box with an ‘X’ in the middle).

Sewing a Neat Corner on a Garment Hem

Neat corners on garment hems, particularly on skirts, trousers, and dresses, contribute significantly to the overall polished appearance of the garment. This method focuses on creating a crisp right-angle.

- Prepare the Hem: Finish the raw edge of the hem allowance (e.g., with a serger or zigzag stitch).

- Fold the Hem: Fold the hem allowance up to the wrong side of the garment by the desired width and press.

- Prepare the Corner: At the corner, unfold the hem allowance. Fold the side seam allowance of the hem allowance diagonally inwards, creating a neat triangle. Press this fold.

- Refold the Hem: Refold the hem allowance upwards, encasing the diagonal fold. The corner should now form a neat, self-contained triangle on the inside of the garment. Press this fold firmly.

- Stitch the Hem: Stitch the hem in place. You can do this by machine stitching along the folded edge, or by hand using a blind hem stitch for an invisible finish. Ensure you catch the folded corner neatly.

- Final Press: Press the finished hem. The corner should appear sharp and unobtrusive from the right side of the garment.

Demonstrating the Method for Sewing a Precise Right-Angle Corner on a Patchwork Block

Achieving perfect right-angle corners where patchwork blocks meet is crucial for a well-constructed quilt. This involves careful seam pressing and alignment.

- Prepare the Blocks: Ensure your patchwork blocks are pieced with accurate seam allowances. Press all seams in the same direction or open, as per your pattern instructions.

- Align Blocks: Place two blocks right sides together. Carefully align the seams where the blocks will join. This is a critical step for a precise intersection.

- Stitch the Seam: Sew the seam with the correct seam allowance, backstitching at the beginning and end.

- Press the Seam: Press the seam allowance towards one of the blocks, or press it open. For intersecting seams, pressing them open can help reduce bulk and make the points meet more cleanly.

- Creating the Point: When joining multiple blocks, the points where the corners meet are formed by the intersection of these pressed seams. For a sharp point, ensure the seam allowances from the adjacent seams are pressed in opposite directions where they meet. This allows the seam lines to “nest” together, creating a crisp point.

- Checking the Intersection: Before sewing, or during the sewing process, you can check the intersection. If the points are not meeting cleanly, you may need to adjust your seam allowances or how you’ve pressed the seams. Sometimes, a tiny snip into the seam allowance at the intersection point can help the fabric lie flat.

- Final Press: After all blocks are joined, give the entire patchwork unit a final pressing to ensure all points are sharp and seams lie flat.

Last Point

In conclusion, mastering the art of sewing perfect corners elevates the quality and polish of any handmade item. By understanding the fundamentals, preparing your fabric diligently, employing the right stitching techniques, and knowing how to troubleshoot, you can confidently tackle any corner challenge. Embrace these practices, and your sewing projects will showcase a level of detail and professionalism that truly stands out.