Embark on a delightful creative journey with “How to Sew a Scarf with Your Sewing Machine,” your comprehensive guide to crafting beautiful and personalized scarves. This accessible project is perfect for beginners, offering a rewarding introduction to sewing machine basics while allowing for a truly custom touch. Discover the satisfaction of transforming fabric into a stylish accessory that reflects your unique taste and flair.

This guide meticulously details every step, from understanding your sewing machine’s essential functions and selecting the ideal fabrics to mastering cutting techniques and executing precise stitches. We will explore various scarf styles, from simple rectangles to elegant infinity designs, and even touch upon advanced embellishments for those seeking to add extra flair. Troubleshooting common sewing challenges will ensure a smooth and enjoyable experience, empowering you to create a finished product you’ll be proud to wear or gift.

Introduction to Scarf Sewing

Sewing a scarf is an exceptionally rewarding project for beginners, offering a fantastic entry point into the world of garment creation. Its simplicity in construction and the immediate gratification of a wearable finished product make it an ideal choice for those just starting with a sewing machine. This project allows you to gain confidence with basic sewing techniques without being overwhelmed by complex patterns or intricate details.Creating a custom scarf provides a unique opportunity to express personal style and cater to specific needs.

The benefits extend beyond mere aesthetics; you can choose fabrics that are perfect for your skin type, select colors and patterns that complement your wardrobe, and even adjust the dimensions for a truly bespoke fit. This personalization transforms a simple accessory into a statement piece that is uniquely yours.Several types of scarves can be easily and successfully made using a standard sewing machine, making the possibilities quite extensive for a beginner.

These designs often involve straight seams and minimal finishing, allowing you to focus on fabric selection and machine operation.

Types of Scarves for Beginner Sewing

The appeal of sewing a scarf lies in its versatility and the ease with which it can be created. This section explores the most accessible scarf styles that are well-suited for individuals new to sewing. These designs emphasize straightforward construction techniques, making them perfect for building foundational sewing skills.

- Infinity Scarves: These are continuous loops, often made by sewing two long rectangular pieces together at the ends to form a circle. They are simple to construct and offer a stylish, no-fuss accessory that stays in place. The primary skill involved is sewing a straight seam to join the fabric ends.

- Rectangular Scarves: The most basic scarf type, these are essentially long pieces of fabric with finished edges. For beginners, this can involve hemming the raw edges of a pre-cut fabric rectangle. Techniques like double-fold hems are commonly used and are relatively easy to master.

- Fringed Scarves: Many rectangular or square scarves can be enhanced with fringe. This can be achieved by cutting notches along the edge and then unraveling threads, or by attaching pre-made fringe using a straight stitch. This adds a decorative element without significant complexity.

- Pleated Scarves: While slightly more advanced, simple pleats can be incorporated into rectangular scarves. This involves creating evenly spaced folds along the edges and securing them with stitching. This technique adds texture and volume to the scarf.

The advantages of creating a custom scarf are numerous, extending beyond personal satisfaction to practical and stylistic benefits. When you sew your own scarf, you gain complete control over every aspect of its design and creation.

- Fabric Choice: You can select from a vast array of materials, such as soft silks, cozy flannels, breathable cottons, or luxurious velvets, ensuring the scarf is comfortable and suitable for the intended season or occasion. This also allows for hypoallergenic or specific-feel fabric selections.

- Color and Pattern: Customization of color and pattern means you can perfectly match your scarf to existing outfits or create a bold new statement piece. This is particularly useful for finding unique prints not readily available in stores.

- Size and Shape: You can tailor the length, width, and even the overall shape of the scarf to your preferences. Whether you prefer a long, flowing wrap or a shorter, more compact neck warmer, the dimensions are entirely up to you.

- Cost-Effectiveness: For certain fabrics, especially if purchased on sale or from remnant bins, sewing your own scarf can be more economical than buying a comparable quality designer scarf.

- Skill Development: Each scarf sewn is an opportunity to refine sewing techniques, learn new stitches, and gain confidence in operating your sewing machine, which can lead to tackling more complex projects in the future.

Essential Sewing Machine Setup and Materials

Before we begin stitching our beautiful scarves, it’s crucial to ensure your sewing machine is properly set up and you have the right materials. This preparation will make the sewing process smooth, efficient, and enjoyable, leading to a professional-looking finished product. Understanding your machine’s basic components and selecting appropriate fabrics and notions are key to success.This section will guide you through identifying the essential parts of your sewing machine relevant to scarf making, provide recommendations for suitable fabrics, detail the necessary sewing notions, and offer a comparative table for different thread types.

Basic Sewing Machine Parts for Scarf Making

Your sewing machine, while complex in its entirety, has several key components that are particularly important when sewing simple projects like scarves. Familiarizing yourself with these will help you operate the machine confidently and troubleshoot any minor issues.A sewing machine typically includes:

- Needle: This is the component that pierces the fabric, carrying the upper thread through to form stitches. The type and size of the needle are important for different fabric weights.

- Presser Foot: This part holds the fabric down against the feed dogs as you sew. For scarf making, the standard presser foot is usually sufficient, but specialized feet can offer benefits.

- Feed Dogs: Located beneath the presser foot, these are small, serrated teeth that grip and move the fabric forward, creating an even feed.

- Bobbin and Bobbin Case: The bobbin holds the lower thread, which is then pulled up through the fabric by the needle to form a stitch. The bobbin case secures the bobbin and regulates the tension of the lower thread.

- Tension Dial: This adjustable dial controls the tightness of the stitches. Proper tension is vital for creating balanced stitches where the top and bottom threads meet neatly between the fabric layers.

- Stitch Selector: This allows you to choose the type of stitch, such as a straight stitch (most common for scarves) or a zigzag stitch for finishing edges.

- Handwheel: Located on the side of the machine, this allows you to manually raise or lower the needle and move the fabric stitch by stitch, which is useful for starting and finishing seams.

Recommended Fabrics for Scarves

The choice of fabric significantly impacts the drape, feel, and overall aesthetic of your scarf. For scarf making, it’s generally best to opt for fabrics that are lightweight to medium-weight, have a good drape, and are comfortable against the skin.Here are some recommended fabric types:

- Cotton: Versatile and breathable, cotton comes in various weights. Quilting cottons are stable and easy to sew, while lighter cotton lawn or voile offer a softer drape. Cotton is durable and easy to care for.

- Linen: Known for its breathability and natural texture, linen creates elegant and slightly rustic scarves. It has a beautiful drape and softens with wear and washing. Linen can wrinkle, but this is often considered part of its charm.

- Silk: Luxurious and smooth, silk offers an exquisite drape and a beautiful sheen. Charmeuse, chiffon, and crepe de chine are popular choices for scarves, providing a sophisticated feel. Silk requires delicate handling and care.

- Rayon/Viscose: These semi-synthetic fabrics mimic the feel of silk or cotton but are often more affordable. They offer excellent drape and a soft hand, making them ideal for flowy scarves. Rayon can be prone to stretching, so careful handling is advised.

- Polyester Blends: Many polyester fabrics are designed to imitate natural fibers like silk or cotton, offering durability and ease of care. They can provide a good drape and are often wrinkle-resistant.

- Wool: For warmer scarves, fine wools like merino or cashmere offer exceptional warmth and a luxurious feel. They can be slightly more challenging to sew due to their thickness and tendency to fray, but the results are often worth it.

Necessary Sewing Notions

Beyond the fabric and sewing machine, a few essential notions will facilitate the scarf-making process. These are the small but vital tools and supplies that help you cut, mark, and sew your fabric accurately.The essential sewing notions include:

- Sewing Thread: The thread that forms your stitches. The type and color should be chosen to complement your fabric.

- Sewing Machine Needles: While your machine comes with a needle, having a variety of sizes and types is beneficial for different fabrics. Universal needles are a good starting point.

- Fabric Scissors: A dedicated pair of sharp scissors specifically for cutting fabric is crucial for clean, precise cuts. Do not use them for paper, as this will dull them.

- Pins: Used to hold fabric layers together before and during sewing. Straight pins with flat heads are most common.

- Measuring Tape or Ruler: For accurately measuring fabric and marking cutting lines.

- Iron and Ironing Board: Essential for pressing seams and hems, which is critical for a professional finish.

Thread Types for Scarf Construction

Thread is the backbone of any sewn project, and choosing the right type ensures durability, appearance, and ease of sewing. For scarf construction, the most common and suitable threads are made from cotton or polyester. The properties of each can influence the final look and longevity of your scarf.Here is a comparison of common thread types:

| Thread Type | Material | Properties | Best For |

|---|---|---|---|

| All-Purpose Polyester Thread | Polyester | Strong, durable, good elasticity, resistant to shrinking and mildew. Available in a vast range of colors. | Most fabrics, including cotton, linen, rayon, and blends. Excellent for general scarf construction. |

| Cotton Thread | Cotton | Breathable, natural feel, good for natural fibers. Can be prone to shrinking and abrasion. | Natural fiber scarves like 100% cotton or linen, where a natural look and feel is desired. |

| Silk Thread | Silk | Very fine, strong, and lustrous. Excellent for delicate fabrics and invisible stitching. Expensive. | Delicate silk scarves where a fine, almost invisible stitch is required. |

| Microfiber Polyester Thread | Polyester | Extremely fine and strong, with a soft hand. Offers excellent stitch quality and is virtually invisible on some fabrics. | Lightweight and delicate fabrics such as chiffon, silk, and fine rayons for a very refined finish. |

Preparing Your Fabric for Sewing

Before we can begin the exciting process of sewing your scarf, it’s crucial to prepare your fabric properly. This step ensures your finished scarf will be the correct size, lie flat, and have a professional finish. Skipping this stage can lead to shrinkage or distortions after sewing, which can be disappointing. We will cover pre-washing and drying, ironing, and squaring off your fabric edges.

Pre-washing and Drying Scarf Fabrics

Pre-washing your fabric is a vital step that mimics the laundering process your finished scarf will eventually undergo. This allows any residual manufacturing chemicals to be removed and, more importantly, allows the fabric to shrink before you cut it. If you skip this, your beautiful, perfectly sewn scarf might shrink unevenly after its first wash, altering its intended dimensions and drape.

- Cotton and Linen: These natural fibers are prone to significant shrinkage. Wash them in a washing machine on a warm or hot cycle, depending on the fabric’s weight and your machine’s settings. Use a gentle detergent.

- Silk and Rayon: These delicate fibers often require hand washing or a very gentle machine cycle on a cool setting. Always check the fabric care label if available. If hand washing, use cool water and a mild detergent specifically for delicates.

- Polyester and Blends: Synthetic fabrics generally shrink less, but it’s still good practice to pre-wash. A warm machine wash is usually sufficient.

After washing, avoid high heat drying, as this can also cause shrinkage and damage delicate fibers.

- Air Drying: This is the safest method for most fabrics. Hang your fabric on a drying rack or a clothesline, ensuring it’s spread out to prevent deep wrinkles.

- Machine Drying (Low Heat): If you must use a dryer, select the lowest heat setting. Remove the fabric while it is still slightly damp to minimize wrinkles.

Cutting Your Scarf Fabric

With your fabric prepared and your sewing machine ready, the next crucial step is accurately cutting your scarf fabric. This stage ensures your scarf will have the desired dimensions and shape, forming the foundation for a well-made accessory. Precision here will make the subsequent sewing steps much smoother and the final result more professional.Cutting your fabric correctly involves careful measuring, marking, and executing straight, clean lines.

The type of fabric and the desired scarf shape will influence the best techniques to employ. This section will guide you through the process, ensuring your fabric is cut to perfection for your sewing project.

Measuring and Marking Scarf Dimensions

Accurate measurements are fundamental to achieving the desired scarf size and shape. Before making any cuts, it’s essential to determine the final dimensions of your scarf and transfer these measurements precisely onto your fabric. This involves using a measuring tool and a marking implement to create visible guidelines.To begin, decide on the length and width of your scarf. Common scarf dimensions can vary widely, but a good starting point for a standard rectangular scarf might be 180 cm (approximately 70 inches) in length and 30 cm (approximately 12 inches) in width.

For infinity scarves, the length will determine the number of loops, and the width will be similar to a standard scarf. Always consider the intended use and the wearer when deciding on dimensions.Here are the steps for measuring and marking:

- Measure Your Fabric: Lay your fabric flat on a large, clean surface, such as a cutting mat or a large table. Ensure it is smooth and free of wrinkles.

- Mark the Length: Using a measuring tape or ruler, measure the desired length of your scarf from one end of the fabric. Mark this point with a fabric pen, chalk, or tailor’s pencil. For a long scarf, you may need to mark multiple points along the length to ensure accuracy.

- Mark the Width: From the marked length line, measure the desired width of your scarf. Again, mark this point. Ensure you are measuring perpendicular to the length line.

- Create the Cutting Lines: Connect your marks to form a straight cutting line. A long ruler or a yardstick is ideal for this. For rectangular scarves, you will need to mark four sides to create a complete rectangle. For infinity scarves, you will mark a long rectangle.

- Double-Check Measurements: Before cutting, re-measure all sides to confirm accuracy. It’s better to catch an error now than after cutting.

Techniques for Cutting Straight Lines

Achieving straight, clean cuts is vital for a professional-looking scarf. The method you use will depend on the fabric type, as some materials are more prone to shifting or fraying than others. Employing the right tools and techniques will ensure your edges are precise and ready for sewing.For delicate fabrics like silk or chiffon, a rotary cutter and a self-healing cutting mat are highly recommended.

The rotary cutter provides a clean, continuous cut, minimizing the risk of snagging or pulling the fabric. For sturdier fabrics like cotton or linen, sharp fabric scissors can also be very effective. Always ensure your cutting tools are sharp for the cleanest results.Consider these techniques for cutting straight lines:

- Rotary Cutter and Cutting Mat: Place your fabric flat on a self-healing cutting mat. Align a quilting ruler with your marked cutting line. Hold the ruler firmly in place with one hand, and with the other, run the rotary cutter along the edge of the ruler. Apply even pressure for a smooth cut. This method is excellent for most fabric types and offers superior precision.

- Sharp Fabric Scissors: If using scissors, ensure they are dedicated fabric scissors and are very sharp. Hold the fabric steady with your non-cutting hand. Begin cutting at one end of your marked line, moving the scissors smoothly and deliberately along the line. Avoid “chopping” motions, which can lead to uneven edges. For very long lines, it can be helpful to cut in sections, repositioning your fabric as needed.

- Using a Walking Foot (for some fabrics): While primarily a sewing tool, a walking foot can sometimes assist in keeping fabric layers even during cutting if you are using a very large piece of fabric and need to manage its weight. However, this is more applicable to the sewing stage. For cutting itself, manual precision is key.

- Cutting Along the Grain: Whenever possible, align your cuts with the grain of the fabric. The grain runs parallel to the selvage (the finished edge of the fabric). Cutting along the grain helps prevent distortion and ensures your scarf drapes correctly. You can often identify the grain by looking at the weave of the fabric.

Cutting Fabric for Different Scarf Shapes

The shape of your scarf will dictate the pattern of your cuts. While rectangular scarves are the most common, other shapes like infinity scarves or even more uniquely shaped designs require specific cutting approaches. Understanding these variations will allow you to create a diverse range of scarves.For a standard rectangular scarf, you are essentially cutting a large rectangle. An infinity scarf involves cutting a long rectangle that is then joined at the ends to form a loop.

More complex shapes might involve curves or angled edges, which require careful pattern drafting and cutting.Here are some examples of cutting for different scarf shapes:

- Rectangular Scarf: As discussed, this involves marking and cutting a simple rectangle. The dimensions you choose will determine the scarf’s width and length. Ensure all four sides are cut straight and at 90-degree angles to each other.

- Infinity Scarf: For an infinity scarf, you will cut a long rectangle. A common ratio is to cut a rectangle that is twice the desired circumference of the finished loop, multiplied by the desired width. For instance, if you want a loop circumference of 120 cm and a width of 30 cm, you would cut a rectangle approximately 240 cm long and 30 cm wide.

This long piece is then folded and sewn to create the continuous loop.

- Triangular Scarf (e.g., Bandana style): This shape is created by cutting a square or rectangle and then cutting it diagonally. For a simple triangular scarf, you might cut a square and then cut from one corner to the opposite corner.

- Asymmetrical or Shaped Scarves: For scarves with more intricate shapes, such as those with angled ends or curved edges, you will need to create a paper pattern first. This pattern is then laid on the fabric and traced. Cutting follows the lines of the pattern precisely. It’s often beneficial to cut a mock-up in cheaper fabric first to test the shape and fit before cutting into your final fabric.

“Precision in cutting is the silent architect of a well-crafted garment.”

Basic Scarf Sewing Techniques

Now that your fabric is prepared and cut to size, we can delve into the fundamental sewing techniques that will bring your scarf to life. These techniques are the building blocks of garment construction and are essential for creating a professional-looking finish. We will focus on the straight stitch, a versatile stitch perfect for scarf making, and how to effectively use it to create neat hems and join fabric pieces.The straight stitch is the most common and fundamental stitch used in sewing.

It’s created by the needle moving up and down, forming a continuous line of stitches. For scarf making, a straight stitch is ideal for securing seams, creating hems, and attaching embellishments. Its simplicity and strength make it a reliable choice for most fabric types and projects.

The Straight Stitch and Machine Setup

Setting up your sewing machine for a basic straight stitch is a straightforward process. Ensuring proper setup will guarantee strong, even stitches and prevent common sewing issues.To prepare your machine for a straight stitch:

- Thread the Machine: Follow your sewing machine’s manual to correctly thread both the upper thread and the bobbin. Ensure the thread is pulled taut and through all the guides.

- Select the Straight Stitch: Locate the stitch selection dial or buttons on your machine. Choose the straight stitch setting, which is usually represented by a straight line icon.

- Adjust Stitch Length: For most scarf sewing, a stitch length of 2.0 to 2.5 millimeters is appropriate. This provides a good balance of strength and flexibility. A shorter stitch length can be used for very delicate fabrics, while a slightly longer one might be suitable for heavier materials, though less common for typical scarf fabrics.

- Choose the Right Needle: Select a universal needle appropriate for your fabric weight. A size 70/10 or 80/12 needle is generally suitable for lightweight to medium-weight scarf fabrics like cotton, linen, or silk blends.

- Test Stitch: Before sewing on your actual scarf, practice sewing a straight stitch on a scrap piece of your fabric. Check for evenness, tension, and any skipped stitches. Adjust tension if necessary according to your machine’s manual.

Sewing a Simple Hem

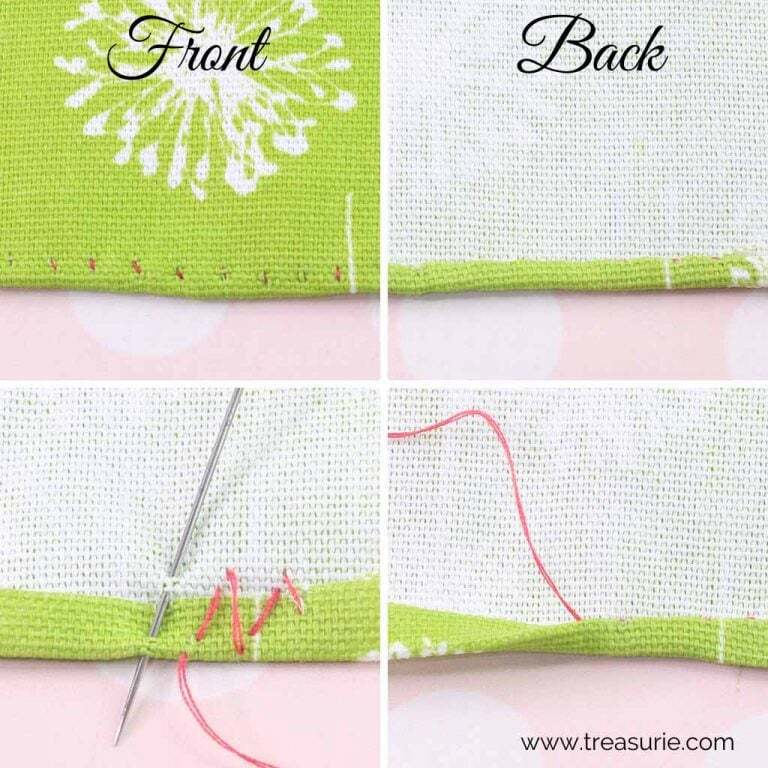

A hem is a finished edge on a fabric, and for scarves, a simple hem is both practical and aesthetically pleasing. It prevents fraying and provides a clean, polished look. There are several methods for hemming, but for a simple scarf, a double-fold hem is recommended for its durability and neat appearance.To sew a simple double-fold hem:

- Prepare the Hem Allowance: Fold the raw edge of the scarf fabric over by approximately 1/4 inch (about 6mm) towards the wrong side of the fabric. Press this fold firmly with an iron.

- Fold Again: Fold the fabric over a second time, this time by about 1/2 inch (about 12mm), enclosing the raw edge within the fold. Press this second fold to create a crisp edge. This creates a double-folded hem that will not fray.

- Stitch the Hem: Carefully stitch along the inner folded edge of the hem, keeping your stitching line as straight and close to the folded edge as possible. Ensure you are catching both layers of the folded fabric.

- Backstitch: At the beginning and end of your hem, backstitch for a few stitches to secure the seam and prevent it from unraveling.

For very delicate fabrics like silk chiffon, a narrow rolled hem might be preferred for a more subtle finish. This technique involves rolling the very edge of the fabric and stitching it down, often using a specialized rolled hem foot on your sewing machine.

Joining Fabric Pieces for a Longer Scarf

If your desired scarf length exceeds the width of your fabric, you will need to join two or more pieces together. The key to a seamless join is to align the fabric pieces accurately and use a strong, straight stitch.To sew two fabric pieces together for a longer scarf:

- Align Fabric: Place the two pieces of fabric right sides together, ensuring that the cut edges you wish to join are perfectly aligned. Pin them securely in place along the edge.

- Stitch the Seam: Using your sewing machine set up for a straight stitch, sew along the pinned edge. A common seam allowance for this purpose is 1/2 inch (about 12mm). This provides enough fabric for a strong seam and allows for finishing if desired.

- Press the Seam: After stitching, press the seam open flat. This means unfolding the two fabric pieces and pressing the seam allowance to each side. This creates a smooth, flat join that will be less noticeable on the right side of the scarf.

- Finish the Seam Allowance (Optional but Recommended): To prevent fraying of the raw edges of the seam allowance, you can finish them. This can be done with a zigzag stitch along the raw edges, or by using pinking shears before sewing the seam.

Consider the pattern or design of your fabric when joining pieces. If your fabric has a directional print, ensure the pattern flows correctly across the joined sections. For patterned fabrics, you may need to carefully match the pattern at the seam for a more professional appearance, which can sometimes require a bit more fabric.

Advanced Scarf Embellishments and Finishes

Once you have mastered the basic construction of your scarf, you can elevate its appearance and texture through various embellishments and sophisticated finishing techniques. These methods add a professional touch and allow for significant personalization, transforming a simple scarf into a unique statement piece.Exploring these advanced options will not only enhance the aesthetic appeal of your scarves but also broaden your sewing repertoire, enabling you to create more intricate and high-quality accessories.

Decorative Stitches for Scarf Edges

Decorative stitches offer a fantastic way to add visual interest and a custom feel to the edges of your scarf. Many sewing machines come equipped with a variety of built-in decorative stitch patterns, ranging from simple geometric designs to more elaborate floral or abstract motifs.When selecting a decorative stitch, consider the weight and fiber content of your fabric. A heavier fabric can support bolder stitches, while a lighter fabric might benefit from a more delicate pattern.

Always test your chosen stitch on a scrap piece of fabric to ensure it lays flat and doesn’t pucker the material. Adjusting stitch length and width can further customize the look.Here are some popular decorative stitch options:

- Satin Stitch: This stitch creates a solid, filled-in effect, perfect for outlining or creating dense decorative borders.

- Zigzag Stitch: While a basic stitch, a decorative zigzag with varying widths and lengths can create a textured edge.

- Scallop Stitch: This stitch creates a series of curved, overlapping segments, resembling a row of small scallops along the edge.

- Specialty Decorative Patterns: Many machines offer unique patterns like waves, stars, or intricate lace-like designs that can add a very distinct flair.

Attaching Fringe or Tassels to Scarf Ends

Fringe and tassels are classic embellishments that bring movement and a bohemian or elegant feel to scarf ends. Their attachment requires careful planning to ensure a neat and secure finish.The method of attachment will depend on whether you are using pre-made fringe or creating your own, and the desired density and look. For a professional appearance, it’s crucial that the fringe or tassels are evenly spaced and securely sewn.Here are techniques for attaching fringe and tassels:

- Sewing Pre-Made Fringe:

- Ensure the fringe is the desired length and width for your scarf ends.

- Turn the scarf end under by your chosen hem allowance (e.g., 1/2 inch).

- Place the top edge of the fringe along the folded edge of the scarf, with the fringe hanging down.

- Stitch through the folded hem and the top of the fringe, using a straight stitch. Reinforce the stitching by going over it a second time.

- Attaching Tassels:

- Tassels can be purchased or made by winding yarn around a piece of cardboard and securing it.

- For a clean finish, it’s often best to attach tassels to the corners of the scarf or at evenly spaced intervals along the ends.

- You can either sew the loop of the tassel directly onto the scarf edge before hemming, or sew them on after the hem is complete, ensuring the knot or attachment point is reinforced.

- Consider using a strong thread and a small, sturdy needle for secure attachment.

- Creating and Attaching Tassels (DIY):

- Cut a piece of cardboard to the desired length of your tassel.

- Wrap yarn around the cardboard until you have a thick bundle.

- Cut the yarn at one end.

- Tie a separate piece of yarn tightly around the top of the bundle to create the hanging loop.

- Gather another piece of yarn and wrap it around the bundle a few inches down from the top to form the tassel head. Secure this with a knot.

- Trim the bottom of the tassel to create an even edge.

- Attach to the scarf as described above.

Creating a Rolled Hem for a Delicate Finish

A rolled hem is an exquisite finishing technique that creates a very narrow, almost invisible hem, ideal for lightweight and delicate fabrics like silk, chiffon, or fine cotton. It gives a professional, high-end look and is perfect for scarves where a bulky hem would detract from the fabric’s drape.Achieving a perfect rolled hem can take practice, but many modern sewing machines are equipped with a rolled hem foot that significantly simplifies the process.

This specialized foot guides the fabric edge into a tiny fold, creating the characteristic rolled edge.Here are steps for creating a rolled hem:

- Using a Rolled Hem Foot:

- Attach the rolled hem foot to your sewing machine.

- Thread your machine with a matching or contrasting thread.

- Fold the very edge of your fabric over by about 1/8 inch and press.

- Feed this folded edge into the narrow channel at the front of the rolled hem foot.

- Begin sewing slowly. The foot will automatically guide the fabric, folding it over again and encasing the raw edge within the roll.

- Continue sewing, guiding the fabric gently to maintain an even width.

- Manual Rolled Hem (without a special foot):

- Fold the raw edge of the fabric over by 1/8 inch and press.

- Fold it over again by another 1/8 inch, enclosing the raw edge, and press firmly.

- Stitch close to the inner folded edge using a straight stitch. This method is simpler but may result in a slightly less refined finish than using a rolled hem foot.

Adding Applique or Embroidery to a Scarf

Applique and embroidery are advanced techniques that allow for intricate designs and personalized artistic expression on your scarves. These methods can transform a plain scarf into a wearable piece of art.Applique involves layering pieces of fabric onto the scarf and stitching them in place, while embroidery uses needle and thread to create designs directly on the fabric. Both techniques require precision and can be achieved by hand or machine.Here are design ideas for adding applique or embroidery:

- Applique Designs:

- Floral Motifs: Cut out petal and leaf shapes from contrasting fabrics and layer them onto the scarf to create dimensional flowers. Use a satin stitch or a tight zigzag stitch to secure the edges.

- Geometric Shapes: Create abstract patterns using squares, circles, or triangles of various fabrics. This can add a modern and graphic element.

- Animal Silhouettes: Cut out the shapes of birds, butterflies, or other animals and applique them onto the scarf for a whimsical touch.

- Embroidery Designs:

- Monogramming: Add a personal touch by embroidering your initials or a loved one’s initials onto a corner of the scarf. This can be done using machine embroidery or hand-embroidered lettering.

- Nature-Inspired Motifs: Embroider delicate vines, leaves, or small blossoms directly onto the fabric. Techniques like French knots can add texture and detail.

- Abstract Stitch Patterns: Experiment with different embroidery stitches to create unique textural patterns across the scarf. This could involve a mix of running stitches, backstitches, and decorative stitches.

- Free-Motion Embroidery: If your sewing machine allows for free-motion sewing, you can “draw” designs with your needle, creating fluid and artistic lines. This is excellent for creating painterly effects.

When applying applique or embroidery, consider the overall balance and scale of the design in relation to the scarf’s size and intended use. Pre-washing your fabric and using appropriate stabilizers for embroidery are crucial steps to ensure the longevity and neatness of your embellishments.

Common Sewing Machine Issues and Solutions for Scarves

Sewing delicate and slippery fabrics like those often used for scarves can sometimes present unique challenges for your sewing machine. Understanding these common issues and knowing how to address them will ensure a smooth and enjoyable sewing experience, leading to beautifully finished scarves. This section provides practical solutions to help you overcome any sewing machine hiccups.When working with lightweight and slippery materials, it’s crucial to be prepared for potential snags, skipped stitches, or uneven seams.

These problems are often due to the fabric’s tendency to shift or its fine weave. Fortunately, most of these issues can be resolved with simple adjustments and the right techniques.

Skipped Stitches and Thread Tangles

Skipped stitches and thread tangles are frequent frustrations when sewing thin or slippery fabrics. These problems typically arise from incorrect needle selection, improper thread tension, or the fabric not being fed correctly through the machine. Addressing these requires a systematic approach to identify the root cause.To troubleshoot skipped stitches and thread tangles, consider the following:

- Needle Selection: Ensure you are using the correct needle type and size for your fabric. For thin or slippery materials, a sharp, fine-point needle such as a Microtex or a specialized needle for silk or synthetics is recommended. A dull or bent needle can cause skipped stitches.

- Thread Quality: Use good quality thread that is appropriate for your fabric. Cheap or old thread can be prone to breaking or tangling.

- Bobbin Winding: A poorly wound bobbin can cause thread tangles and skipped stitches. Ensure the bobbin is wound evenly and smoothly.

- Thread Path: Double-check that the thread is correctly threaded through all the guides and tension discs on your sewing machine. Sometimes, the thread can slip out of a guide.

- Presser Foot Pressure: For very thin fabrics, the presser foot might be applying too much pressure, causing the fabric to stretch or distort, leading to skipped stitches. Adjust the presser foot pressure if your machine allows for it.

Adjusting Tension for Different Fabric Weights

Proper thread tension is paramount for achieving neat and durable seams. Different fabric weights require different tension settings to prevent puckering, thread breakage, or loose stitches. The goal is to have the top thread and bobbin thread interlock evenly between the fabric layers.Here’s how to adjust tension for various fabric weights:

- Thin and Lightweight Fabrics: For delicate fabrics like silk chiffon or organza, you will typically need to decrease the top thread tension. This prevents the fine threads from pulling too tightly and creating puckers. Start with a lower tension setting and test on a scrap piece of fabric.

- Medium-Weight Fabrics: Cotton, linen, and many quilting cottons usually require a standard tension setting. If you notice your stitches are looping on the underside, the top tension might be too loose. If the stitches are forming a visible line on the top, the bobbin tension might be too tight, or the top tension too loose.

- Heavier Fabrics: While less common for scarves, if you are working with a heavier material like a thick knit or velvet, you might need to slightly increase the top thread tension. However, always test first.

It is always best practice to perform a tension test on a scrap piece of your actual scarf fabric before starting your project. Create a small seam, and examine the stitches from both sides. The ideal stitch will have the top and bobbin threads meeting perfectly in the middle of the fabric, creating a clean line of stitching with no puckering.

Preventing Fabric Fraying During Sewing

Fraying is a common issue when working with fabrics that have a tendency to unravel, especially after cutting. Preventing excessive fraying during the sewing process is key to maintaining a professional finish and ensuring the longevity of your scarf.Effective methods to prevent fabric fraying include:

- Appropriate Cutting Tools: Use sharp scissors or a rotary cutter with a sharp blade. A dull blade can snag and pull threads, increasing fraying. Consider using pinking shears for a decorative, albeit less robust, edge finish that also helps reduce fraying.

- Seam Finishes: Applying a seam finish to the raw edges of your fabric is the most effective way to prevent fraying. Common finishes suitable for scarves include:

- Serging: If you have a serger, this is an excellent method for finishing raw edges neatly and securely, especially on lightweight and slippery fabrics.

- Zigzag Stitch: A narrow zigzag stitch sewn close to the raw edge on your regular sewing machine can effectively enclose the threads and prevent unraveling. Adjust the stitch width and length for optimal coverage.

- French Seams: This is a beautiful and clean finish, particularly for sheer or lightweight fabrics. It encases the raw edges within the seam itself, leaving no raw edges exposed.

- Rolled Hem: While often considered a finishing technique, a narrow rolled hem can also serve to secure the raw edge and prevent fraying, especially on silks and fine materials.

- Handling the Fabric: Handle your fabric gently during the sewing process. Avoid pulling or stretching the fabric as you feed it through the machine, as this can cause threads to loosen and fray.

- Basting: For very slippery fabrics, consider basting the edges together with a temporary stitch before sewing the final seam. This can help keep the layers aligned and reduce the chances of fraying during machine sewing.

Creating Different Scarf Styles

Beyond the basic rectangular scarf, your sewing machine opens up a world of creative possibilities for crafting unique and stylish scarves. This section will guide you through several popular scarf styles, each offering a distinct aesthetic and feel, from the effortless loop of an infinity scarf to the rich texture of a patchwork design.Exploring different scarf styles allows you to tailor your creations to various occasions, personal preferences, and even to utilize fabric remnants effectively.

By mastering these techniques, you can expand your sewing repertoire and create a diverse collection of beautiful scarves.

Sewing a Simple Infinity Scarf

An infinity scarf, also known as a loop scarf, is a continuous circle of fabric that can be wrapped around the neck multiple times for a chic and cozy look. Its construction is straightforward, making it an excellent project for beginners.To sew a simple infinity scarf, you will need your chosen fabric, a sewing machine, thread, and scissors.

- Prepare Your Fabric: Wash and press your fabric according to its care instructions. For an infinity scarf, you’ll typically cut two identical rectangular pieces. The length of each piece will determine how many times the scarf can be looped around your neck. A common length is around 60-70 inches, and the width can vary from 8-12 inches, depending on your desired fullness.

- Sew the Long Edges: Place the two fabric rectangles right sides together. Sew along one of the long edges with a 1/2-inch seam allowance.

- Turn and Press: Turn the fabric tube right side out. Press the seam flat.

- Join the Ends: Bring the two raw ends of the fabric tube together, ensuring they are aligned and right sides are facing each other. Pin them securely.

- Sew the Final Seam: Sew the remaining open ends together with a 1/2-inch seam allowance, leaving a small opening (about 3-4 inches) unsewn to allow for turning.

- Turn and Close: Turn the entire scarf right side out through the opening. Press the seams. Hand-stitch or machine-stitch the opening closed.

Creating a Lined Scarf

A lined scarf offers a more polished finish, added warmth, and can provide structure, especially for scarves made from lighter fabrics. The lining also conceals raw edges, creating a professional look.The process involves preparing two separate pieces of fabric: the outer scarf fabric and the lining fabric.

- Fabric Selection: Choose an outer fabric and a lining fabric that have similar weights and drape. Common lining fabrics include satin, silk, or lightweight cotton.

- Cutting: Cut both the outer fabric and the lining fabric to the same dimensions, typically a rectangle.

- Sewing the Outer Scarf: Sew the outer fabric pieces together as you would a single scarf, leaving an opening for turning.

- Sewing the Lining: Sew the lining fabric pieces together in the same manner, also leaving an opening for turning.

- Joining Outer and Lining: Place the outer scarf and the lining scarf right sides together, aligning all edges. Pin them securely.

- Stitching the Scarf: Sew around the entire perimeter of the scarf with a 1/2-inch seam allowance, ensuring the opening in both layers is aligned.

- Turning and Pressing: Turn the scarf right side out through the unsewn opening. Gently push out the corners. Press the scarf flat, paying attention to the edges.

- Closing the Opening: Hand-stitch or machine-stitch the opening closed for a neat finish.

Sewing a Patchwork Scarf from Fabric Scraps

A patchwork scarf is a wonderful way to use up fabric scraps and create a unique, visually interesting accessory. This technique involves sewing together smaller pieces of fabric to form a larger panel.This method requires careful planning and precise sewing to ensure a cohesive and durable final product.

- Scrap Selection: Gather a variety of fabric scraps. Consider coordinating colors, patterns, and textures for a harmonious design. Ensure all fabrics are pre-washed and pressed.

- Cutting Scraps: Cut your fabric scraps into uniform shapes and sizes, such as squares, rectangles, or triangles. The size will depend on your desired patchwork design.

- Arranging the Patchwork: Lay out your cut scraps on a flat surface to create your desired pattern. Experiment with different arrangements until you are satisfied.

- Sewing Strips: Sew the individual fabric pieces together into strips, using a 1/4-inch or 1/2-inch seam allowance. Press the seams open or to one side.

- Joining Strips: Sew the completed strips together to form the full patchwork panel for your scarf. Again, press the seams carefully.

- Finishing the Scarf: Once your patchwork panel is complete, you can finish it as a single-layer scarf by hemming the edges, or you can add a lining for a more structured and durable finish.

Incorporating Gathering or Pleating for Textural Interest

Adding gathered or pleated elements to your scarf can introduce beautiful texture, volume, and visual appeal. These techniques are relatively simple and can dramatically enhance a basic scarf design.Gathering and pleating involve manipulating the fabric to create folds and ruffles, adding dimension and softness.

Gathering Techniques

Gathering involves creating a series of small, even folds in the fabric, which are then drawn together to create a ruched or ruffled effect.

- Gathering Stitch: Loosen the tension on your sewing machine and increase the stitch length to its longest setting. Sew two parallel lines of stitching along the edge of the fabric you wish to gather, about 1/4 inch and 1/2 inch from the raw edge. Do not backstitch.

- Pulling Threads: Gently pull the bobbin threads of both stitch lines simultaneously. As you pull, the fabric will begin to gather. Continue pulling until the gathered edge matches the desired length of the fabric it will be attached to.

- Securing the Gather: Once gathered, you can secure the threads by tying them off.

- Attaching Gathered Fabric: Pin the gathered edge to the desired location on your scarf and stitch it in place with a regular stitch length and tension.

Pleating Techniques

Pleating involves folding the fabric into uniform folds, creating crisp lines and structure. There are various types of pleats, such as knife pleats, box pleats, and accordion pleats.

- Marking Pleats: Carefully measure and mark the fold lines for your pleats on the wrong side of the fabric. Ensure the spacing and depth of each pleat are consistent.

- Folding and Pressing: Fold the fabric along the marked lines to create the pleats. Press each pleat firmly with an iron to set the fold.

- Securing Pleats: You can secure the pleats by basting them together along the top edge with a hand stitch or a long machine stitch.

- Attaching Pleated Fabric: Once secured, you can attach the pleated section to your scarf. For a more structured finish, you might consider interfacing the pleated section before sewing it onto the scarf.

Caring for Your Handmade Scarf

Congratulations on completing your beautiful handmade scarf! Proper care will ensure it remains a cherished accessory for years to come. This section will guide you through the essential steps of washing, drying, storing, and mending your creation, tailored to various fabric types.

Washing and Drying Different Scarf Fabrics

The best approach to cleaning your scarf depends entirely on the material it’s made from. Gentle care is key to preserving the fabric’s texture, color, and integrity. Always check the fabric’s care label if available, or proceed with caution based on the material type.

- Silk: Silk is delicate and often requires hand washing. Use cool water and a mild detergent specifically designed for silk or delicates. Gently agitate the water and avoid wringing or twisting the fabric. Rinse thoroughly with cool water until all soap residue is gone. For a final rinse, you can add a tablespoon of white vinegar to the water to help preserve the sheen.

- Cotton: Cotton scarves are generally more durable and can often be machine washed. Use a gentle cycle with cold or lukewarm water and a mild detergent. It’s advisable to place cotton scarves in a mesh laundry bag to prevent snagging or stretching.

- Linen: Linen can be washed in a washing machine on a gentle cycle with cold water. Like cotton, using a mesh bag is recommended. Linen can be ironed while damp to reduce wrinkles.

- Wool: Wool is prone to shrinking and felting if exposed to heat and agitation. Hand wash wool scarves in cool water with a wool-specific detergent. Gently squeeze out excess water without wringing. Avoid machine washing or drying wool.

- Synthetic Fabrics (Polyester, Rayon, Acrylic): These fabrics are typically more resilient. They can often be machine washed on a gentle cycle with cold water and a mild detergent. Always check the specific care instructions for the synthetic blend.

For drying all scarf types, it is best to avoid machine dryers, as the heat can damage fibers and cause shrinkage.

- Air Drying: Gently roll your washed scarf in a clean, dry towel to absorb excess moisture. Then, lay it flat on a drying rack or hang it on a padded hanger away from direct sunlight or heat. For knits, laying flat is crucial to prevent stretching.

- Ironing: If ironing is necessary, always use the appropriate heat setting for your fabric type. For silk and wool, it’s best to iron on the reverse side while the fabric is still slightly damp or use a pressing cloth to protect the fibers.

Proper Storage Techniques to Maintain Scarf Shape

The way you store your scarves significantly impacts their longevity and appearance. Proper storage prevents wrinkles, stretching, and damage from dust or pests.

- Folding: For most fabrics, folding is a good option. Fold scarves neatly and store them in drawers or on shelves. Avoid overstuffing drawers, which can cause excessive creasing.

- Rolling: Rolling can be an excellent method for preventing creases, especially for delicate fabrics like silk or for scarves with intricate patterns. Roll scarves loosely and store them in bins or on shelves.

- Hanging: For bulkier scarves or those prone to wrinkling, hanging can be effective. Use padded hangers or specialized scarf hangers that have multiple loops or bars. This method keeps the scarf suspended and allows air to circulate, which is particularly beneficial for wool or heavier fabrics. Ensure the scarf is not bunched up on the hanger.

- Storage Location: Store scarves in a cool, dry place away from direct sunlight, which can fade colors. Avoid storing them in plastic bags for extended periods, as this can trap moisture and lead to mildew. Natural fiber storage boxes or breathable garment bags are ideal.

Methods for Repairing Minor Snags or Loose Threads

Even with careful handling, minor snags or loose threads can occasionally appear on your handmade scarf. Addressing these issues promptly will prevent them from becoming larger problems.

- Loose Threads: If you notice a loose thread, do not pull it, as this can unravel stitches or create a hole. Carefully trim the thread with sharp fabric scissors as close to the fabric as possible. If the thread is part of a seam, gently try to tuck it back into the seam allowance with a needle.

- Minor Snags: For a minor snag where a thread has been pulled, you can often use a fine-tipped needle to carefully work the snagged thread back into the fabric from the wrong side. Gently manipulate the fabric to ease the pulled thread back into its original position.

- Small Holes: If a small hole has formed, it may require a bit of hand sewing. Using a needle and thread that matches the scarf’s color as closely as possible, carefully stitch the edges of the hole together from the wrong side. For more visible repairs, you can use a darning technique to invisibly mend the area.

- Reinforcing Seams: Periodically inspect the seams of your scarf. If you notice any areas where the stitching appears loose or is starting to fray, reinforce them with a few careful hand stitches to prevent further damage.

Regular inspection and prompt attention to minor issues are crucial for maintaining the beauty and integrity of your handmade scarf.

Epilogue

As you conclude this guide on “How to Sew a Scarf with Your Sewing Machine,” you are equipped with the knowledge and confidence to create a variety of stunning scarves. From the initial fabric preparation to the final care instructions, you’ve learned the fundamental techniques and explored creative possibilities to personalize your creations. Embrace the joy of handmade fashion and continue to explore the endless potential of your sewing machine to craft beautiful accessories that elevate any wardrobe.