How to Sew with Fleece or Minky Fabric Guide introduces you to the delightful world of working with these wonderfully soft and versatile materials. This comprehensive exploration will equip you with the knowledge and techniques needed to transform plush fabrics into beautiful creations, from cozy blankets to adorable apparel.

We will delve into the unique characteristics of both fleece and Minky fabrics, helping you understand their feel, stretch, and drape. Essential tools and supplies specifically suited for these plush textiles will be discussed, along with crucial preparation steps like pre-washing and cutting to ensure your projects go smoothly. Furthermore, we will cover essential sewing techniques, including stitch settings, seam construction, hemming, and handling bulky areas, ensuring professional and durable results.

Finally, we’ll explore finishing touches, project ideas for all skill levels, and how to overcome common challenges, making your sewing experience with fleece and Minky both rewarding and enjoyable.

Understanding Fleece and Minky Fabrics

Embarking on a sewing journey with plush fabrics like fleece and Minky opens up a world of cozy and delightful creations. These materials, while both soft and inviting, possess distinct characteristics that make them suitable for different projects and offer unique sewing experiences. Understanding these differences is key to selecting the right fabric for your vision and achieving beautiful, professional-looking results.Fleece and Minky fabrics are popular choices for a wide range of sewing projects due to their inherent warmth, softness, and ease of use.

They are often favored by both beginner and experienced sewers for their forgiving nature and the comforting feel of the finished products. This section will delve into the specifics of each fabric, highlighting their individual properties and how they compare, to help you make informed decisions for your next sewing endeavor.

Fundamental Characteristics of Fleece Fabric

Fleece is a soft, napped, synthetic fabric, typically made from polyester. Its construction results in a lightweight yet warm material that is both durable and relatively easy to care for. The napping process creates a fuzzy surface on one or both sides of the fabric, giving it its characteristic plush feel.Fleece offers a good balance of stretch and stability, making it versatile for various applications.

It is breathable, which contributes to its comfort, and it resists shrinking and stretching out of shape when properly handled. Its inherent warmth is a primary reason for its widespread use in apparel and home goods.

Unique Properties of Minky Fabric

Minky fabric, also a polyester-based plush fabric, is distinguished by its exceptionally soft, velvety texture and its characteristic “pile” or raised surface. This pile is typically shorter and denser than that of fleece, creating a luxurious feel that is often compared to a mink coat, hence its name.The defining characteristic of Minky is its ultra-soft hand and its tendency to have a slight sheen.

It is known for its incredible drape and its ability to feel very smooth against the skin. Unlike some other plush fabrics, Minky is designed to be highly durable and resistant to shedding, even after repeated washing.

Comparison of Fleece and Minky Fabric

When comparing fleece and Minky, several key differences emerge in their feel, stretch, and drape, influencing their suitability for different projects.

Feel

Fleece generally has a soft, fuzzy, and slightly brushed feel. It can range from smooth to more textured depending on the type of fleece. Minky, on the other hand, boasts an exceptionally smooth, velvety, and luxurious feel with a shorter, denser pile that is incredibly soft to the touch.

Stretch

Both fabrics offer some degree of stretch, which is beneficial for comfort and ease of sewing. Fleece typically has a moderate stretch, particularly across the grain, making it comfortable for garments. Minky also has a stretch, often described as a four-way stretch, which allows it to conform well to shapes and provides a comfortable fit in apparel. However, Minky’s stretch can sometimes be more pronounced than fleece, requiring careful handling to avoid stretching out seams.

Drape

The drape of fleece can vary. Some types of fleece are quite structured, while others have a softer drape. Generally, fleece tends to be a bit stiffer than Minky. Minky fabric is renowned for its excellent drape. Its smooth surface and lighter weight allow it to fall fluidly, making it ideal for items where a graceful flow is desired.

Common Uses and Applications for Fleece and Minky

The distinct properties of fleece and Minky lend themselves to a variety of popular sewing projects.

Fleece Applications

Fleece is a highly versatile fabric, commonly used for:

- Warm clothing: Jackets, vests, hoodies, sweatpants, and pajamas.

- Children’s wear: Soft and cozy items for babies and toddlers.

- Accessories: Scarves, hats, gloves, and blankets.

- Home décor: Throws, pillows, and upholstery for a cozy feel.

- Craft projects: Stuffed animals and toy making.

Minky Applications

Minky’s luxurious softness makes it a prime choice for projects where comfort and a premium feel are paramount. Common uses include:

- Baby items: Receiving blankets, quilts, crib sheets, and plush toys, due to its hypoallergenic and gentle nature.

- Loungewear and intimate apparel: Pajamas, robes, and slippers where supreme softness is desired.

- Decorative items: High-end throws, decorative pillows, and upholstery accents.

- Costumes and cosplay: For creating soft, tactile elements.

- Quilting: As a backing fabric for an extra soft finish.

Identifying the “Right” Side of Fleece and Minky Fabric

Determining the right side (the side intended to be visible on the exterior of the project) of fleece and Minky fabric is generally straightforward, but a close inspection is always recommended.For fleece, the right side is typically the side with the more pronounced nap or fuzz. It will appear softer and more uniformly textured. The wrong side may look slightly flatter or have a more visible weave.Minky fabric usually has a clear distinction between its right and wrong sides.

The right side is the one with the velvety, smooth, and often slightly lustrous pile. The wrong side will typically have a flatter knit texture, often appearing more matte and sometimes showing the base fabric weave more distinctly.

Always check the selvage edge of the fabric for any manufacturer markings or indications of the right side, as some mills will print information there. If in doubt, gently rub your hand over both sides; the side that feels significantly softer and more luxurious is almost always the right side.

Essential Tools and Supplies for Sewing Fleece and Minky

Sewing with plush fabrics like fleece and Minky can be a delightful experience, leading to cozy and comforting finished projects. However, these fabrics have unique characteristics that require specific tools and supplies to ensure a smooth and successful sewing process. Using the right equipment will not only make your sewing more enjoyable but also contribute to a professional and durable final product.Choosing the appropriate tools is crucial for handling the slight stretch, potential for static, and the sometimes bulky nature of fleece and Minky.

This section will guide you through the essential items you’ll need to tackle these wonderful fabrics with confidence.

Sewing Machine Needles

Selecting the correct sewing machine needle is paramount when working with fleece and Minky. These fabrics, especially Minky with its dense pile, can easily snag or skip stitches if the wrong needle is used. A needle that is too fine might break, while one that is too thick can create larger holes than necessary.The following types of needles are highly recommended for sewing fleece and Minky:

- Universal Needles: While a universal needle can work for lighter-weight fleeces, it’s generally advisable to opt for specialized needles for better results, especially with Minky.

- Ballpoint Needles: These needles have a rounded tip that pushes the fabric fibers aside rather than piercing them, minimizing the risk of skipped stitches and fabric damage. They are excellent for knit fabrics, and fleece often has a knit-like construction.

- Stretch Needles: Similar to ballpoint needles, stretch needles are designed to glide through stretchy fabrics without damaging the fibers. They are a very good choice for both fleece and Minky.

- Microtex Needles: For very dense or tightly woven fleeces, a Microtex needle can provide a sharp, precise stitch. However, use with caution as they are very sharp and can snag if not handled carefully.

- Leather Needles: In some cases, for extremely thick or dense fleece, a leather needle might be considered due to its sharp point and strength, but this is less common and usually reserved for specific applications.

It is also beneficial to change your needle frequently, as a dull needle can cause the same problems as using the wrong type.

Cutting Tools

Accurate cutting is the foundation of any sewing project, and with the lofty nature of fleece and Minky, it becomes even more important. The right cutting tools will ensure clean edges, precise measurements, and prevent the fabric from shifting or stretching out of shape during the cutting process.A comprehensive selection of cutting tools is recommended for working with plush fabrics:

- Rotary Cutter and Mat: This is often the preferred method for cutting fleece and Minky. A sharp rotary cutter glides through the fabric, creating a clean, straight edge with minimal distortion. Always use a self-healing cutting mat underneath to protect your work surface and prolong the life of your rotary cutter blade.

- Sharp Fabric Scissors: A good pair of sharp fabric scissors is indispensable. For plush fabrics, consider larger scissors that offer a comfortable grip and a long blade for making long, smooth cuts. Keep these scissors dedicated solely to fabric to maintain their sharpness.

- Pinking Shears: Pinking shears can be useful for finishing the raw edges of fleece to help prevent fraying, although fleece is generally quite stable. They create a zigzag edge that can be decorative and functional.

- Rotary Cutter Blade Sharpener: To ensure your rotary cutter remains effective, a blade sharpener is a worthwhile investment. Regularly sharpening your blades will prevent them from becoming dull and pulling at the fabric.

When cutting, it’s best to work on a large, flat surface and lay the fabric out smoothly, ensuring there are no wrinkles or folds.

Thread Types

The thread you choose plays a vital role in the durability and flexibility of your seams, especially with fabrics that have a natural stretch like fleece and Minky. The thread needs to be strong enough to withstand wear and tear, yet flexible enough to move with the fabric without breaking or causing the seam to pucker.The following thread types are ideal for sewing fleece and Minky:

- Polyester Thread: All-purpose polyester thread is a strong and durable option that offers good elasticity, making it suitable for most fleece and Minky projects. It is resistant to shrinking and stretching, ensuring your seams hold up over time.

- All-Purpose Cotton-Polyester Blend Thread: Similar to pure polyester, this blend offers a good balance of strength and flexibility. It’s a reliable choice for general sewing tasks.

- Stretch Thread: For projects where maximum flexibility is required, such as activewear made from fleece, stretch thread is an excellent choice. It is designed to stretch with the fabric, preventing popped seams.

- Heavy-Duty Polyester Thread: If you are working with very thick fleece or creating items that will undergo significant stress, a heavier-duty polyester thread can provide extra strength and durability.

It’s important to match the thread weight to your fabric weight. For most standard fleece and Minky, an all-purpose thread is sufficient. Always test your stitch on a scrap piece of fabric before sewing your project.

Scissors or Rotary Cutter Considerations

The choice between scissors and a rotary cutter for fleece and Minky often comes down to personal preference and the specific project. However, both must be sharp and well-maintained to achieve the best results.When considering which to use:

- Rotary Cutter: Offers speed and precision, especially for long, straight cuts. It requires a cutting mat and can be more challenging to use for intricate shapes or curves. The blade must be exceptionally sharp to prevent snagging.

- Fabric Scissors: Provide greater control for detailed work and curves. A longer blade allows for smoother cuts on larger pieces. Ensure they are specifically designated for fabric and kept sharp.

For fleece and Minky, the key is sharpness. A dull blade, whether on scissors or a rotary cutter, will snag the fabric, create an uneven edge, and potentially cause frustration. Many sewers find a combination of both tools to be the most effective approach.

Specialized Presser Feet

While many fleece and Minky projects can be successfully sewn with a standard presser foot, certain specialized feet can significantly improve efficiency and the quality of your stitches. These feet are designed to manage the loft and sometimes slippery nature of these fabrics.The following specialized presser feet can be beneficial:

- Walking Foot: This is perhaps the most highly recommended presser foot for fleece and Minky. A walking foot, also known as an even-feed foot, has built-in feed dogs that move the top layer of fabric along with the bottom layer. This prevents the fabric from shifting, stretching, or rippling, ensuring perfectly matched seams and preventing skipped stitches, especially on longer seams or when sewing multiple layers.

- Roller Foot: A roller foot is designed to glide smoothly over difficult-to-feed fabrics like vinyl, leather, and also plush fabrics like Minky. The rollers reduce friction, allowing the fabric to feed evenly without sticking.

- Teflon Foot or Non-Stick Foot: Similar to a roller foot, a Teflon or non-stick foot has a special coating that allows it to glide smoothly over sticky or grippy fabrics. This can be helpful for preventing Minky from sticking to the presser foot.

- Edge-Stitch Foot: While not strictly for managing the fabric itself, an edge-stitch foot can be useful for creating neat topstitching or decorative edges on fleece, ensuring a consistent distance from the fabric edge.

Using the right presser foot can transform the sewing experience with fleece and Minky, making it easier to achieve professional-looking results and saving you time and effort.

Preparing Fleece and Minky for Sewing

Before you begin stitching your cozy creations, proper preparation of fleece and Minky fabrics is crucial for a smooth and successful sewing experience. These fabrics, while wonderfully soft and warm, have unique characteristics that require specific handling to ensure your projects turn out professionally and beautifully. This section will guide you through the essential steps of preparing these plush materials for the sewing machine.

Pre-Washing Fleece and Minky Fabrics

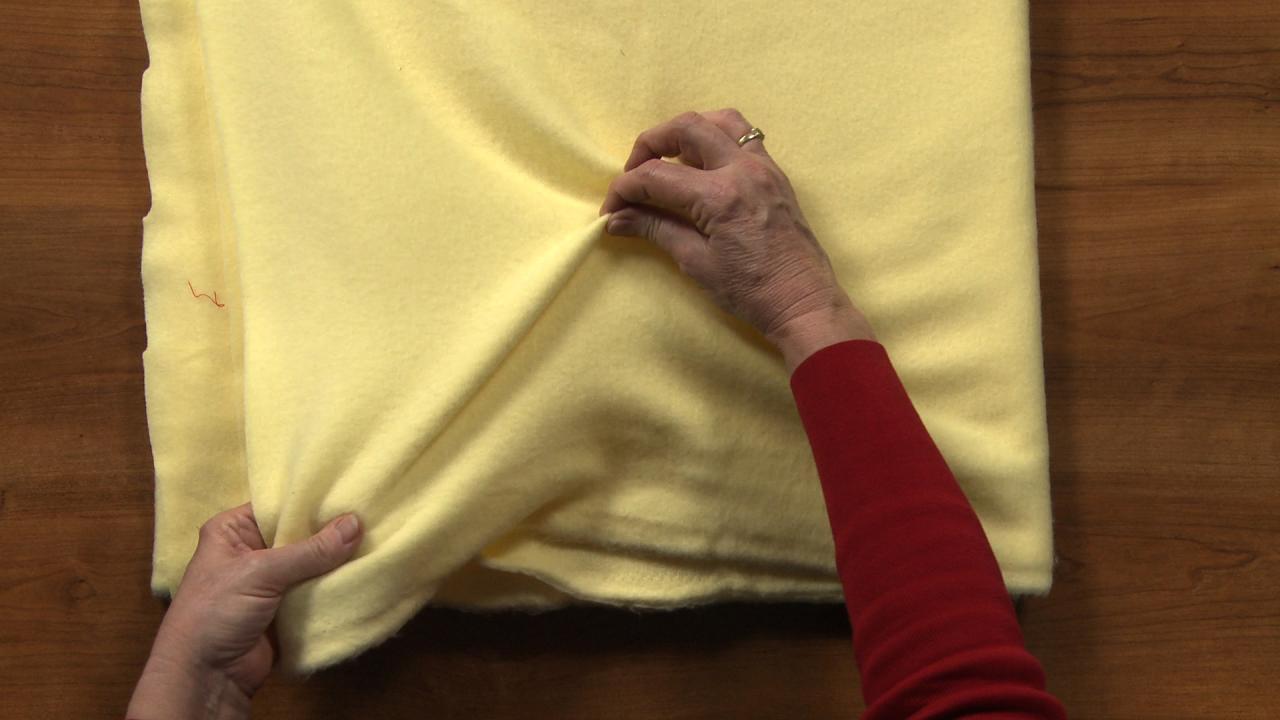

Pre-washing fleece and Minky fabrics before cutting and sewing is a vital step that ensures the final garment or item will not shrink or distort after its first wash. These synthetic materials can sometimes contain residual chemicals from the manufacturing process, and washing them first makes them safer and softer for direct skin contact. It also helps to remove any loose fibers that might interfere with your sewing machine.When pre-washing, it is recommended to use a gentle cycle with cold or lukewarm water.

Avoid using hot water, as it can cause some types of fleece and Minky to melt or lose their fluffiness. A mild detergent is sufficient; fabric softeners are generally not necessary and can sometimes reduce the fabric’s anti-pilling properties. For drying, tumble dry on a low heat setting or air dry. It is advisable to wash these fabrics separately from other laundry items to prevent lint transfer and potential snagging.

Effective Methods for Cutting Fleece and Minky

Cutting fleece and Minky fabrics can be challenging due to their plush, slippery nature and tendency to shift. Employing effective cutting methods will prevent frustration and ensure precise pattern placement, which is essential for symmetrical projects and accurate sizing.To minimize shifting during cutting, consider the following techniques:

- Use a Rotary Cutter and Mat: This is often the most effective method. Place the fabric flat on a self-healing cutting mat and use a sharp rotary cutter. The rotary cutter allows for a clean, precise cut with less pressure, reducing the chance of the fabric moving.

- Weight the Pattern Pieces: Instead of pinning, which can create holes and distort the fabric, use pattern weights to hold your pattern pieces securely in place on the fabric. Ensure the weights are heavy enough to keep the fabric from shifting.

- Cut on a Single Layer: Whenever possible, cut fabric pieces from a single layer rather than a double layer. This provides more control and prevents the layers from sliding against each other during the cutting process.

- Allow for Gravity: When cutting larger pieces, ensure the fabric is laid out flat and that excess fabric is allowed to drape over the edge of your cutting surface. This prevents the weight of the fabric from pulling and distorting the section you are cutting.

Marking Fabric Without Damaging the Pile

Marking patterns onto fleece and Minky requires a gentle touch to avoid crushing or damaging the fabric’s characteristic pile, which is the raised surface of fibers. Using the wrong marking tool can leave permanent impressions or unsightly marks that detract from the finished product’s appearance.Recommended methods for marking include:

- Tailor’s Chalk or Water-Soluble Markers: These tools are generally safe for most fleece and Minky fabrics. Test on a small, inconspicuous scrap first to ensure the mark is easily removable and does not alter the fabric’s texture. Mark lightly and directly on the wrong side of the fabric whenever possible.

- Tailor’s Tacks: These are small, loose stitches made by hand that can be easily removed after sewing. They are an excellent option for marking points or notches without leaving any residue.

- Temporary Fabric Pens (with caution): Some temporary fabric pens are designed for delicate fabrics. Always perform a patch test on a scrap piece first to confirm that the markings disappear completely upon washing or ironing, as per the pen’s instructions.

Stabilizing the Edges of Fleece and Minky

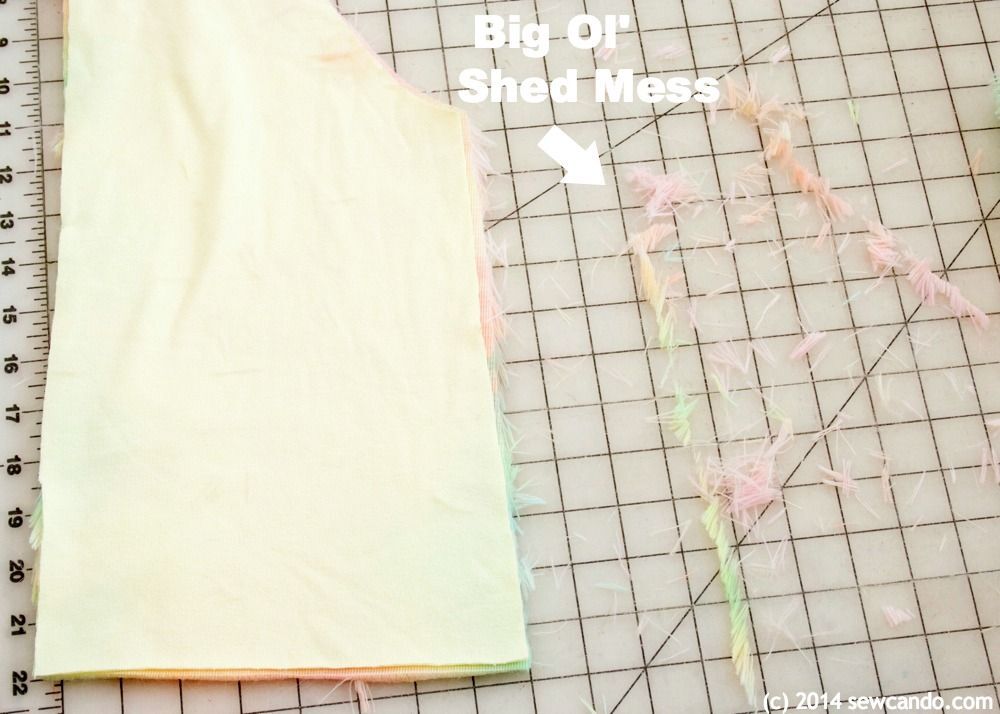

Fleece and Minky fabrics, particularly those with a longer pile, can be prone to shedding and stretching along the cut edges. Stabilizing these edges before and during sewing helps to prevent fraying, maintain the fabric’s shape, and make it easier to handle.Techniques for stabilizing edges include:

- Serging or Overlocking: If you have a serger, finishing the raw edges with a serger stitch is an excellent way to enclose the fibers and prevent fraying. This creates a clean, professional-looking edge.

- Zigzag Stitch: A wide zigzag stitch sewn along the raw edge on a conventional sewing machine can also effectively prevent fraying. Ensure the stitch width is sufficient to cover the raw edge entirely.

- Applying a Lightweight Fusible Interfacing (on wrong side): For areas that require extra stability, such as necklines or armholes, a very lightweight fusible interfacing can be carefully applied to the wrong side of the fabric. Use a low heat setting on your iron and a pressing cloth to avoid melting the fabric.

- Using a Pinking Shears: While not a permanent stabilization method, using pinking shears to cut the edges can help reduce fraying, especially for projects where the edges will not be heavily handled or stressed.

Transferring Patterns onto Textured Materials

Transferring patterns onto the plush surface of fleece and Minky requires attention to detail to ensure accuracy. The texture of these fabrics can sometimes obscure lines, making precise placement a bit more involved than with smoother materials.Consider these methods for transferring patterns:

- Using Pattern Weights and Tracing: Lay your pattern piece on the fabric and secure it with pattern weights. Then, use a fabric marker or tailor’s chalk to trace around the edges of the pattern piece directly onto the fabric. For more intricate patterns or if the fabric has a very deep pile, you might need to carefully feel the edges of the pattern piece as you trace.

- Cutting Around the Pattern: For simpler shapes, you can place the pattern piece on the fabric, weight it down, and then carefully cut around the pattern piece with your rotary cutter or sharp scissors. This method is best for fabrics that do not stretch significantly.

- Using a Clear Plastic Overlay: For complex or very detailed patterns, you can trace the pattern onto a piece of clear plastic sheeting (like a quilting template plastic). Then, place this plastic template onto your fabric, weight it down, and trace the markings onto the fabric or cut around the template.

- Transferring Notches and Dots: Use tailor’s tacks or small snips with pinking shears at notches and dots to transfer these important markings accurately. These methods ensure that these critical alignment points are clearly visible on the fabric.

Sewing Techniques for Fleece and Minky

Sewing with fleece and minky fabrics offers a delightful experience due to their softness and forgiving nature. However, to achieve professional-looking results and ensure the longevity of your projects, employing specific sewing techniques is essential. This section will guide you through the best practices for stitching, hemming, and managing seams on these popular plush materials.Proper stitch settings and seam construction are foundational to creating durable and aesthetically pleasing fleece and minky items.

Understanding how to navigate the unique properties of these fabrics will help you avoid common pitfalls like puckering and skipped stitches, leading to a more enjoyable and successful sewing journey.

Stitch Length and Tension Settings

Achieving the right balance in stitch length and tension is crucial for sewing fleece and minky. These fabrics have a bit of stretch and a dense pile, which can affect how stitches form. Incorrect settings can lead to skipped stitches, thread breakage, or seams that are too tight or too loose, compromising the integrity and appearance of your project.For most fleece and minky projects, a slightly longer stitch length than you would use for woven cotton is recommended.

This allows the fabric to move and stretch slightly without breaking the threads.

- Recommended Stitch Length: A stitch length of 2.5 to 3.0 millimeters is generally ideal for both fleece and minky. For very stretchy minky or fabrics with a deep pile, you might even consider a slightly longer stitch length, up to 3.5 millimeters.

- Recommended Tension: Start with your machine’s standard tension setting, often around 4.0. You may need to slightly decrease the top tension, perhaps to 3.0 or 3.5, especially if you notice the stitches pulling or puckering the fabric. It’s always best to test your settings on a scrap piece of the same fabric before beginning your project.

- Needle Choice: A universal needle in size 80/12 or 90/14 is typically suitable. For minky with a very dense pile or thicker fleece, a stretch needle or a microtex needle can help prevent skipped stitches and fabric damage.

Creating Neat and Durable Seams

Sewing a neat and durable seam on fleece and minky involves paying attention to the fabric’s stretch and tendency to shed. By following these guidelines, you can ensure your seams are strong, lay flat, and contribute to the overall professional finish of your handmade items.It’s important to maintain consistent seam allowances and to finish the raw edges to prevent fraying and enhance durability.

- Seam Allowance: A standard seam allowance of 1/2 inch (1.25 cm) is generally recommended for fleece and minky. This provides enough fabric to work with and ensures a strong seam.

- Sewing Direction: When sewing seams, especially on minky, try to sew with the pile going in the same direction. This helps to prevent the pile from getting caught in the stitches and creating an uneven appearance.

- Stabilizing Seams (Optional): For very stretchy minky or if you are concerned about seam stretching during use, you can consider using a lightweight fusible interfacing or a wash-away stabilizer on the wrong side of the fabric along the seam line. This adds extra stability without significantly altering the fabric’s drape.

- Finishing Seams: While fleece and minky do not fray extensively, finishing the raw edges of your seams will provide a cleaner look and added durability.

- Serger/Overlocker: If you have a serger, this is the ideal tool for finishing fleece and minky seams. A 3-thread or 4-thread overlock stitch will encase the raw edge beautifully and provide a flexible, durable finish.

- Zigzag Stitch: If you don’t have a serger, a wide zigzag stitch (around 3mm width and 2mm length) sewn along the raw edge is a good alternative. Sew this stitch close to the raw edge, enclosing it.

- Pinked Edges: For less demanding projects or as a quick finish, you can simply pink the raw edges with pinking shears. This is particularly effective on fleece that tends to curl.

Creating Clean Hems

Hems on fleece and minky can be tricky due to the fabric’s thickness and stretch. The goal is to create a hem that lies flat, is not bulky, and doesn’t distort the fabric. Several methods can achieve a neat finish, depending on the desired look and the fabric’s weight.A well-executed hem significantly contributes to the polished appearance of your finished garment or accessory.

- Double Fold Hem: This is a classic and durable hemming method.

- Fold the raw edge up by 1/2 inch (1.25 cm) to the wrong side and press.

- Fold it up again by another 1/2 inch (1.25 cm) to enclose the raw edge, creating a double fold. Press well.

- Stitch close to the inner folded edge. For a less visible stitch, you can use a twin needle, which creates two parallel lines of stitching on the top and a zigzag on the underside, mimicking a coverstitch.

- Single Fold Hem with Stabilizer: For a lighter-weight hem or to reduce bulk, you can use a single fold.

- Fold the raw edge up by 1/2 inch (1.25 cm) to the wrong side and press.

- Before stitching, you can apply a narrow strip of lightweight fusible interfacing or a wash-away stabilizer along the folded edge on the wrong side. This helps prevent stretching and puckering.

- Stitch close to the folded edge.

- Rolled Hem (for thinner fleece/minky): For very thin or drapey fleece and minky, a rolled hem can create a delicate finish. This is best achieved with a rolled hem foot on your sewing machine or by carefully hand-rolling and stitching.

- Binding: For a decorative and secure hem, especially on blankets or edges that will see a lot of wear, binding with a coordinating fabric (like cotton or a contrasting fleece) is an excellent option.

Sewing Curves and Corners Without Puckering

Sewing curves and corners on plush fabrics like fleece and minky requires a gentle touch and strategic adjustments to prevent puckering and ensure smooth transitions. The inherent stretch of these materials means they can easily distort if handled too aggressively.Paying attention to your sewing machine’s feed dogs and needle position, along with proper fabric handling, will yield much cleaner results.

- Curves:

- Slow and Steady: Sew curves slowly, allowing the fabric to feed naturally. Avoid pulling or pushing the fabric.

- Pivot and Stitch: For tight curves, stop with the needle down, lift the presser foot, pivot the fabric slightly, lower the presser foot, and continue sewing.

- Clip Inner Curves: If you are sewing an inner curve (like the inside of a hood or armhole), clip small notches into the seam allowance up to, but not through, the stitching line. This allows the curve to lay flat without pulling.

- Trim Outer Curves: For outer curves, trim the seam allowance slightly to reduce bulk and allow the curve to lay smoothly.

- Corners:

- Square Corners: For sharp, square corners, sew to the corner point, stop with the needle down, pivot the fabric 90 degrees, and continue sewing. You can then clip the corner seam allowance diagonally to reduce bulk and allow it to turn out neatly.

- Rounded Corners: Treat rounded corners similar to curves, sewing slowly and pivoting as needed.

- Understitching (Optional): For facing seams on corners or curves, understitching can help the seam roll to the inside and lie flat. This involves stitching through the seam allowance and the facing close to the seam line.

Handling Bulky Seams

Thicker fleece and minky fabrics can create bulky seams, which can be challenging to sew through, especially on standard domestic sewing machines. These seams can distort the fabric, cause skipped stitches, or even damage your needle or machine. Addressing bulkiness is key to achieving a smooth and professional finish.Several techniques can help manage and reduce bulk in your seams, making the sewing process more manageable and the final product more aesthetically pleasing.

- Trim Seam Allowances: After sewing a seam, trim one side of the seam allowance narrower than the other. For example, if you have a 1/2 inch seam allowance, trim one side down to 1/4 inch. This creates a less bulky seam when pressed open or to one side.

- Grade Seam Allowances: Grading involves trimming the seam allowances to different widths. For example, you might trim one layer to 1/4 inch and the other to 1/2 inch. This is particularly useful when sewing multiple layers or when dealing with facings or collars.

- Press Seams Open: Whenever possible, press your seams open. This distributes the bulk over a wider area and helps the seam lie flatter. Use a pressing cloth to protect the fabric from direct heat.

- Use a Walking Foot: A walking foot is invaluable when sewing thick or slippery fabrics like fleece and minky. It helps to feed both the top and bottom layers of fabric evenly, preventing shifting and puckering, which can contribute to bulk.

- Needle Choice: As mentioned earlier, using a sturdy needle (size 80/12 or 90/14) is important. If you encounter significant bulk, consider a denim needle or a quilting needle, as they are designed to penetrate thicker layers.

- Reduce Presser Foot Pressure: Some sewing machines allow you to adjust the presser foot pressure. If your machine has this feature, reducing the pressure slightly can help prevent the presser foot from crushing the fabric too much, which can exacerbate bulkiness. Test this on a scrap first.

- “Stitch in the Ditch” for Thick Layers: For extremely thick seams, sometimes sewing in the ditch (stitching directly in the seam line on the right side of the fabric) can be an effective way to join layers without adding significant bulk.

Finishing Touches and Project Ideas

Once your fleece or Minky project is sewn, the right finishing touches can elevate it from a simple creation to a polished, professional-looking item. These details not only enhance the aesthetic appeal but also contribute to the durability and overall quality of your handmade goods. This section will guide you through techniques for achieving a neat finish and inspire you with a variety of project ideas suitable for different skill levels.

Creating a Professional-Looking Finish on Edges

Achieving clean and attractive edges is crucial for a professional finish. For fleece and Minky, which can be prone to fraying and can be bulky, specific techniques are recommended. These methods ensure that raw edges are neatly enclosed or finished in a way that complements the fabric’s softness and texture.

Edge Finishing Techniques

- Double Fold Hem: This is a classic and effective method for creating a durable and clean edge. Fold the raw edge over by about 1/4 inch (0.6 cm), press (if your fabric allows for pressing, otherwise finger-press), and then fold it over again by another 1/4 inch to enclose the raw edge completely. Stitch close to the inner folded edge. This technique works well for blankets, scarves, and garment hems.

- Pinking Shears: For projects where a raw edge is acceptable or for decorative purposes, pinking shears can be used. The zigzag cut created by pinking shears helps to minimize fraying. While not a complete edge finish, it offers a simple and quick way to neaten edges, especially on items like toy stuffing openings or temporary edges.

- Serging: If you have a serger, it’s an excellent tool for finishing fleece and Minky edges. A 3-thread or 4-thread overlock stitch will neatly trim and enclose the raw edge simultaneously, providing a professional and durable finish. This is ideal for garments, blankets, and accessories.

- Bias Tape Binding: Applying bias tape is a beautiful way to finish edges, especially curved ones. Pre-made or self-made bias tape can be attached to the raw edge, folded over to the other side, and stitched down. This adds a decorative element and a clean, finished look. Ensure you use a stitch length appropriate for the fabric’s thickness.

Embellishing Fleece and Minky Projects

Fleece and Minky fabrics provide a wonderful canvas for embellishments, adding personality and visual interest to your creations. The soft texture of these fabrics lends itself well to various decorative techniques that enhance their cozy appeal.

Ideas for Embellishing Fleece and Minky

- Appliqué: Cut shapes from contrasting fabrics (cotton, felt, or even other types of fleece) and stitch them onto your fleece or Minky project. Use a tight zigzag stitch or a blanket stitch to secure the appliqué and create a decorative border. This is perfect for personalizing blankets, pillows, and clothing.

- Embroidery: Hand or machine embroidery can add intricate designs and details. For machine embroidery, use a stabilizer to prevent the stitches from sinking too deeply into the fabric. Simple embroidered motifs like stars, hearts, or monograms can significantly enhance a project.

- Puff Paint or Fabric Paint: Use fabric paints or puff paints to draw designs, patterns, or add text. Puff paint creates a raised, dimensional effect that is particularly appealing on soft fabrics. Allow ample drying time for the paint to cure properly.

- Buttons and Charms: For decorative purposes, especially on stuffed animals or cozy accessories, securely attach buttons or small charms. Ensure they are firmly attached to prevent them from becoming a choking hazard if the item is intended for young children.

- Ric-rac or Pom-pom Trim: Edging your projects with decorative trims like ric-rac or pom-pom fringe adds a playful and charming touch. Stitch these trims along the edges before or after enclosing the raw edge, depending on the desired look and the trim type.

Beginner-Friendly Projects for Fleece

Fleece is an excellent choice for beginners due to its stability, minimal fraying, and forgiving nature. These projects are straightforward and allow new sewers to practice basic techniques while creating satisfyingly cozy items.

List of Beginner-Friendly Fleece Projects

- Simple Blanket: A basic no-sew tied blanket or a simply hemmed blanket is an ideal starting point. For a sewn hem, practice straight stitching and edge finishing.

- Fleece Scarf: A rectangular scarf requires only straight stitching and can be finished with a simple hem or pinked edges.

- Pillow Covers: Envelope-style pillow covers are easy to construct with just a few straight seams.

- Pet Bandanas: Small, triangular bandanas are quick to make and perfect for practicing basic sewing and turning corners.

- Cozy Cuffs or Headbands: Simple elasticized cuffs or headbands involve basic cutting and stitching, offering a fast and rewarding project.

Intermediate Projects Showcasing Minky Fabric

Minky fabric, with its luxurious softness and plush pile, can be more challenging to work with due to its tendency to shift and shed. Intermediate projects allow sewers to develop techniques for handling these characteristics while creating beautiful and tactile items.

List of Intermediate Minky Projects

- Stuffed Animals or Plush Toys: Working with Minky for stuffed toys requires careful pinning, accurate seam allowances, and often involves turning small pieces. It’s a great way to practice precise stitching and stuffing techniques.

- Baby Blankets with Appliqué: Combining Minky with cotton for a baby blanket allows for beautiful decorative appliqués. Handling the different fabric textures and ensuring they lie flat together is a key intermediate skill.

- Quilted Minky Projects: Quilting Minky requires specific needles and thread, and careful handling to prevent the pile from getting caught in the stitches. Simple patchwork or channel quilting can be a rewarding intermediate challenge.

- Loungewear or Pajamas: Sewing garments from Minky, such as pajama pants or a simple robe, involves working with larger pieces and understanding how to manage the fabric’s stretch and loft for a comfortable fit.

- Baby Bibs or Burp Cloths: While simple in concept, creating these items with Minky often involves sandwiching it between a more stable fabric like cotton and requires careful stitching around the curves and edges to prevent the Minky from shifting.

Attaching Bindings or Trims to Fleece and Minky Garments

Attaching bindings and trims to fleece and Minky requires a slightly different approach than with woven fabrics due to their stretch and plushness. Patience and careful handling are key to achieving a neat and secure finish.

Methods for Attaching Bindings and Trims

- Pre-made Bias Tape: When using pre-made bias tape, it’s often beneficial to use a walking foot on your sewing machine to help feed the layers evenly. For Minky, consider using a slightly wider bias tape than usual to ensure good coverage of the pile. Stitch the tape to the right side of the fabric, encasing the raw edge, and then fold it over to the wrong side and stitch again, or topstitch from the right side.

- Self-Fabric Binding: Cut strips of fleece or Minky on the straight grain (avoiding the bias unless a specific stretch is needed) to create your own binding. For fleece, a 1.5 to 2-inch wide strip is often sufficient. Attach as you would with pre-made bias tape, ensuring the fabric doesn’t stretch out of shape.

- Decorative Trims (e.g., Pom-poms, Ric-rac): These are typically attached as a decorative edge finish. For pom-pom or ball fringe, you can often sandwich the fringe between the fabric and a folded-over hem or bind the edge and then stitch the fringe to the seam line. For ric-rac, it can be stitched directly onto the right side of the fabric before enclosing the edge with a binding or hem, or stitched along an already finished edge.

- Using a Binder Attachment: If you have a binder attachment for your sewing machine that is compatible with thicker fabrics, it can be a very efficient way to apply binding to fleece and Minky, especially for straight edges like blankets or scarves. Ensure the binder is set up correctly for the width of your binding strip.

When attaching bindings or trims, a slightly longer stitch length than usual can be beneficial, as it is less likely to pucker the fabric and can accommodate the fabric’s slight stretch.

Common Challenges and Solutions

Working with plush fabrics like fleece and Minky can be incredibly rewarding, but they also present unique challenges that can sometimes lead to frustration. Understanding these common issues and knowing how to address them will significantly improve your sewing experience and the quality of your finished projects. This section will guide you through the most frequent problems and provide practical, effective solutions.Fleece and Minky fabrics, due to their napped and often stretchy nature, can be prone to various sewing difficulties.

By preparing your fabric correctly, using the right tools, and employing specific techniques, you can overcome these hurdles and achieve professional-looking results.

Skipped Stitches Prevention

Skipped stitches are a frequent concern when sewing fleece and Minky. This occurs when the needle fails to catch the bobbin thread, creating gaps in your seam. Several factors can contribute to this, but fortunately, there are straightforward remedies.To prevent skipped stitches, consider the following:

- Needle Selection: Always use a new, sharp ballpoint or stretch needle. These needles are designed to glide between the fabric fibers without snagging or damaging them. A size 80/12 or 90/14 ballpoint needle is generally recommended for most fleece and Minky weights.

- Thread Choice: Use a good quality all-purpose polyester thread. Avoid cotton threads, as they can be too weak and prone to breaking with these fabrics. Ensure your bobbin is wound evenly and that the thread tension is correctly balanced.

- Presser Foot Pressure: Many sewing machines have adjustable presser foot pressure. Reducing the pressure slightly can prevent the fabric from being stretched or distorted as it feeds through the machine, which can also contribute to skipped stitches.

- Stitch Length: A slightly longer stitch length, around 2.5 to 3.0 mm, can be more forgiving on these fabrics than a very short stitch.

- Stabilizing: For very stretchy fleece or Minky, consider using a lightweight wash-away stabilizer on the underside of the seam to provide extra support and prevent skipped stitches.

Static Electricity Management

Minky fabric, in particular, is notorious for generating static electricity. This can cause the fabric to cling to itself, to your machine, and even to you, making it difficult to cut, handle, and sew accurately. Static can also cause the fabric to lift and distort under the presser foot.Effective methods for managing static electricity include:

- Anti-static Spray: Lightly misting the fabric with an anti-static spray designed for fabric before cutting and sewing can significantly reduce static cling. Test the spray on a small scrap first to ensure it doesn’t affect the fabric’s color or texture.

- Dryer Sheets: Gently rub a dryer sheet over the fabric. This is a quick and easy method that can neutralize static.

- Humidifier: Using a humidifier in your sewing room can increase the ambient moisture in the air, which helps to dissipate static charges.

- Metal Contact: Touching a metal object (like your sewing machine or a metal lamp) before handling the Minky can help discharge static electricity from your body.

- Washing: Sometimes, pre-washing Minky with a fabric softener can help reduce its tendency to generate static.

Fabric Bunching or Stretching During Sewing

The soft, often stretchy nature of fleece and Minky means they can easily bunch up or stretch out under the presser foot, leading to uneven seams and puckering. This is a common frustration that requires a gentle but firm approach.To prevent fabric bunching or stretching, implement these strategies:

- Walking Foot: A walking foot (also known as an even-feed foot) is invaluable for sewing plush fabrics. It has a set of feed dogs that work in conjunction with your machine’s feed dogs, ensuring even feeding of the fabric from both the top and bottom.

- Roller Foot or Teflon Foot: If a walking foot is not an option, a roller foot or a Teflon foot can also help the fabric glide smoothly under the presser foot, reducing drag and the likelihood of stretching.

- Pinning: Use plenty of pins to secure your fabric layers together. Place pins perpendicular to the seam line and remove them just before you reach them with the needle.

- Stabilizers: As mentioned for skipped stitches, using a lightweight fusible or wash-away stabilizer on the wrong side of the fabric can provide necessary structure and prevent stretching.

- Controlled Feeding: Avoid pulling or pushing the fabric through the machine. Instead, guide it gently with your hands, allowing the machine’s feed dogs to do the work.

- Basting: For complex curves or long seams, consider basting the fabric layers together by hand or with a long machine stitch before sewing the final seam.

Repairing Small Tears or Mistakes

Mistakes happen, and with plush fabrics, small tears or seam issues can occur. Fortunately, these are often repairable without compromising the overall appearance of your project.Methods for repairing small tears or mistakes include:

- Seam Ripper and Re-sewing: For slightly misaligned seams or small holes, carefully use a seam ripper to undo the stitches. Then, re-pin and re-sew the seam, paying close attention to the fabric handling techniques discussed previously.

- Fray Check or Fabric Glue: For very small snags or tiny holes that are not along a stress point, a small amount of Fray Check or a fabric glue can be applied to the wrong side to prevent further unraveling and secure the area. Use sparingly to avoid stiffness.

- Patching (Internal): If a small tear occurs within the seam allowance or on the wrong side of the fabric, you can often apply a small patch of matching or coordinating fabric to the wrong side using fabric glue or by carefully hand-stitching it in place. This is particularly effective for larger tears that cannot be easily re-sewn.

- Hand Stitching: For minor imperfections or small holes, a careful hand stitch using matching thread can often be almost invisible on the right side of the fabric. Use a ladder stitch or a blind stitch for the best results.

Concluding Remarks

In conclusion, mastering the art of sewing with fleece and Minky fabrics opens up a world of creative possibilities. By understanding their unique properties, utilizing the right tools, and employing specific sewing techniques, you can confidently tackle a variety of projects, from simple gifts to more intricate garments. Remember to prepare your fabric carefully, pay attention to stitch settings, and don’t shy away from experimenting with embellishments and finishes.

With the insights gained from this guide, your fleece and Minky creations are sure to be cherished for their comfort and quality.