Embarking on your sewing journey is an exciting endeavor, and mastering the foundational skill of sewing your first seam allowance is paramount to creating beautifully crafted garments and projects. This guide is meticulously designed to demystify the process, offering clear, actionable steps that will build your confidence and ensure precision from the very beginning.

We will delve into the essential understanding of what a seam allowance is, why its consistency is vital for project success, and the common measurements you’ll encounter. Furthermore, we will explore the necessary tools and preparation techniques, from pre-washing your fabric to accurate cutting, ensuring a solid foundation for your sewing endeavors.

Understanding Seam Allowance Basics

Embarking on your sewing journey involves mastering fundamental techniques, and understanding seam allowance is paramount. It forms the invisible yet critical foundation for nearly every garment and project you create. This section will demystify the concept of seam allowance, its importance, common measurements, and the tools you’ll need to work with it confidently.A consistent seam allowance is the bedrock of successful sewing.

It ensures that your pieces align correctly when joined, that your finished project fits as intended, and that it holds its shape and integrity over time. Without a uniform seam allowance, your seams can pucker, your garments might be misshapen, and the overall professional appearance of your work will be compromised.

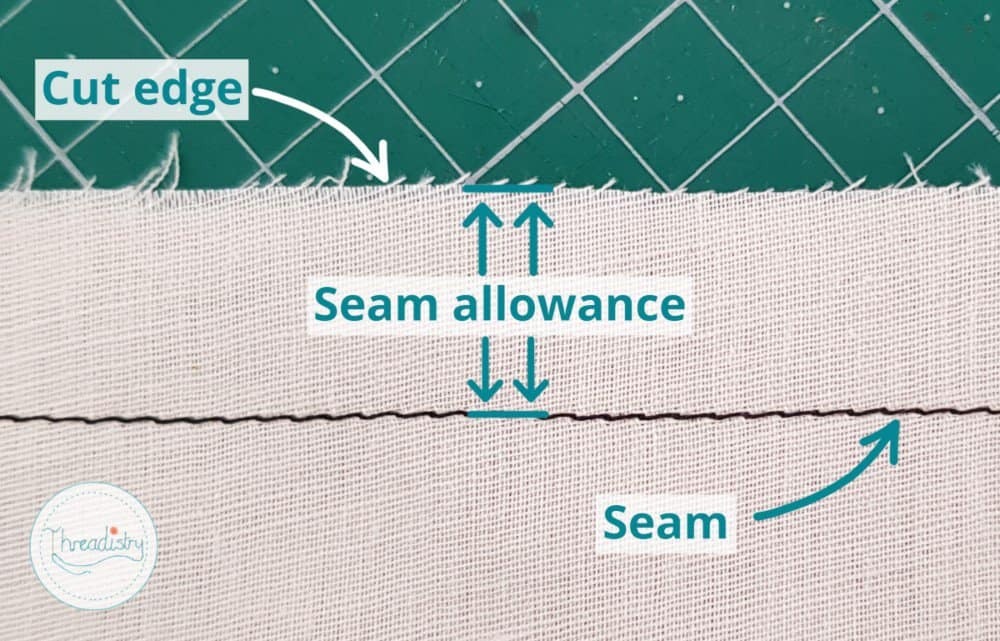

The Fundamental Concept of Seam Allowance

Seam allowance refers to the distance between the raw edge of a piece of fabric and the stitching line. It is the portion of fabric that is folded and enclosed within the seam, providing strength and structure to the construction. Think of it as the extra fabric that allows your seams to be sewn and finished without unraveling or becoming too narrow.

The Crucial Role of Consistent Seam Allowance

Maintaining a consistent seam allowance throughout your project is vital for several reasons. Firstly, it ensures that all pattern pieces will fit together accurately. If one seam allowance is wider than another, the pieces will not align correctly, leading to misalignment and potential fitting issues. Secondly, a consistent allowance allows for proper finishing techniques, such as serging or turning under the raw edge, which prevents fraying and enhances durability.

Finally, a uniform seam allowance contributes to a professional and polished finish, making your handmade items look as good as store-bought.

Common Seam Allowance Measurements and Their Variation

The width of a seam allowance can vary depending on the pattern, the type of fabric, and the intended use of the seam. However, certain measurements are more common in the sewing world.

- 1/4 inch (6mm): This is frequently used for French seams, flat-felled seams, and in quilting, where precision is key.

- 3/8 inch (1cm): A common measurement for general garment construction, offering a good balance of seam strength and fabric usage.

- 5/8 inch (1.5cm): This is the standard seam allowance for many commercial sewing patterns, particularly for apparel. It provides ample fabric for seam finishing and allows for some adjustment if needed.

- 1 inch (2.5cm) or wider: Larger seam allowances are sometimes used for heavier fabrics, for areas that require extra strength, or when a specific finishing technique, like a very wide hem, is intended.

The variation in these measurements exists because different sewing techniques and fabric types benefit from specific allowances. For instance, delicate fabrics might require a narrower seam allowance to avoid bulk, while heavier fabrics might need a wider one for structural integrity. Always refer to your pattern instructions for the specified seam allowance.

Essential Tools for Accurate Seam Allowance Measurement and Marking

Achieving a precise and consistent seam allowance requires the right tools. These tools help you measure, mark, and guide your fabric accurately as you sew.

- Sewing Machine Needle Plate or Throat Plate: Many sewing machines have markings on the needle plate that indicate common seam allowance widths (e.g., 1/4 inch, 3/8 inch, 5/8 inch). These markings act as a guide for feeding your fabric.

- Seam Gauge: This is a small, retractable metal ruler with a sliding marker. It’s excellent for measuring and marking precise distances on fabric, especially for hems and smaller seam allowances.

- Rotary Cutter and Ruler: For projects involving cutting fabric, a rotary cutter and a quilting ruler with clear measurement markings are invaluable for cutting fabric with a consistent seam allowance.

- Fabric Marking Tools: These include chalk pencils, fabric pens, or tailor’s tacks. They are used to draw the seam allowance line onto the fabric, especially when the sewing machine markings are not sufficient or when working with complex curves.

- Clear Quilting Ruler: A large, clear ruler with grid lines and measurements is versatile for marking seam allowances on larger pieces of fabric and for guiding cuts.

Using these tools diligently will ensure that your seam allowances are accurate from the very first stitch, setting you up for sewing success.

Preparing Your Fabric for Sewing

Before you can begin stitching your very first seam allowance, it’s crucial to prepare your fabric. This step might seem like an extra effort, but it’s a fundamental part of ensuring your finished project looks professional and fits correctly. Proper fabric preparation prevents common sewing mishaps and makes the entire process smoother.Preparing your fabric involves a few key stages, each contributing to the success of your sewing project.

These stages are designed to address potential issues before they arise, leading to more accurate cuts and a more stable final garment or item.

Pre-washing and Pressing Fabric

Pre-washing your fabric is a vital step to prevent unexpected shrinkage after you’ve completed your sewing. Many fabrics, especially natural fibers like cotton and linen, will shrink when exposed to water and heat. Washing and drying your fabric before cutting ensures that any shrinkage occurs before you measure and cut your pattern pieces. This guarantees that your finished project will maintain its intended size and shape.The process of pre-washing should mimic how you intend to care for the finished item.

If you plan to machine wash and dry the garment, then machine wash and dry the fabric. For delicate fabrics, hand washing and air drying might be more appropriate. After washing and drying, pressing the fabric is essential. A good press removes wrinkles and provides a smooth, flat surface, which is critical for accurate cutting.

Laying Out Fabric for Accurate Cutting

The way you lay out your fabric on your cutting surface directly impacts the accuracy of your pattern pieces. Fabric has a grainline, which is the direction of the threads woven into the fabric. Most patterns will indicate how to align your pattern pieces with this grainline. Cutting fabric off-grain can lead to garments that twist, hang unevenly, or don’t drape as intended.When laying out your fabric, ensure it is smooth and free of wrinkles.

If your fabric has a distinct right and wrong side, or a pattern, pay close attention to its orientation. It’s also important to consider the direction of any nap or pile on fabrics like velvet or corduroy, as these should generally all run in the same direction. Using a large, flat surface, like a cutting table or a clean floor, is recommended for this step.

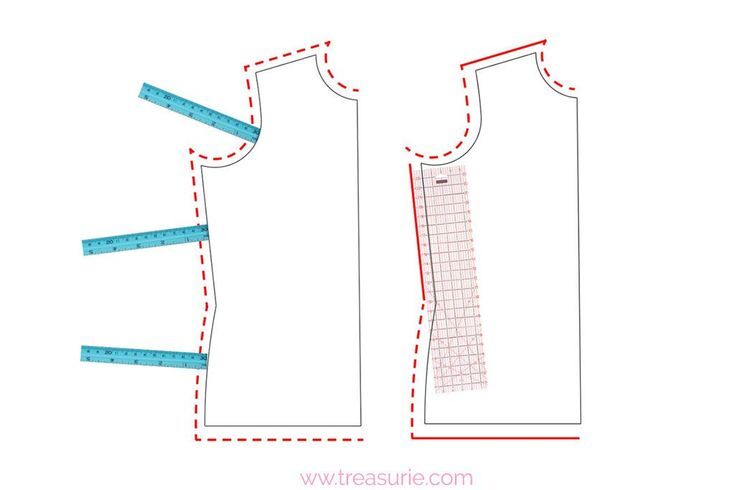

Cutting Fabric Pieces with Designated Seam Allowance

Once your fabric is prepared and laid out correctly, you can begin cutting. Your sewing pattern will typically include markings for the cutting line and often indicate the seam allowance. The seam allowance is the distance between the stitching line and the raw edge of the fabric. It’s this space that you will use to join fabric pieces together.When cutting, use sharp fabric scissors or a rotary cutter and mat.

Follow the marked cutting lines precisely. If your pattern pieces do not have the seam allowance included, you will need to draw it on yourself using a ruler and tailor’s chalk or a fabric marker. For beginners, it is often recommended to use patterns that clearly mark the seam allowance to avoid confusion.

The seam allowance is the hidden margin of fabric that allows for the integrity and structure of your sewn seams.

Here is a step-by-step procedure for cutting fabric pieces with a designated seam allowance:

- Ensure your fabric is properly pre-washed, dried, and pressed.

- Lay your fabric flat on your cutting surface, ensuring the grainline is correctly aligned with the pattern pieces.

- Pin your pattern pieces securely to the fabric, taking care not to distort the fabric.

- If your pattern does not include the seam allowance, measure and mark the seam allowance around each pattern piece using a ruler and tailor’s chalk or fabric marker.

- Using sharp fabric scissors or a rotary cutter, carefully cut along the marked cutting lines, including the seam allowance if it was drawn on.

- Remove pins as you cut around them.

- Transfer any necessary markings from the pattern pieces to the fabric, such as notches or dots.

Essential Fabric Preparation Checklist

To ensure you don’t miss any critical steps in preparing your fabric, refer to this checklist before you begin cutting. Completing these steps will set you up for success in your sewing endeavors.

- Fabric has been pre-washed according to its fiber content and intended care.

- Fabric has been thoroughly dried.

- Fabric has been pressed smooth and is free of wrinkles.

- Fabric is laid out on a flat surface with the correct grainline alignment.

- Pattern pieces are pinned securely to the fabric.

- Cutting lines, including seam allowance, are clearly marked or understood.

- Sharp cutting tools are ready for use.

- Necessary markings (notches, dots) are planned for transfer.

Marking and Sewing the First Seam Allowance

Now that your fabric is prepared and you understand the fundamental concept of seam allowance, it’s time to translate this knowledge into action. This section will guide you through the precise steps of marking your seam allowance and successfully sewing your very first seam. Accuracy in these initial steps is crucial for achieving professional-looking results in your sewing projects.The ability to accurately mark and sew a seam allowance is a foundational skill in sewing.

It ensures that your pattern pieces will fit together as intended, creating garments and projects that are both functional and aesthetically pleasing. We will explore various marking tools and techniques, and then delve into the mechanics of sewing a consistent and straight seam.

Fabric Marking Methods

Precisely marking your seam allowance onto the fabric is the first step in ensuring your stitches land in the correct place. Several tools can be used, each with its own advantages depending on the fabric type and your personal preference.Here are common methods for marking seam allowances:

- Tailor’s Chalk: This is a traditional and versatile marking tool. It comes in various colors and can be easily brushed or washed off most fabrics. For delicate fabrics, a very light touch is recommended to avoid damage.

- Fabric Pens/Markers: These are available in both temporary and permanent varieties. Temporary fabric markers often disappear with water or heat, making them ideal for projects where precision is key. Always test on a scrap piece of fabric first to ensure it washes out completely.

- Thread Tracing (Basting Stitches): For a very accurate and non-permanent mark, you can use a contrasting color of basting thread to stitch along your seam line or cutting line. This method is particularly useful for curved seams or when you need a very visible guide.

- Rotary Cutter and Ruler with Seam Allowance Guides: If you are cutting multiple pieces or working with precise measurements, using a rotary cutter and a quilting ruler with marked seam allowance increments can be highly effective. You simply align the ruler’s seam allowance line with the fabric edge and cut.

- Sewing Machine Needle Plate: Many sewing machines have etched lines on the needle plate that indicate common seam allowance widths (e.g., 1/4 inch, 3/8 inch, 5/8 inch). These can be used as a guide without any pre-marking on the fabric itself.

Aligning Fabric Edges for the First Seam

Before you even start sewing, the careful alignment of your fabric edges is paramount. This ensures that your seam allowance will be consistent from the beginning to the end of your stitching. Misaligned edges will lead to uneven seams and can cause fitting issues later on.The process of aligning fabric edges involves several key steps:

- Place Fabric Right Sides Together: For most garment construction, you will place your fabric pieces with the “right sides” (the sides that will be visible on the finished project) facing each other.

- Match Raw Edges: Carefully align the raw, cut edges of the fabric pieces that will be joined by the seam. Ensure that any notches or markings on the pattern pieces also match up.

- Pin Securely: Use sewing pins to hold the aligned edges together. Place pins perpendicular to the edge, about 2-3 inches apart, to prevent the fabric from shifting as you sew. For delicate fabrics, consider using fine silk pins.

- Smooth Out Fabric: Gently smooth out any wrinkles or puckers in the fabric between the pins to ensure a flat sewing surface.

Starting to Sew a Seam

Beginning a seam correctly sets the stage for a smooth and consistent sewing experience. The goal is to have the needle enter the fabric exactly at the edge of your seam allowance, preventing any “puckering” or skipped stitches at the start.Here’s how to initiate sewing a seam:

- Position Fabric Under the Presser Foot: With the presser foot lowered, position the aligned fabric edges so that the needle is positioned just to the right of the edge of your fabric, precisely at the point where you want to begin sewing. This typically means aligning the raw edge of the fabric with the seam allowance guide on your machine’s needle plate.

- Lower the Presser Foot: Ensure the presser foot is fully lowered onto the fabric. This holds the fabric securely in place.

- Engage the Handwheel (Optional but Recommended): For the very first stitch, it is often beneficial to manually turn the handwheel towards you to lower the needle into the fabric. This gives you precise control over the starting position.

- Sew a Few Stitches Forward: Once the needle is in place, gently press the foot pedal to sew a few stitches forward. Many sewers recommend sewing 2-3 stitches forward and then engaging the reverse stitch function to create a small “backstitch.” This secures the beginning of your seam and prevents it from unraveling.

- Sew Forward to the End: After backstitching, continue sewing forward along your marked seam line until you reach the end of the seam.

Maintaining Consistent Stitch Length

A consistent stitch length is vital for a strong and professional-looking seam. Inconsistent stitches can create a “puckered” or uneven appearance, and can weaken the seam over time.To achieve a consistent stitch length:

- Use Your Machine’s Settings: Most sewing machines allow you to adjust the stitch length. For standard seams, a stitch length of 2.0 to 2.5 millimeters is generally recommended. Consult your sewing machine manual for specific recommendations.

- Utilize Needle Plate Guides: As mentioned earlier, the markings on your sewing machine’s needle plate are your best friends for maintaining a consistent seam allowance width. Align the raw edge of your fabric with the desired seam allowance marking (e.g., the 5/8 inch line).

- Feed Fabric Evenly: The key to consistent stitch length is to feed the fabric smoothly and evenly under the presser foot without pushing or pulling. Let the machine’s feed dogs do the work.

- Practice: Like any skill, consistent stitch length improves with practice. Sew straight lines on scrap fabric, focusing on maintaining the same distance from the edge.

Feeding Fabric Evenly Under the Presser Foot

The even feeding of fabric under the presser foot is directly responsible for a consistent stitch length and a straight seam. If you push or pull the fabric, you will create uneven stitches and potentially distort the fabric.Consider this visual guide for feeding fabric evenly:

|

Imagine the fabric being gently guided, not forced, through the sewing machine. The feed dogs, the little metal teeth under the presser foot, are designed to grip the fabric and move it backward at a consistent rate. Your role is to simply guide the fabric, ensuring its edge stays aligned with your chosen seam allowance marking on the needle plate. Think of it as holding the fabric lightly and allowing the machine to pull it along. Avoid the temptation to push the fabric forward with your fingers or to pull it backward. A light, steady hand is all that is needed. |

Techniques for Accurate Seam Allowance Control

Achieving consistent seam allowances is fundamental to creating professional-looking and well-fitting garments. This section delves into practical techniques and tools that will help you maintain precision throughout your sewing projects. Mastering these methods will elevate your sewing from functional to fabulous.Maintaining a precise seam allowance is not just about aesthetics; it’s crucial for the structural integrity and proper fit of your sewn items.

A consistent seam allowance ensures that pattern pieces align correctly, that seams lie flat, and that garments can be altered or finished neatly. This section will explore various methods to achieve this accuracy.

Guiding Fabric Accurately Along the Presser Foot

The edge of the presser foot serves as a primary guide for many sewing tasks. However, the fabric’s edge must be kept consistently aligned with this guide. This requires a combination of careful fabric handling and understanding your machine’s features.There are several effective techniques to ensure your fabric stays perfectly positioned:

- Finger Placement: Position your fingers on the fabric just behind the presser foot, guiding it gently. Avoid pushing or pulling the fabric, as this can distort the seam. Your fingers should act as a gentle stabilizer, ensuring the fabric feeds smoothly and evenly.

- Fabric Tension: Maintain even tension on the fabric as it feeds through the machine. Both hands should work in tandem to support and guide the fabric without stretching or bunching it.

- Visual Cues: Continuously watch the fabric edge as it moves towards the needle, comparing its position to the chosen seam allowance guide on your machine.

Sewing Machine Guides: Needle Plate and Presser Foot Markings

Most sewing machines are equipped with built-in guides designed to assist with seam allowance accuracy. Understanding and utilizing these markings is one of the most straightforward ways to achieve consistent results.The needle plate and presser foot are often marked with lines indicating common seam allowance widths. These markings are incredibly helpful for beginners and experienced sewers alike.

- Needle Plate Markings: Look for lines etched or printed on the metal plate surrounding your needle. These lines are typically spaced at intervals like 1/4 inch, 3/8 inch, 1/2 inch, and 5/8 inch (1.5 cm), which are common seam allowance measurements. Align the edge of your fabric with the desired marking.

- Presser Foot Markings: Some presser feet also have markings on their sides or front. These can be particularly useful as they are closer to the needle and can provide a more immediate visual reference.

Presser Feet for Seam Allowance Accuracy

While standard presser feet can be effective, specialized presser feet are designed to enhance seam allowance precision, especially for specific tasks or fabrics.Different presser feet offer unique advantages for maintaining accurate seam allowances. Choosing the right foot for the job can significantly improve your results.

- Edge Stitch Foot (or Edging Foot): This foot has a small blade or guide in the center that runs along the folded edge of a hem or seam. It’s excellent for creating perfectly straight topstitching or edge stitching at a consistent distance from the fold, which directly translates to accurate seam allowance control.

- 1/4 Inch Foot: As the name suggests, this foot has a built-in guide that helps you sew a precise 1/4 inch seam. It’s invaluable for quilting and other projects where this specific seam allowance is crucial.

- Walking Foot: For thick or slippery fabrics, a walking foot can be a game-changer. It feeds multiple layers of fabric evenly, preventing them from shifting and ensuring a consistent seam allowance throughout the entire length of the seam.

Checking Seam Allowance Accuracy as You Sew

It is possible to verify the accuracy of your seam allowance in real-time as you sew, allowing for immediate corrections. This proactive approach prevents mistakes from compounding.A simple yet effective method for checking your seam allowance accuracy involves using scrap fabric.

- Prepare a Scrap: Take a piece of the same fabric you are currently sewing with.

- Mark Your Seam Allowance: On this scrap, draw a line representing your desired seam allowance width (e.g., 5/8 inch from the raw edge).

- Sew Along the Line: Place the scrap under your presser foot and sew along the marked line, using your machine’s guides as you normally would.

- Inspect: After sewing, remove the scrap and measure the distance from the raw edge to your stitching line. If it matches your desired seam allowance, you are sewing accurately. If not, adjust your fabric guiding or machine settings accordingly. This can be done periodically as you sew your main project.

Troubleshooting Common Issues with Uneven Seam Allowances

Even with the best intentions, seam allowances can sometimes become uneven. Understanding the common causes and their solutions will help you overcome these challenges.Here is a set of tips to address and prevent uneven seam allowances:

- Fabric Slippage: If your fabric is slipping, ensure your presser foot is appropriate for the fabric type and that it is engaging the fabric properly. A walking foot or even a piece of tissue paper placed under the fabric can help provide grip.

- Uneven Feeding: Ensure your feed dogs are engaged and functioning correctly. If they are not moving the fabric evenly, consult your sewing machine manual or a technician.

- Excessive Pushing or Pulling: Re-evaluate your fabric guiding technique. Remember to let the machine feed the fabric and only gently guide it into place.

- Incorrect Presser Foot Pressure: Some machines allow you to adjust presser foot pressure. If it’s too high, it can distort delicate fabrics; if it’s too low, it may not feed the fabric evenly. Experiment with slight adjustments if your machine offers this feature.

- Worn Machine Parts: Occasionally, worn needle plates or presser feet can contribute to uneven stitching. Inspect your machine’s components for any signs of damage or wear.

Finishing Your First Seam Allowance

Congratulations on successfully sewing your first seam allowance! The finishing touches are crucial for ensuring your project looks polished and professional. This section will guide you through the essential steps to properly complete your seam allowance, making your sewing endeavors even more rewarding.Properly finishing a seam allowance involves several key techniques that enhance durability and aesthetics. These steps, while seemingly small, contribute significantly to the overall quality of your handmade items.

Let’s explore these finishing techniques in detail.

Securing the Seam with Backstitching

Backstitching is a fundamental technique used to reinforce the beginning and end of a seam, preventing it from unraveling during use and washing. This creates a strong anchor point for your stitches.When you start sewing a seam, the first few stitches are vulnerable to pulling apart. Backstitching involves sewing forward a few stitches, then reversing the machine’s direction to sew backward over those same stitches, and finally sewing forward again to continue the seam.

This process is repeated at the end of the seam.

Backstitching at the beginning and end of a seam is essential for structural integrity and longevity.

The number of stitches to backstitch can vary depending on the fabric and the stress the seam will endure. Generally, two to three stitches forward and backward are sufficient for most fabrics. For heavier fabrics or areas that will experience significant strain, like the crotch of trousers, you might consider a few more stitches.

Trimming Excess Seam Allowance

In some instances, trimming the excess seam allowance is necessary to reduce bulk or to achieve a specific aesthetic. The amount to trim will depend on the fabric type and the project’s requirements.For fine or lightweight fabrics, you may not need to trim the seam allowance at all, as it generally lies flat. However, for medium to heavier weight fabrics, or when sewing multiple seams that will be layered, trimming can prevent an unsightly bulky edge.Consider trimming the seam allowance when:

- Sewing with bulky fabrics like denim, wool, or fleece.

- Finishing seams that will be pressed open, to reduce the overall thickness.

- Preparing to turn corners or create sharp edges, where excess fabric can hinder a clean finish.

The amount to trim can range from a scant 1/8 inch (approximately 3mm) to half of the original seam allowance. Always use sharp fabric scissors for a clean cut.

Pressing Seams for a Professional Finish

Pressing seams is an indispensable step in achieving a professional and neat appearance in your sewing projects. It not only flattens the fabric but also sets the stitches and guides the fabric layers into their final position.There are two primary methods for pressing seams: pressing them open or pressing them to one side. The choice often depends on the fabric, the pattern, and the desired outcome.

- Pressing Seams Open: This method involves laying the seam flat and then pressing each side of the seam allowance outward, away from the stitching line. This is particularly beneficial for reducing bulk, especially in areas where multiple seams converge. It creates a very flat and smooth finish.

- Pressing Seams to One Side: In this technique, both seam allowances are pressed together in the same direction, typically towards the back of the garment or towards a less visible side. This can be useful for reinforcing a seam or when the seam line needs to be concealed.

Always use the appropriate heat setting on your iron for the fabric you are working with. A pressing cloth can be used to protect delicate fabrics from direct heat or to prevent shine.

The Benefits of Pressing Seams as You Sew

Pressing seams as you sew, rather than waiting until the entire garment is assembled, offers numerous advantages that significantly improve the sewing process and the final product. This continuous pressing ensures that each step is executed with precision.Pressing as you go helps to:

- Maintain Accuracy: Each seam is flattened and set before the next step, ensuring that your measurements and stitching remain accurate throughout the project.

- Reduce Bulk: By pressing seams open or to one side immediately after sewing, you prevent the buildup of fabric layers, which can lead to a smoother and more professional finish.

- Easier Handling: Fabric that is pressed as you work is easier to manipulate and guide through your sewing machine, reducing the likelihood of puckering or distortion.

- Identify Errors Early: Pressing can reveal any mistakes in stitching or fabric alignment early on, allowing for easy correction before they become more difficult to fix.

“Pressing is as important as stitching.”

Many experienced sewers

Managing Bulky Seams

Bulky seams can detract from the professional appearance of a garment and can be challenging to work with. Fortunately, several techniques can be employed to manage and reduce this bulk for a smoother finish.For seams that remain too bulky even after pressing, consider these additional methods:

- Notching and Clipping: For curved seams, clipping into the seam allowance (making small V-shaped cuts) or notching (making small triangular cuts) at intervals allows the fabric to lie flat when turned.

- Grading Seams: This technique involves trimming the seam allowances to different widths. For example, trim one side to 1/4 inch and the other to 1/2 inch. This reduces the overall bulk by staggering the fabric layers.

- Using a Rotary Cutter and Mat: For precise trimming, especially when grading seams, a rotary cutter and mat can provide cleaner and more accurate cuts than scissors.

- Topstitching: In some cases, topstitching along the edge of a pressed seam can help to flatten it further and provide a decorative element.

Last Word

By diligently following these steps and embracing the techniques for accurate seam allowance control and finishing, you will not only successfully sew your first seam allowance but also gain the confidence to tackle more complex sewing projects. Remember, practice and attention to detail are your greatest allies in achieving professional-looking results. Happy sewing!