Embarking on the journey of sewing delicate fabrics can be a rewarding experience, especially when you have the right tools to achieve professional-looking finishes. The rolled hem foot stands out as a remarkable accessory, designed to elegantly tame the fraying edges of fine materials and impart a polished look to your creations. This guide will equip you with the knowledge to transform your sewing projects, from the fundamental understanding of this specialized foot to mastering intricate techniques that elevate your craft.

Discover the versatility of the rolled hem foot as we explore its different types and their specific applications, alongside the advantages it offers over conventional hemming methods. We will also delve into essential fabric and machine preparations, ensuring a smooth and successful sewing experience with various delicate textiles. Understanding the nuances of needle selection, thread tension, and stitch length will be key to achieving flawless results.

Understanding the Rolled Hem Foot

The rolled hem foot is a specialized sewing machine attachment designed to create neat, consistent, and professional-looking rolled hems with ease. It simplifies a traditionally intricate sewing technique, making it accessible for both beginner and experienced sewers looking to enhance the finish of their projects. This attachment guides the fabric edge into a precise fold, allowing the needle to stitch over it smoothly and uniformly.The primary function of a rolled hem foot is to fold the raw edge of the fabric twice, encasing it within the fold to create a clean, narrow hem.

This process is particularly useful for lightweight and delicate fabrics that can be challenging to hem using standard methods, preventing fraying and providing a beautiful, finished edge.

Types of Rolled Hem Feet and Their Applications

Rolled hem feet come in various widths and designs, each suited for different fabric types and desired hem aesthetics. Understanding these variations ensures you select the most appropriate foot for your project.

- Narrow Rolled Hem Foot: Typically measures between 2mm and 4mm. This is ideal for very fine fabrics like silk chiffon, organza, and lightweight cottons. It creates a delicate, barely-there hem, perfect for scarves, lingerie, and sheer garments.

- Wide Rolled Hem Foot: Usually ranges from 6mm to 12mm. This wider foot is suitable for slightly heavier fabrics or when a more prominent rolled hem is desired. It can be used on handkerchiefs, placemats, or even on the edges of some skirts and blouses for a decorative effect.

- Double/Folded Rolled Hem Foot: Some feet are designed to create a double-folded hem in one pass, offering an even more secure and opaque finish. These are excellent for fabrics that tend to fray significantly.

- Edge Stitching Rolled Hem Foot: Certain rolled hem feet have a groove on the top that allows for decorative stitching or topstitching to be applied directly over the hem, adding an extra layer of detail.

Advantages of Using a Rolled Hem Foot

The rolled hem foot offers significant benefits over traditional hemming methods, especially when working with delicate materials or when aiming for a high-quality finish.

The rolled hem foot automates the precise folding and stitching required for a professional rolled hem, saving time and ensuring consistent results.

The advantages include:

- Speed and Efficiency: It significantly reduces the time and effort required to create a rolled hem compared to hand-folding or using a standard presser foot.

- Consistency: The foot guides the fabric precisely, ensuring a uniform hem width throughout the project, which is difficult to achieve manually.

- Neatness and Professionalism: It produces a clean, crisp edge that elevates the appearance of any garment or home décor item.

- Fabric Handling: It is particularly adept at handling slippery, sheer, and lightweight fabrics that are prone to bunching or puckering with other methods.

- Reduced Fraying: By encasing the raw edge, it effectively prevents fraying, extending the lifespan and appearance of the fabric.

Sewing Machine Needle Types for Rolled Hem Feet

The choice of sewing machine needle is crucial for achieving a smooth and successful rolled hem, especially when working with delicate fabrics. Using the correct needle type minimizes skipped stitches, fabric damage, and ensures the thread passes cleanly through the fabric and the hemmer.The following needle types are generally recommended when using a rolled hem foot:

- Universal Needles: These are a good all-around choice for a variety of fabrics, including cottons and blends. For delicate fabrics, opt for a finer universal needle (e.g., size 70/10 or 80/12).

- Microtex/Sharp Needles: These needles have a very fine, sharp point and are excellent for tightly woven fabrics, silks, and synthetics. Their sharpness helps to pierce the fabric cleanly without snagging, which is essential for delicate materials.

- Sharps Needles: Similar to Microtex needles, Sharps have a fine point and are designed for precision work on fine fabrics.

- Ballpoint/Jersey Needles: While less common for rolled hems on very delicate fabrics, if you are working with a fine knit that requires a rolled hem, a fine ballpoint needle (size 70/10 or 80/12) can prevent skipped stitches by pushing the fabric fibers aside rather than piercing them.

It is important to always use a sharp, high-quality needle and to change it regularly, as a dull needle can cause damage to delicate fabrics and lead to poor stitch quality.

Preparing Your Fabric and Machine

Achieving a perfect rolled hem on delicate fabrics requires meticulous preparation of both your material and your sewing machine. This careful attention to detail ensures that your stitches are even, your fabric remains undamaged, and the final hem is beautifully crisp and professional.Before you even bring your fabric to the machine, understanding its properties is key. Different delicate materials, such as silk chiffon, organza, fine cotton lawn, or lace, will behave differently and may require slightly varied approaches to ensure the best outcome.

Preparing Delicate Fabrics

The preparation of delicate fabrics for a rolled hem focuses on preventing fraying, ensuring a smooth feeding surface, and maintaining the integrity of the material. This often involves a combination of cutting techniques and, in some cases, stabilization.

- Pre-washing: For fabrics like silk or fine cotton, pre-washing is crucial to account for any shrinkage that might occur. Wash them on a gentle cycle with a mild detergent and dry them according to the fabric care instructions. Iron them while slightly damp to achieve a smooth surface.

- Cutting: Use a very sharp rotary cutter and a self-healing mat, or sharp fabric scissors. Cut along the grain as precisely as possible. For extremely sheer fabrics like organza, consider using pinking shears to create a zig-zag edge that inherently helps to reduce fraying, though this may slightly alter the finished edge appearance.

- Stabilization (Optional): For exceptionally slippery or prone-to-fraying fabrics like chiffon or georgette, a temporary stabilizer might be beneficial. A very fine, water-soluble stabilizer can be basted to the wrong side of the fabric along the hemline. After sewing the rolled hem, the stabilizer can be carefully dissolved or washed away. Alternatively, a lightweight fusible interfacing, cut into a very thin strip, can be fused to the wrong side of the fabric just above the hemline to provide a bit of body and prevent excessive stretching.

- Marking the Hemline: Use a fabric marker that is easily removed or a chalk pencil to mark your desired hemline. For rolled hems, the width is typically quite narrow, so precise marking is important. A seam gauge or a ruler can help ensure consistency.

Thread Tension and Stitch Length Settings

The correct thread tension and stitch length are paramount when working with delicate fabrics and a rolled hem foot. Incorrect settings can lead to puckering, skipped stitches, or thread breakage.The general principle for delicate fabrics is to use a lower tension and a shorter stitch length.

- Thread Tension: Start with a slightly lower top thread tension than you would use for regular cottons. For most delicate fabrics, a tension setting between 2 and 4 (on a typical machine dial) is a good starting point. Always test on a scrap piece of your actual fabric. The bobbin tension should ideally be left at its factory setting unless you are experiencing significant issues.

- Stitch Length: A shorter stitch length is necessary to create the dense, neat fold of the rolled hem. For fine fabrics, a stitch length between 1.0 and 1.8 mm is usually ideal. This creates a secure and attractive finish without overwhelming the delicate material.

Threading the Sewing Machine

Proper threading is fundamental for any sewing project, but it’s especially critical when using fine threads and delicate fabrics. Using the correct thread and ensuring it’s threaded smoothly prevents lint buildup and ensures even stitch formation.

For delicate fabrics, it is highly recommended to use a high-quality, fine thread. Silk thread is an excellent choice for silk fabrics, while a fine polyester or cottonized polyester thread (often labeled as “sewing thread” or “all-purpose”) in a fine denier (like 40/2 or 50/2) is suitable for most other delicate materials.

The process of threading a sewing machine is generally consistent, but always refer to your machine’s manual for specific instructions. Here’s a general guide:

- Turn off the machine: Always ensure your sewing machine is switched off before threading to prevent accidental movement.

- Raise the presser foot: This opens the tension discs, allowing the thread to pass through smoothly.

- Thread the upper thread:

- Pass the thread through the upper guides and tension discs.

- Thread through the take-up lever, ensuring the thread goes through the eye from front to back.

- Continue threading through the lower guides and down to the needle.

- Thread the needle from front to back.

- Thread the bobbin: Wind the bobbin with the same type of thread as the upper thread. Ensure the bobbin is inserted correctly into the bobbin case or holder.

- Bring up the bobbin thread: Hold the upper thread taut with one hand and turn the handwheel towards you to bring the bobbin thread up through the needle plate. You should now have both upper and bobbin threads hanging behind the presser foot.

“The quality of your thread directly impacts the appearance and durability of your rolled hem on delicate fabrics. Opt for fine, strong threads that complement your material.”

Essential Pre-Sewing Preparations Checklist

To ensure a smooth and successful rolled hem experience with delicate fabrics, a comprehensive checklist can be invaluable. This checklist covers the final checks before you begin sewing.

| Preparation Step | Notes for Delicate Fabrics |

|---|---|

| Fabric Inspection | Check for any flaws, stains, or inconsistencies. Pre-wash and press if necessary. |

| Cutting Precision | Use sharp tools and cut accurately along the grain. Consider stabilizing very fine or slippery fabrics. |

| Thread Selection | Choose a high-quality, fine thread that matches or complements your fabric. |

| Machine Threading | Ensure the machine is threaded correctly with the upper and bobbin threads. |

| Tension and Stitch Settings | Perform test stitches on a fabric scrap to determine optimal tension (lower) and stitch length (shorter). |

| Rolled Hem Foot Installation | Ensure the correct rolled hem foot is securely attached to your sewing machine. |

| Needle Selection | Use a fine, sharp needle appropriate for your fabric type (e.g., microtex or universal needle size 60/8 or 70/10). |

Mastering the Technique: Basic Rolled Hem

Now that your fabric and machine are prepped, it’s time to dive into the art of creating a beautiful rolled hem. This section will guide you through the fundamental steps, ensuring you achieve consistent, professional-looking results on straight edges and even navigate those tricky corners with ease.The magic of the rolled hem foot lies in its ability to fold and press the fabric edge precisely as you sew.

This process, when done correctly, creates a clean, narrow hem that is both decorative and functional, perfect for lightweight and delicate fabrics where traditional hemming might be too bulky.

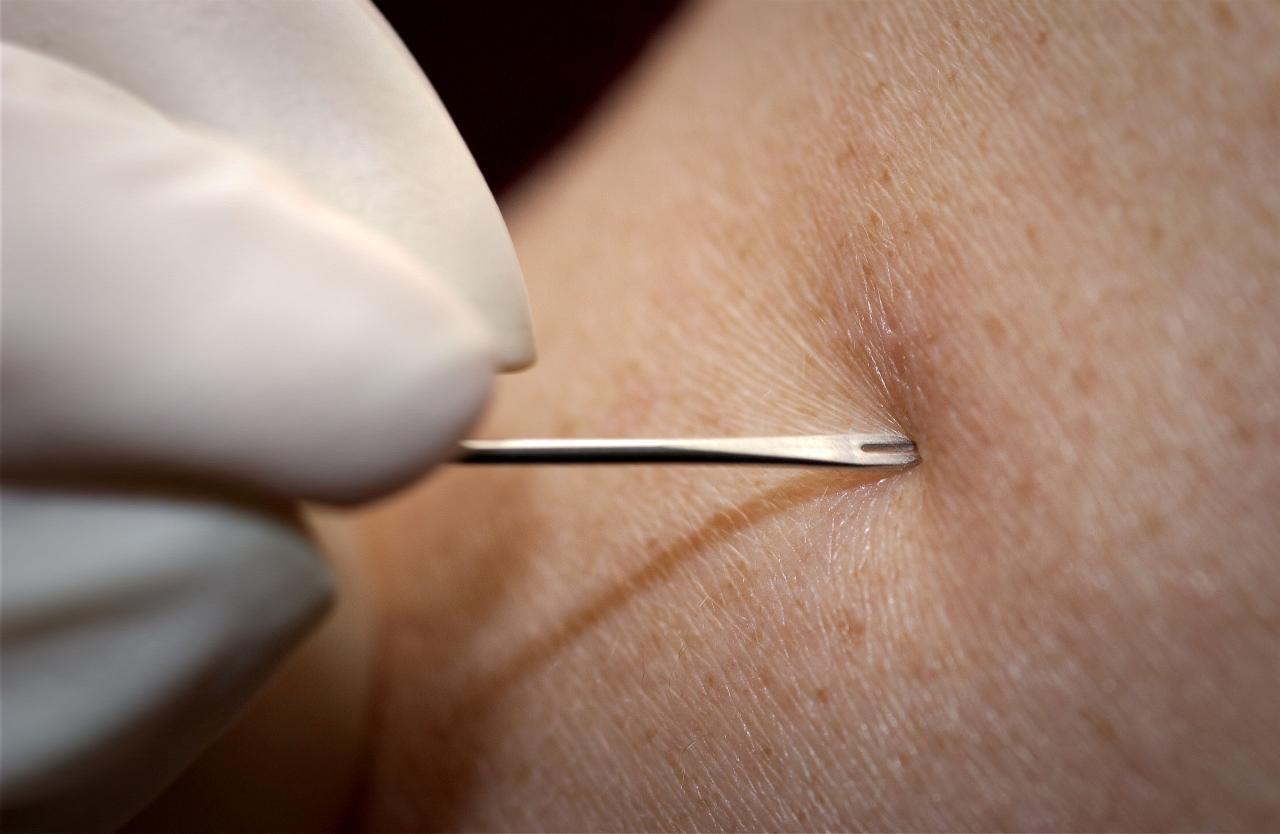

Feeding Fabric into the Rolled Hem Foot

Successfully feeding your fabric is the cornerstone of a perfect rolled hem. The foot is designed with a special channel that guides the fabric through a series of folds, creating the hem automatically.The fundamental process involves guiding the raw edge of your fabric into the small opening at the front of the rolled hem foot. As you begin to sew, the foot’s design will naturally catch the edge and begin to fold it.

It’s crucial to maintain a steady, even feed of the fabric to ensure the folds are consistent and the hem remains narrow and neat.

Creating a Consistent, Narrow Rolled Hem on Straight Edges

Achieving a uniform hem on straight edges requires patience and attention to detail. The goal is to have the fabric enter the foot smoothly and emerge as a perfectly folded and stitched edge.To create a consistent, narrow rolled hem on straight edges:

- Begin by carefully feeding the raw edge of your fabric into the narrow channel of the rolled hem foot.

- Start sewing at a moderate, consistent speed. The foot will automatically create the double fold.

- Gently guide the fabric from behind, ensuring it doesn’t bunch up or get pulled unevenly. Your hands should be positioned to control the fabric’s movement without interfering with the foot’s folding action.

- Maintain consistent stitch length and tension throughout the process.

- As you approach the end of a seam, sew off the edge of the fabric, allowing the needle to secure the hem.

Starting a Rolled Hem Without Bulk or Puckering

Initiating a rolled hem can sometimes lead to bulk or puckering, especially with very fine fabrics. A few techniques can help you start smoothly and avoid these common issues.To start a rolled hem without creating bulk or puckering:

- Pre-fold the Edge: For a cleaner start, you can manually fold the very beginning of your fabric edge over by about 1/8 inch (3mm) and press it. This gives the rolled hem foot a head start.

- Use a Leader Fabric: Sew a small piece of scrap fabric (a “leader”) through the rolled hem foot first. Once the leader is folded and stitched, slide your actual project fabric behind it, feeding it into the channel. This helps the foot create the initial folds more easily.

- Slow and Steady: Begin sewing very slowly. This allows the foot to catch and fold the fabric correctly without forcing it.

- Needle Position: Ensure your needle is in the correct position before you start. Some machines allow you to lower the needle into the fabric to hold it in place as you begin.

Turning Corners Smoothly with a Rolled Hem Foot

Navigating corners with a rolled hem foot presents a unique challenge, but with the right approach, you can achieve beautifully turned corners. The key is to manipulate the fabric and the foot at the turning point.To demonstrate the technique for turning corners smoothly:

- As you approach the corner, sew up to the point where you want the turn to begin. Stop with your needle down.

- Lift the presser foot.

- Carefully pivot the fabric so that the edge you want to hem is now aligned with the direction you need to sew around the corner.

- You may need to slightly ease or gently fold the fabric at the corner to help it feed smoothly into the rolled hem foot’s channel. The fabric should form a natural curve.

- Lower the presser foot and resume sewing, guiding the fabric through the foot as it curves around the corner. The rolled hem foot will adapt to the change in direction.

- For sharp inside corners, you might need to make a small snip into the seam allowance, being careful not to cut into your stitching. For outside corners, gently easing the fabric is usually sufficient.

Visual Description of Fabric Guidance for a Perfect Fold

Imagine the rolled hem foot as a tiny, intricate guide. The raw edge of your fabric enters a small, funnel-like opening at the front. As you sew, this opening, combined with the foot’s internal mechanism, performs two precise folds. The first fold tucks the raw edge under, and the second fold encloses that first fold, creating the narrow, double-folded hem.For a perfect fold, the fabric should be guided so that its raw edge consistently enters the center of the foot’s channel.

Your hands should be positioned to gently direct the fabric, not to push or pull forcefully. The fabric should appear to be drawn into the foot smoothly, almost as if by magic. The top surface of the fabric should lie flat and even as it enters the foot, and the folded edge emerging from the back should be uniformly narrow and free of wrinkles or distortions.

Advanced Rolled Hem Techniques for Delicate Fabrics

Once you’ve mastered the basic rolled hem, the world of delicate fabrics opens up a realm of sophisticated finishing possibilities. This section delves into advanced techniques that elevate your creations, ensuring a professional and beautiful result even on the most challenging materials. We’ll explore how to enhance durability, navigate curves and bias cuts, achieve whisper-thin hems, and troubleshoot common pitfalls.

Double-Folded Rolled Hem for Enhanced Durability

For garments that will undergo frequent washing or require extra structural integrity, a double-folded rolled hem provides a robust and elegant solution. This technique encloses the raw edge twice, preventing fraying and creating a clean, finished look on both sides of the fabric.To achieve a double-folded rolled hem, you will essentially perform the rolled hem process twice. After the initial fold and guide through the rolled hem foot, you will then re-feed the already hemmed edge back into the foot to create a second, smaller fold.

This method is particularly effective on fabrics that tend to fray easily, such as lightweight silks, chiffons, and even some fine linens. The result is a hem that feels substantial yet remains delicate and unobtrusive.

Adapting the Rolled Hem Foot for Curves and Bias-Cut Fabrics

Working with curved edges and bias-cut fabrics presents unique challenges for achieving a consistent rolled hem. The inherent stretch and drape of these materials can cause puckering and unevenness if not handled with care. The rolled hem foot can be adapted, with practice, to manage these situations.For curved edges, a slower sewing speed is paramount. Gently guide the fabric, allowing the foot to do the folding work without forcing it.

Small, precise adjustments to the fabric’s tension can help. For bias-cut fabrics, which are prone to stretching, consider using a stabilizer or a walking foot in conjunction with the rolled hem foot if the fabric is particularly unruly. Alternatively, a fine mist of starch can provide temporary crispness.

Creating a Very Fine Rolled Hem on Sheer or Lightweight Materials

Achieving an almost invisible rolled hem on materials like chiffon, organza, or fine silk is the hallmark of expert sewing. This requires a combination of the right tools, precise preparation, and a gentle touch.The key to a fine rolled hem lies in the width of the rolled hem foot and the fabric’s preparation.

- Foot Selection: Utilize a rolled hem foot specifically designed for very narrow hems (e.g., 2mm or 3mm).

- Fabric Preparation: Ensure your fabric is perfectly pressed. A very fine mist of water or a specialized fabric stabilizer can help control the sheer material.

- Needle and Thread: Use a fine, sharp needle (e.g., microtex or silk needle) and a high-quality, fine thread that matches your fabric.

- Slow and Steady: Sew at an extremely slow speed, allowing the foot to guide the fabric without any pulling or stretching.

- Practice: Practice on scraps of the same fabric until you achieve the desired delicate finish.

The goal is to have the fabric edge fold into the tiny channel of the foot so seamlessly that it creates a nearly imperceptible hem.

Rolled Hem Foot Application: Woven vs. Knit Delicate Fabrics

The application of a rolled hem foot differs significantly between delicate woven fabrics and delicate knit fabrics, primarily due to their inherent elasticity and structure.

| Characteristic | Delicate Woven Fabrics (e.g., Silk Chiffon, Fine Cotton Lawn) | Delicate Knit Fabrics (e.g., Jersey, Rayon Knit) |

|---|---|---|

| Stretch Factor | Minimal stretch; prone to fraying. | Significant stretch; less prone to fraying but can stretch out of shape. |

| Rolled Hem Foot Use | Ideal for creating a crisp, clean edge. Requires careful guiding to prevent puckering. | Can be used, but often requires a stretch stitch or a twin needle for a more flexible hem. The rolled hem foot may need careful adjustment to accommodate the knit’s stretch. |

| Resulting Hem | A defined, flat, and often very narrow hem. | A slightly more rounded, flexible hem that moves with the fabric. May appear less “crisp” than on wovens. |

| Troubleshooting Focus | Preventing fraying, achieving a consistent width, avoiding skipped stitches. | Preventing stretching, ensuring stitches don’t break, maintaining elasticity. |

While a rolled hem foot can be used on both, the techniques and expectations for the final result will vary. For knits, consider using a ballpoint or jersey needle to avoid snagging the fibers.

Troubleshooting Common Issues with Rolled Hems on Delicate Materials

Even with careful preparation, issues can arise when working with delicate fabrics. Here are common problems and their solutions:

- Skipped Stitches: This is often due to a dull or incorrect needle. Ensure you are using a sharp, fine needle appropriate for your fabric type (e.g., microtex for silks, ballpoint for knits). Check that the thread is not old or damaged.

- Uneven or Puckered Hem: This can be caused by uneven tension, pulling the fabric, or inconsistent guiding. Sew at a slower speed, allowing the foot to guide the fabric. Ensure your machine’s tension is correctly balanced. For very fine fabrics, consider using a walking foot or a silk plate to help feed the fabric evenly.

- Fabric Bunching in the Foot: The fabric may be too thick for the foot’s channel, or you might be trying to feed too much fabric at once. Ensure you are using the correct size rolled hem foot for the desired hem width. Start with a very small amount of fabric folded into the foot.

- Raw Edge Still Visible/Fraying: The fabric may not be folded deeply enough into the foot. You might need to slightly adjust the foot’s pressure or guide the fabric more precisely to ensure the raw edge is fully captured by the fold.

- Stitches Breaking: This can occur if the needle is too large for the fabric, causing it to snag, or if the thread is too thick. Use a finer needle and thread. Also, check that the machine’s upper tension isn’t too tight.

“Patience and precision are the twin virtues for mastering rolled hems on delicate fabrics.”

Applications and Project Ideas

The rolled hem foot is a versatile sewing tool that can elevate a wide range of projects, adding a touch of professionalism and finesse. Its ability to create a neat, narrow hem makes it ideal for fabrics that are prone to fraying or where a delicate finish is desired. By understanding its capabilities, you can unlock new creative possibilities for both garment construction and decorative items.This section explores the diverse applications of the rolled hem foot, highlighting its usefulness in various sewing endeavors.

From personal accessories to home décor, the rolled hem offers both functional and aesthetic advantages, transforming simple projects into polished creations.

Garment Types Benefiting from a Rolled Hem

A rolled hem is particularly well-suited for specific types of garments where a lightweight, clean edge is essential. This technique avoids bulk, which is crucial for fabrics that drape or are used in delicate construction.

- Sheer Blouses and Tops: For fabrics like chiffon, georgette, and organza, a rolled hem provides an elegant finish without adding weight or stiffness, maintaining the fabric’s natural drape.

- Dresses and Skirts: Especially in flowing or A-line styles made from lightweight materials, a rolled hem prevents the fabric from looking heavy or cumbersome at the hemline.

- Scarves and Handkerchiefs: These accessories often require a very fine and neat edge. A rolled hem is the perfect solution for achieving a professional and durable finish on small, delicate items.

- Lingerie and Sleepwear: In items made from silk, satin, or fine cotton, a rolled hem offers a soft, smooth edge that is comfortable against the skin and visually appealing.

- Children’s Clothing: For delicate fabrics used in baby clothes or children’s wear, a rolled hem is gentle and less likely to irritate sensitive skin, while also being durable for frequent washing.

- Table Linens and Napkins: Lightweight table runners, placemats, and napkins can benefit from a neat rolled hem, adding a touch of sophistication to dining settings.

Creative Project Ideas Utilizing Rolled Hems

Beyond basic hemming, the rolled hem foot can be employed for decorative effects and to enhance the overall design of a project. Its precision allows for creative applications that might not be possible with other hemming methods.

- Decorative Edging on Curtains: Adding a subtle rolled hem to the bottom or sides of lightweight curtains can create a refined look, especially for sheer or voile fabrics.

- Ruffled Scarves: For lightweight fabrics, a rolled hem can be used on the edges of fabric strips that are then gathered or pleated to create delicate ruffles for scarves or embellishments.

- Appliqué Borders: After applying an appliqué, a rolled hem can be used to finish the raw edges of the appliqué itself, creating a clean, defined border that prevents fraying and adds a professional touch.

- Fabric Bunting: For fabric bunting made from lightweight materials, a rolled hem on each triangular piece ensures a neat finish and prevents the edges from unraveling, making the bunting more durable.

- Lace or Trim Integration: A rolled hem can be used to neatly encase the edge of a fabric before attaching lace or trim, providing a stable edge for sewing the decorative element.

Finishing Edges of Scarves, Handkerchiefs, and Small Accessories

The rolled hem foot is exceptionally well-suited for small, intricate projects like scarves and handkerchiefs. The narrow width of the hem created by the foot is ideal for these items, providing a professional and durable finish without adding bulk.To achieve this, ensure your fabric is cut precisely and your machine is set up correctly as described in previous sections. The key is to guide the fabric edge smoothly into the foot’s channel.

For handkerchiefs, start by folding the edge of the fabric over once, pressing it, and then feeding it into the rolled hem foot. The foot will automatically fold the fabric over again and stitch it down. For scarves made from very fine materials, you might need to use a stabilizer or a temporary spray adhesive to manage the fabric’s tendency to shift, ensuring a consistent and even hem.

Experiment with stitch length and tension to find the perfect setting for your specific fabric.

Enhancing Home Décor Items with Rolled Hems

The aesthetic appeal of home décor items can be significantly enhanced by the clean, refined finish of a rolled hem. It adds a touch of understated elegance, particularly to items made from delicate or flowing fabrics.

- Cushion Covers: For cushion covers made from lightweight upholstery fabrics or even silk, a rolled hem on the opening or edges provides a neat and professional finish that complements the overall design.

- Table Runners and Placemats: As mentioned earlier, these items benefit greatly from a rolled hem, offering a sophisticated edge that enhances their visual appeal on a dining table.

- Lightweight Curtains and Valances: The delicate nature of sheer curtains is perfectly matched by the subtle finish of a rolled hem, allowing the fabric to drape beautifully without the distraction of a bulky hem.

- Fabric Banners and Wall Hangings: For decorative fabric banners or simple wall hangings, a rolled hem ensures a clean edge that prevents fraying and contributes to a polished presentation.

Fabric Types Well-Suited for Rolled Hem Finishes

The success of a rolled hem often depends on the fabric type. Certain fabrics lend themselves beautifully to this technique, showcasing its benefits most effectively.

The following list details fabric types that are particularly well-suited for rolled hem finishes, considering their weight, weave, and tendency to fray, making them ideal for various craft projects:

- Silks (Charmeuse, Crepe de Chine, Habotai): These luxurious fabrics are lightweight and can fray easily. A rolled hem creates a delicate, elegant edge that preserves the fabric’s drape and sheen.

- Chiffon and Georgette: Known for their sheer, lightweight nature, these fabrics require a fine hem. A rolled hem prevents them from looking heavy and maintains their ethereal quality.

- Voile and Batiste: Often used for lightweight garments, curtains, and handkerchiefs, these cotton or cotton-blend fabrics benefit from a neat, narrow hem that doesn’t add bulk.

- Linen (Lightweight): While some linens can be heavy, lighter weights are excellent candidates for rolled hems, especially for accessories like napkins or delicate garments, providing a crisp finish.

- Rayon and Viscose: These fabrics have a beautiful drape but can be prone to fraying. A rolled hem offers a durable and attractive finish that complements their fluid nature.

- Organza: This crisp, sheer fabric is perfect for decorative edges and structured items where a clean, defined hem is desired.

- Fine Cottons (Lawn, Cambric): These smooth, lightweight cottons are ideal for handkerchiefs, lingerie, and children’s clothing where a delicate and durable hem is needed.

Ending Remarks

In conclusion, mastering the rolled hem foot opens up a world of possibilities for finishing delicate fabrics with sophistication and ease. From simple straight edges to complex curves and sheer materials, this guide has provided a comprehensive roadmap to achieving beautiful, durable hems. By applying these techniques, you can confidently tackle a wide array of projects, enhancing the aesthetic appeal and longevity of your handmade garments and accessories, and truly elevate your sewing artistry.